Carbon/carbon composite material crucible pot and preparing technique thereof

A carbon composite material and production process technology, applied in the field of carbon/carbon composite material crucible for single crystal furnace and its production process, can solve the problems of complex process and high impurity content, and achieve stable structure, simple process and strong cohesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A crucible for carbon / carbon composite material, which is made of carbon fiber through blanking, densification, purification, and machining.

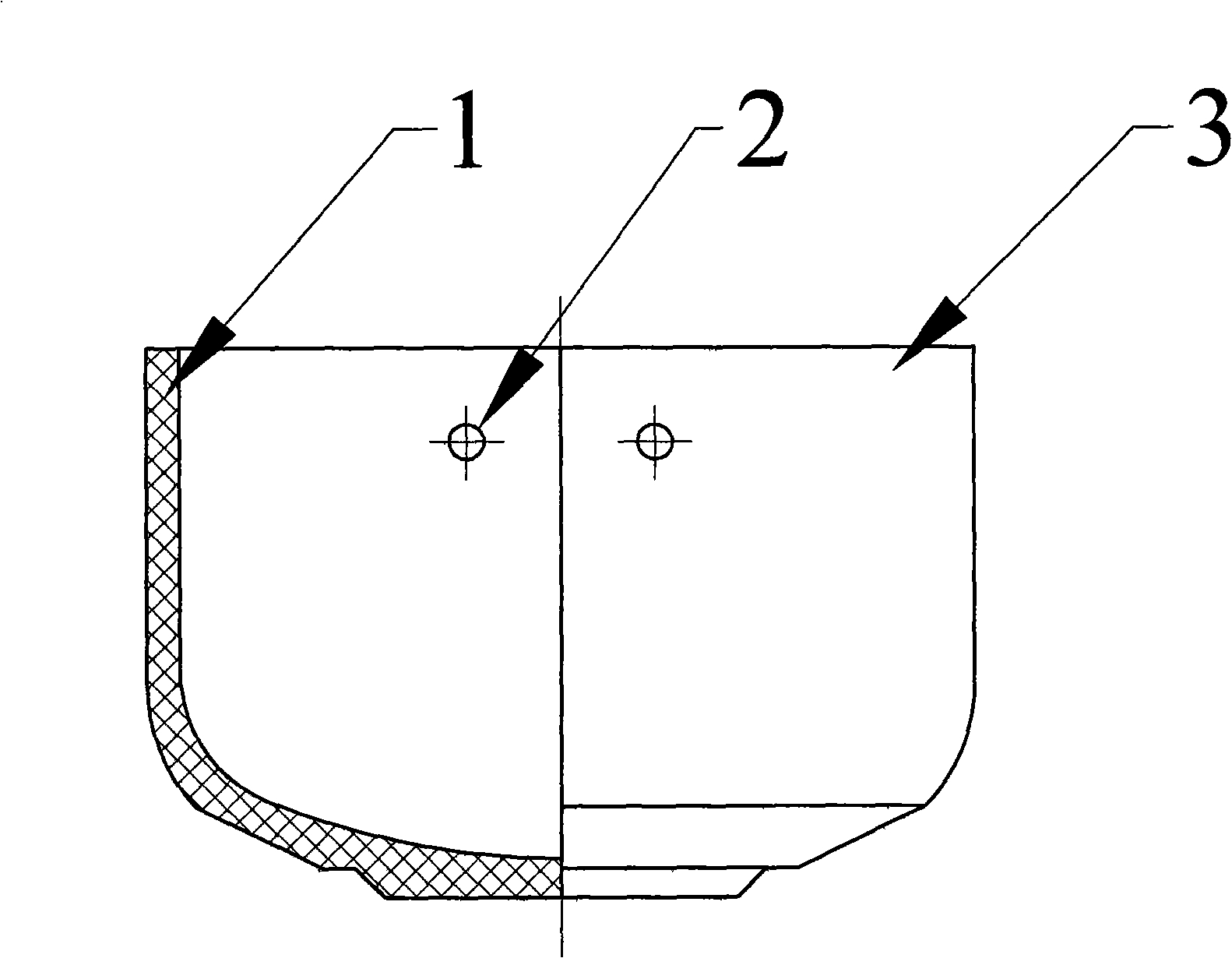

[0025] by figure 1 As shown, the carbon / carbon composite crucible of the present invention is composed of 2-4 petals (two petals in this embodiment); it is composed of a left petal 1, a right petal 3, and a left petal 1, a right petal 3 There are mounting holes 2 on it. The production process includes the following steps:

[0026] (1) Billet making: open into a web, select short carbon fibers 25mm~70mm long, open them into fluffy needle-like fibers by opening equipment, and then airflow and / or card the opened carbon fibers Form a web, then use a web-laying machine to spread a fiber web and pre-puncture it into a mesh, the surface density of the mesh is 20g / m 2 ~160g / m 2 (This example is 100g / m 2 ); The mesh and surface density is 200g / m 2 ~320g / m 2 (This embodiment is 240g / m 2 ) Carbon cloth needle-punched composite felt, the appare...

