Preparation method of composite modified rubber asphalt with excellent anti-stripping performance

A compound modified asphalt and compound modified technology, which is applied in building components, building insulation materials, buildings, etc., can solve problems such as insufficient adhesion, and achieve the effects of improving construction ease, reducing dosage, and reducing asphalt viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Prepare modified rubber asphalt as follows:

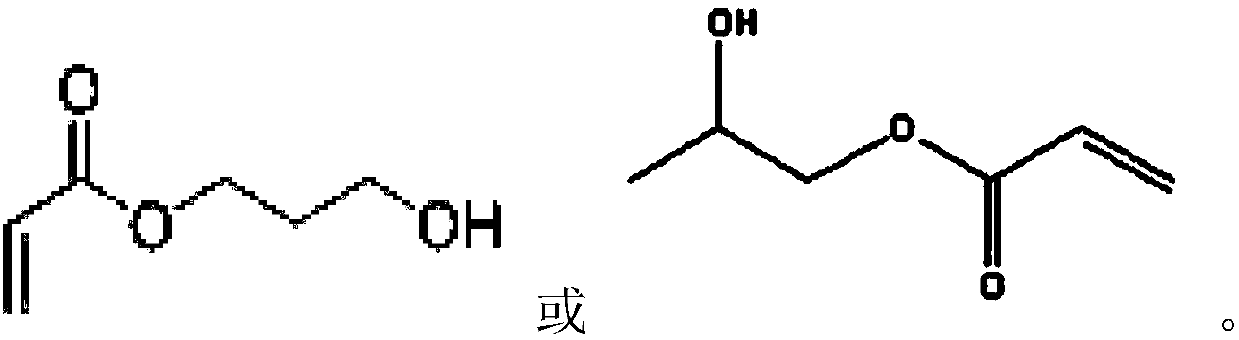

[0045]Put 18 parts by weight of tire rubber powder, 73.7 parts by weight of road petroleum asphalt, under the condition of 210-220 ° C, stir and react for 45 minutes. Then 3 parts by weight of hydroxypropyl acrylate, 3 parts by weight of ethyl dimethacrylate Glycol ester, 0.3 parts by weight of elemental sulfur as a crosslinking agent, at a temperature of about 200 ° C, first use a high-speed shearing machine to cut at a speed of 3500 rpm for 30-45 minutes, and then pass through the rest of the temperature Set aside for 30 minutes, then add 2 parts by weight of diisopropyl phthalate, and use a mixer to stir at a constant speed for 180 minutes under the condition of 180-200 ° C to complete the preparation of modified rubber asphalt. Then it was subjected to part of the asphalt test and Hamburg immersion rutting test in the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering". The test results are shown ...

Embodiment 2

[0047] Prepare modified rubber asphalt as follows:

[0048] Mix 19 parts by weight of tire rubber powder and 73.7 parts by weight of road petroleum asphalt under the condition of 210-220 ° C for 45 minutes. Then 2 parts by weight of hydroxypropyl acrylate, 3 parts by weight of ethyl dimethacrylate Glycol ester, 0.3 parts by weight of elemental sulfur as a crosslinking agent, at a temperature of about 200 ° C, first use a high-speed shearing machine to cut for 30 minutes at a speed of 3500 rpm, and then add 2 parts by weight of ophthalmic Diisopropyl phthalate, under the condition of 180-200 ℃, use a mixer to stir at a constant speed for 180min to prepare the modified rubber asphalt. Then it was subjected to part of the asphalt test and Hamburg immersion rutting test in the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering". The test results are shown in Table 2.

Embodiment 3

[0050] Prepare modified rubber asphalt as follows:

[0051] Put 20 parts by weight of tire rubber powder, 71.7 parts by weight of road petroleum asphalt, under the condition of 210-220 ° C, stir and react for 45 minutes. Then 2 parts by weight of hydroxypropyl acrylate, 4 parts by weight of ethylene dimethacrylate Glycol ester, 0.3 parts by weight of elemental sulfur as a crosslinking agent, at a temperature of about 200 ° C, first use a high-speed shearing machine to cut for 30 minutes at a speed of 3500 rpm, and then add 2 parts by weight of ophthalmic Diisopropyl phthalate, under the condition of 180-200 ℃, use a mixer to stir at a constant speed for 180min to prepare the modified rubber asphalt. Then it was subjected to part of the asphalt test and Hamburg immersion rutting test in the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering". The test results are shown in Table 2.

[0052] In the comparative example, an example of compound modification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com