Three-dimensional Pt-Pb nano floricome type enzyme-free glucose sensor electrode as well as preparation and application thereof

A glucose sensor and nanoflower technology, applied in the direction of electrochemical variables of materials, can solve the problems of not easy to generate response current, slow overall kinetics, low sensitivity, etc., and achieve strong anti-interference ability, wide linear range, and good application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

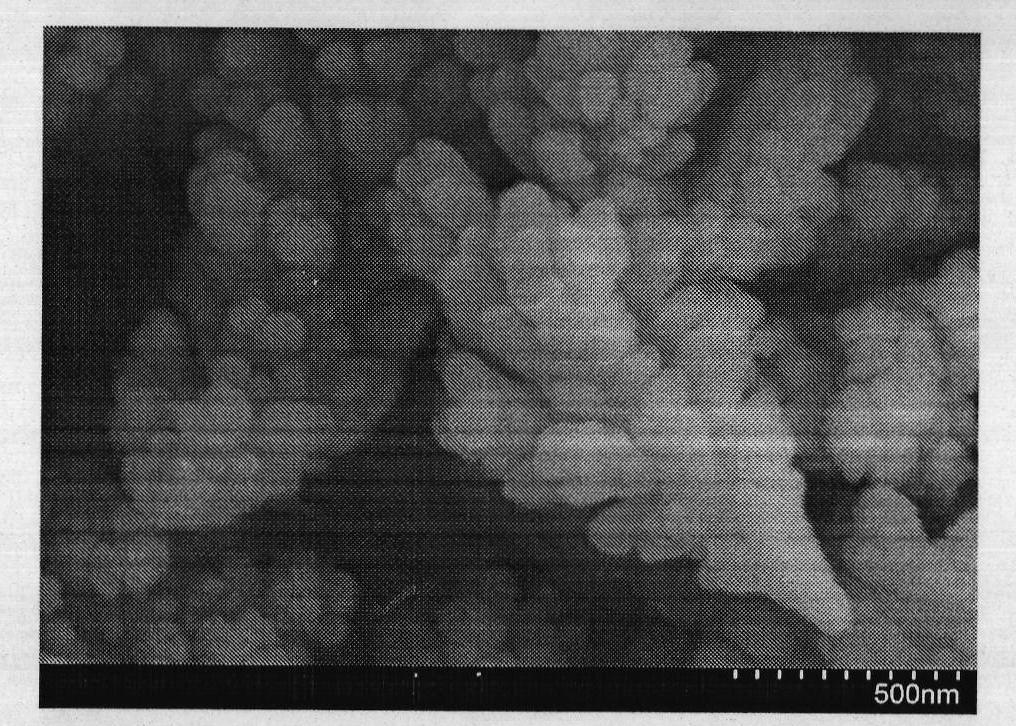

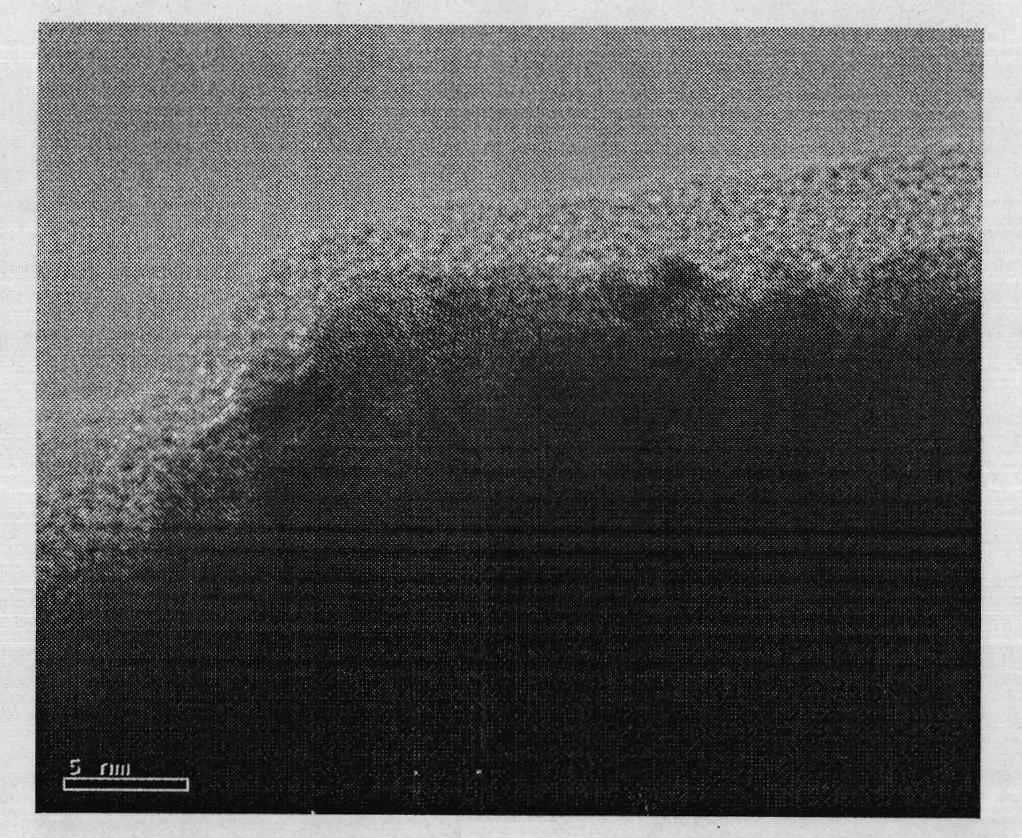

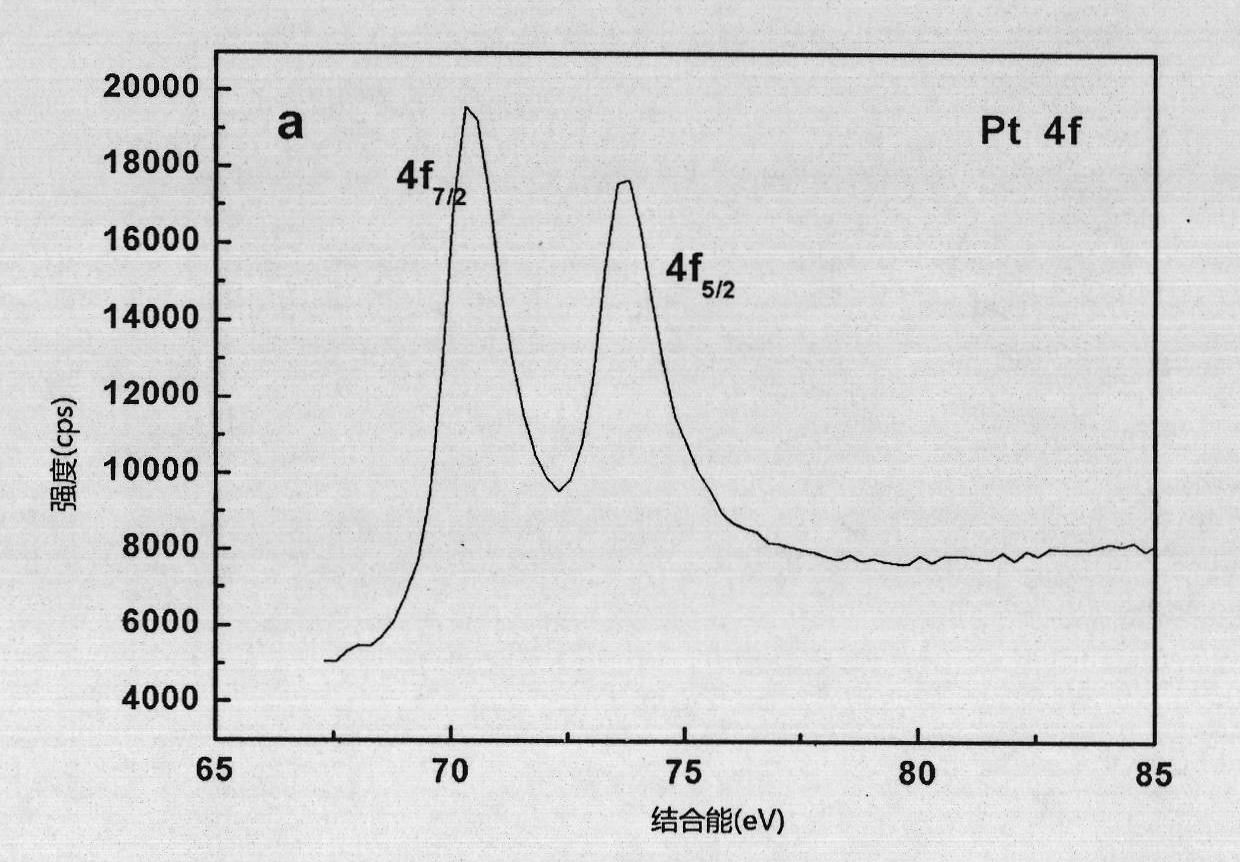

[0024] Stainless steel acupuncture needles (0.35mm×15mm, Tianjin Yipeng Medical Instrument Co., Ltd.) were taken, rinsed repeatedly with twice distilled water, ultrasonicated, placed in PBS buffer solution with pH=7.0, and activated by cyclic voltammetry for 10 cycles. Electrolyte composition: the concentration of chloroplatinic acid is 3.3×10 -3 mol / L, the concentration of lead acetate is 1.65×10 -3 mol / L, the concentration of hydrochloric acid is 0.5mol / L. A three-electrode system was used in the experiment, with pretreated stainless steel acupuncture needles as working electrodes, platinum electrodes