Method for preparing platinum and nitrogen codoped active carbon supported titanium dioxide photocatalyst

A photocatalyst and titanium dioxide technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of low catalytic activity, achieve good degradation effect, solve the difficulty of recycling, and improve photocatalytic degradation rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a method for preparing a platinum-nitrogen co-doped activated carbon-supported titanium dioxide photocatalyst for liquid dye decolorization in response to visible light, so as to solve the problems of low photocatalytic efficiency and photocatalyst recovery in the liquid phase. The specific steps are as follows:

[0022] 1) Add 12.5 mL tetrabutyl titanate to 45 mL absolute ethanol, slowly drop into 100 mL distilled water under vigorous stirring, add 10 mL acetylacetone and 2 mL polyethylene glycol at the same time, and adjust with 1 mol / L hydrochloric acid Until the pH is 2.0-3.0, stir vigorously for 2 hours to complete the hydrolysis and obtain a clear and transparent colloidal solution;

[0023] 2) The TiO prepared in 1) 2 Add 7.6 g of urea to the sol under magnetic stirring, react for 30 minutes, add activated carbon that has been washed and dried for 1 hour, continue to stir for 1 hour, sonicate for 20 minutes, filter after standing for 24 hou...

Embodiment 1

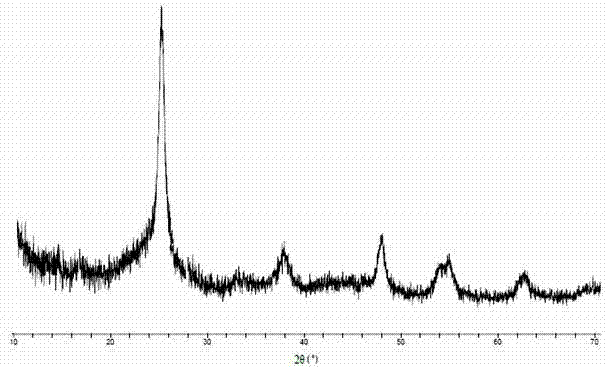

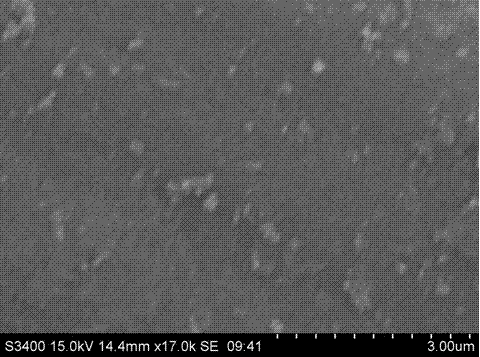

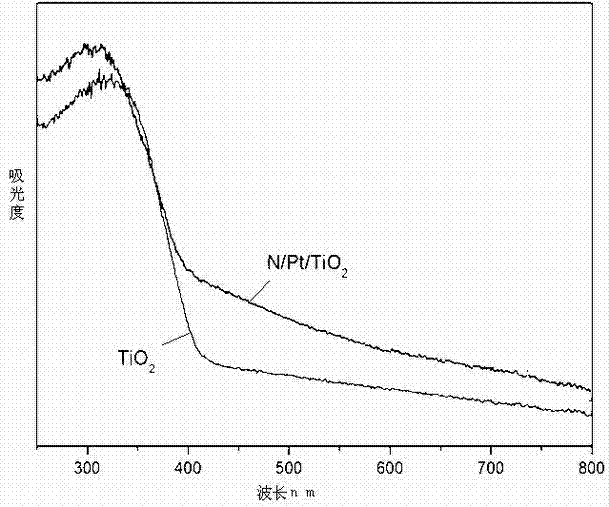

[0031] Add 12.5 mL of tetrabutyl titanate to 45 mL of absolute ethanol, slowly drop into 100 mL of distilled water under vigorous stirring, add 10 mL of acetylacetone and 2 mL of polyethylene glycol at the same time, and adjust the pH with 1 mol / L hydrochloric acid 2.0-3.0, vigorously stirred for 2 hours to complete the hydrolysis, and a clear and transparent sol was obtained. Then add 9.6 g of 6-10 mesh granular activated carbon and 7.6 g of urea at the same time, stir for 1 hour, then ultrasonicate for 20 minutes, clean the stain for 24 hours, filter, and wash several times with absolute ethanol and deionized water. The loaded activated carbon was dried at 120 °C for 2 h and calcined at 400 °C for 2 h to obtain nitrogen-doped activated carbon-supported nano-TiO 2 . Nitrogen-doped activated carbon-supported nano-TiO 2 After impregnating with chloroplatinic acid (weighed according to the mass fraction of Pt in the catalyst of 1%) solution by equal volume impregnation method,...

Embodiment 2

[0033] Add 12.5 mL of tetrabutyl titanate to 45 mL of absolute ethanol, slowly drop into 100 mL of distilled water under vigorous stirring, add 10 mL of acetylacetone and 2 mL of polyethylene glycol at the same time, and adjust the pH with 1 mol / L hydrochloric acid 2.0-3.0, vigorously stirred for 2 hours to complete the hydrolysis, and a clear and transparent sol was obtained. Then add 9.6 g of 6-10 mesh granular activated carbon and 7.6 g of urea at the same time, stir for 1 hour, then ultrasonicate for 20 minutes, clean the stain for 24 hours, filter, and wash several times with absolute ethanol and deionized water. The loaded activated carbon was dried at 120 °C for 2 h and calcined at 450 °C for 2 h to obtain nitrogen-doped activated carbon-supported nano-TiO 2 . Nitrogen-doped activated carbon-supported nano-TiO 2 After impregnating with chloroplatinic acid (weighed according to the mass fraction of Pt in the catalyst of 1%) solution by equal volume impregnation method,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com