Embodiment 2

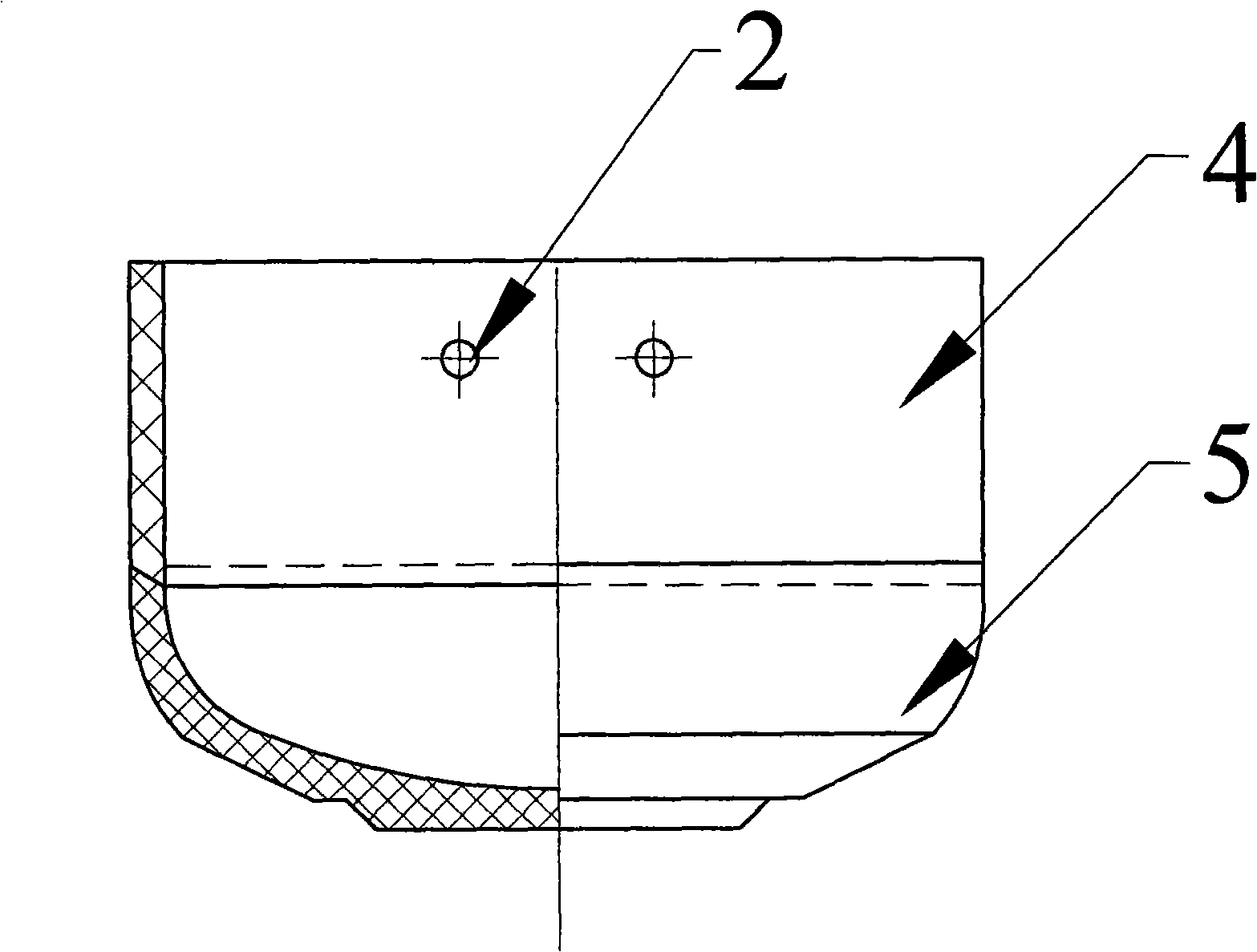

[0034] by figure 2 As shown, the carbon / carbon composite material crucible formed in step (4) is integrated, and the integrated crucible is cut into a cylinder 4 and a bowl-shaped tray 5 at a distance of 15 mm from the boundary line of the inner arc and the inner cylinder on the cylindrical part. In the upper and lower parts, the cylinder 4 is turned into an outer cone and the bowl-shaped tray 5 is turned into an inner cone. The apex angles of the two cones are the same at 120°C to ensure a firm fit. The operation is convenient, and the cylinder 4 is provided with a lifting hole 2. The same as in Example 1.

Embodiment 3

[0036] by image 3 As shown, when the carbon / carbon composite material crucible of the present invention is a whole, in order to facilitate the cleaning of the quartz crucible residue after the crystal pulling is completed, pluggable through holes can be drilled in the cylindrical and arc transition parts of the crucible 6. These through holes 6 can be made into countersunk screw holes, taper holes, or threaded holes, and the through holes 6 can be plugged with tapered pins or slotted studs. The same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com