as auxiliary electrodes, and saturated calomel electrodes as reference electrodes. During the electrodeposition process, the electrolyte beaker was placed in ultrasonic vibration (100 watts), first deposited at a constant current of 10 mA for 10 min, and then deposited at a constant potential of -0.1 V for 6 min, taken out, rinsed with double distilled water, and dried. The s...

Embodiment 2

[0026] Stainless steel acupuncture needles (d=0.35 mm) were taken, rinsed repeatedly with twice distilled water, ultrasonicated, placed in PBS buffer solution with pH=7.0, and activated by cyclic voltammetry scanning for 10 cycles. Electrolyte composition: the concentration of chloroplatinic acid is 3.3×10 - 3 mol / L, the concentration of lead acetate is 1.65×10 -3 mol / L, the concentration of hydrochloric acid is 0.5mol / L. A three-electrode system was used in the experiment, with pretreated stainless steel acupuncture needles as working electrodes, platinum electrodes as auxiliary electrodes, and saturated calomel electrodes as reference electrodes. During the electrodeposition process, the electrolyte beaker was placed in ultrasonic vibration (100 watts), first deposited at a constant current of 10 mA for 6 min, and then deposited at a constant potential of -0.1 V for 6 min, taken out, rinsed with twice distilled water, and dried. The electrochemical test adopts a three-ele...

Embodiment 3

[0028] Stainless steel acupuncture needles (d=0.35 mm) were taken, rinsed repeatedly with twice distilled water, ultrasonicated, placed in PBS buffer solution with pH=7.0, and activated by cyclic voltammetry scanning for 10 cycles. Electrolyte composition: the concentration of chloroplatinic acid is 3.3×10 - 3 mol / L, the concentration of lead acetate is 1.65×10 -3mol / L, the concentration of hydrochloric acid is 0.5mol / L. A three-electrode system was used in the experiment, with pretreated stainless steel acupuncture needles as working electrodes, platinum electrodes as auxiliary electrodes, and saturated calomel electrodes as reference electrodes. During the electrodeposition process, the electrolyte beaker was placed in ultrasonic vibration (100 watts), first deposited at a constant current of 0.1mA for 10 minutes, and then deposited at a constant potential of -0.1V for 10 minutes, taken out, rinsed with twice distilled water, and dried . The electrochemical test adopts a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com