Polyurethane modified asphalt waterproof paint for buildings and production method thereof

A technology of asphalt waterproof coating and polyurethane modification, which is applied in asphalt coatings, antifouling/underwater coatings, anti-corrosion coatings, etc. The effect of improving aging resistance and acid and alkali resistance, excellent storage stability, and improving waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

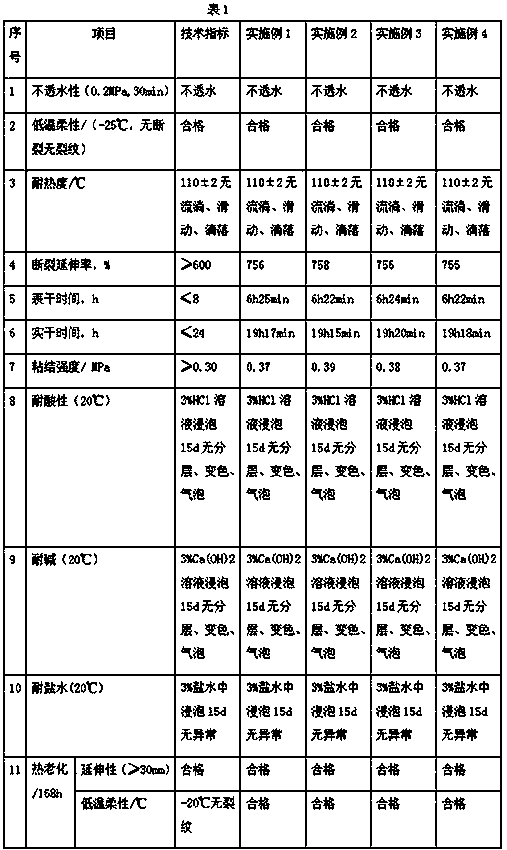

Examples

Embodiment 1

[0027] A kind of polyurethane modified asphalt waterproof coating for construction, which is composed of the following raw materials in parts by weight: 25 parts of polyurethane prepolymer; 70 parts of 90# petroleum asphalt; 40 parts of water; 20 parts of neoprene latex, 4 parts of emulsifier, poly 2 parts of vinyl alcohol, 1 part of coupling agent N-phenyl-3-aminopropyltrimethoxysilane; 1 part of polypropylene glycol; 3 parts of acetyl trihexyl citrate, 0.1 part of hydrogenated rosin pentaerythritol ester; 1 part of polyacrylamide Parts; 10 parts of modified nano calcium carbonate.

[0028] The polyurethane prepolymer is a prepolymer with NCO end groups formed by polymerizing diphenylmethane diisocyanate and polyether diol as the main raw materials, and the molecular weight is between 4000-10000; the emulsifying The agent is obtained by mixing octadecyltrimethylammonium chloride and polyoxyethylene sorbitan monooleate in a weight ratio of 8:1.

[0029] The preparation method...

Embodiment 2

[0035] A kind of polyurethane modified asphalt waterproof paint for construction, which is composed of the following raw materials in parts by weight: 27 parts of polyurethane prepolymer; 72 parts of 90# petroleum asphalt; 50 parts of water; 22 parts of neoprene latex, 5 parts of emulsifier, poly 3 parts of vinyl alcohol, 2 parts of coupling agent γ-aminopropyltriethoxysilane; 1.5 parts of polypropylene glycol; 4 parts of acetyl trihexyl citrate, 0.3 parts of hydrogenated rosin pentaerythritol ester; 2 parts of polyacrylamide; modified 12 parts of nanometer calcium carbonate.

[0036] The polyurethane prepolymer is a prepolymer with NCO end groups formed by polymerizing diphenylmethane diisocyanate and polyether diol as the main raw materials, and the molecular weight is between 4000-10000; the emulsifying The agent is obtained by mixing octadecyltrimethylammonium chloride and polyoxyethylene sorbitan monooleate in a weight ratio of 8:2.

[0037] The preparation method of the...

Embodiment 3

[0043] A kind of polyurethane modified asphalt waterproof paint for construction, which is composed of the following raw materials in parts by weight: 30 parts of polyurethane prepolymer; 75 parts of 90# petroleum asphalt; 60 parts of water; 25 parts of neoprene latex, 7 parts of emulsifier, poly 4 parts of vinyl alcohol, 3 parts of coupling agent; 2 parts of polypropylene glycol; 5 parts of acetyl trihexyl citrate, 0.5 part of hydrogenated rosin pentaerythritol ester; 3 parts of polyacrylamide; 15 parts of modified nano calcium carbonate.

[0044] The polyurethane prepolymer is a prepolymer with NCO end groups formed by polymerizing diphenylmethane diisocyanate and polyether diol as the main raw materials, and the molecular weight is between 4000-10000; the emulsifying The agent is obtained by mixing octadecyltrimethylammonium chloride and polyoxyethylene sorbitan monooleate in a weight ratio of 8:2. The coupling agent is a mixture of γ-aminopropyltriethoxysilane, γ-methacryl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com