Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

113 results about "Contact lens material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

There are three main categories of contact lenses, based on the materials they are made of: soft contacts, rigid gas permeable (GP) contacts, and hybrid contact lenses. Soft contacts are made of pliable hydrophilic (water-loving) plastics called hydrogels.

Contact lens materials, designs, substances, and methods

InactiveUS7878650B2Improve performanceReduce the possibilityOptical partsPerformance enhancementReduced size

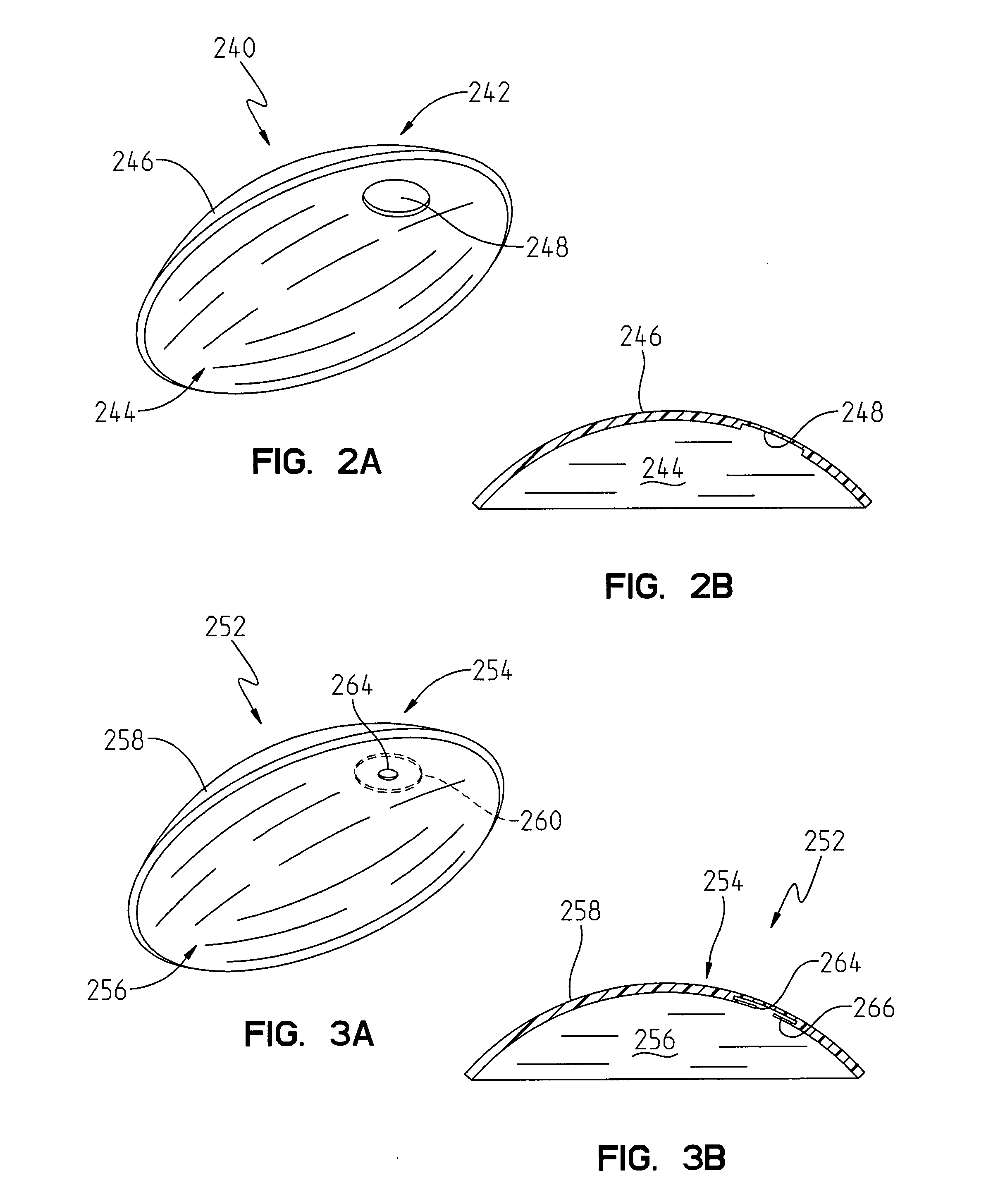

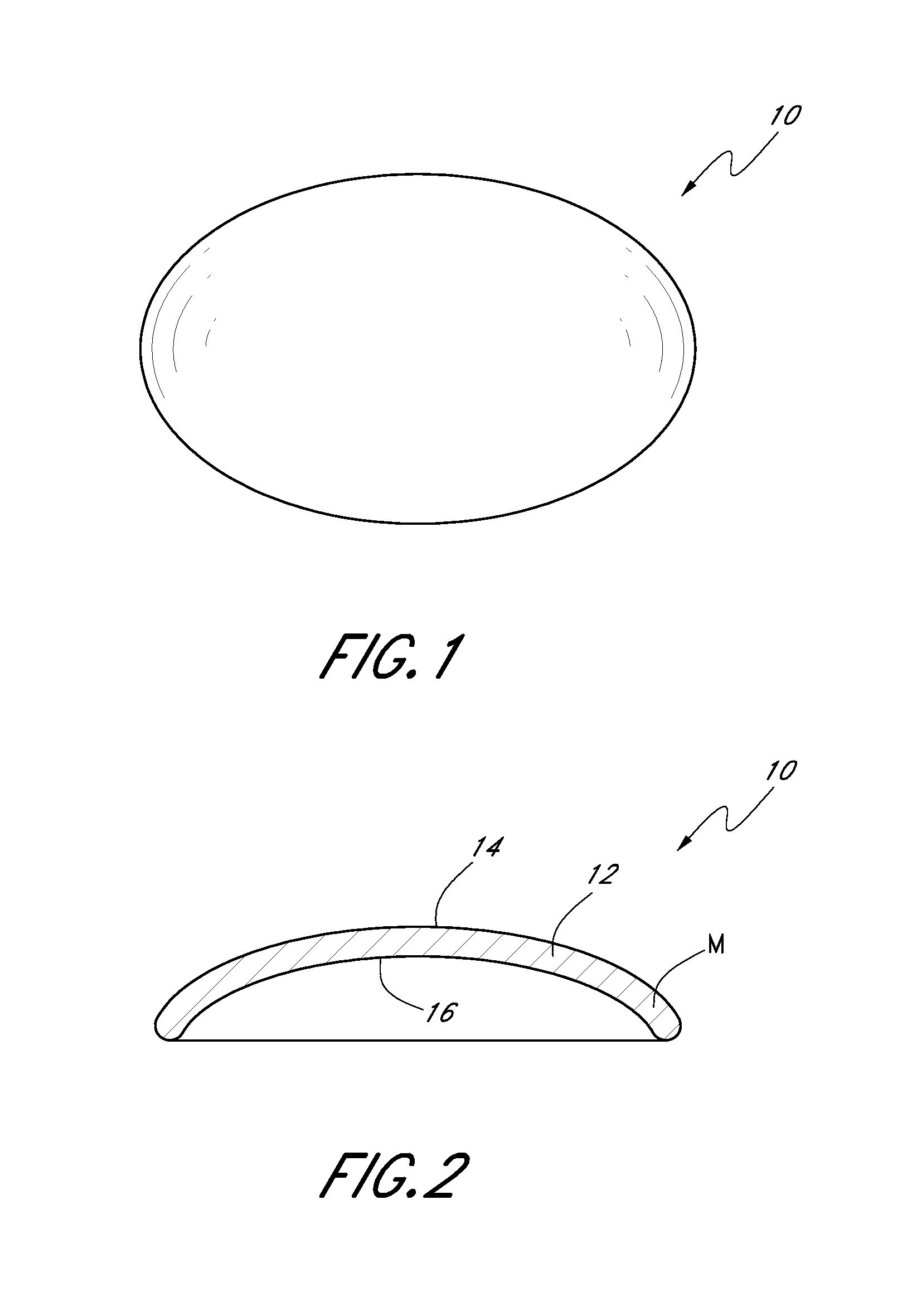

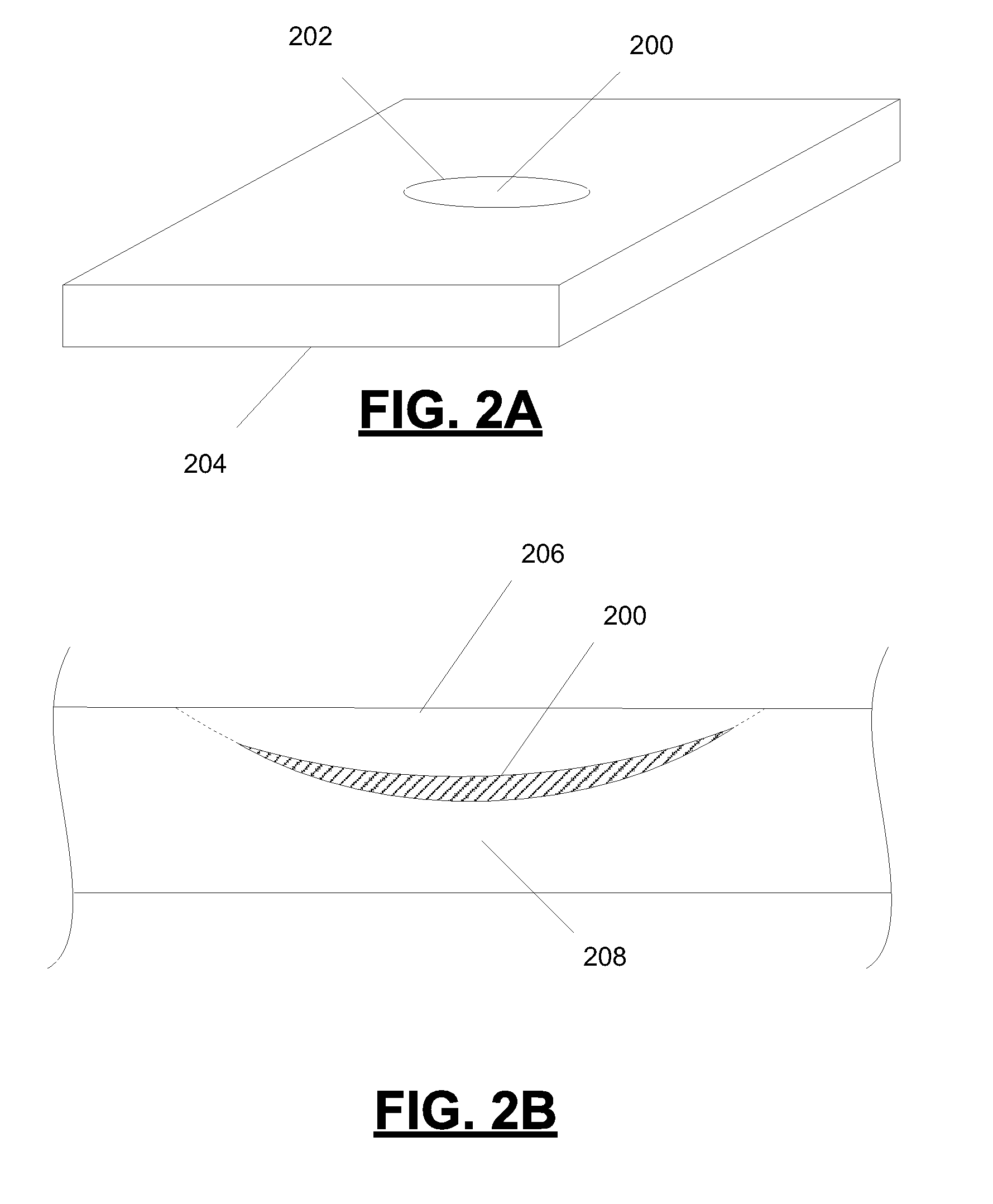

A contact lens is provided that is capable of being worn by a user. The lens includes a contact lens body having an eye-engaging surface placeable against a surface of an eye and an outer surface. Microphobic features are provided in the lens for eliminating microbes from the eye-engaging surface. Preferably, these microphobic features are chosen from a group consisting of electrical charge inducing agents, magnetic field inducing agents, chemical agents and textural features. In another embodiment of the present invention, a contact lens is provided that can include a reservoir portion capable of holding a performance enhancement agent for enhancing the performance of the lens. The performance enhancement agent can include such thins as sealant solutions, protective agents, therapeutic agents, anti-microbial agents, medications and reduced size transparent portions. In other embodiments, a wide variety of designs, materials and substances are disclosed for use with contact lenses.

Owner:DOMESTIC ASSET LLP

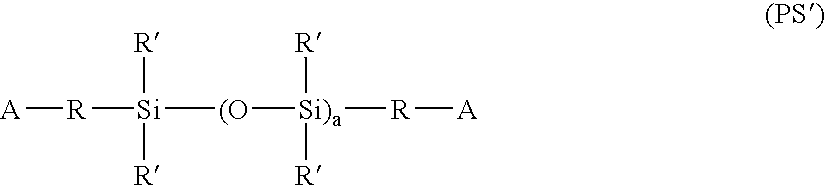

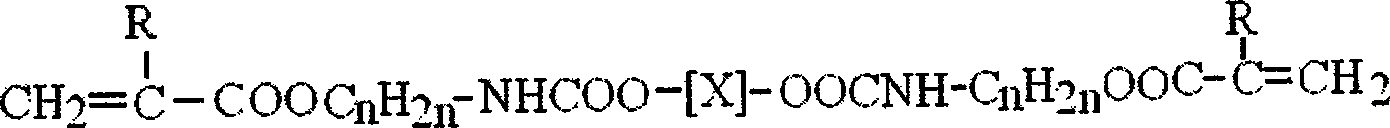

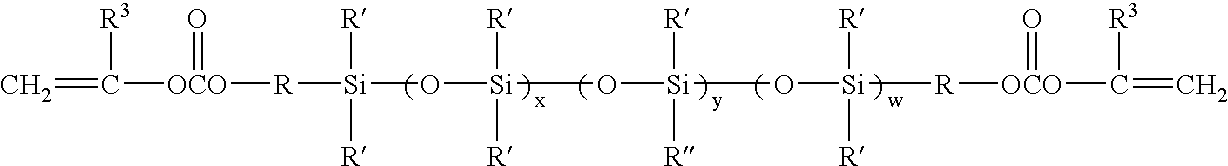

Rigid gas permeable lens material

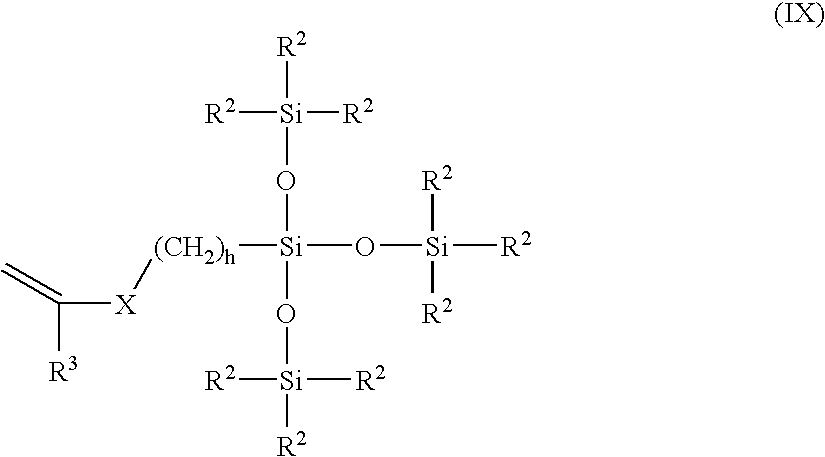

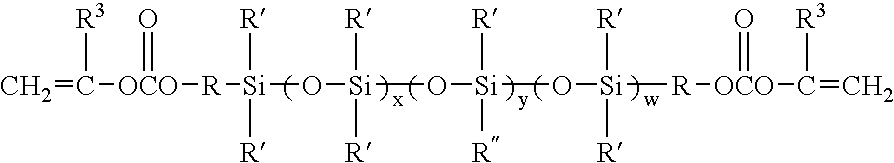

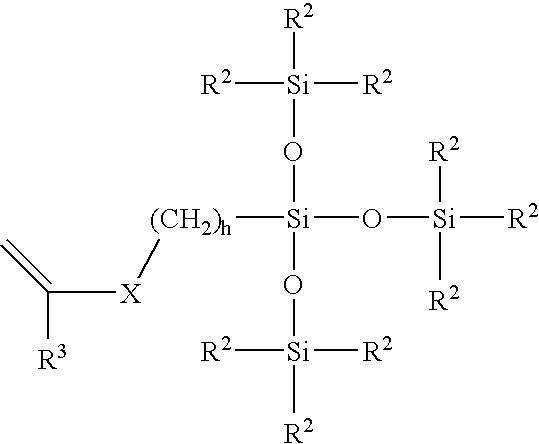

A copolymer useful as a rigid gas permeable contact lens material is the polymerization product of a monomeric mixture comprising a polysiloxane-containing urethane or urea prepolymer endcapped with polymerizable ethylenically unsaturated radicals.

Owner:BAUSCH & LOMB INC

Optical device and method for non-invasive real-time testing of blood sugar levels

A device and method for non-invasive real-time testing of blood sugar levels in a diabetic patient. Specifically, this invention is directed to an optical device comprising a contact lens having a glucose-sensing optical pattern imprinted, marked, coated or otherwise disposed on or incorporated within the contact lens. The indicator pattern is further comprised of a glucose-sensing coating containing a boronic acid derivative, which reacts in the presence of glucose to create a readable pattern, which can then be correlated to a pre-determined or pre-calibrated blood glucose level. A polarized light source is one method that may be used to read the indicator pattern. The invention is also directed to methods for quantifying blood glucose levels using the inventive optical device and manufacturing methods for disposing the glucose-sensing coating onto, or incorporating it into, the contact lens material.

Owner:THE UNIVERSITY OF AKRON

Contact lens materials

InactiveUS6921802B2High oxygen permeabilityLow densityOptical partsOptical elementsSingle vesselTrimethylsilyl

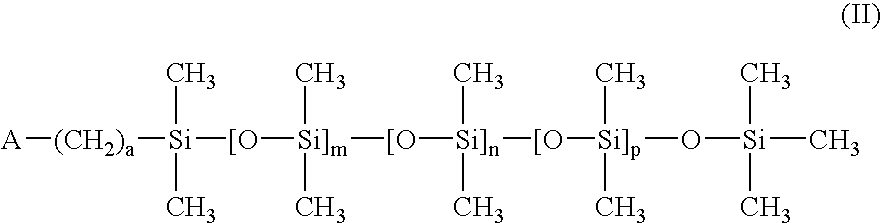

A method for reducing the modulus of polymer silicone hydrogel compositions by employing monomeric polysiloxanes endcapped with trimethylsilyl to reduce the crosslinking density of the hydrogel. The synthesis consists of a single vessel acid catalyzed ring opening polymerization and may be employed to produce copolymers useful as hydrogel contact lens materials.

