Marking film for surface of hard smooth substrate

A smooth substrate, hard technology, applied in the direction of copying/marking method, film/flake release coating, film/flake adhesive, etc., can solve glass, ceramic damage, poor performance, economical Good and other problems, to avoid damage, strong acid and alkali corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A marking film for the surface of a hard and smooth substrate, which is made by the following method: use a thermal printer to heat the thermal transfer ribbon by means of pulse heating, so that the marking information is thermally transferred to the surface of the TPU film, and then heat and add pressure (temperature 140-150°C, pressure 1.3MPa-1.5MPa, heating time 5-8s) to melt the surface of the TPU film and bond it to the surface of the metal. After cooling, the marking film is obtained; the thermal transfer ribbon includes A tape base, the two sides of the tape base are respectively coated with a back coating layer and a heat transfer layer, and the heat transfer layer is sequentially composed of a protective layer and an adhesive layer from the inside to the outside of one side of the tape base;

[0031] In this embodiment, the thermal transfer carbon ribbon is a high temperature resistant resin-based ribbon, which is prepared from the following raw materials:

[0...

Embodiment 2

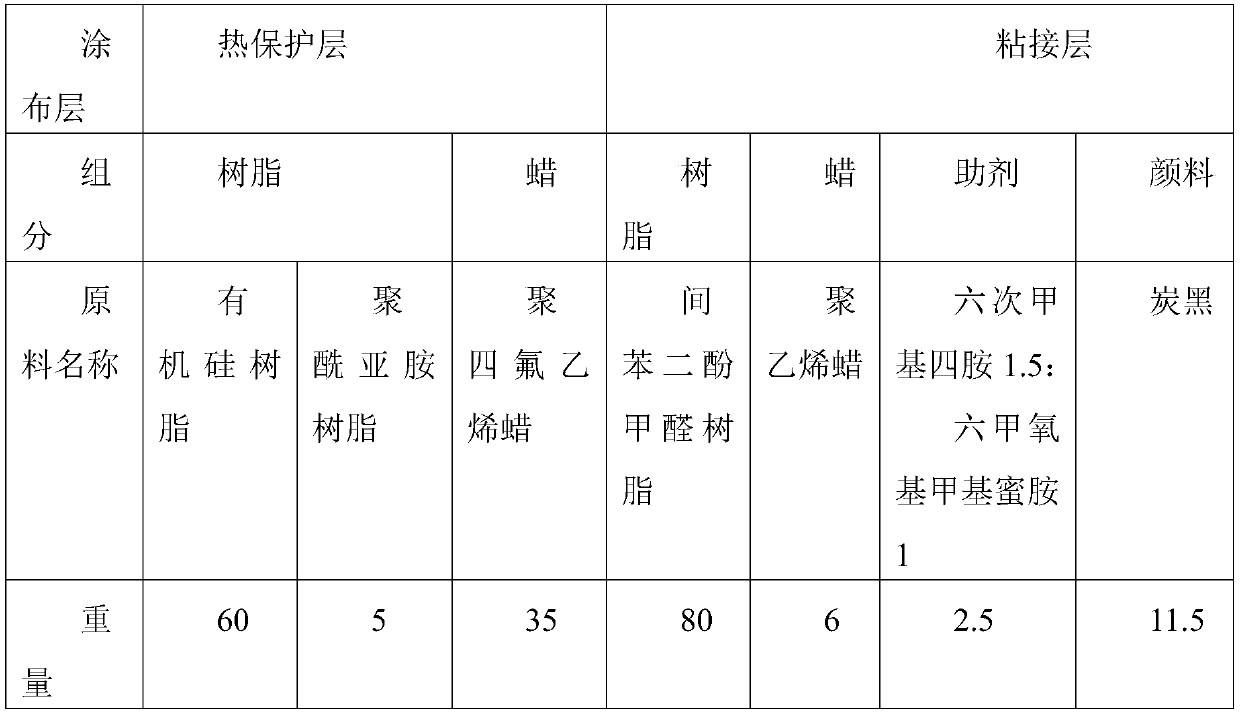

[0038] The difference between this embodiment and Example 1 is that the thermal transfer carbon ribbon is a high temperature resistant resin-based carbon ribbon with different raw material ratios and different coating thicknesses. High-temperature resin-based carbon ribbons are prepared from the following raw materials:

[0039]

[0040] When coating, the thickness of the back coat layer is 0.2 μm, the thickness of the protective layer is 1.0 μm, and the thickness of the adhesive layer is 1.3 μm.

Embodiment 3

[0042] The difference between this embodiment and Example 1 is that the thermal transfer carbon ribbon is a high temperature resistant resin-based carbon ribbon with different raw material ratios and different coating thicknesses. High-temperature resin-based carbon ribbons are prepared from the following raw materials:

[0043]

[0044]

[0045] When coating, the thickness of the back coat layer is 0.2 μm, the thickness of the protective layer is 1 μm, and the thickness of the adhesive layer is 1.4 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com