Modified asphalt waterproof paint for buildings and production method thereof

A technology of modified asphalt and waterproof coatings, which is applied in the direction of asphalt coatings, anti-corrosion coatings, coatings, etc. It can solve the problems that technical indicators are difficult to meet the relevant requirements, the production of water-emulsified asphalt is cumbersome, and the binding force of polymer bodies is poor. Good waterproof effect, improved aging resistance, acid and alkali resistance, and enhanced chemical affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

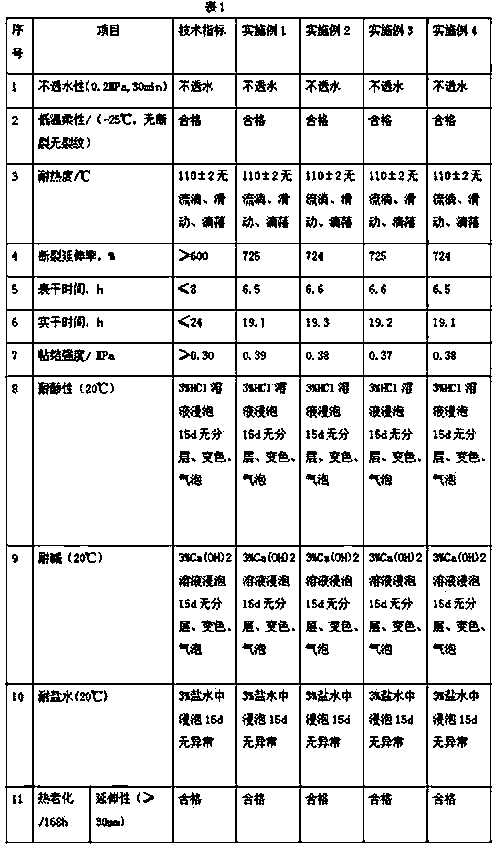

Examples

Embodiment 1

[0027] A kind of modified asphalt waterproof coating for building, is made up of the raw material of following parts by weight:

[0028] 50 parts of 90# petroleum asphalt; 60 parts of water; 25 parts of styrene-butadiene latex, 5 parts of emulsifier, 2 parts of polyvinyl alcohol, 1 part of coupling agent tri-tert-butoxyvinylsilane; 5 parts of polyoxypropylene glyceryl ether; 3 parts of triethyl citrate, 0.1 part of rosin glyceride; 1 part of sodium polyacrylate; 10 parts of modified nano calcium carbonate.

[0029] The emulsifier is obtained by mixing N-alkyltrimethylammonium chloride and coconut acid diethanolamide in a weight ratio of 9:2.

[0030] The above-mentioned modified asphalt waterproof coating for construction, the preparation method of the modified nano-calcium carbonate is: dehydrate and dry the nano-calcium carbonate powder at 115°C, then add it to a high-speed mixer, stir and heat up, and stop heating at 90°C , adding chelating titanate coupling agent KR-201 w...

Embodiment 2

[0036] A kind of modified asphalt waterproof coating for building, is made up of the raw material of following parts by weight:

[0037] 55 parts of 90# petroleum asphalt; 67 parts of water; 26 parts of styrene-butadiene latex, 6 parts of emulsifier, 3 parts of polyvinyl alcohol, 2 parts of coupling agent γ-ethylenediaminotriethoxysilane; polyoxypropylene glyceryl ether 6 parts; 4 parts of triethyl citrate, 0.3 part of rosin glyceride; 2 parts of sodium polyacrylate; 12 parts of modified nano calcium carbonate.

[0038] The emulsifier is obtained by mixing N-alkyltrimethylammonium chloride and coconut acid diethanolamide in a weight ratio of 9:2.

[0039] The preparation method of the modified nano-calcium carbonate is as follows: dehydrate and dry the nano-calcium carbonate powder at 117° C., then add it to a high-speed mixer, stir and heat up, stop heating at 90° C., and add chelate powder with a mass of 2.0% of the nano-calcium carbonate. Formed titanate coupling agent KR-...

Embodiment 3

[0045] A kind of modified asphalt waterproof coating for building, is made up of the raw material of following parts by weight:

[0046] 65 parts of 90# petroleum asphalt; 70 parts of water; 28 parts of styrene-butadiene latex, 7 parts of emulsifier, 4 parts of polyvinyl alcohol, 3 parts of coupling agent; 7 parts of polyoxypropylene glyceryl ether; 5 parts of triethyl citrate, 0.5 parts of rosin glyceride; 3 parts of sodium polyacrylate; 15 parts of modified nano-calcium carbonate.

[0047] The emulsifier is obtained by mixing N-alkyltrimethylammonium chloride and coconut acid diethanolamide in a weight ratio of 9:2. The coupling agent is a mixture of tri-tert-butoxyvinylsilane and γ-ethylenediaminotriethoxysilane.

[0048] The preparation method of the modified nano-calcium carbonate is as follows: dehydrate and dry the nano-calcium carbonate powder at 120° C., then add it to a high-speed mixer, stir and heat up, stop heating at 90° C., and add 2.0% chelate powder of the na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com