Owner:BARCLAYS BANK PLC AS SUCCESSOR AGENT

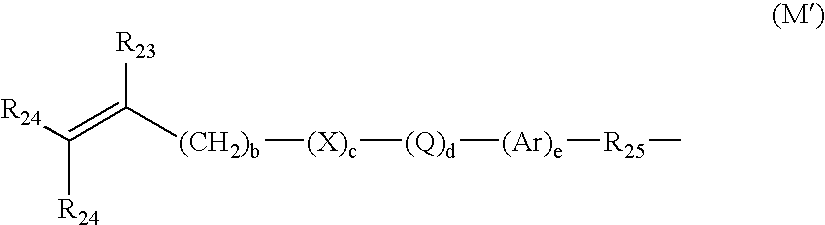

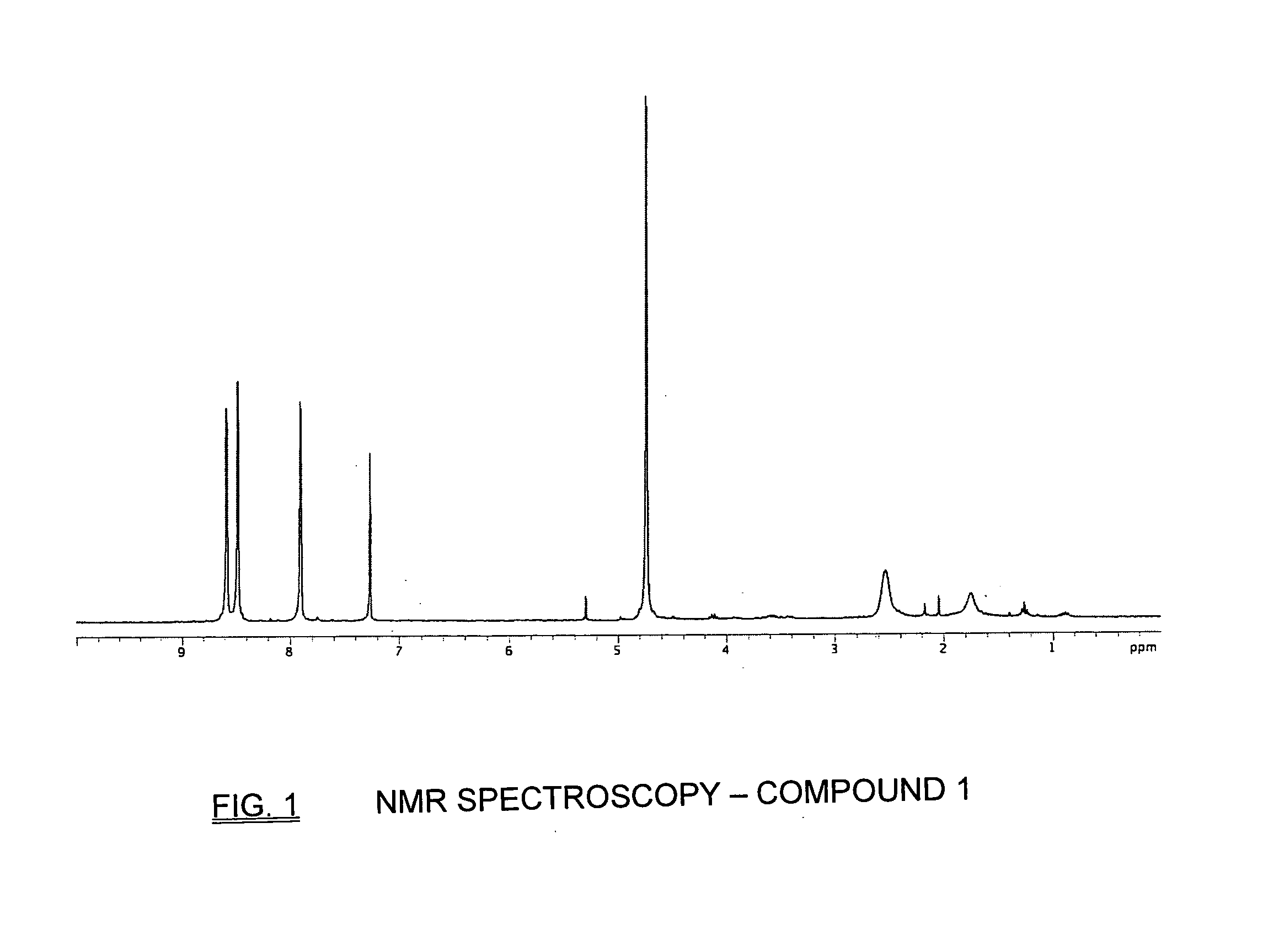

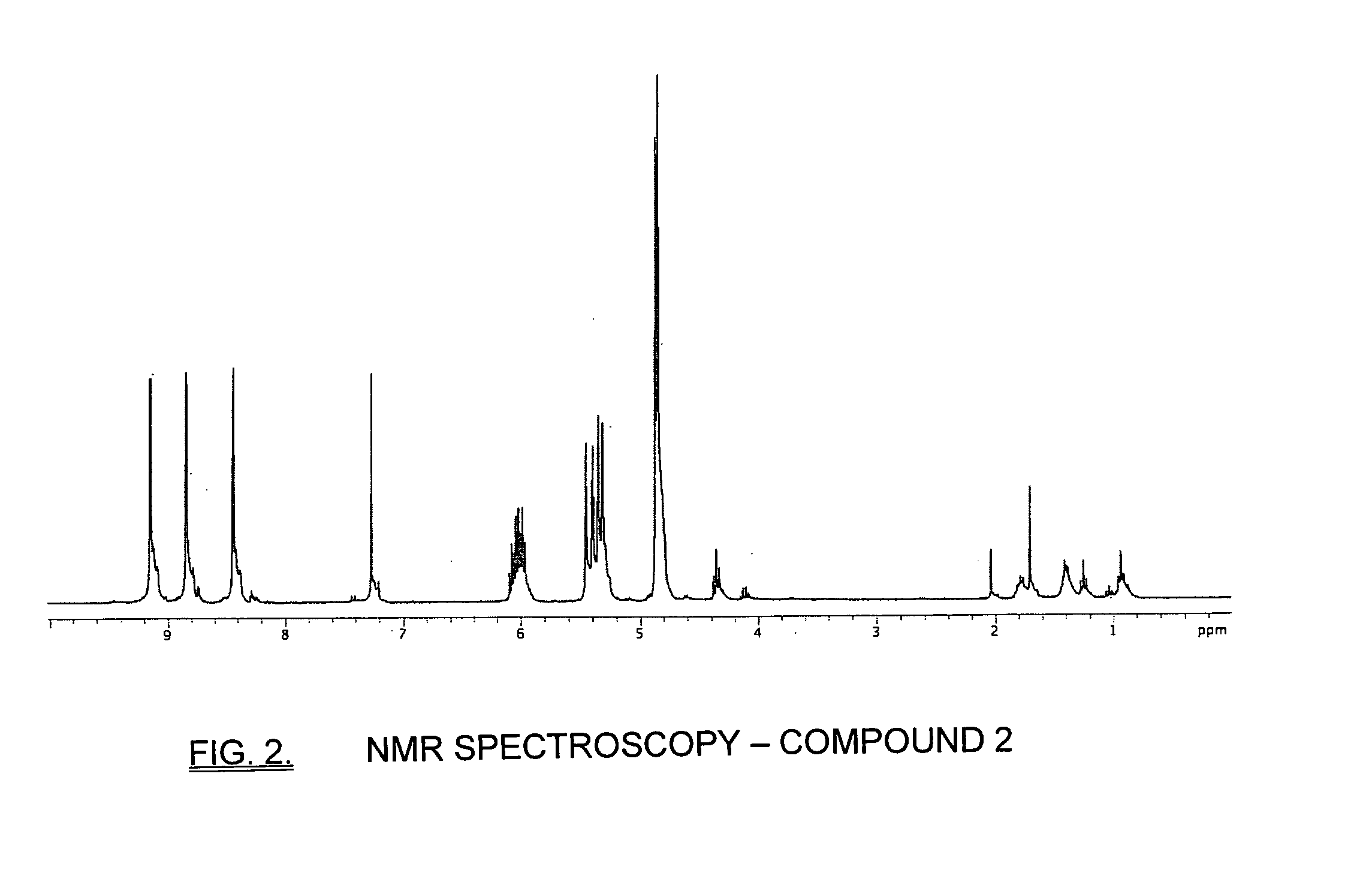

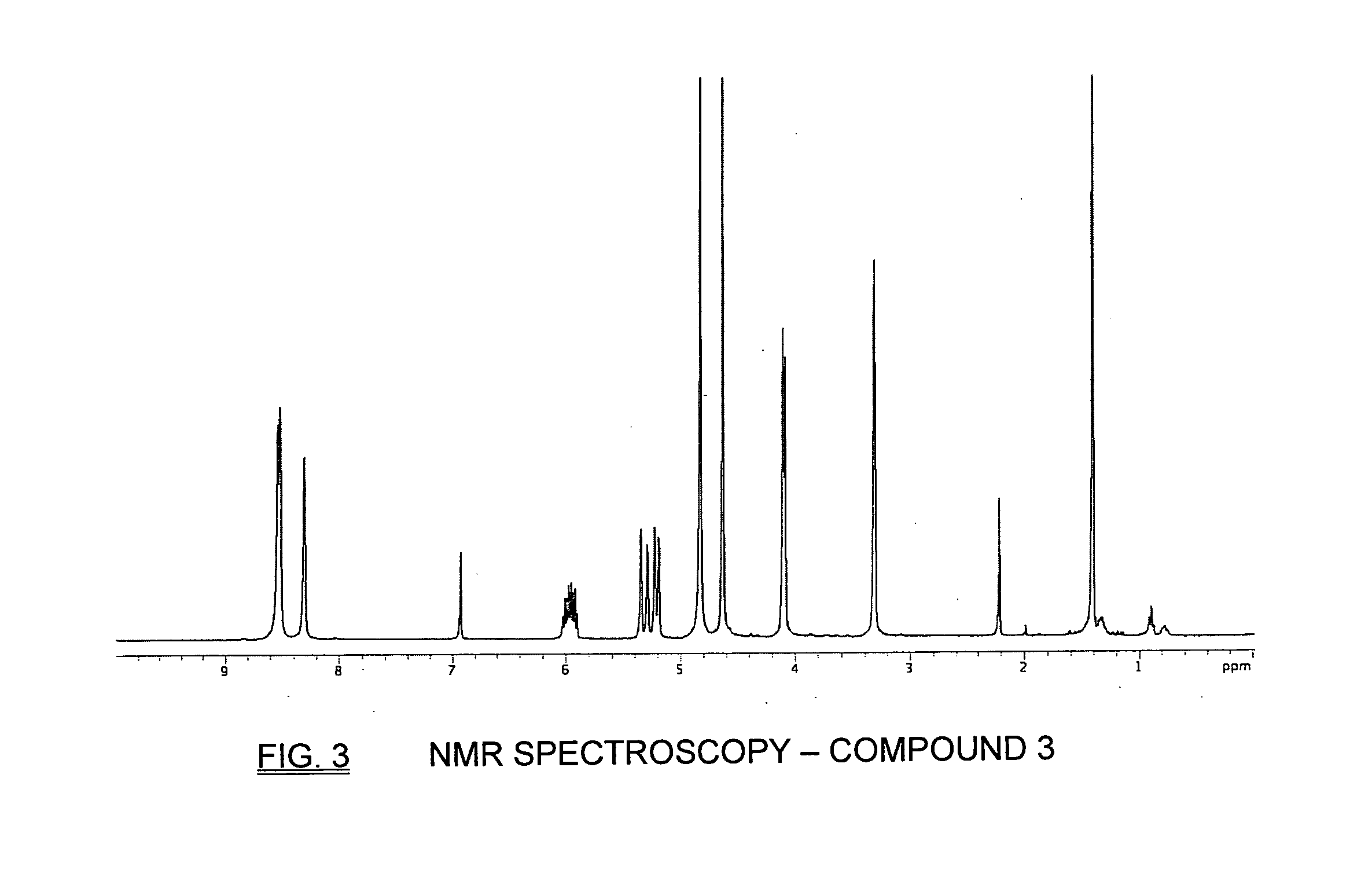

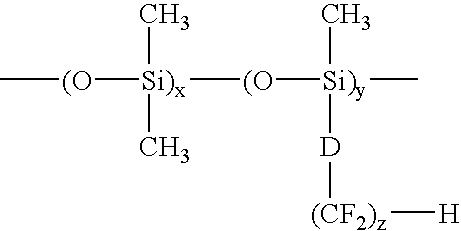

Silicone hydrogels based on vinyl carbonate endcapped fluorinated side chain polysiloxanes

InactiveUS6891010B2Maintain good propertiesLow modulusOptical partsProsthesisEndcappingSilicone Gels

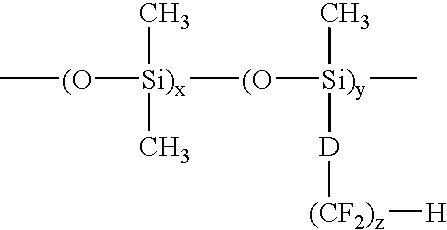

Vinyl carbonate endcapped polysiloxanes containing a fluorinated side chain are useful as biomaterials, especially hydrogel biomaterials, including contact lens materials.

Owner:BAUSCH & LOMB INC

Contact lens materials, designs, substances, and methods

InactiveUS20080002149A1Improve performanceReduce the possibilityOptical partsPerformance enhancementReduced size

A contact lens is provided that is capable of being worn by a user. The lens includes a contact lens body having an eye-engaging surface placeable against a surface of an eye and an outer surface. Microphobic features are provided in the lens for eliminating microbes from the eye-engaging surface. Preferably, these microphobic features are chosen from a group consisting of electrical charge inducing agents, magnetic field inducing agents, chemical agents and textural features. In another embodiment of the present invention, a contact lens is provided that can include a reservoir portion capable of holding a performance enhancement agent for enhancing the performance of the lens. The performance enhancement agent can include such thins as sealant solutions, protective agents, therapeutic agents, anti-microbial agents, medications and reduced size transparent portions. In other embodiments, a wide variety of designs, materials and substances are disclosed for use with contact lenses.

Owner:DOMESTIC ASSET LLP

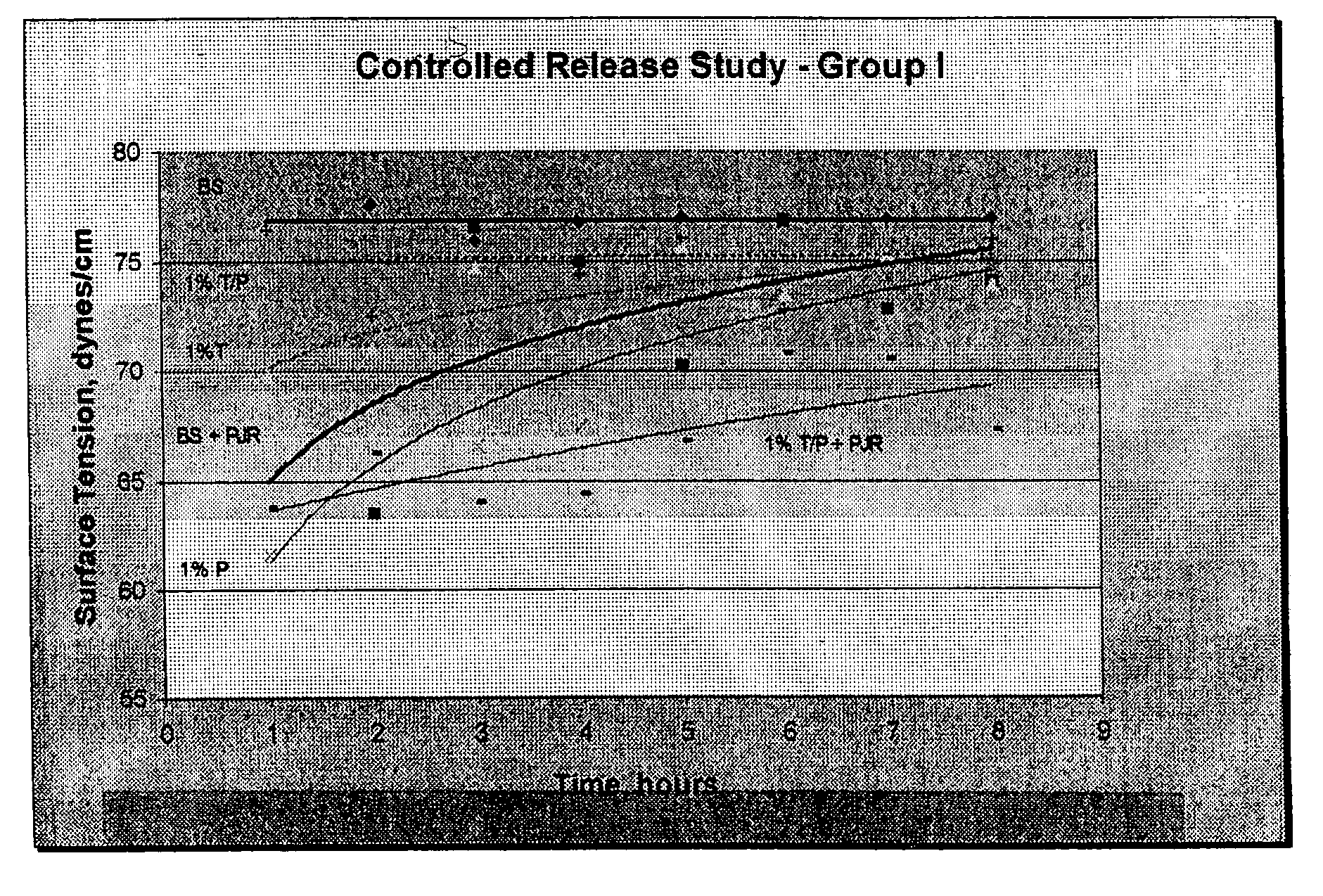

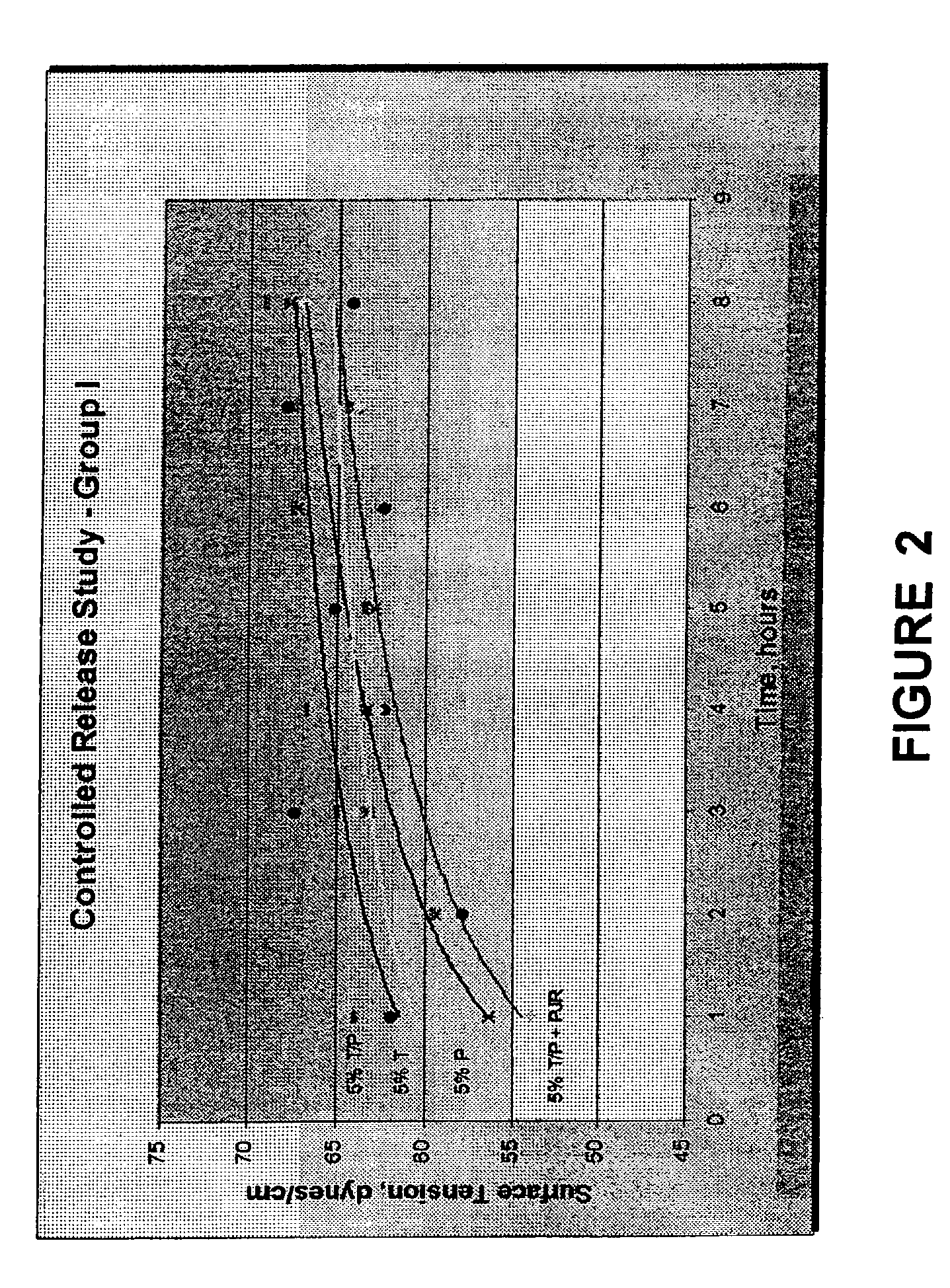

Method and composition for contact lenses

InactiveUS20060073185A1Reduce drynessLonger wetting performancePharmaceutical delivery mechanismProsthesisCationic polyelectrolytesChemistry

A solution for soft, hydrogel contact lenses includes a polyether that is controllably released into an eye's tear film when the lens is worn. Polyether components of the subject solution are released from the soft contact lens material matrix over long time periods to produce longer lasting wetting performance, improved lubricity, improved comfort, and / or reduced feeling of dryness from wearing contact lenses. The solution further includes a cationic polyelectrolyte.

