Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Increase the amount of filler" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame retardant high-heat-conductivity epoxy resin electronic adhesive glue

InactiveCN102533192AImprove thermal conductivityDisperse quicklyNon-macromolecular adhesive additivesEpoxynovolac adhesivesHalogenAdhesive glue

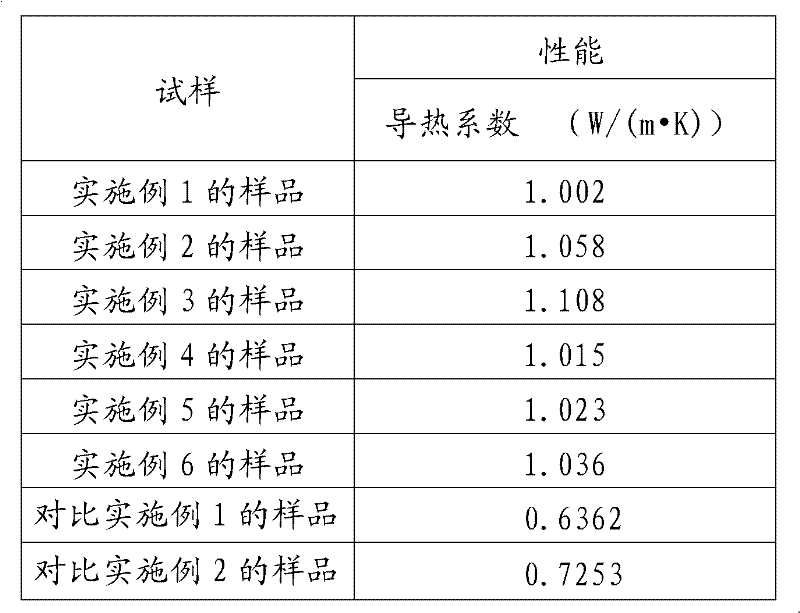

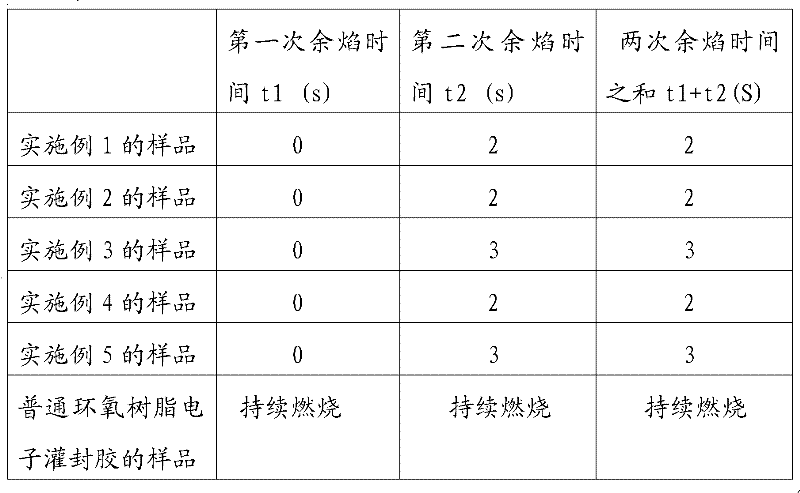

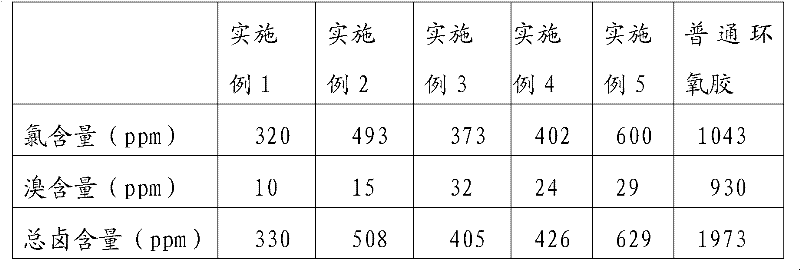

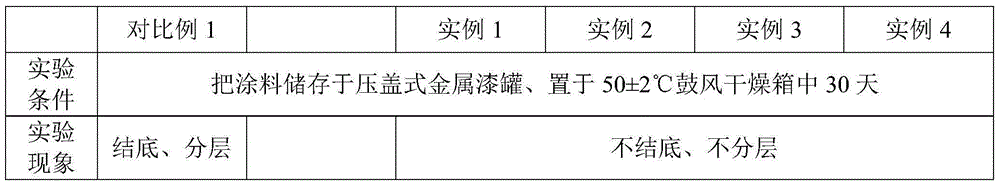

The invention relates to flame retardant high-heat-conductivity epoxy resin electronic adhesive glue, which is formed by mixing ingredients A with amine curing agents according to the weight ratio of 100:(5-12), wherein the ingredients A comprises the following ingredients in parts by weight: 50 to 60 parts of spherical alumina powder, 20 to 30 parts of flame retardant fillings, 10 to 20 parts of epoxy resin, 1.5 to 2.5 parts of reactive diluents, 2 to 3 parts of halogen-free liquid flame retardants, 2 to 3 parts of toughening agents, 0.2 to 0.8 parts of thixotropic agents and 0.1 to 0.5 parts of coupling agents. According to the adhesive glue provided by the invention, the adhesive glue filled by the spherical alumina has higher condensate heat conductivity when being compared with the adhesive glue filled by the non-spherical alumina, and the heat accumulation of heating devices can be fast dispersed.

