Glass ceramic containing micro nano crystals and preparation method of glass ceramic

A kind of glass ceramics and micro-nano technology, which is applied in the field of glass ceramics containing micro-nano crystals and its preparation, can solve the problems that the contained micro-crystals are easy to grow, the tendency of glass devitrification is serious, cutting, grinding and polishing are difficult, etc. Avoid easy crystallization, wide applicability, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

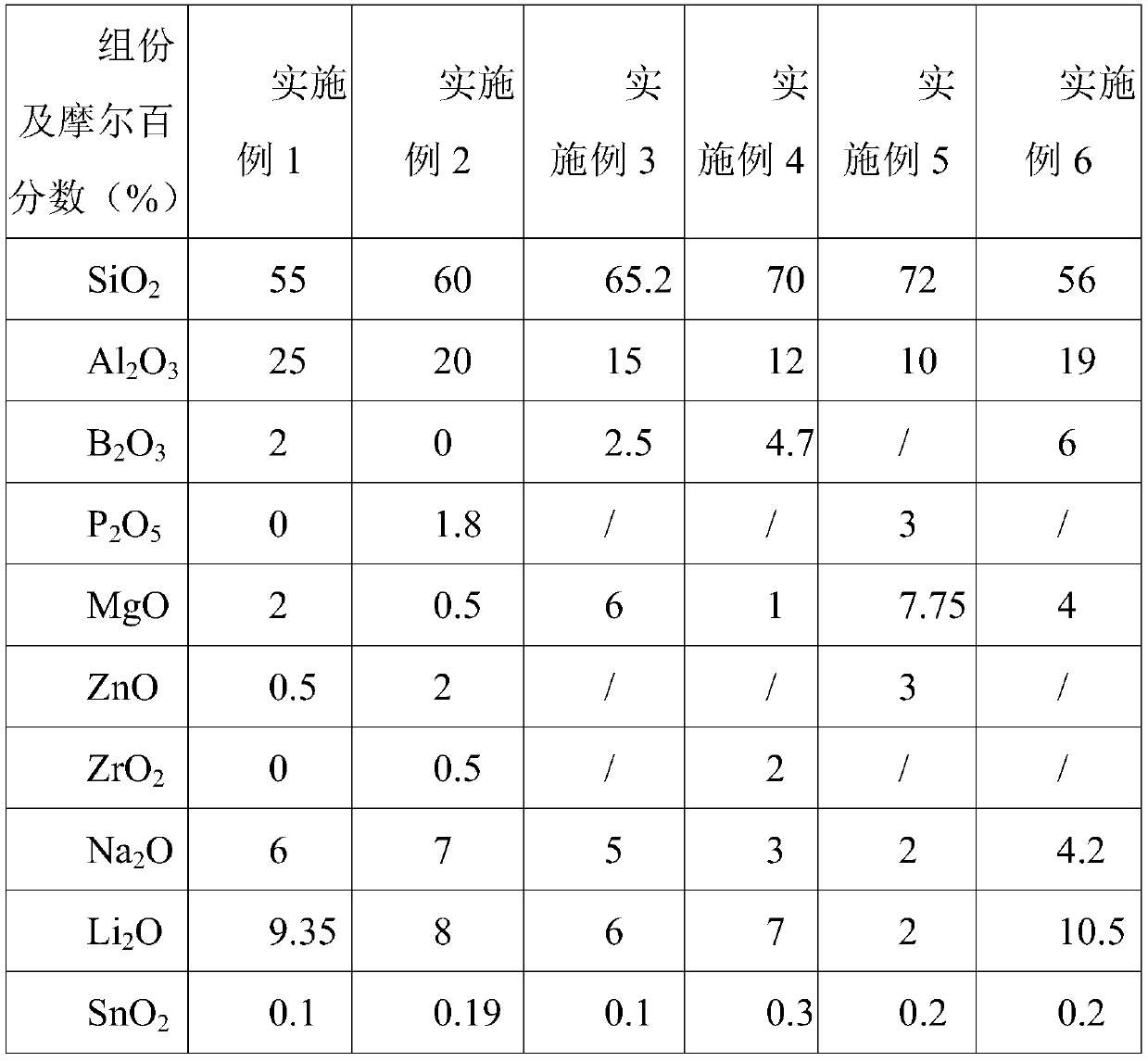

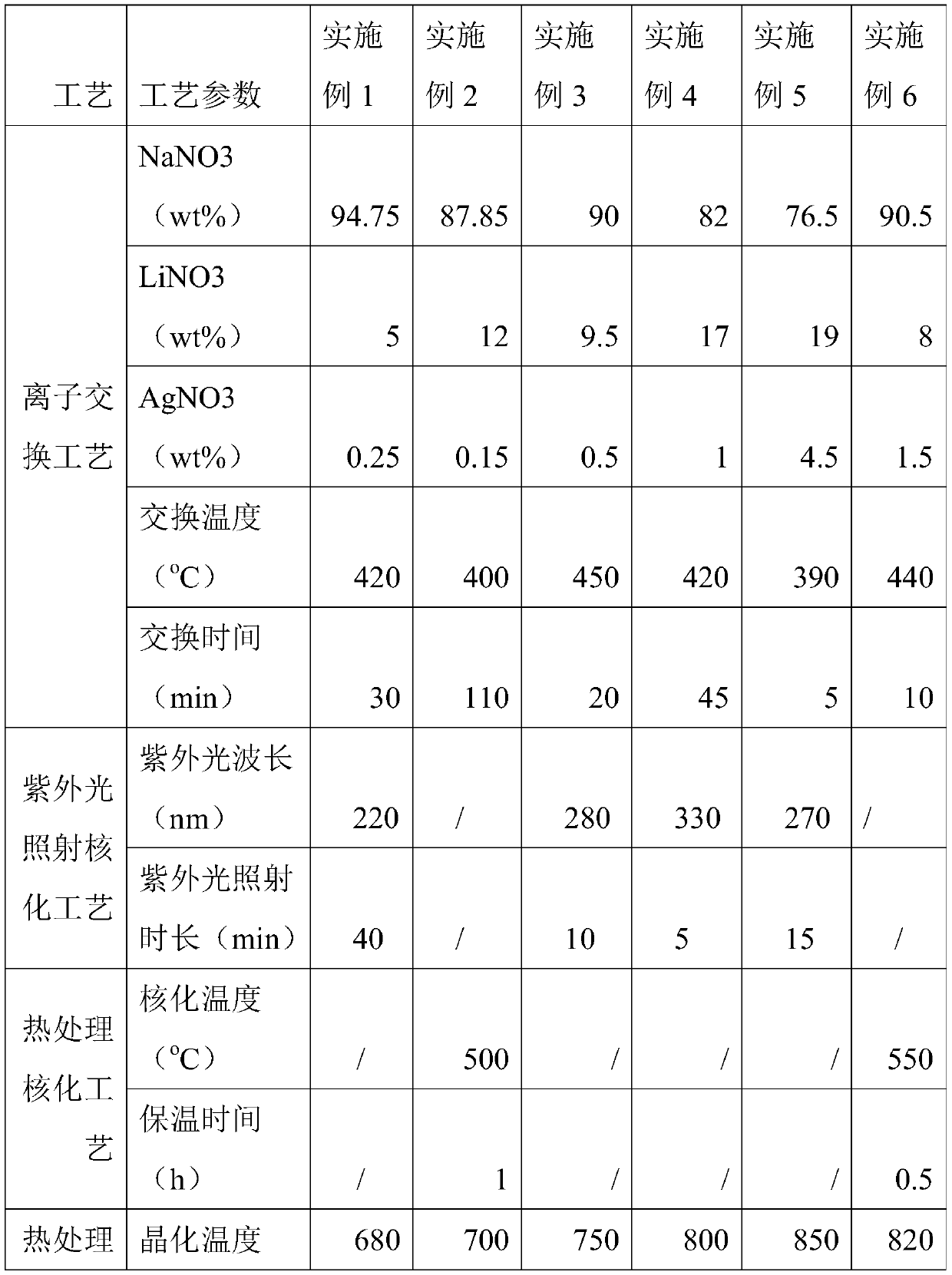

[0032] The present invention will be described in detail below in conjunction with specific embodiments.

[0033] The invention provides a glass ceramic containing micro-nano crystals, the micro-nano crystals are formed in a glass substrate through post-processing, and the crystal phase of the micro-nano crystals includes at least one of β-quartz solid solution, nepheline and nepheline solid solution A sort of. The average crystal size of the micro-nano crystals is less than or equal to 100nm, preferably less than or equal to 50nm, more preferably 5-20nm, and the proportion of crystal mass is greater than or equal to 30%. At this time, the average visible light of the 1mm thick glass ceramics is The transmittance is greater than or equal to 90%. The Vickers hardness of the glass ceramic is higher than 600kgf / mm 2 , preferably higher than 620kgf / mm 2 . The post-processing refers to introducing crystal nuclei elements into the glass substrate through ion exchange, and using ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com