Owner:BAUSCH & LOMB INC

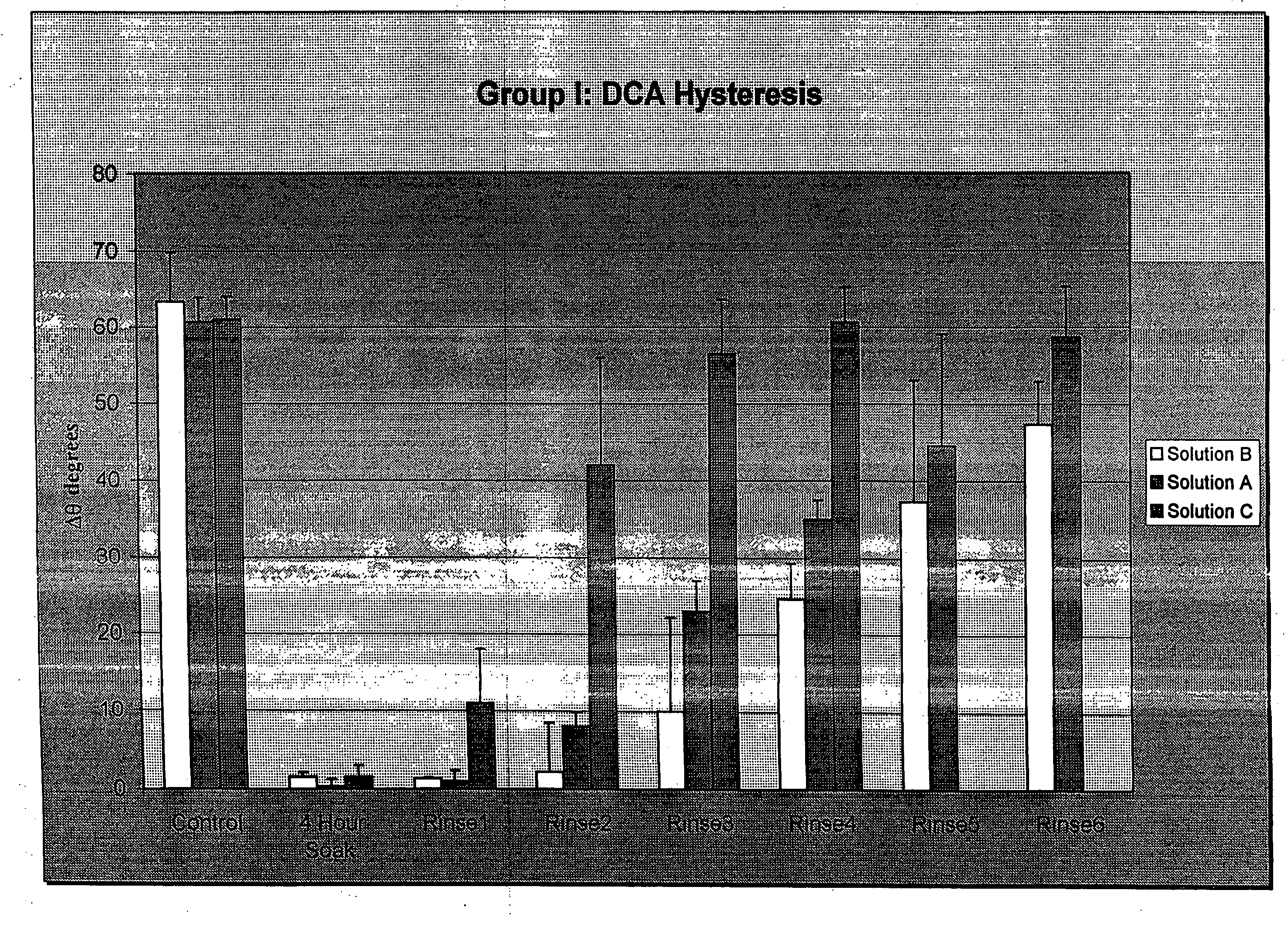

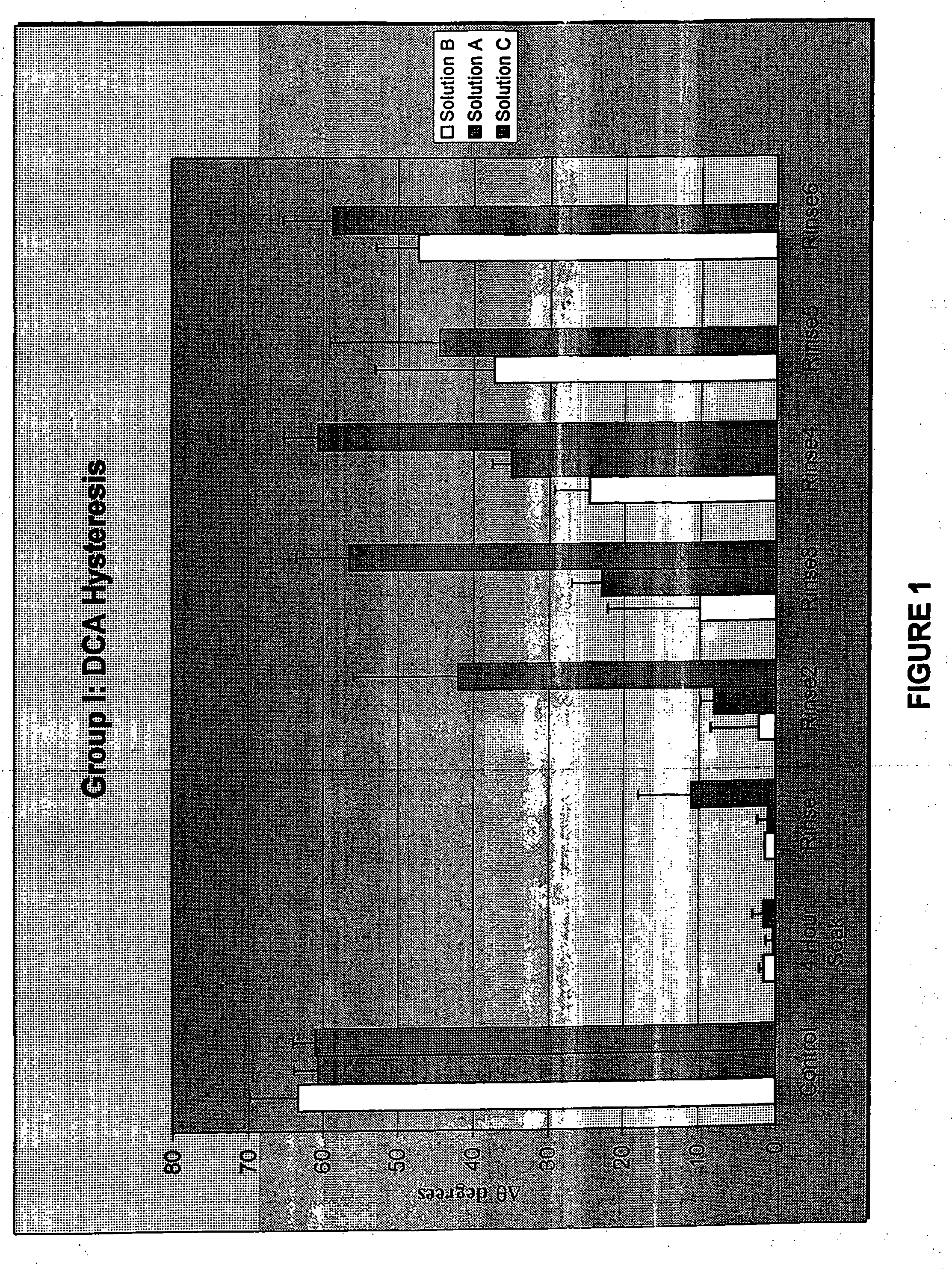

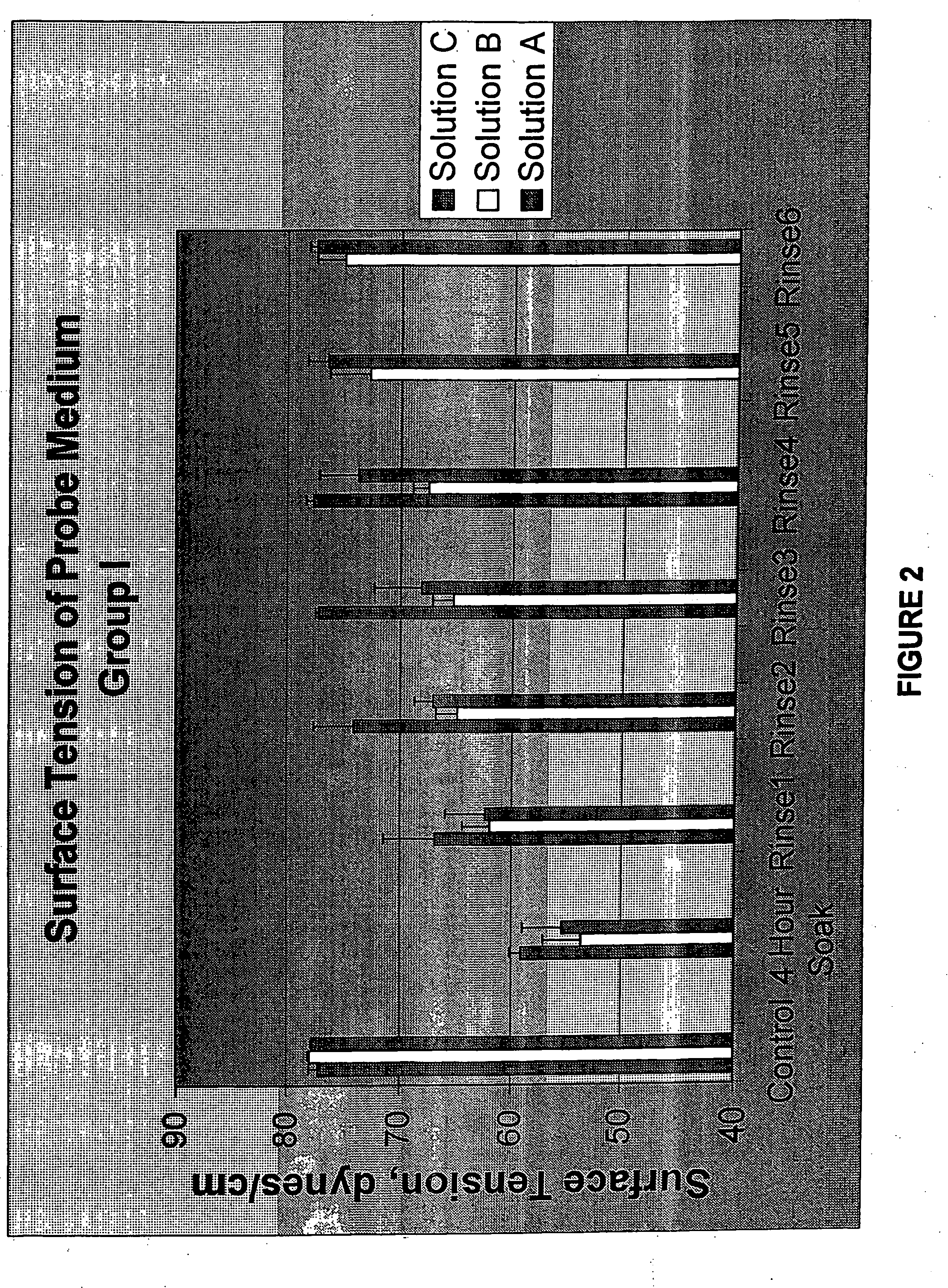

Methods for improving the hydrophilicity of contact lenses and contact lenses having the same

ActiveUS7329001B2Improve wettabilitySmooth connectionSpectales/gogglesOptical partsGas-permeable contact lensChemical agent

