Seven-layer co-extrusion high-isolating packaging film

A packaging film and high-barrier technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve problems such as poor barrier resistance and high temperature resistance, unreasonable structural materials, and easy deformation under heat, etc., to achieve elasticity and flexibility Good, not afraid of mechanical force, increase barrier performance and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

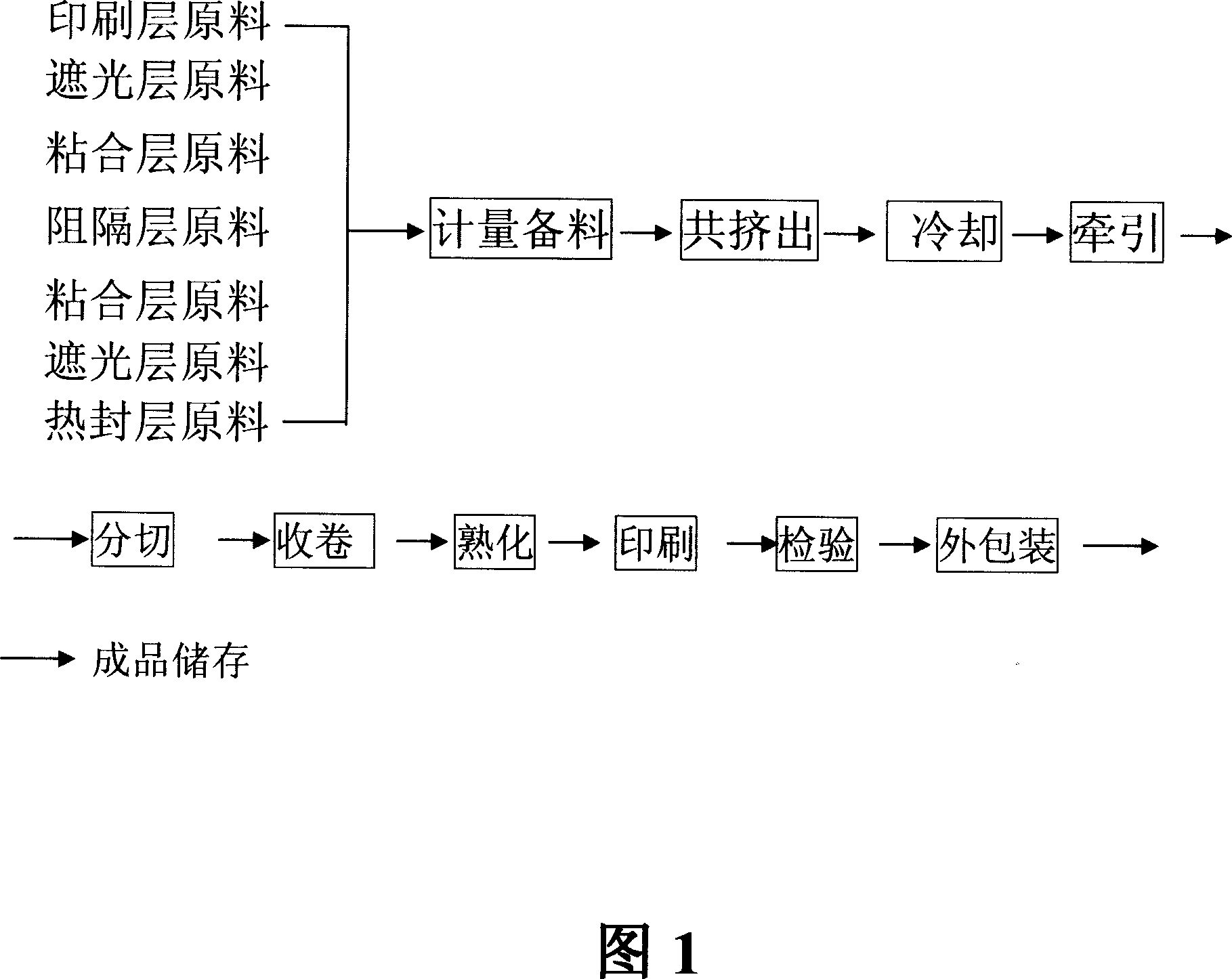

Method used

Image

Examples

Embodiment Construction

[0045] Seven-layer co-extruded high-barrier packaging film, which includes seven layers, the raw material formula of each layer from the inside to the outside is as follows:

[0046] First Layer: Metallocene Polyethylene LLDPE 12%

[0047] Low Density Polyethylene LDPE 9%

[0048] FSU slip agent 0.5%

[0049] Second layer: polyethylene white masterbatch 7%

[0050] Linear Low Density Polyethylene LLDPE 9%

[0051] Low Density Polyethylene LDPE 7%

[0052] Third Layer: Tie Adhesive 5%

[0053] Fourth layer: EVOH ethylene-vinyl alcohol copolymer 5%

[0054] Fifth layer: Tie adhesive 5%

[0055] The sixth layer: linear low density polyethylene LLDPE 9%

[0056] Low Density Polyethylene LDPE 5%

[0057] Polyethylene Black Masterbatch 5%

[0058] Seventh layer: metallocene polyethylene LLDPE 12%

[0059] Low Density Polyethylene LDPE 7%

[0060] Slip agent FSU 1.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com