Owner:SYNERGEYES

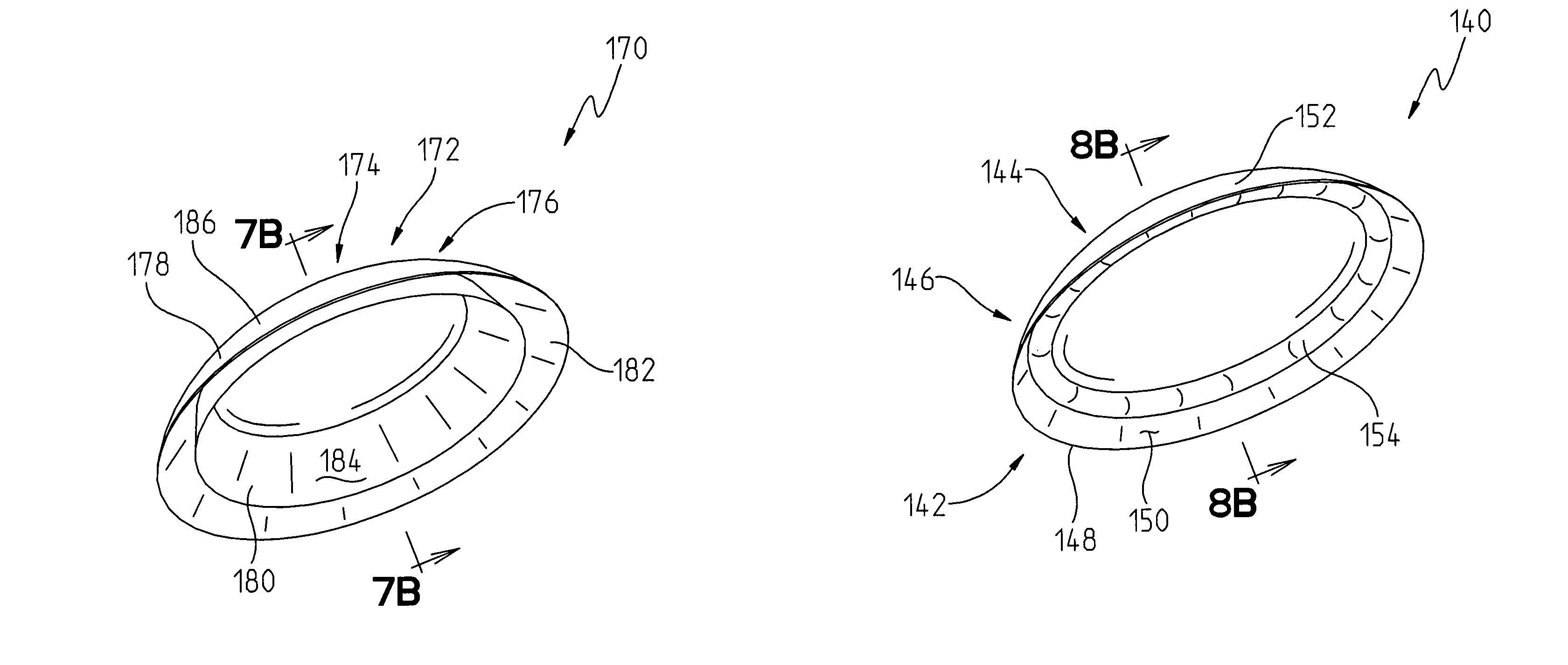

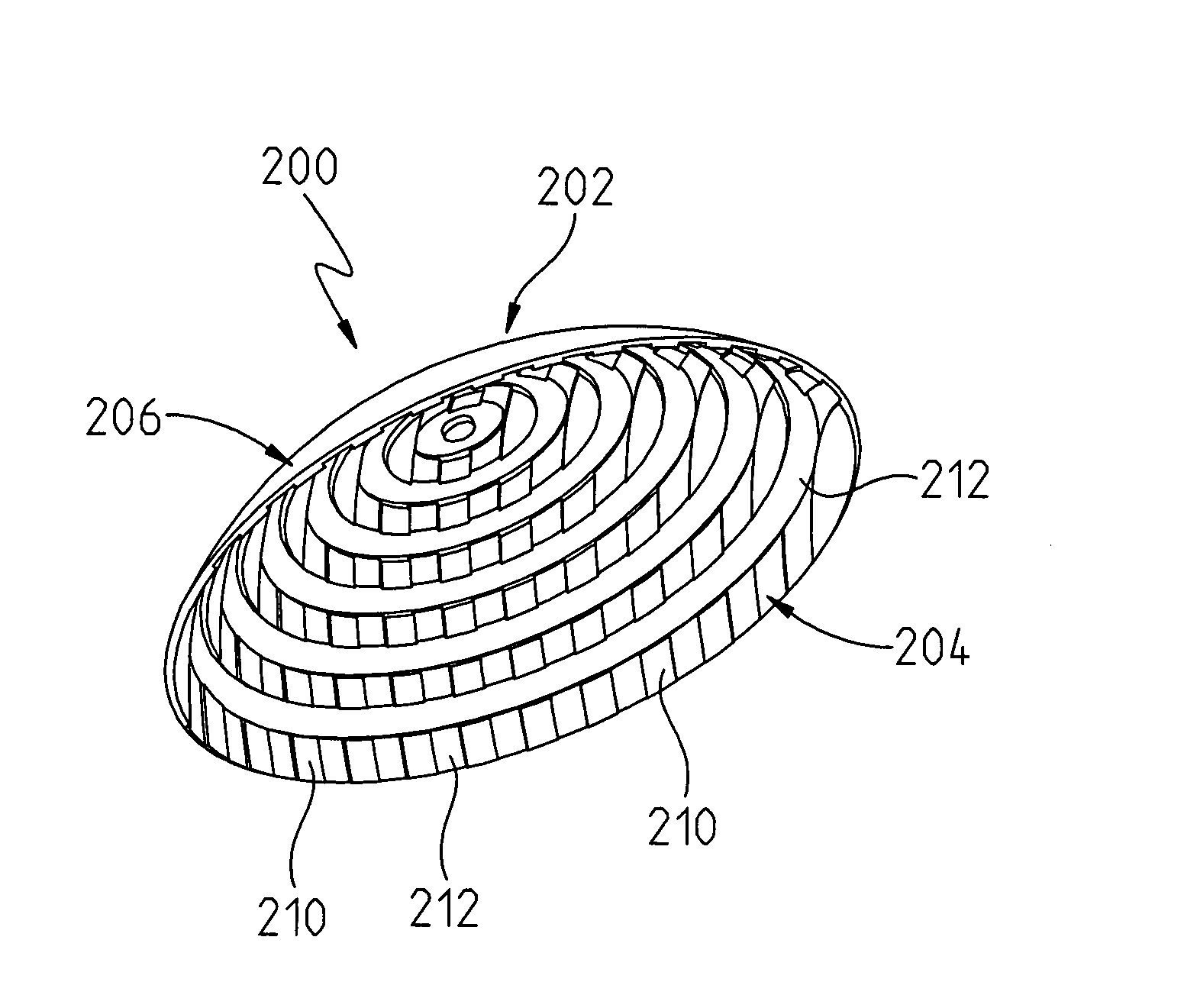

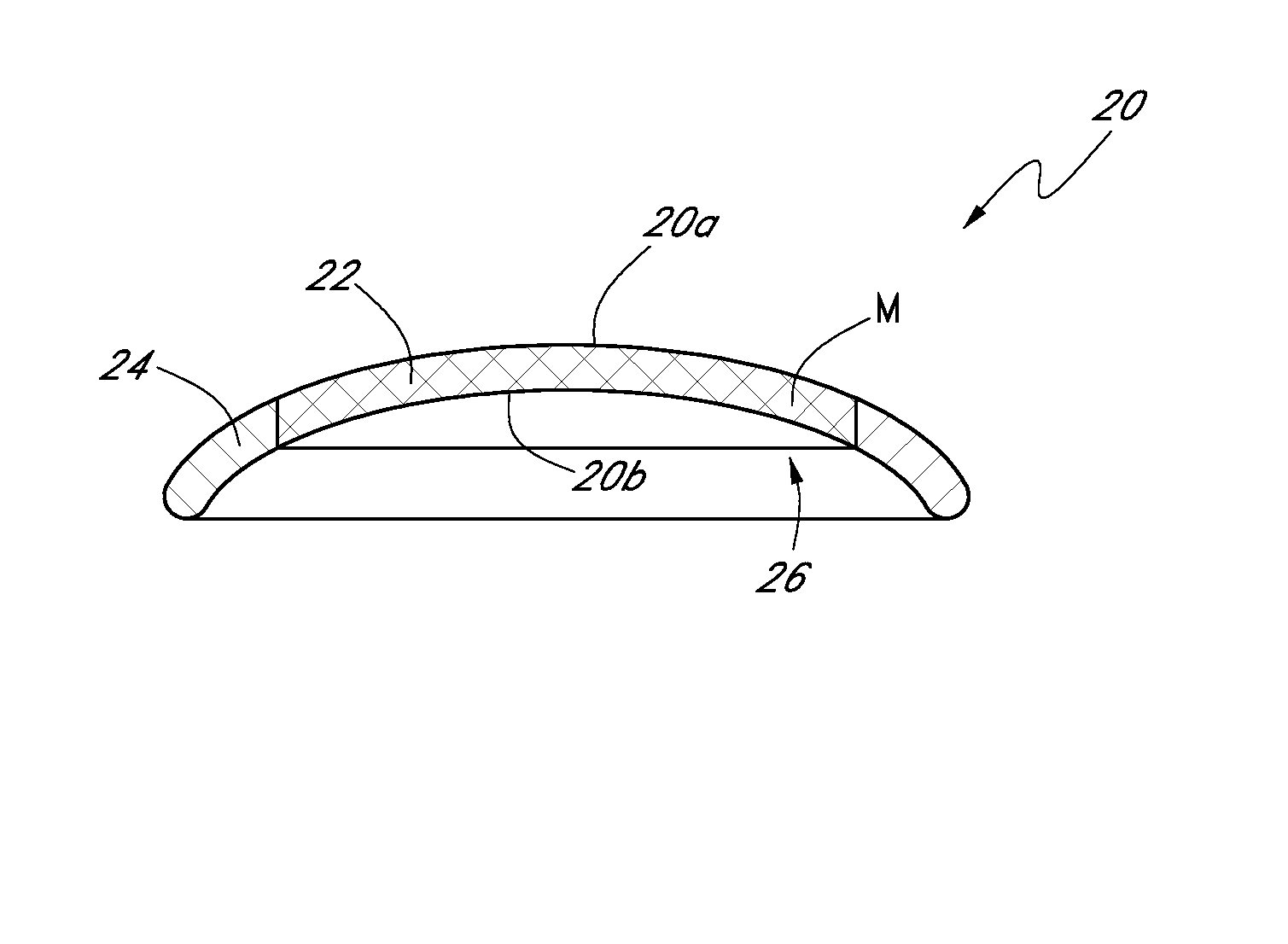

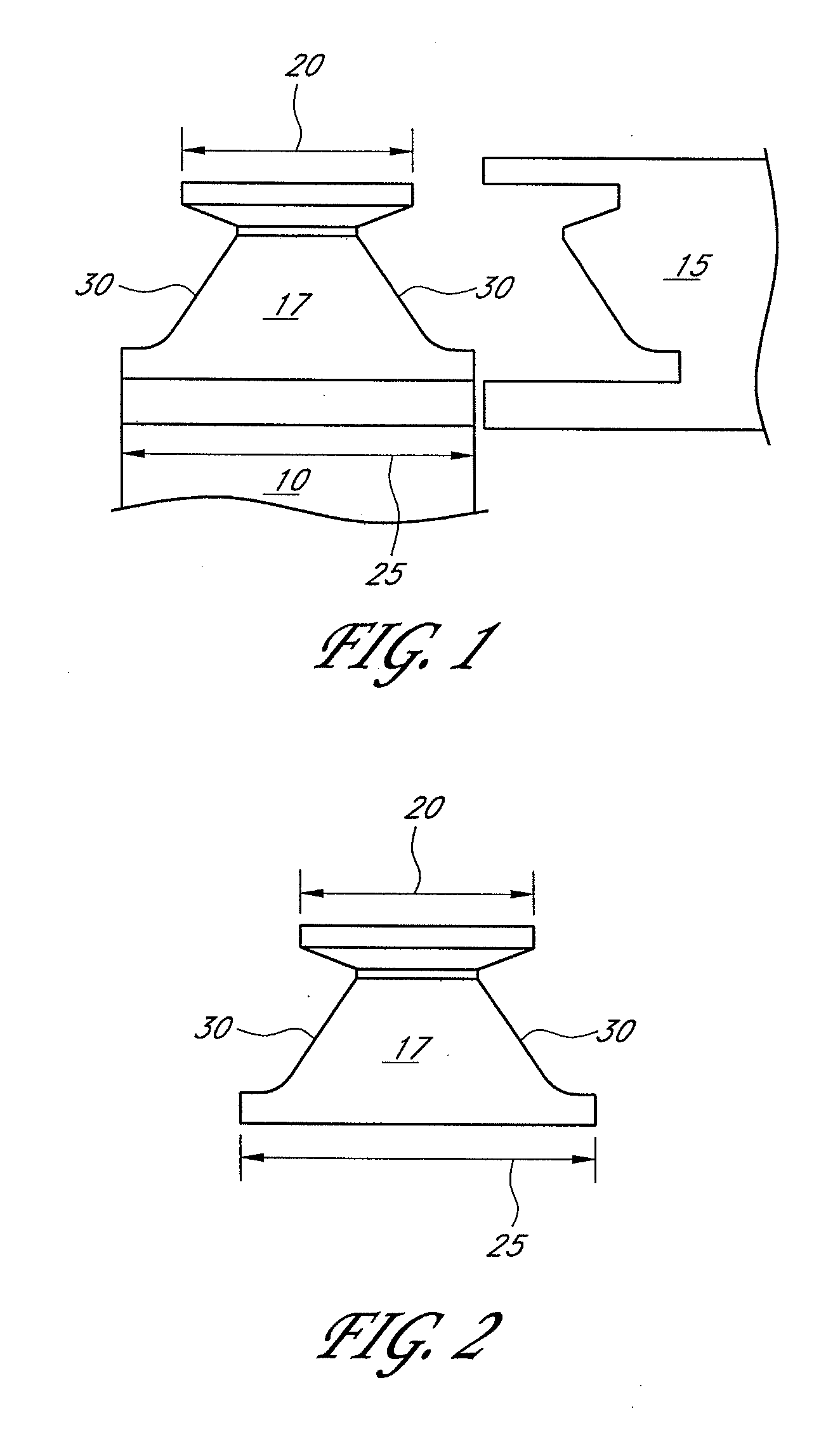

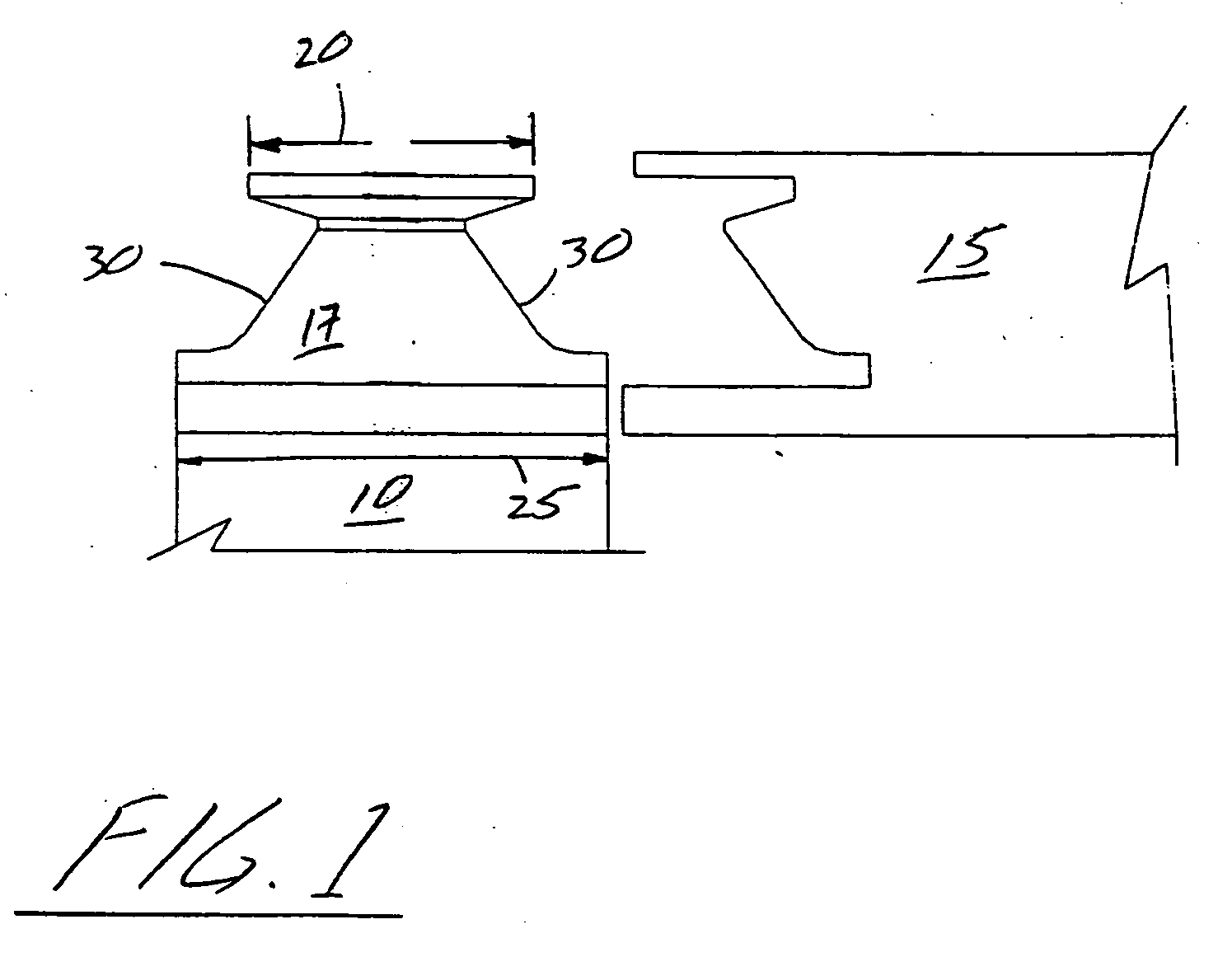

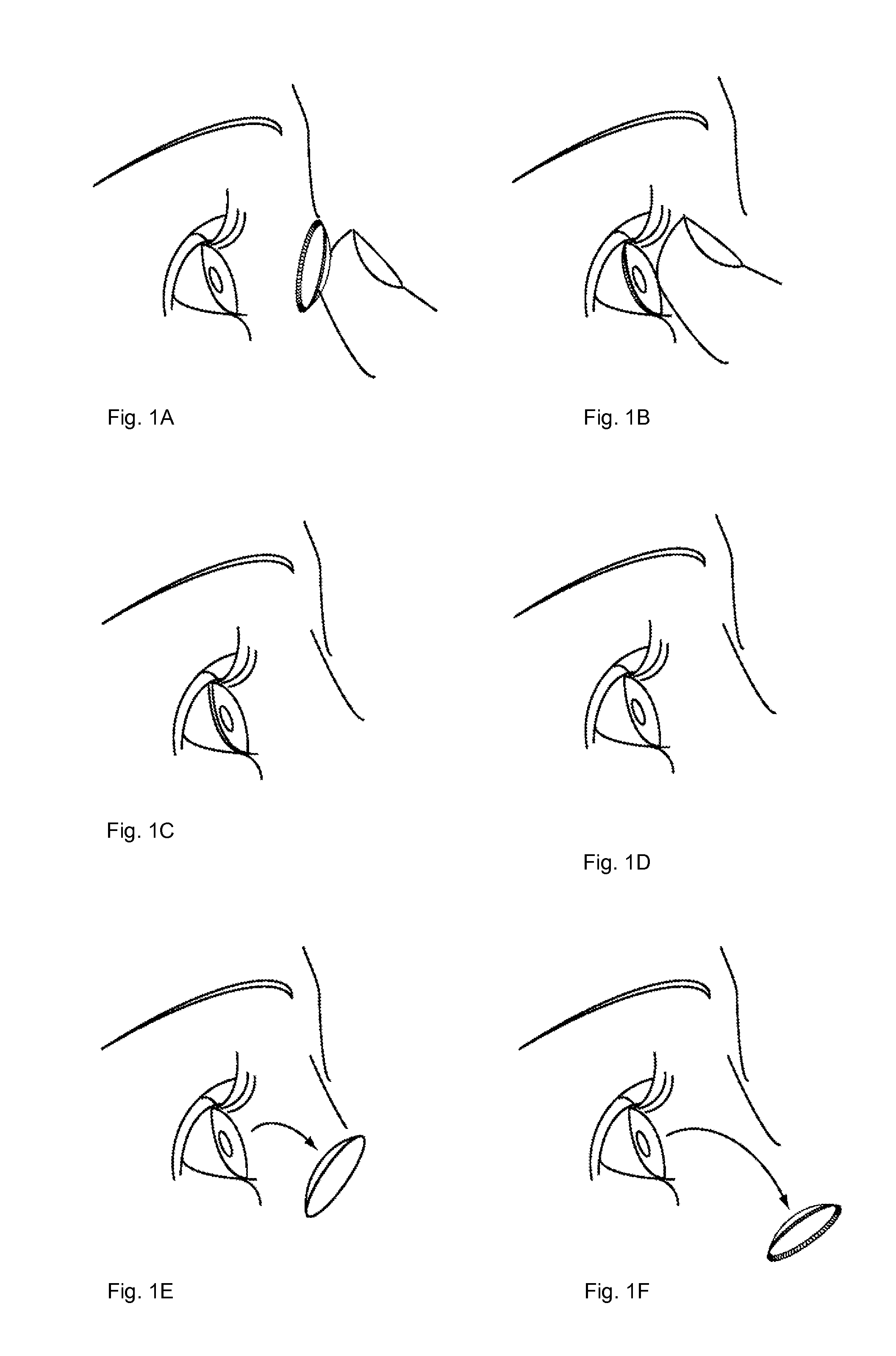

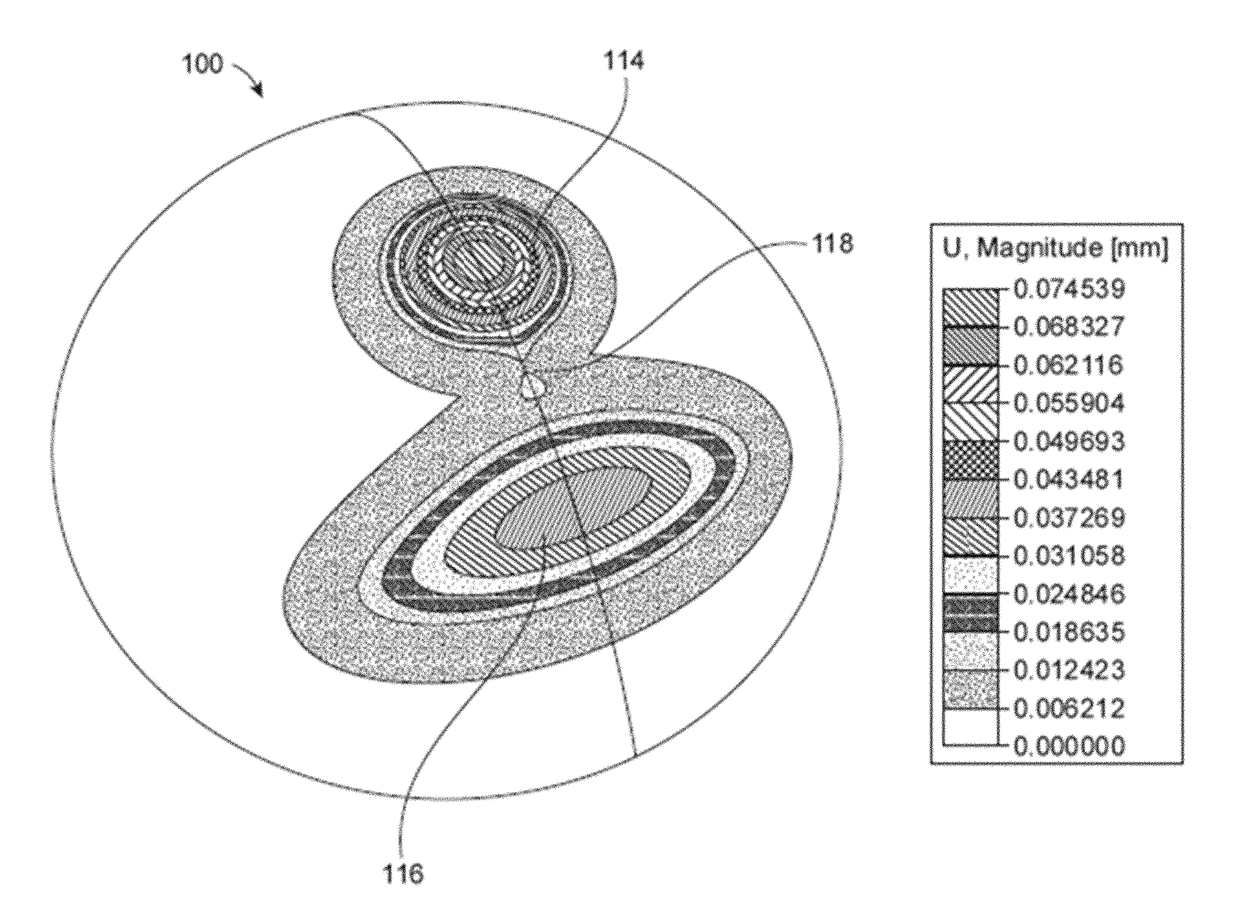

Hybrid contact lens system and method

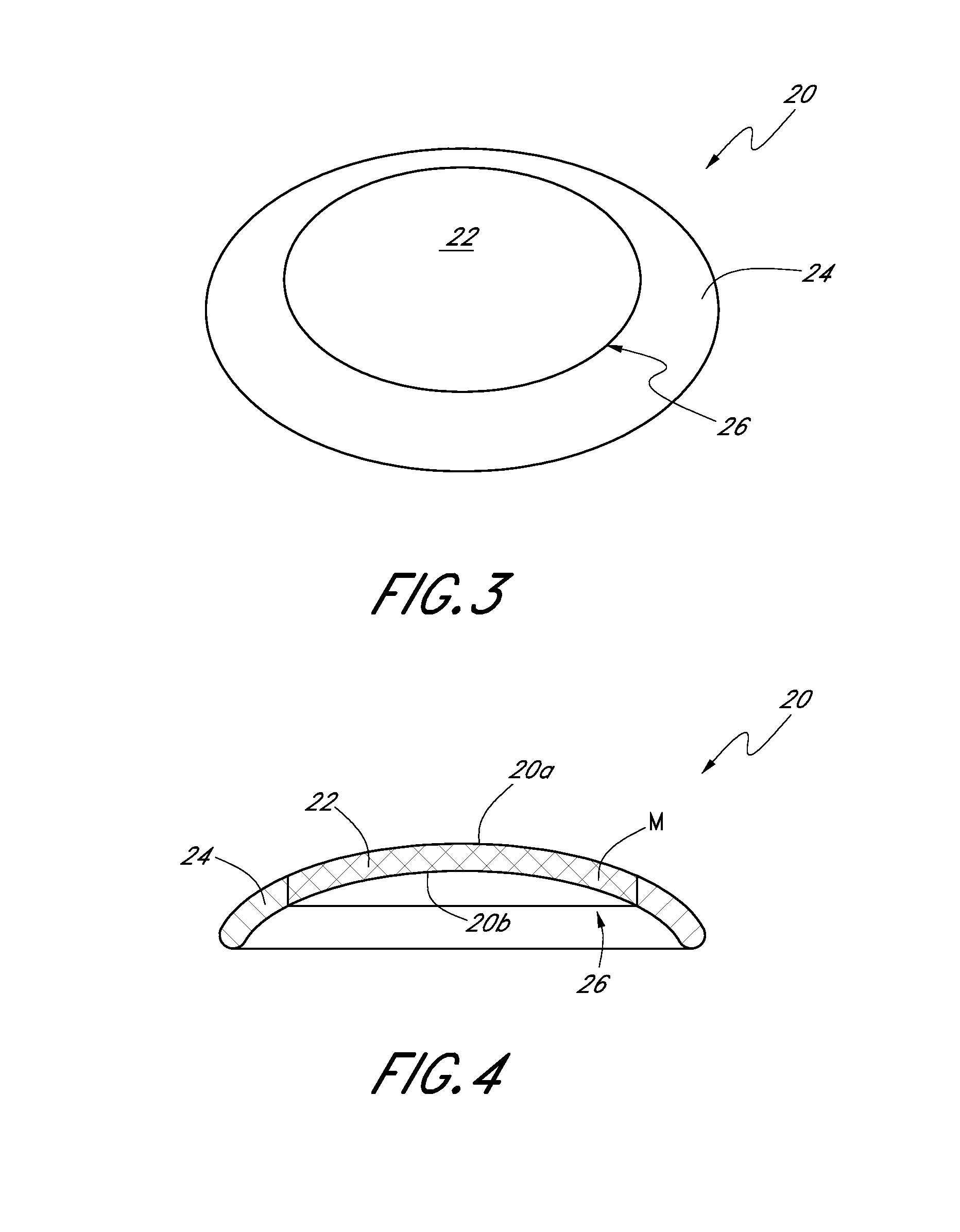

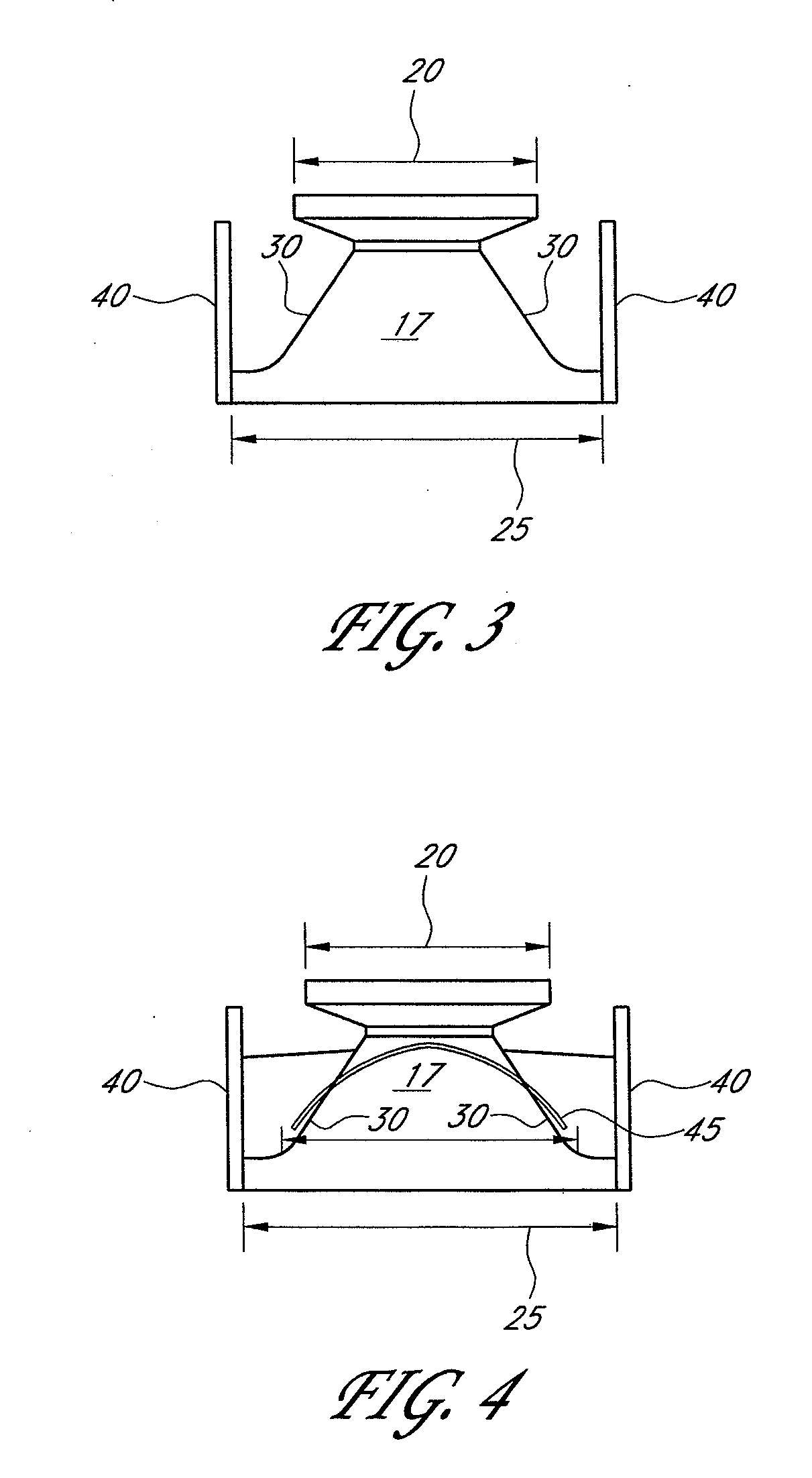

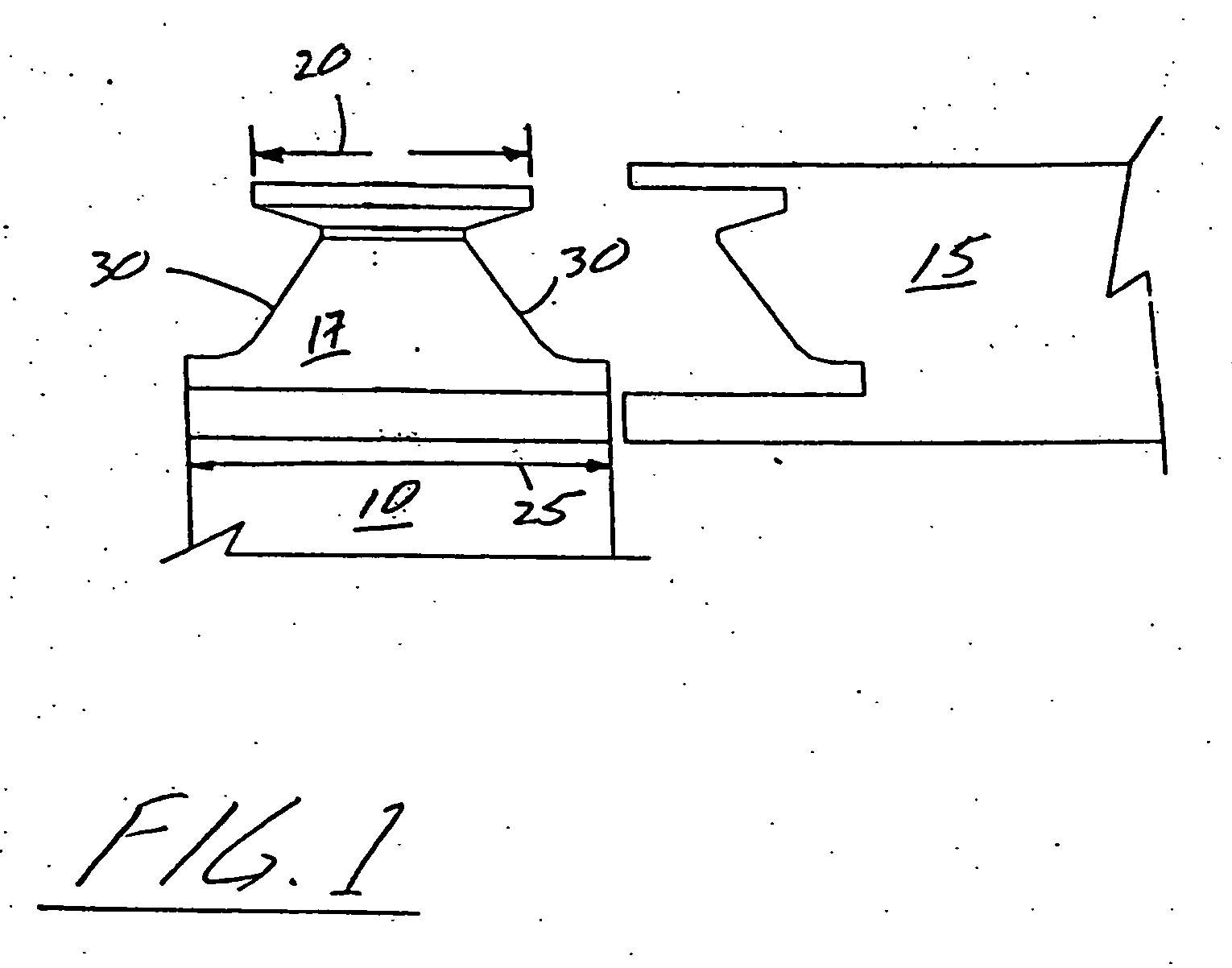

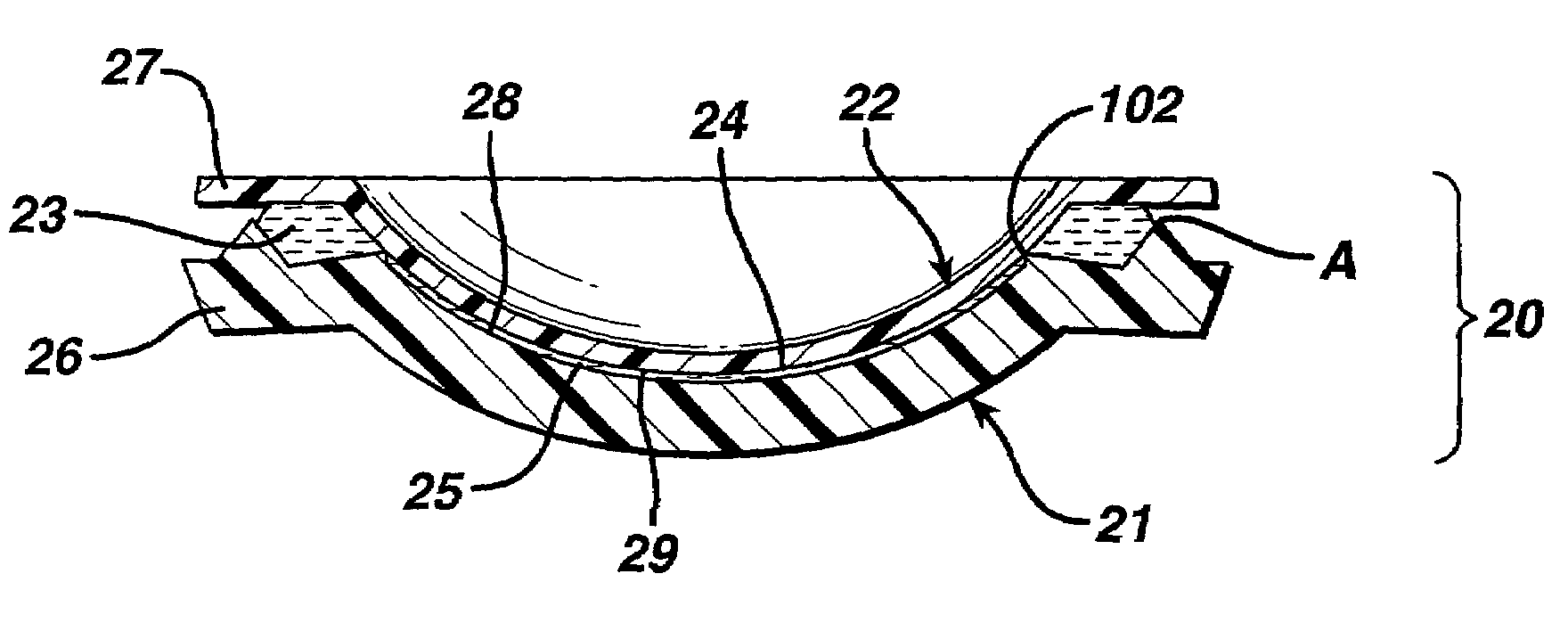

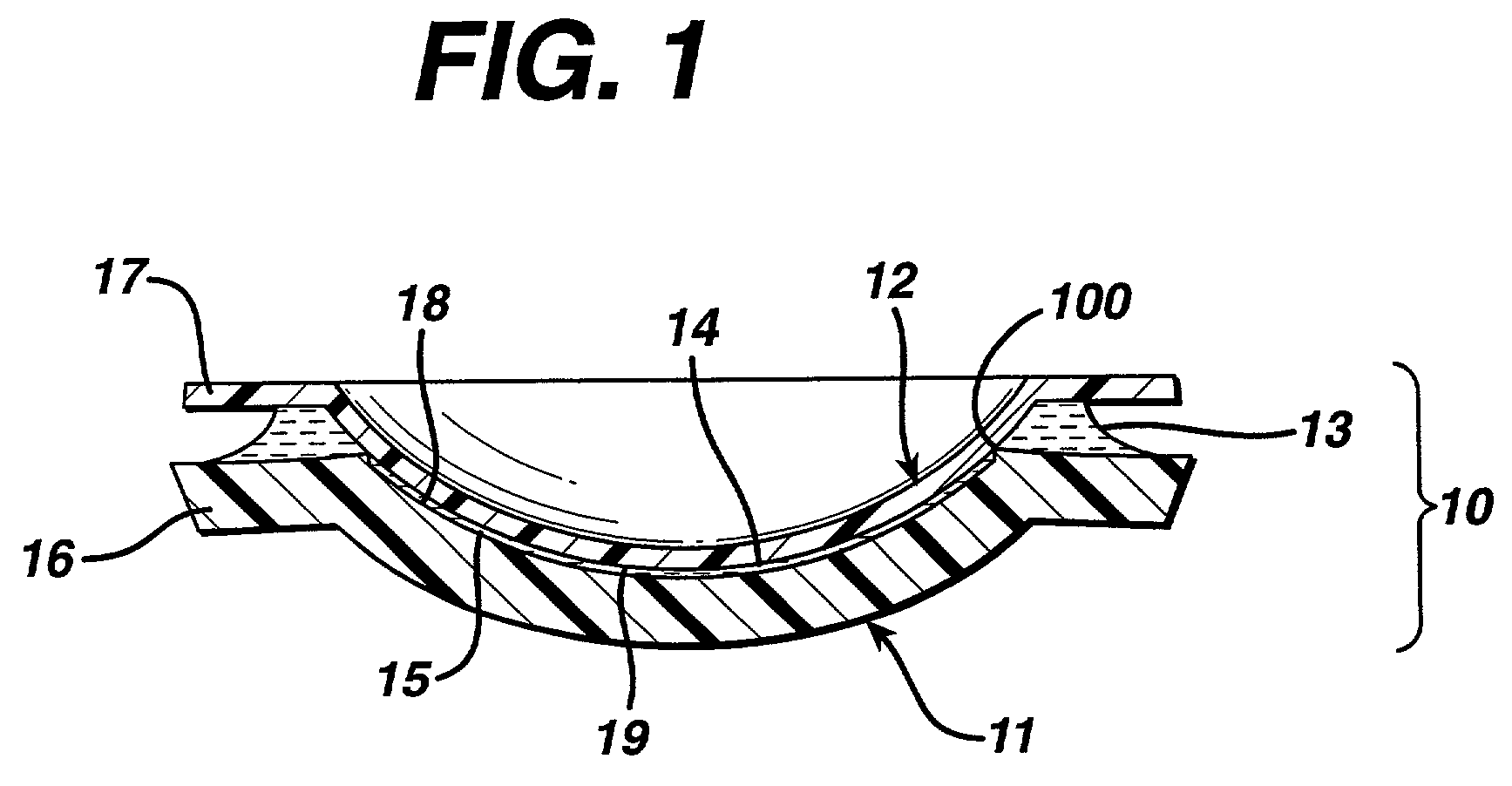

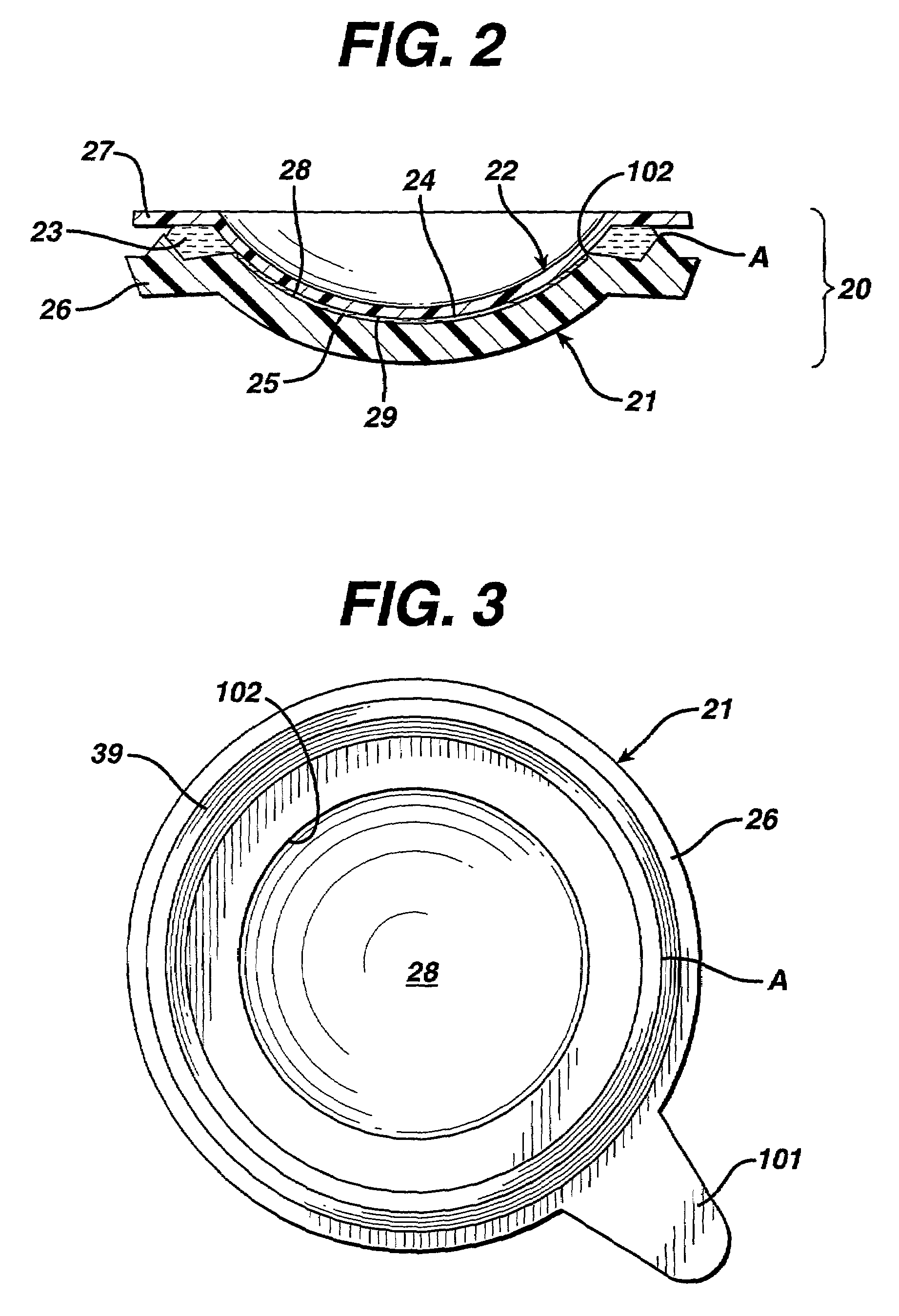

InactiveUS7097301B2Increased Oxygen TransmissionCost-effective manufacturing methodOptical articlesOptical partsSubject matterEngineering

A hybrid hard-soft contact lens is provided. Several embodiments of the invention include methods of coupling the hard and soft sections of the contact lens. Other embodiments of the invention include contact lens materials and coatings that increase oxygen transmission though the lens. Yet other embodiments of the invention are directed to cost-effective manufacturing methods of a hybrid hard-soft contact lens. This Abstract is provided for the sole purpose of complying with the Abstract requirement rules that allow a reader to quickly ascertain the subject matter of the disclosure contained herein. This Abstract is submitted with the explicit understanding that it will not be used to interpret or to limit the scope or the meaning of the claims.

Owner:SYNERGEYES

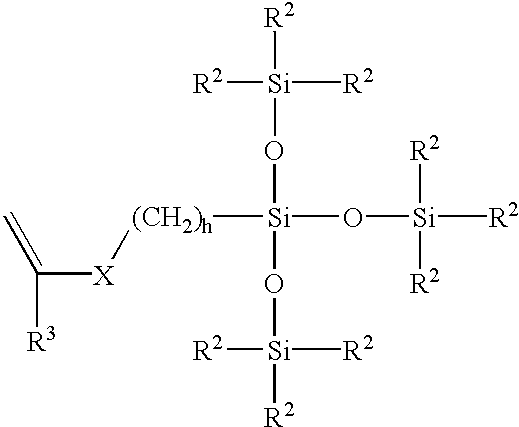

Highly oxygen-permeable fluorosiloxanes aquogel contact lens material and preparation thereof

ActiveCN101503491AHigh oxygen permeabilityImprove comfortOptical partsOptical elementsMethacrylateHydrophilic monomer

The invention discloses a high oxygen-permeability fluorosilicone hydrogel contact lens material and a preparation method thereof. The high oxygen-permeability fluorosilicone hydrogel contact lens material is obtained by crosslinking copolymerization of a fluorine-containing polysilicone monomer with hydrophilic groups and ends capped by methacrylate and one or more hydrophilic monomers and siloxane monomers initiated by ultraviolet light or heat. The content of a fluorosilicone amphiphilic monomer in the mixed monomers is 20%-60%. The preparation method comprises the following steps: evenly mixing the fluorosilicone amphiphilic monomer, the hydrophilic monomers, the siloxane monomers, a crosslinking agent, an initiator and a diluent, injecting the mixture into a mold, initiating polymerization by ultraviolet irradiation or heat, then demolding, removing unreacted monomers or oligomers, and immersing in water to obtain hydrogel. The hydrogel material has high oxygen permeability, wettability, proteinosis resistance and the like, and is a corneal contact lens with excellent properties.

Owner:HAICHANG CONTACT LENSES +1

Hybrid contact lens system and method

A hybrid hard-soft contact lens is provided. Several embodiments of the invention include methods of coupling the hard and soft sections of the contact lens. Other embodiments of the invention include contact lens materials and coatings that increase oxygen transmission though the lens. Yet other embodiments of the invention are directed to cost-effective manufacturing methods of a hybrid hard-soft contact lens. This Abstract is provided for the sole purpose of complying with the Abstract requirement rules that allow a reader to quickly ascertain the subject matter of the disclosure contained herein. This Abstract is submitted with the explicit understanding that it will not be used to interpret or to limit the scope or the meaning of the claims.

Owner:LEGERTON JEROME +2

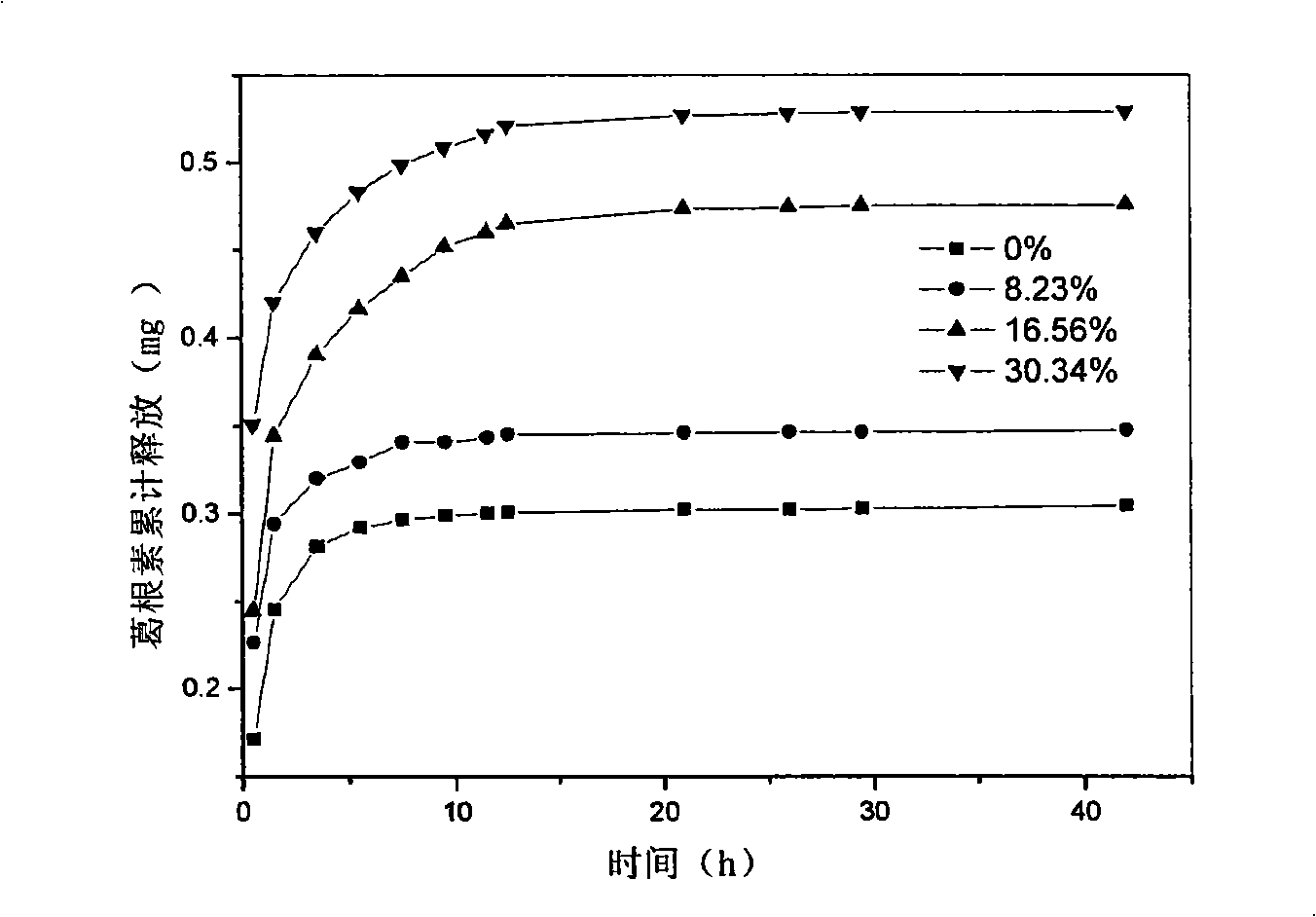

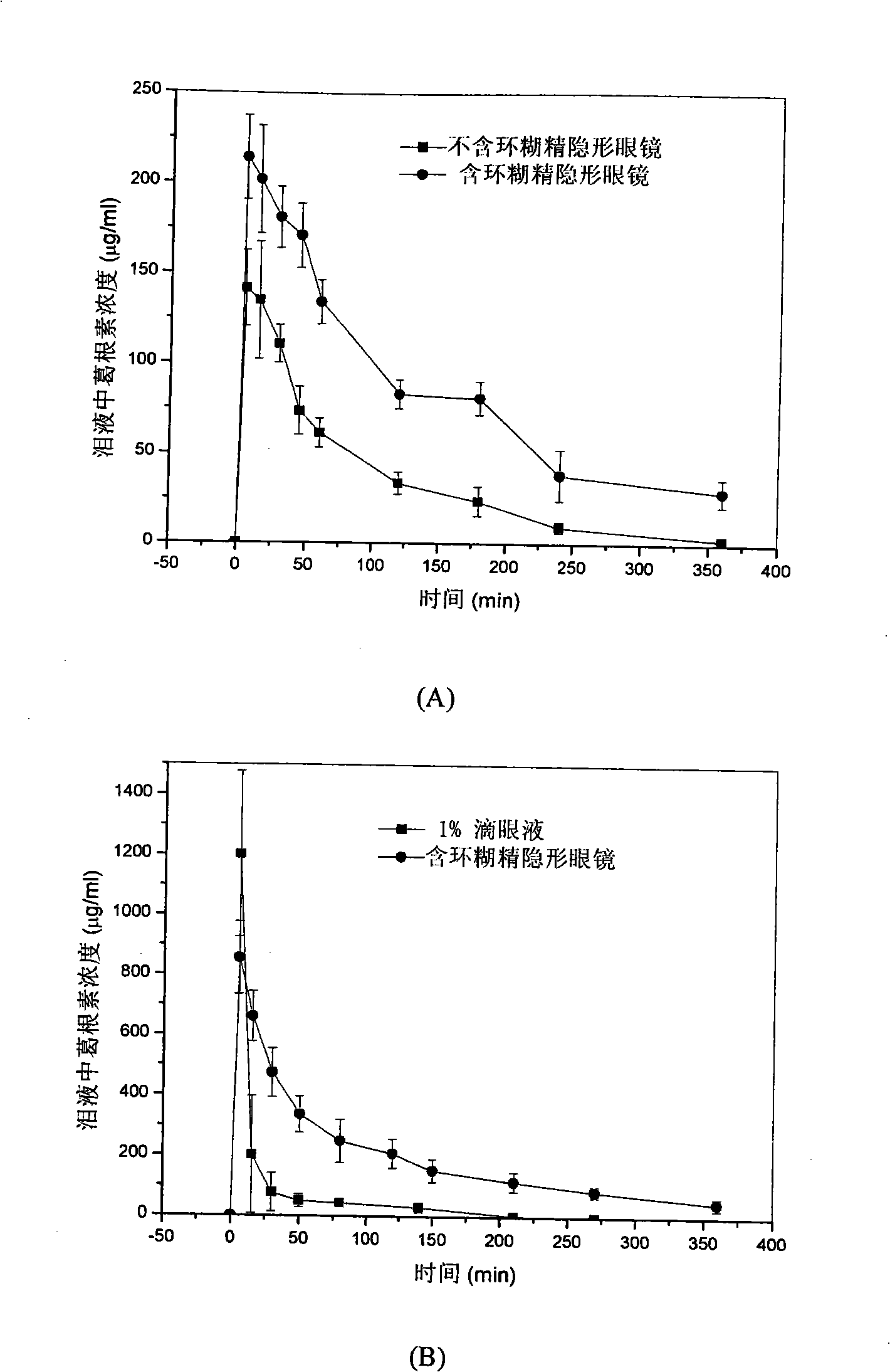

Medicine-carrying contact lens and preparation method thereof

InactiveCN101344648AEasy to fixChange the amount addedOrganic active ingredientsSenses disorderPuerarinDrug release

The invention relates to a drug-loaded contact lenses and a corresponding preparation method. The drug-loaded contact lenses are obtained firstly through UV-curing or heat-curing and then through drug-liquid immersion. The drug-loaded contact lenses can be particularly defined as a combination of a contact lenses material containing cyclodextrin and drug molecules and comprise the contact lenses formed by combining a crosslinked polymer hydrogel formed by copolymerizing mono-substituted cyclodextrin monomers, polymerization monomers and crosslinkers with one kind or a plurality of acetazolamide, methazolamide, puerarin or prostaglandin. The characteristic of forming inclusion compounds between the cyclodextrin molecules and drug molecules is adopted to increase the quantity of loaded drugs so as to reduce the stimulation to eyes by drugs and control the drug release speed for eye diseases of curing glaucoma, etc.

Owner:SOUTHEAST UNIV

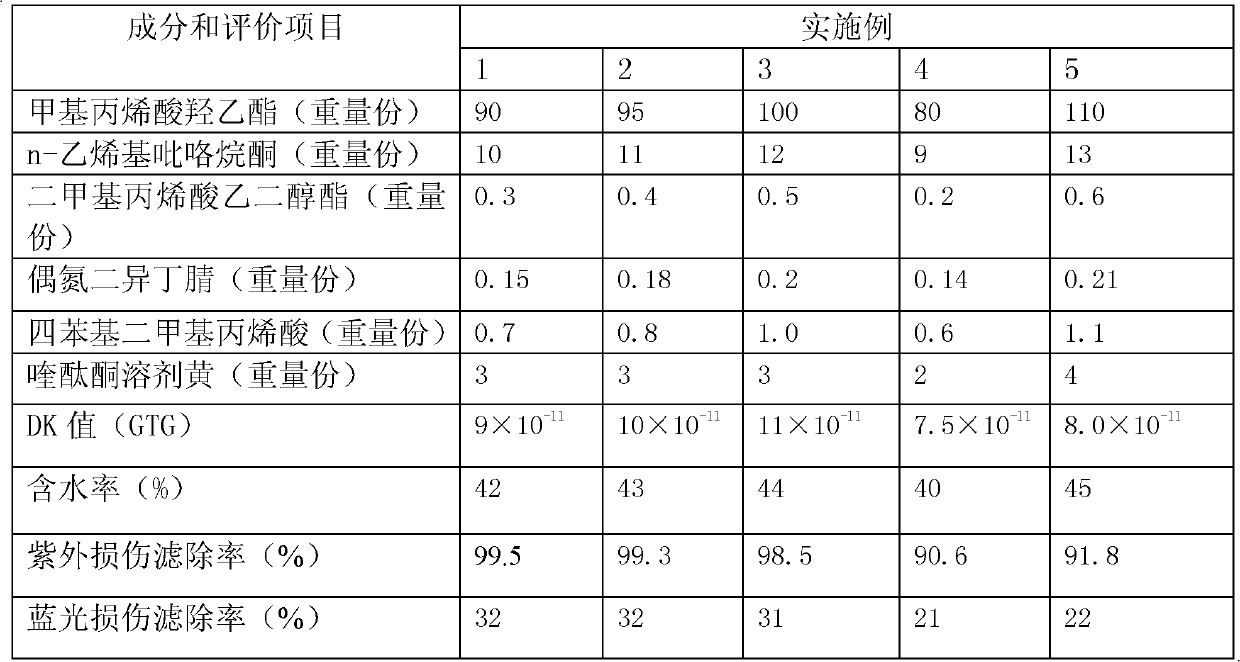

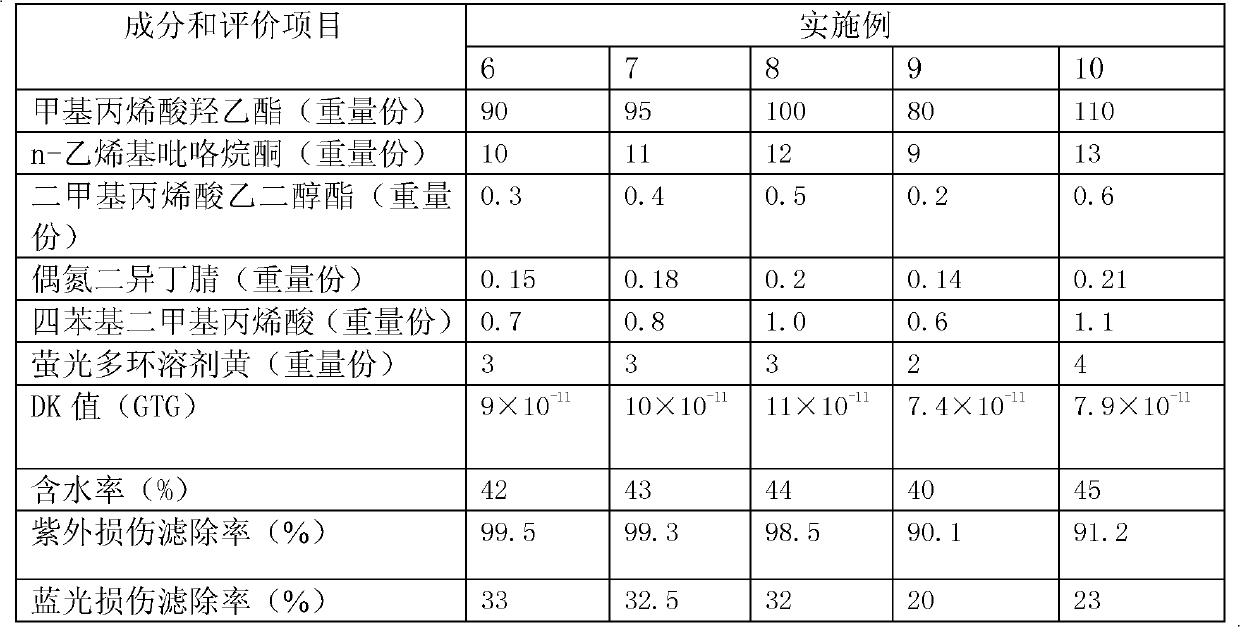

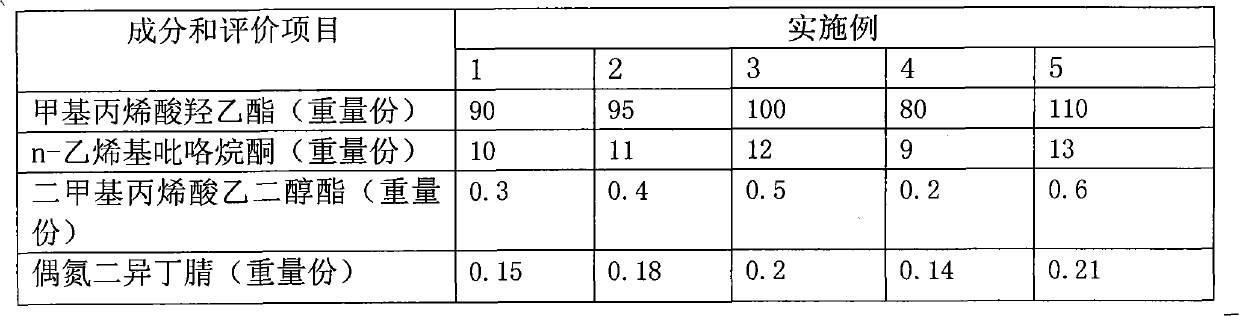

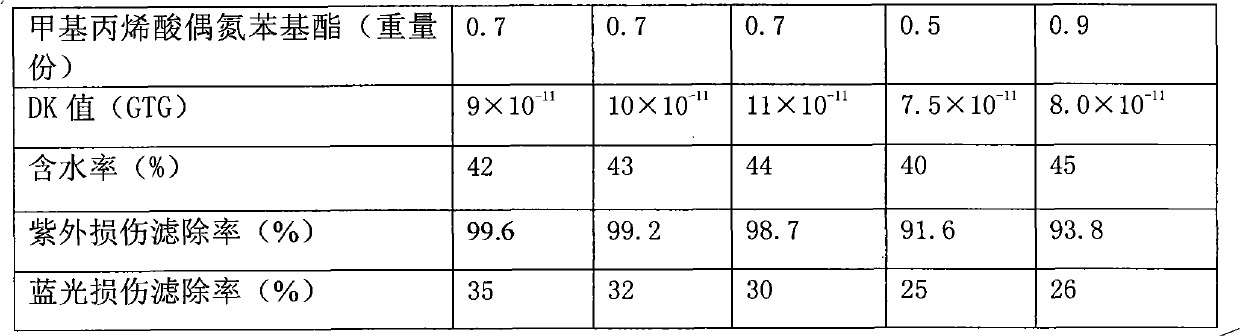

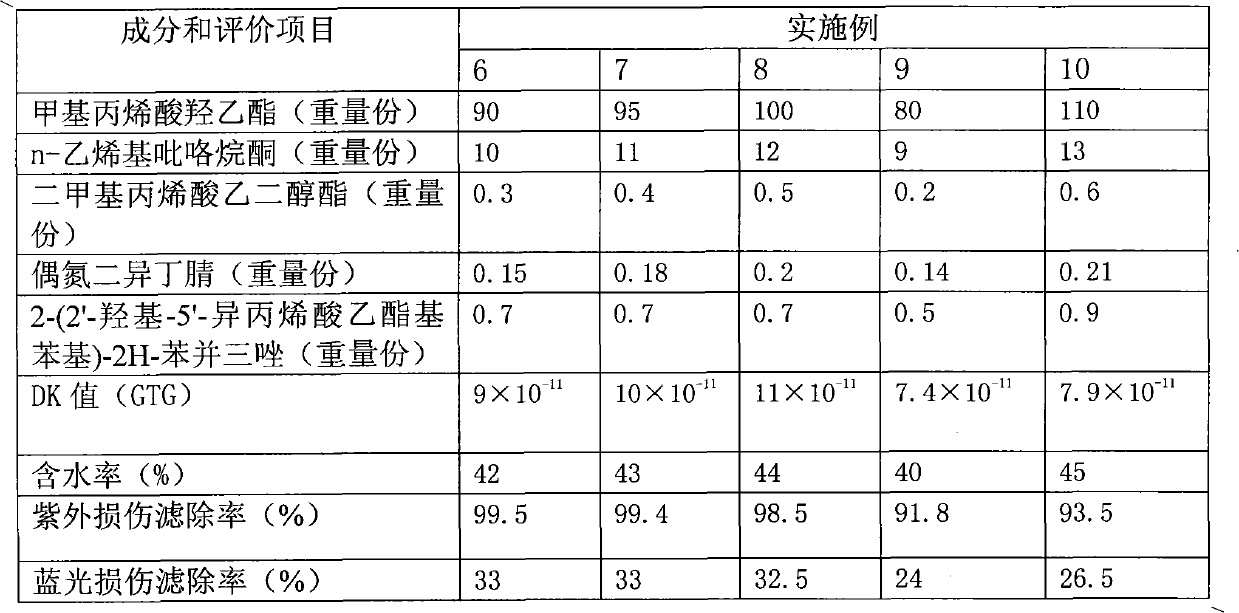

Radiation-proof light-filtering contact lens and production method thereof

ActiveCN102382237AGood oxygen transmission coefficientIncrease moisture contentOptical articlesOptical parts(Hydroxyethyl)methacrylateUltraviolet

A radiation-proof light-filtering contact lens is characterized in that the weight ratio of each component of liquid material is as follows: 90 to 100 parts of hydroxyethyl methacrylate; 10 to 12 parts of ethenyl pyrrolidinone; 0.3 to 0.5 part of 2-propenoic acid, oxybis(2,1-ethanediyloxy-2,1-ethanediyl)ester; acrylic acid, diester with tetraethylene glycol; 0.15 to 0.2 part of 2,2'-dicyano-2,2'-azopropane azobisisbutyronitrile; 0.7 to 1 part of 4-[(E)-phenyldiazenyl]phenyl-2-methacrylate; and 3 parts of yellow pigment and dye for contact lenses. The contact lens has a good oxygen permeation coefficient, high moisture content, moderate hardness and fewer residues, and also has a good ultraviolet radiation protection effect and a good filtering effect on purple light and blue light.

Owner:北京自然美光学有限公司

Hybrid contact lens system and method

A hybrid hard-soft contact lens is provided. Several embodiments of the invention include methods of coupling the hard and soft sections of the contact lens. Other embodiments of the invention include contact lens materials and coatings that increase oxygen transmission though the lens. Yet other embodiments of the invention are directed to cost-effective manufacturing methods of a hybrid hard-soft contact lens. This Abstract is provided for the sole purpose of complying with the Abstract requirement rules that allow a reader to quickly ascertain the subject matter of the disclosure contained herein. This Abstract is submitted with the explicit understanding that it will not be used to interpret or to limit the scope or the meaning of the claims.

Owner:LEGERTON JEROME +2

Silicone hydrogels based on vinyl carbonate endcapped fluorinated side chain polysiloxanes

InactiveUS20050165187A1Low modulusMaintain good propertiesProsthesisOptical partsPolymer scienceSide chain

Vinyl carbonate endcapped polysiloxanes containing a fluorinated side chain are useful as biomaterials, especially hydrogel biomaterials, including contact lens materials.

Owner:BARCLAYS BANK PLC AS SUCCESSOR AGENT

Method and composition for reducing contact lens swelling

InactiveUS7037469B2Preserve visual acuityLonger lasting wetting performanceSenses disorderCationic surface-active compoundsHigh concentrationControlled release

The present invention is directed to an ophthalmic solution for soft contact lenses for controlled release of polyethers into an eye's tear film. Polyether components of the subject solution are released from the soft contact lens material matrix over long time periods to produce longer lasting wetting performance, improved lubricity, improved end-of-the-day comfort and reduced feeling of dryness from wearing contact lenses. The present invention also includes the use of cationic polyelectrolytes for controlling the swelling of hydrogel contact lenses typically caused by the absorption of high concentrations of polyethers.

Owner:BAUSCH & LOMB INC

Hybrid contact lens system and method

A hybrid hard-soft contact lens is provided. Several embodiments of the invention include methods of coupling the hard and soft sections of the contact lens. Other embodiments of the invention include contact lens materials and coatings that increase oxygen transmission though the lens. Yet other embodiments of the invention are directed to cost-effective manufacturing methods of a hybrid hard-soft contact lens. This Abstract is provided for the sole purpose of complying with the Abstract requirement rules that allow a reader to quickly ascertain the subject matter of the disclosure contained herein. This Abstract is submitted with the explicit understanding that it will not be used to interpret or to limit the scope or the meaning of the claims.

Owner:LEGERTON JEROME +2

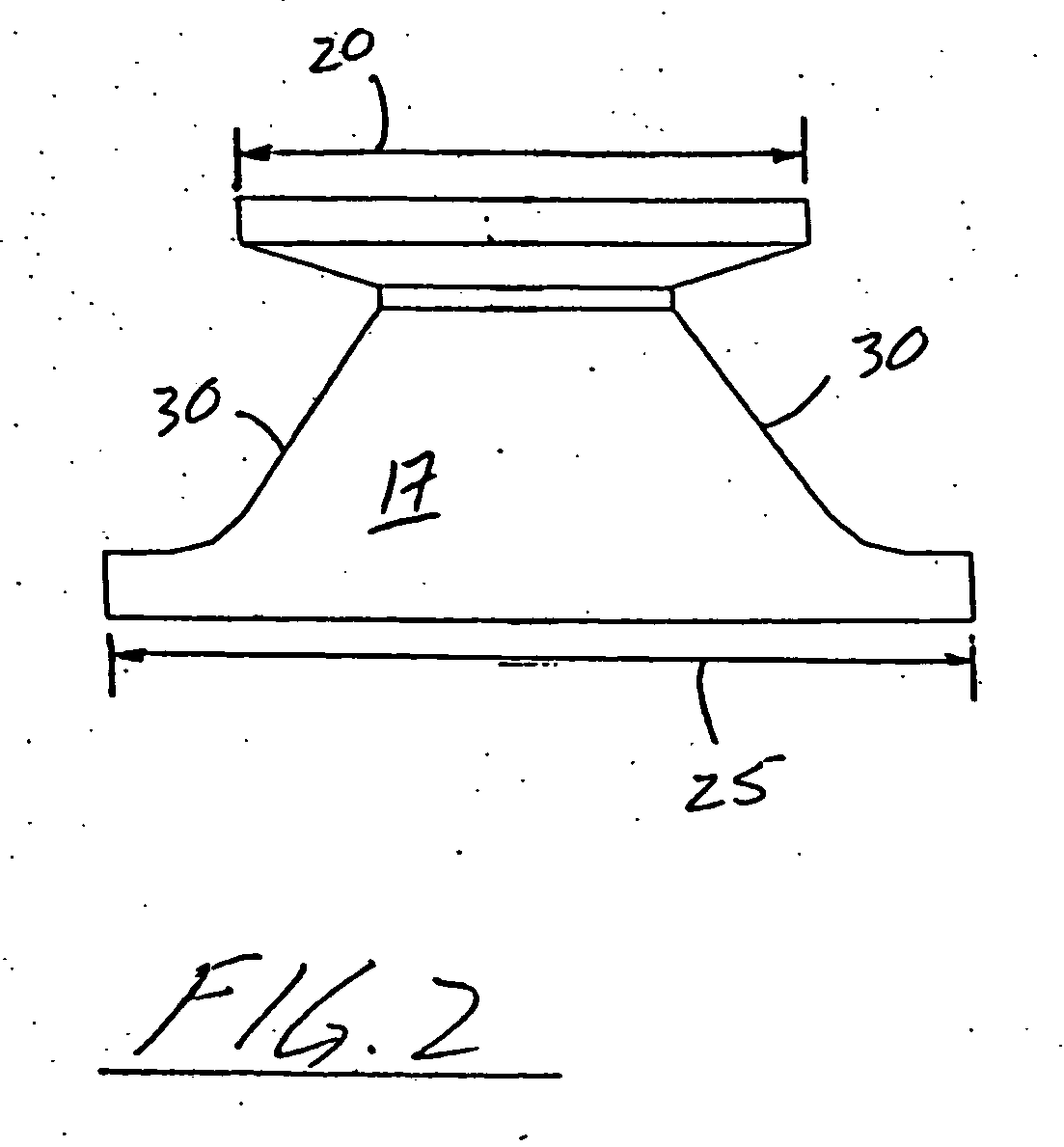

Drug delivery from contact lenses with a fluidic module

InactiveUS20160018671A1Inhibited DiffusionReduce diffuseOrganic active ingredientsSenses disorderAqueous solutionOptometry

A soft contact lens comprises a module embedded in a soft contact lens material. The module comprises a hydrophobic material having channels formed therein, such that a surface tension of the aqueous solution within the channels inhibits release of therapeutic agent, such as a drug, through the one or more channels. The surface tension of the aqueous solution within the channel can inhibit diffusion of the therapeutic agent through the channel. The channels may comprise a cross-sectional area and optionally a length, such that therapeutic agent is released through the channels when pressure of the eyelid increases. In many embodiments, the contact lens is configured to inhibit release of the therapeutic agent when the contact lens comprises a free floating configuration, for example when stored in a contact lens solution, such that the storage time of the contact lens can be increased substantially.

Owner:ONEFOCUS TECH

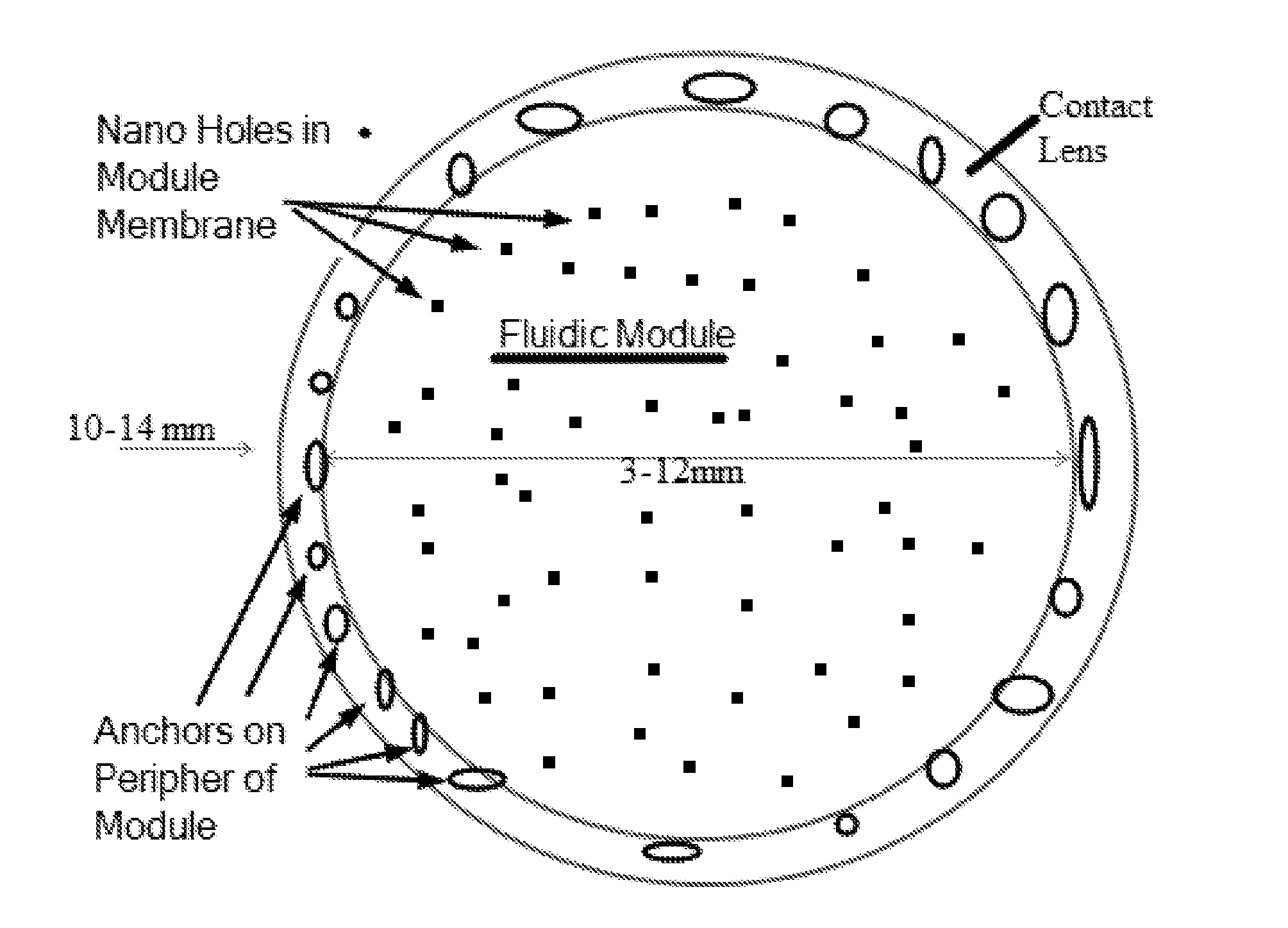

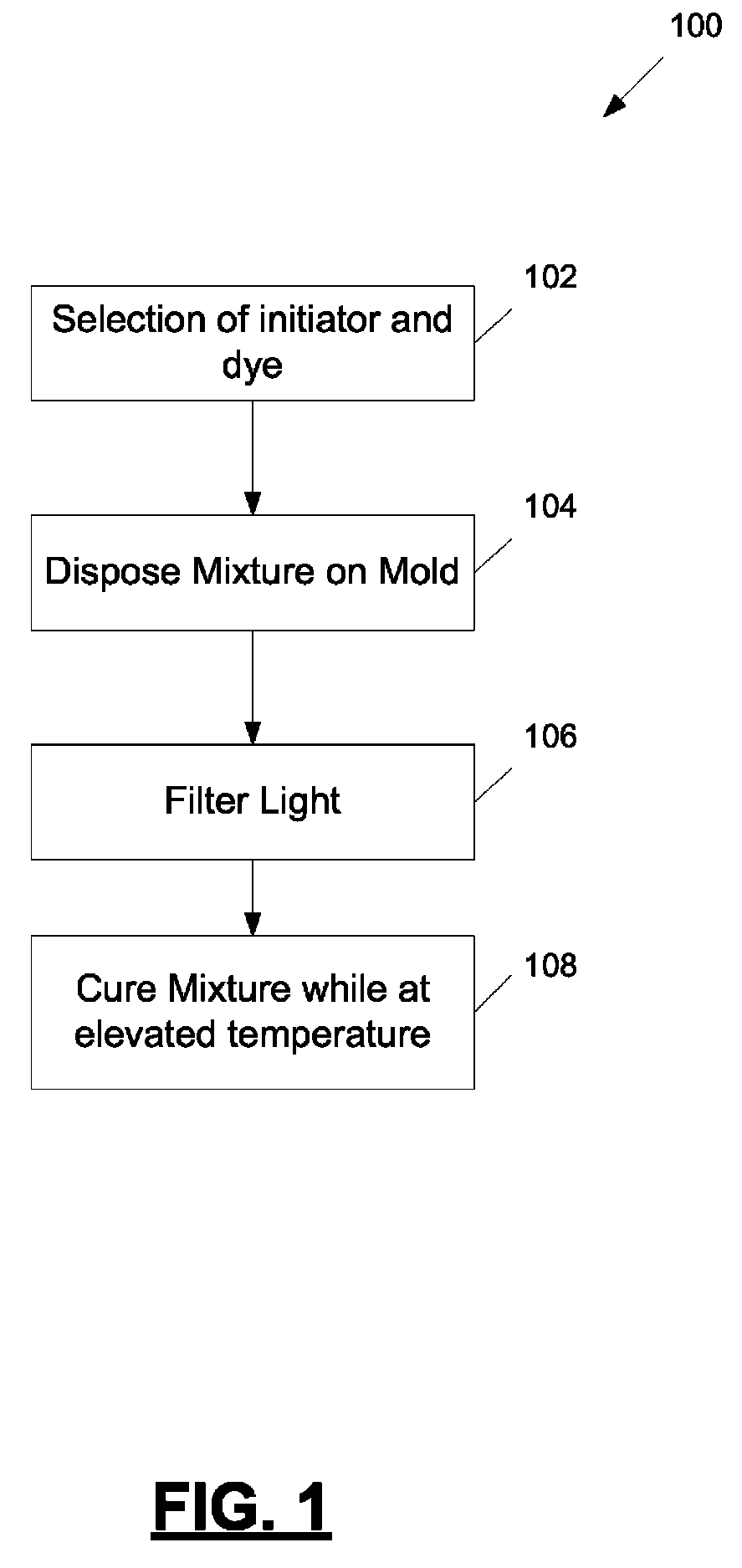

Process for manufacture of a thermochromic contact lens material

Disclosed in this specification is a process for manufacturing a thermochromic contact lens. The process includes (1) selecting a photoinitiator that absorbs at a first wavelength and at least one thermochromic dye that displays substantial absorption at the first wavelength when the dye is at a first temperature and exhibits at least an 80% reduction in absorbance at the first wavelength at a second temperature, (2) maintaining the reaction mixture at the second temperature and (3) providing cure light that includes the first wavelength.

Owner:JOHNSON & JOHNSON VISION CARE INC

Methods materials and systems for producing a contact lens and contact lenses produced using said methods materials and systems

InactiveUS20120113384A1Change colorFacilitate easy localizationOptical articlesOptical partsPigmentContact lens

Disclosed are methods, materials and systems for producing contact lenses and contact lenses produced using said methods, materials and systems. According to some embodiments, a contact lens produced by said methods, materials and systems includes an extra-ocular indicator (“EOI”) adapted to alter in color upon removal of said lens from an eye. The EOI may be at least partially composed of a pigment adapted to become relatively more visible when the contact lens is outside an eye than when the contact lens is placed in an eye.

Owner:PASTERNAK JONATHAN BARUCH +1

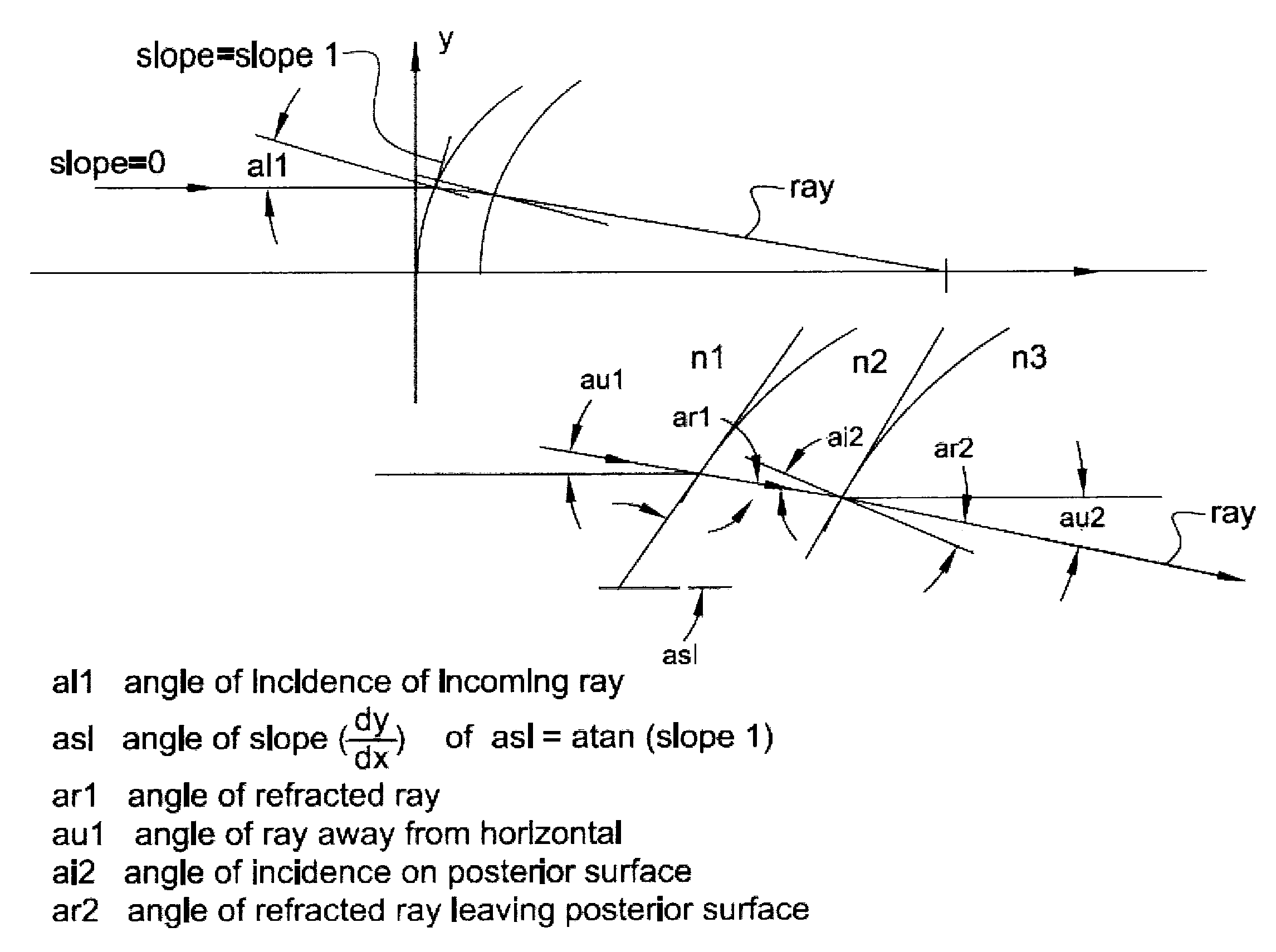

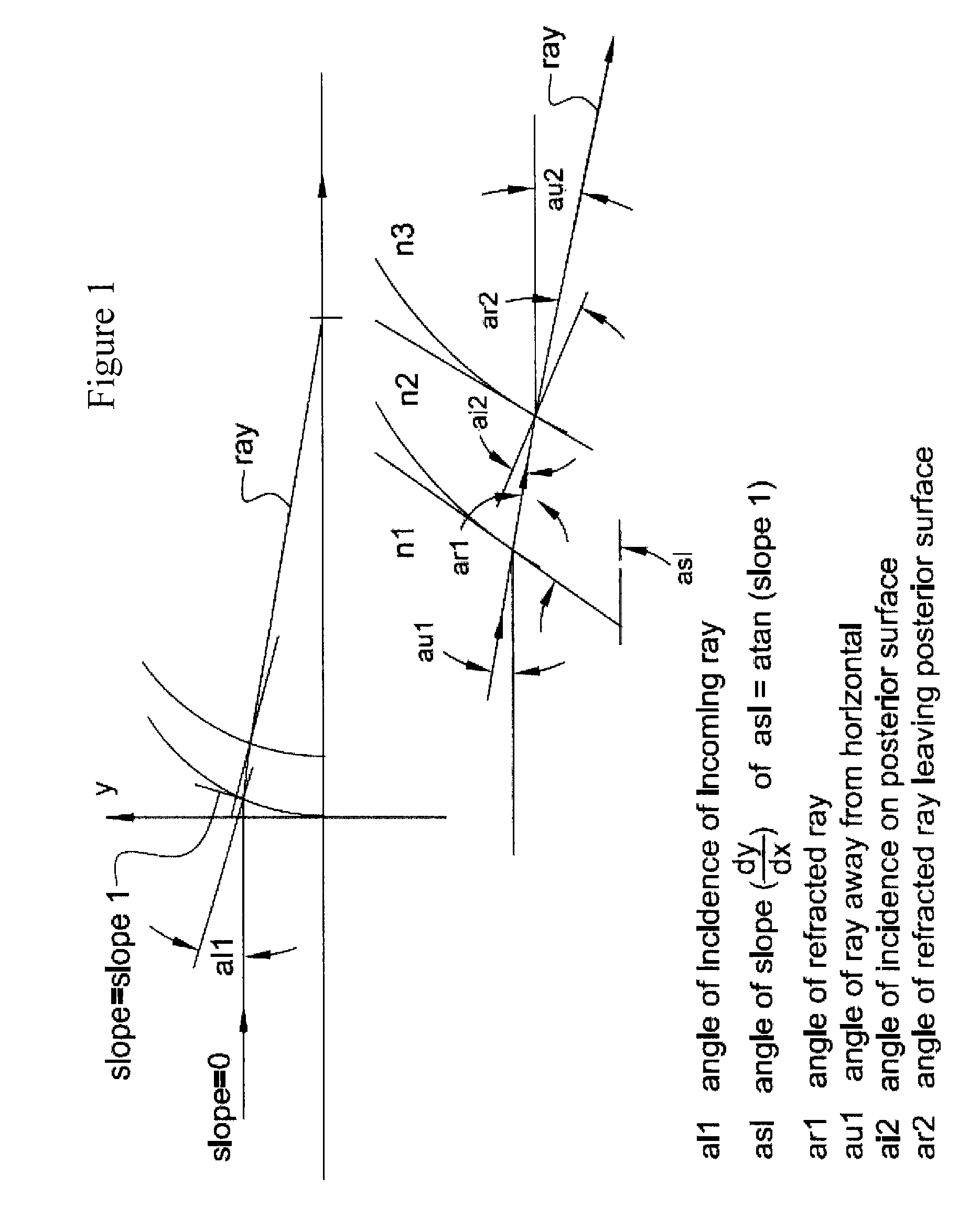

Method for designing an anterior curve of a contact lens

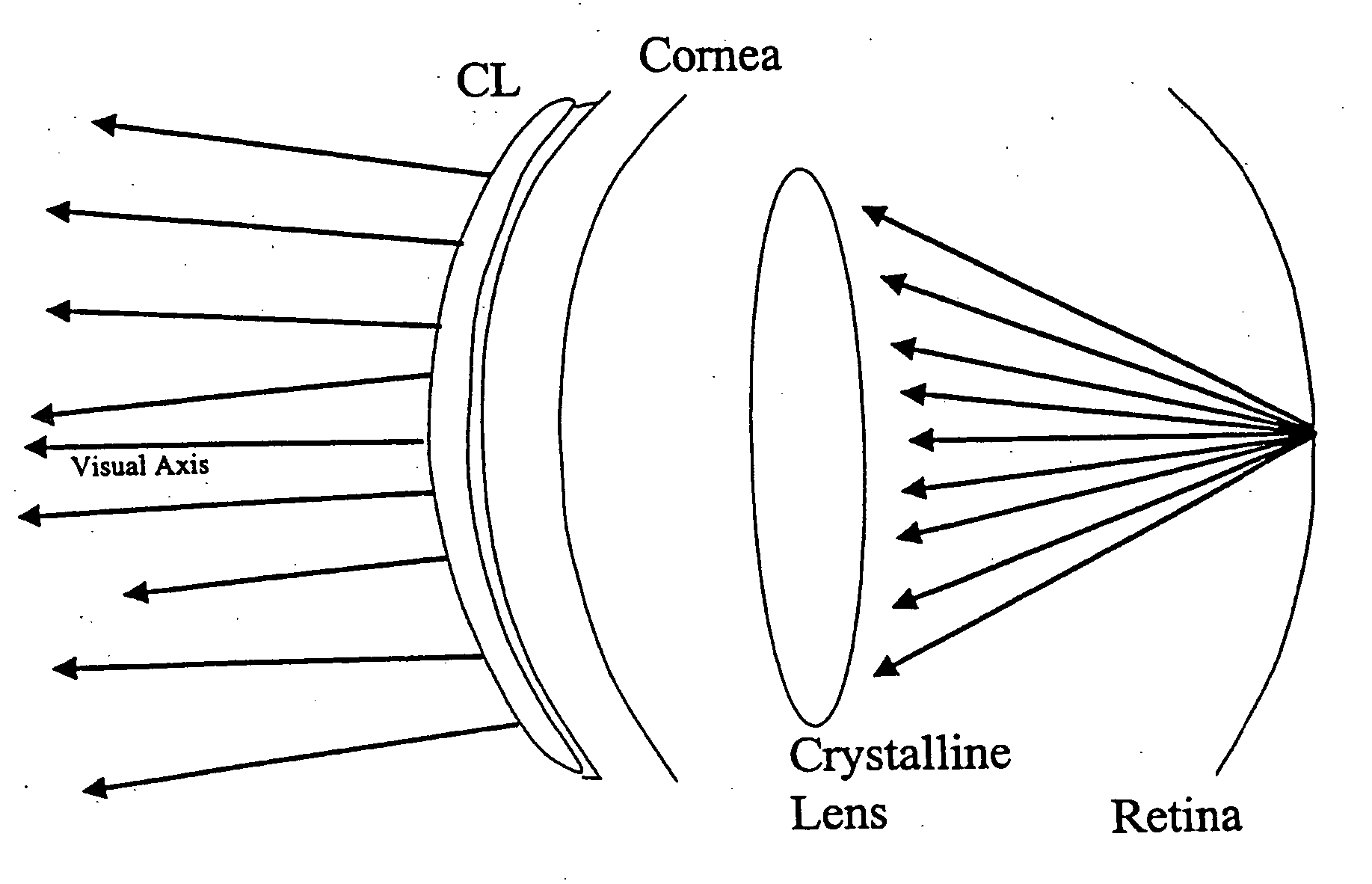

In accordance with the disclosure there is described herein a method of designing an anterior curve of a contact lens for the eye of a patient comprising the steps of providing a contact lens material having a posterior, a posterior curve having a predetermined asphericity, an anterior, an index of refraction and a center thickness; providing a geometry of a cornea, a distance power correction for the cornea and a near power correction for the cornea; determining a central distance power of the contact lens in air; calculating a central anterior radius of the contact lens using the posterior curve of the contact lens material, the index of refraction of the contact lens material, the center thickness of the contact lens material and the central distance power of the contact lens in air; calculating a center power of the contact lens on the eye of the patient using the index of refraction of tears at the posterior of the contact lens; and using an on-eye ray trace, said on-eye ray trace having a null lens compensation to create a targeted on-eye power profile.

Owner:UNILENS CORP USA

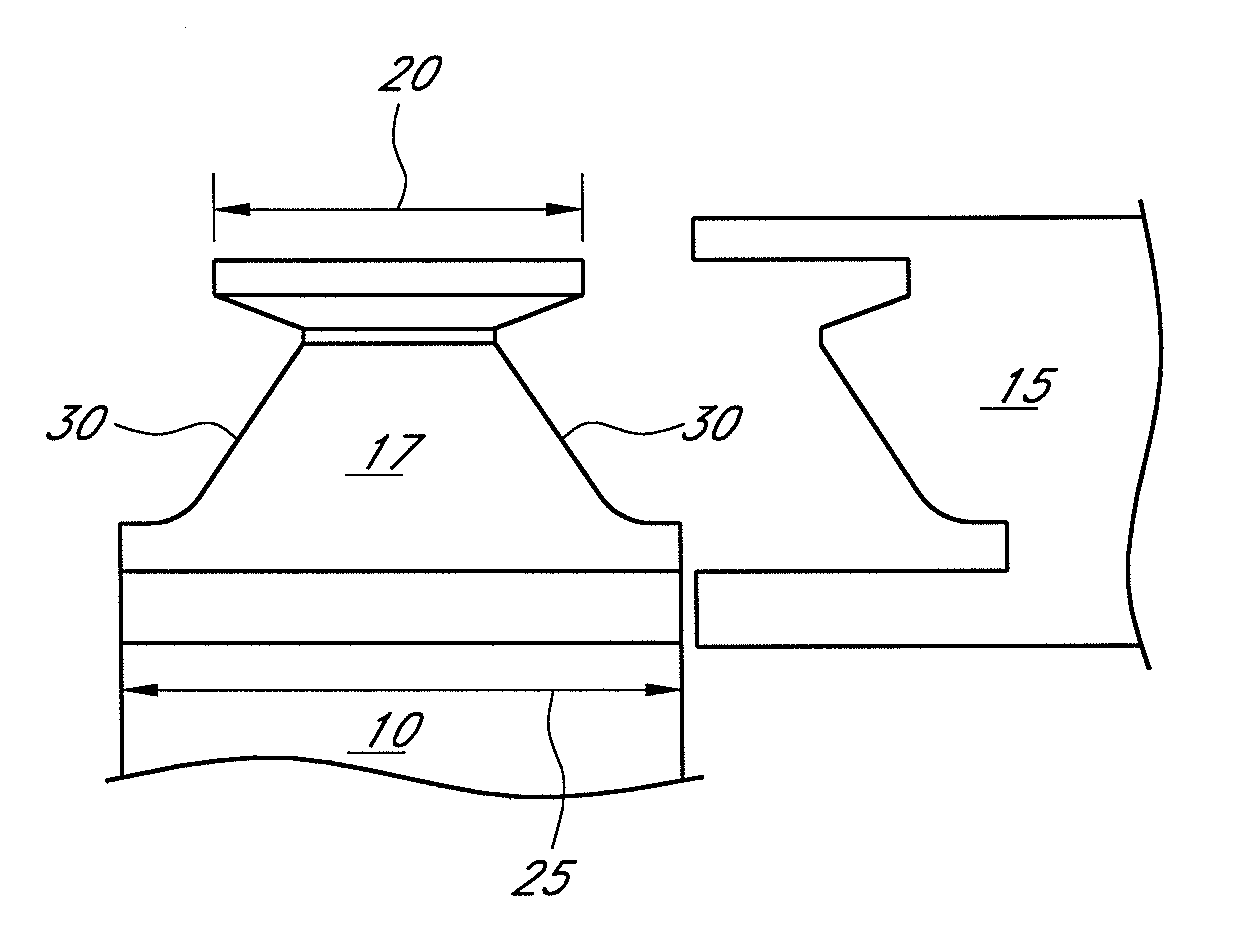

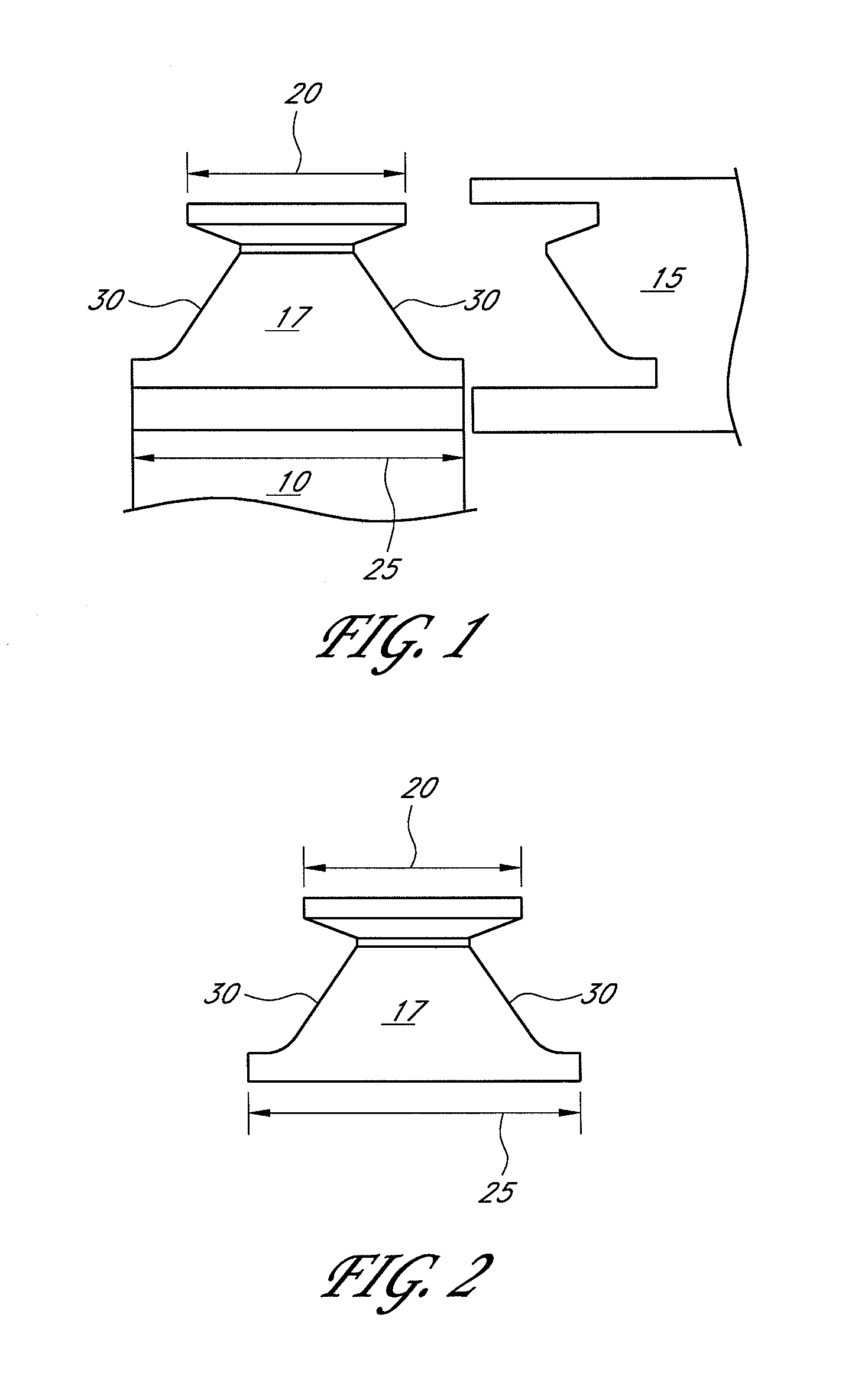

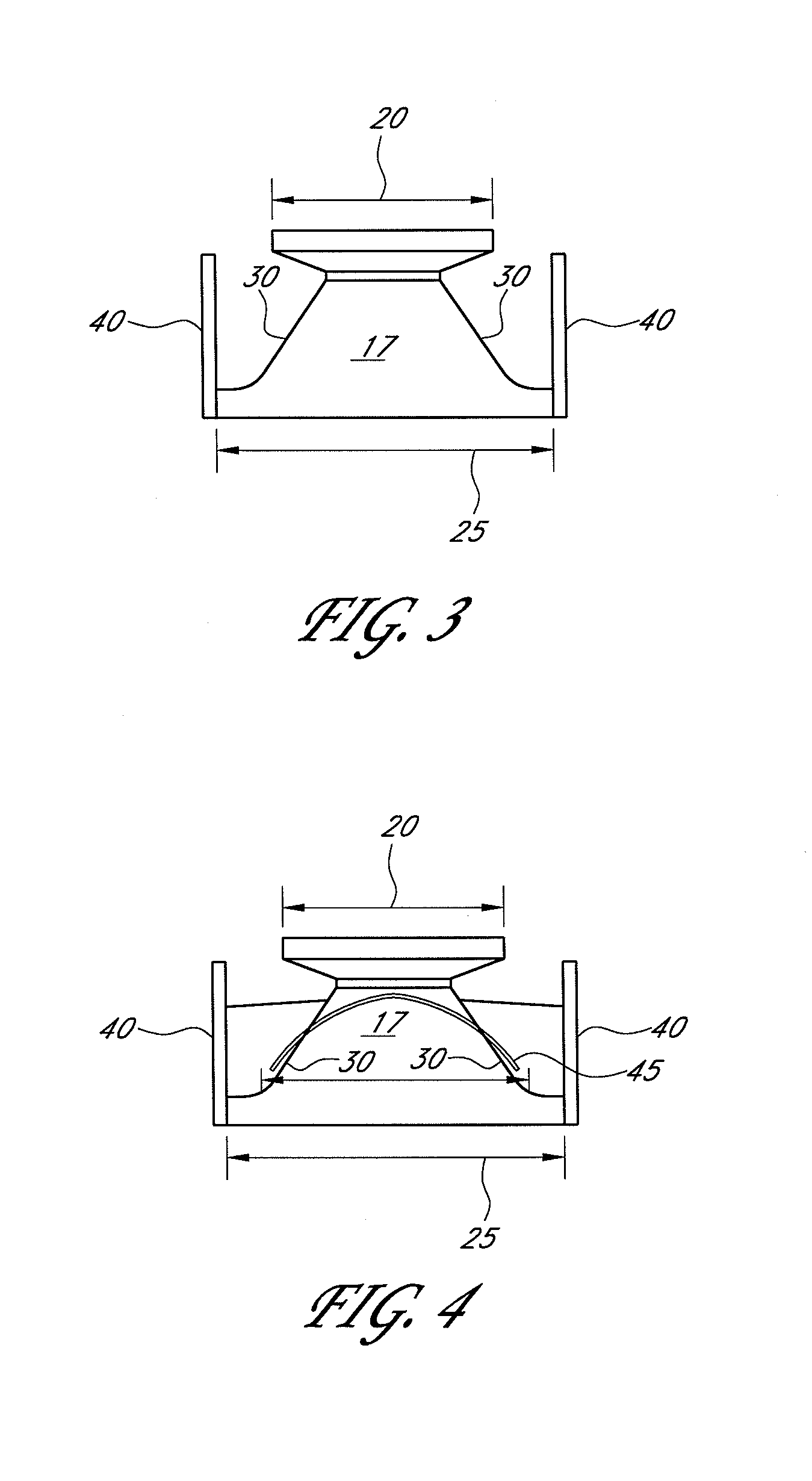

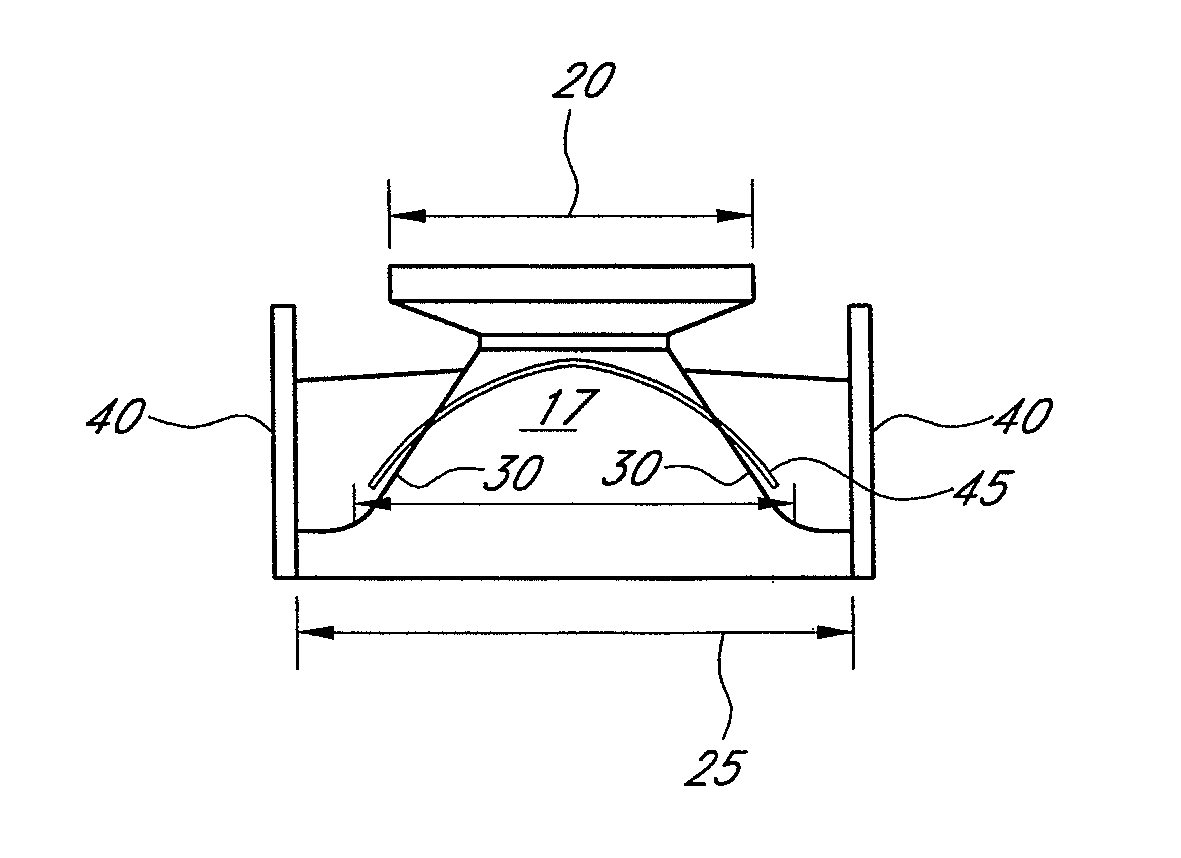

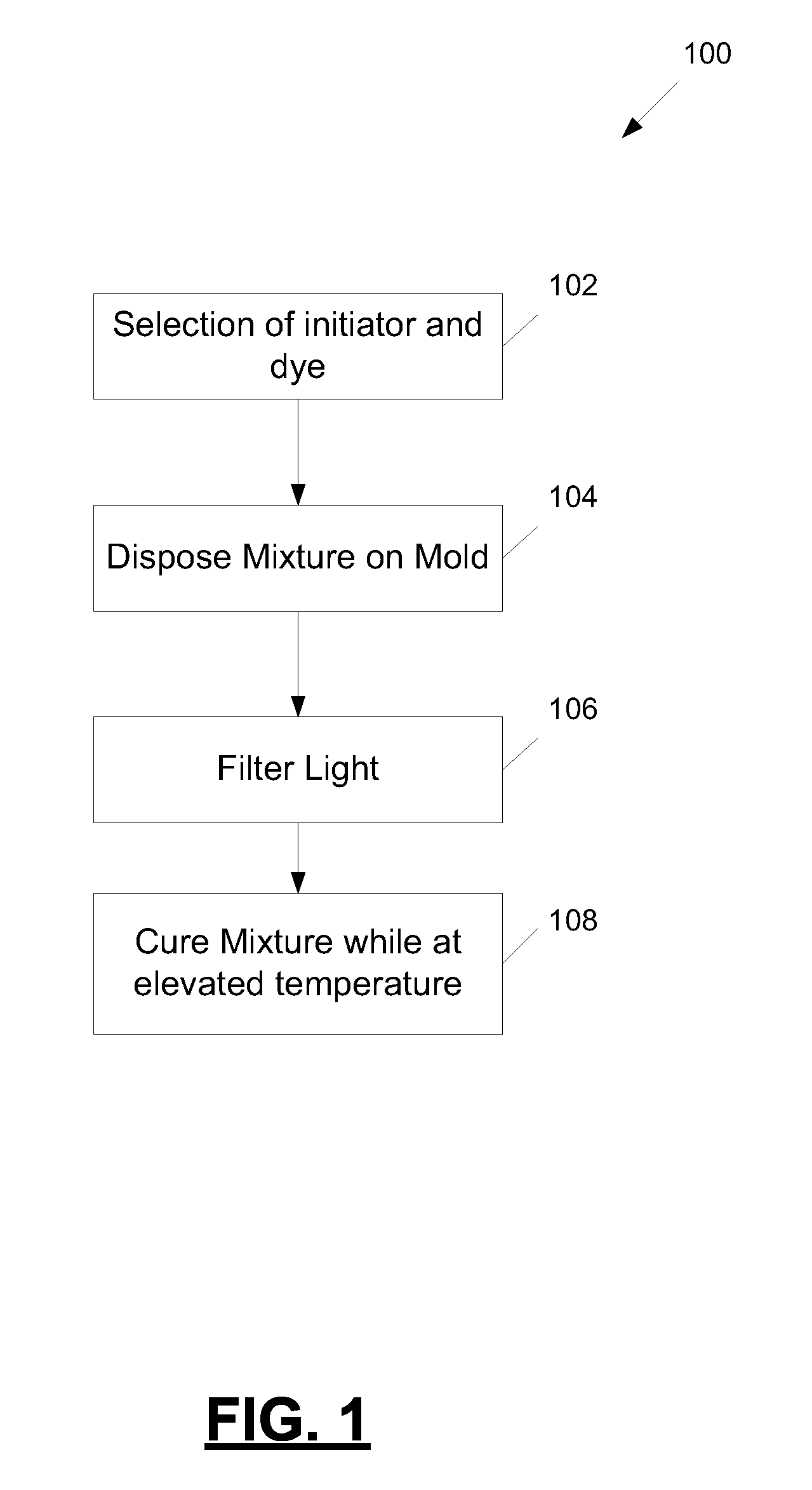

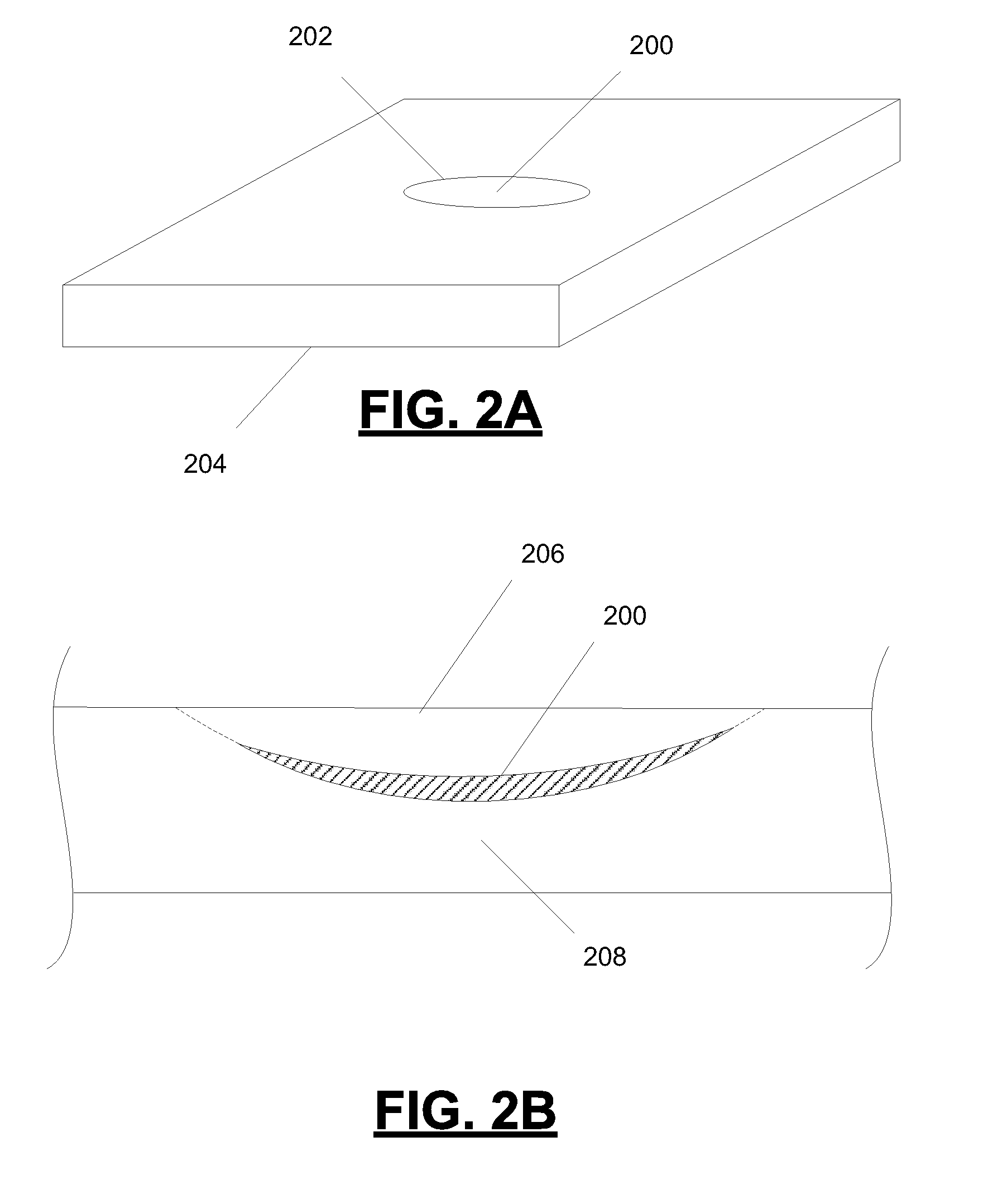

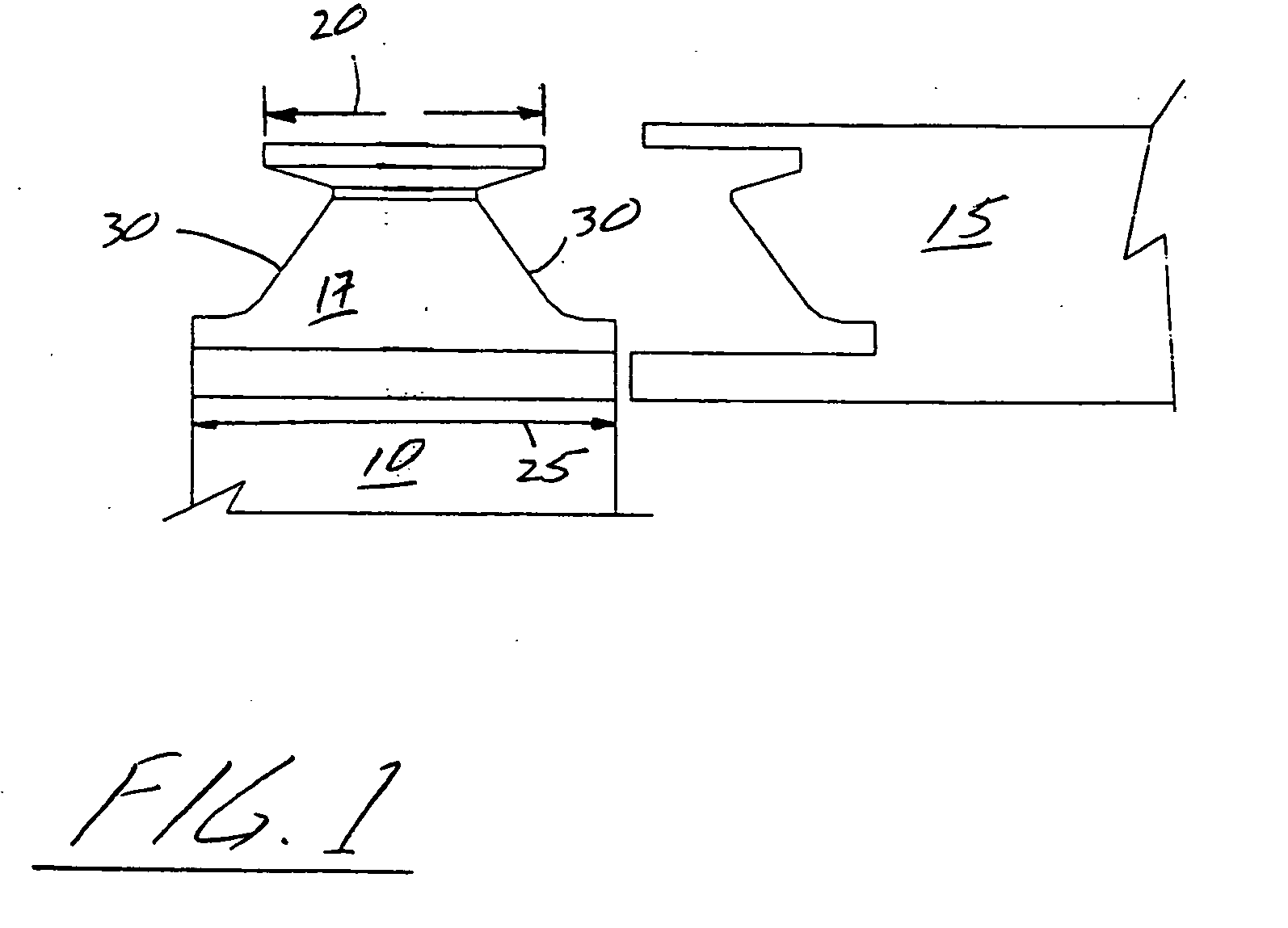

Mold for forming a contact lens and method of preventing formation of small strands of contact lens material during contact lens manufacture

InactiveUS7156641B2Reduce the amount requiredInhibition formationConfectioneryOptical articlesState of artEngineering

This invention provides a mold for forming a contact lens comprising an overflow collector, which causes the overflow reactive mixture to be accumulated, and not to spread out as it would upon the typically flat surface of a prior art mold. This invention further provides a method of preventing the formation of contaminating pieces of overflow reactive mixture comprising the step of: preventing the overflow reactive mixture from spreading out on the mold.

Owner:JOHNSON & JOHNSON VISION CARE INC

Process for manufacture of a thermochromic contact lens material

Disclosed in this specification is a process for manufacturing a thermochromic contact lens. The process includes (1) selecting a photoinitiator that absorbs at a first wavelength and at least one thermochromic dye that displays substantial absorption at the first wavelength when the dye is at a first temperature and exhibits at least an 80% reduction in absorbance at the first wavelength at a second temperature, (2) maintaining the reaction mixture at the second temperature and (3) providing cure light that includes the first wavelength.

Owner:JOHNSON & JOHNSON VISION CARE INC

Hybrid contact lens system and method

A hybrid hard-soft contact lens is provided. Several embodiments of the invention include methods of coupling the hard and soft sections of the contact lens. Other embodiments of the invention include contact lens materials and coatings that increase oxygen transmission though the lens. Yet other embodiments of the invention are directed to cost-effective manufacturing methods of a hybrid hard-soft contact lens. This Abstract is provided for the sole purpose of complying with the Abstract requirement rules that allow a reader to quickly ascertain the subject matter of the disclosure contained herein. This Abstract is submitted with the explicit understanding that it will not be used to interpret or to limit the scope or the meaning of the claims.

Owner:SYNERGEYES

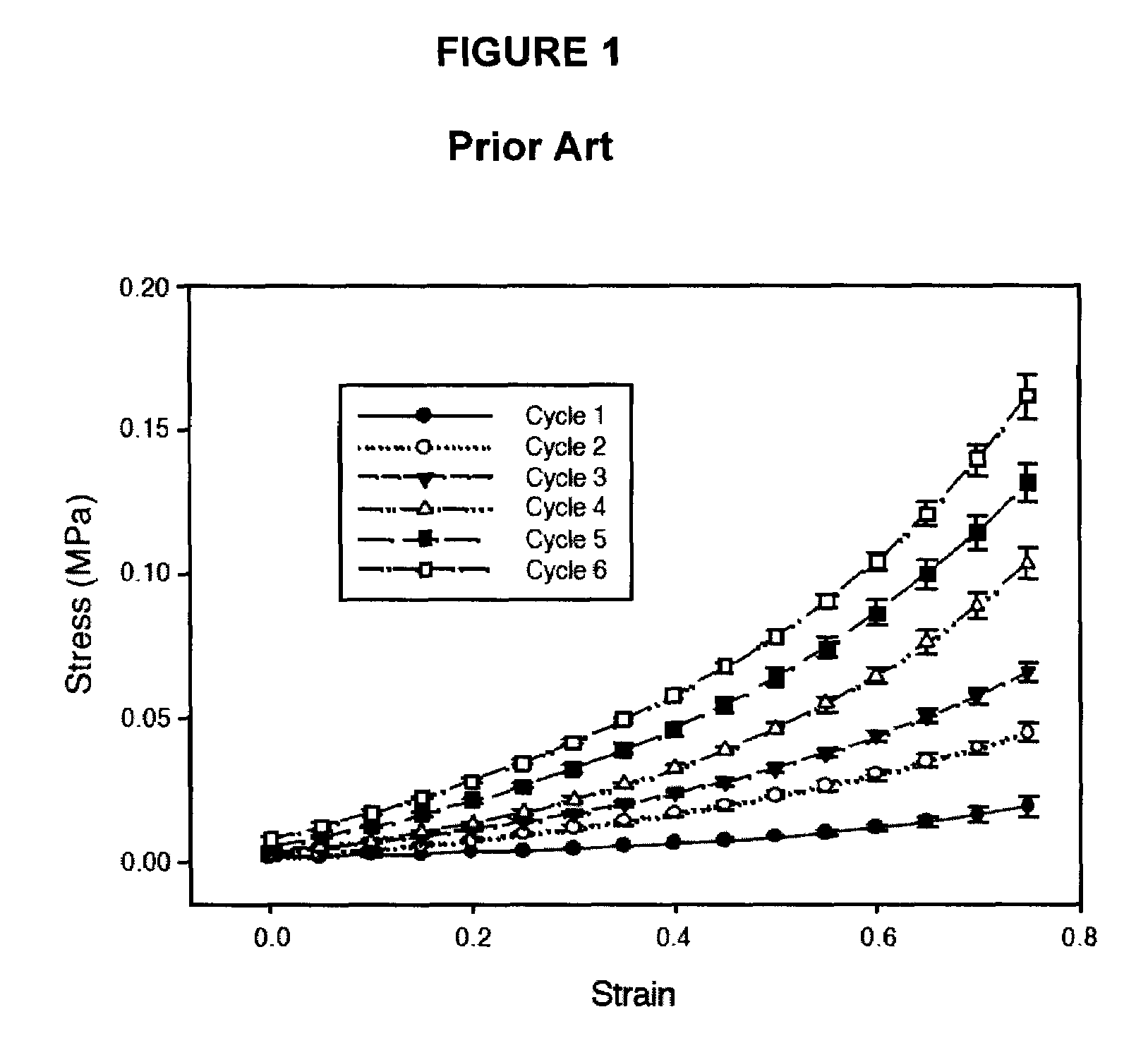

Anisotropic hydrogels

The invention relates to an anisotropic hydrogel and a method of producing the anisotropic hydrogel. The hydrogel exhibiting anisotropic properties is poly(vinyl alcohol) produced by preparing a solution of poly(vinyl alcohol) with a pre-selected concentration, thermally cycling the solution by freezing and thawing, stretching the hydrogel and thermally cycling the hydrogel at least one more time The anisotropic hydrogel is used for tissue replacement and reconstruction, bioagent entrapment and delivery, in preparing ultrasound or radiofrequency thermal therapy transmission pads and substitutes for ice bags, as denture base, in soft contact lens material, for wound covering bandages and phantoms for medical-related use.

Owner:UNIV OF WESTERN ONTARIO

Hydrogel contact lens material and preparation method thereof

InactiveCN102617787AExcellent anti-dehydration performanceImprove stabilityOptical partsOptical elementsPolymer scienceMeth-

The invention provides a hydrogel contact lens material and a preparation method thereof. The material comprises N-(1,3-dihydroxy-2-propyl) methyl acrylamide, acrylate monomer, acrylate crosslinker and initiating agent and is prepared through one-step ultraviolet-initiated or thermal-initiated polymerization. The preparation method comprises the steps as follows: the N-(1,3-dihydroxy-2-propyl) methyl acrylamide and acrylic acid or acrylamide monomer are uniformly mixed with the acrylate crosslinker and the initiating agent, or the N-(1,3-dihydroxy-2-propyl) methyl acrylamide and the acrylic acid or acrylamide monomer are uniformly mixed with the acrylate crosslinker, the initiating agent and diluent; then the mixture is poured into a mould to be subjected to one-step ultraviolet irradiation curing or heat curing in a baking oven; and the mould is opened and immersed in water or alcohol, so as to remove the diluent and unreacted monomer to obtain a hydrogel contact lens. The material has high water content and excellent water retention capacity.

Owner:SOUTHEAST UNIV

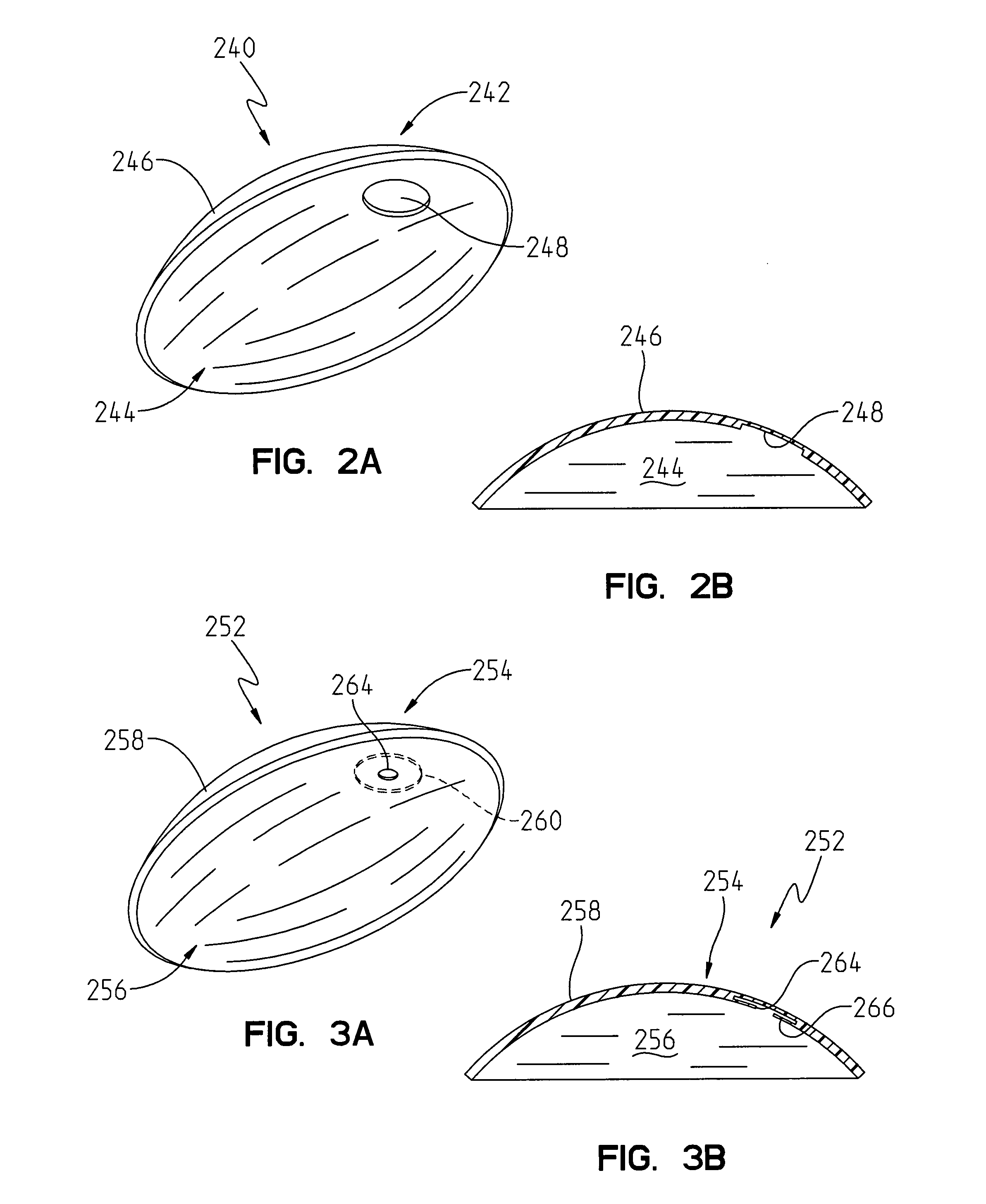

Accommodating lens with cavity

A lens comprises an internal cavity structure formed by dissolution of a soluble insert material. The internal soluble material may dissolve through a body of a lens such as a contact lens in order to form the cavity within the contact lens. The cavity within the lens can be shaped in many ways, and corresponds to the shape of the dissolved material, such that many internal cavity shapes can be readily fabricated within the contact lens. The insert can be placed in a mold with a pre-polymer material, and the pre-polymer material cured with the insert placed in the mold to form the lens body. The polymerized polymer may comprise a low expansion polymer in order to inhibit expansion of the lens when hydrated. The polymer may comprise a hydrogel when hydrated. The soft contact lens material comprises a sufficient amount of cross-linking to provide structure to the lens and shape the cavity.

Owner:ONEFOCUS VISION

Radiation-protection filtering contact lenses and production method therefor

InactiveCN103374097ADefense against photochemical damageControl short-wave violet lightOptical partsOptical elements(Hydroxyethyl)methacrylateFiltration

Provided is a contact lens material. The material is characterized by comprising liquid raw materials, by weight, 90-100 parts of hydroxyethyl methylacrylate, 10-12 parts of n-vinyl pyrrolidone, 0.3-0.4 part of ethylene glycol dimethacrylate, 0.15-0.2 part of azodiisobutyronitrile and 0.7-1 part of yellow UV absorbents for contact lenses. The contact lenses have good oxygen permeation coefficient, good moisture content, moderate hardness and less residual components, and have functions of good ultraviolet protection and filtration of purple light and blue light.

Owner:北京自然美光学有限公司

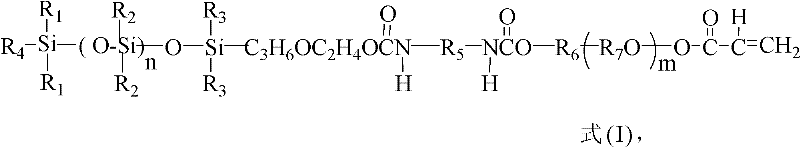

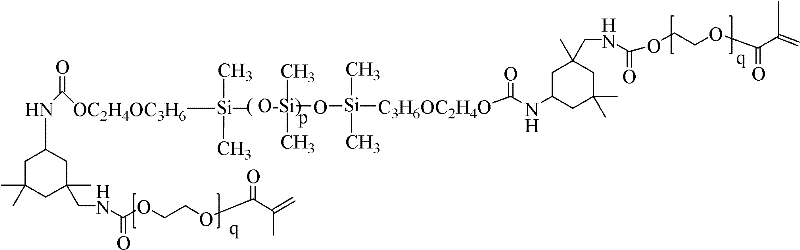

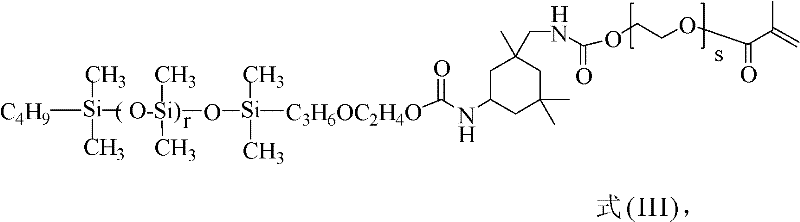

Contact lens material, contact lenses, and manufacturing method for contact lenses

ActiveCN102558458AHigh oxygen permeabilityIncrease moisture contentOptical partsOptical elementsHydrophilic monomerPolymer science

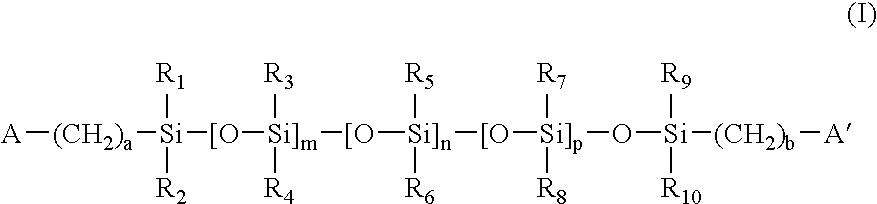

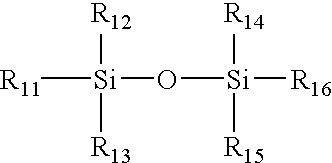

The invention discloses a contact lens material, contact lenses, and a manufacturing method for contact lenses. The contact lens material comprises a siloxane polymer expressed by formula (I), wherein in the formula (I), R1, R2 and R3 are C1-C4 alkyl group, R4 is C1-C6 alkyl group, R5 is the residue obtained by removing NCO group from aliphatic or aromatic diisocyanate, R6 and R7 are alkylene group, n is an integer ranging from 4 to 80, and m is an integer ranging from 3 to 40; and the molecular weight of the siloxane polymer expressed by formula (I) is about 1000 to 10000. The contact lens material further comprises at least one hydrophilic monomer; a cross-linking agent or a siloxane polymer expressed by formula (II), wherein in the formula (II), p is an integer ranging from 4 to 80, and q is an integer ranging from 3 to 40; and an initiator.

Owner:BENQ MATERIALS +1

Accommodating lens with cavity

ActiveUS20170371180A1Increase optical powerChange in optical powerOptical articlesCoatingsCross-linkDissolution

A lens comprises an internal cavity structure formed by dissolution of a soluble insert material. The internal soluble material may dissolve through a body of a lens such as a contact lens in order to form the cavity within the contact lens. The cavity within the lens can be shaped in many ways, and corresponds to the shape of the dissolved material, such that many internal cavity shapes can be readily fabricated within the contact lens. The insert can be placed in a mold with a pre-polymer material, and the pre-polymer material cured with the insert placed in the mold to form the lens body. The polymerized polymer may comprise a low expansion polymer in order to inhibit expansion of the lens when hydrated. The polymer may comprise a hydrogel when hydrated. The soft contact lens material comprises a sufficient amount of cross-linking to provide structure to the lens and shape the cavity.

Owner:ONEFOCUS VISION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com