Owner:YANTAI DARBOND TECH

Halogen-free flame-retardant epoxy resin electronic pouring sealant

InactiveCN102516914ASatisfy Halogen Free RequirementsImprove flame retardant performanceNon-macromolecular adhesive additivesOther chemical processesEpoxyHalogen

The invention relates to a halogen-free flame-retardant epoxy resin electronic pouring sealant which is formed by mixing an A component and an amine curing agent according to the weight ratio of 100:4-13, wherein the A component comprises the following raw materials in parts by weight: 30-40 parts of halogen-free epoxy resin, 40-65 parts of flame-retardant fillers, 2-7 parts of halogen-free active diluting agents, 2-7 parts of halogen-free liquid flame retardants, 1-5 parts of toughening agents, 0.1-0.5 part of coupling agent and 0.1-0.5 part of pigment. The invention has the beneficial effects that the pouring sealant is free from halogen and satisfies the halogen-free requirements; the flame retardance is independent of a halogen-added flame retardant, so that the environment friendliness is achieved; the fame retardant ability is strong and can achieve the grade UL94-V0; and with the adoption of a double-component system, not only can the room-temperature curing be achieved, but also the thermal curing can be achieved, so that the operation is covneneint.

Owner:YANTAI DARBOND TECH

Floating body material and manufacturing technique thereof

The invention relates to a floating body material, in particular to a floating body material and a manufacturing technique thereof for an observation platform at the bottom of the sea. The floating body material comprises bisphenol A type epoxy resin, modified acrylonitrile-butadiene rubber latex, hollow glass microsphere, polyether amine, gamma-glycidoxypropyltrimethoxysilane, a silane coupling agent and polyvinyl alcohol fiber; and the floating body material comprises the following components in parts by weight: 100 parts of bisphenol A type epoxy resin, 0-10 parts of modified acrylonitrile-butadiene rubber latex, 12-18 parts of hollow glass microsphere, 15-20 parts of polyether amine, 2-3 parts of gamma-glycidoxypropyltrimethoxysilane, 1-2 parts of silane coupling agent and 2 parts of polyvinyl alcohol fiber. The invention provides the floating body material and the manufacturing technique thereof for the observation platform at the bottom of the sea; and the observation platform adopting the floating body material can be soaked in the seawater for use in a long term.

Owner:SECOND INST OF OCEANOGRAPHY MNR

PVC (Poly Vinyl Chloride) profile added with chloroethylene-acrylate copolymer resin and preparation method thereof

The invention relates to a PVC (Poly Vinyl Chloride) profile added with a chloroethylene-acrylate copolymer resin and a preparation method thereof, and belongs to the technical application of the chloroethylene-acrylate copolymer resin in PVC resin processing. According to the invention, the common PVC resin is modified by using the special properties of the chloroethylene-acrylate copolymer resin such as internal plasticization property, excellent processability and tenacity; the processing formulation by weight is as follows: 100 parts of PVC resin, 5-10 parts of chloroethylene-acrylate copolymer resin, 1-5 parts of heat stabilizer, 5-20 parts of filler and 3-6 parts of other additives. In the processing process of the PVC profile, the chloroethylene-acrylate copolymer resin is used for substituting for processing modifiers ACR (Acrylic Rubber) and CPE (Chlorinated Polyethylene), and a specific mixing process is adopted so as to achieve the synergistic effect of the chloroethylene-acrylate copolymer resin with inorganic particles, and consequently, the processing temperature of the PVC profile is reduced and the mechanical properties of the PVC profile are improved.

Owner:XINJIANG TIANYE GRP

Adhesive for slow-binding prestress reinforcement

InactiveCN1775889AHas internal toughening effectIncrease elasticityEpoxy resin adhesivesAdhesiveThermoplastic polyurethane

The invention relates to an adhesive used to cementing tendon that is made up from bisphenol-A type epoxy resin, active thinner bisphenol A diglycerol aether, active toughening agent thermal plasticity polyurethane and filling concrete. The concreting speed could be regulated according to the actual request of the project. It has good fluidity, cohesion, and toughness.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

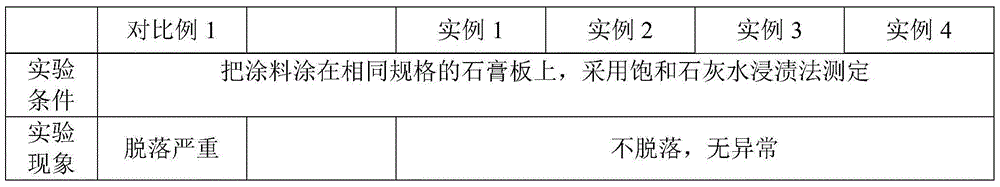

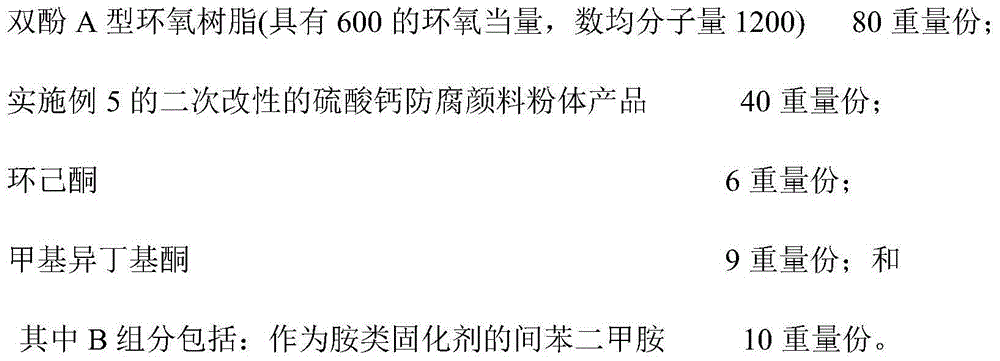

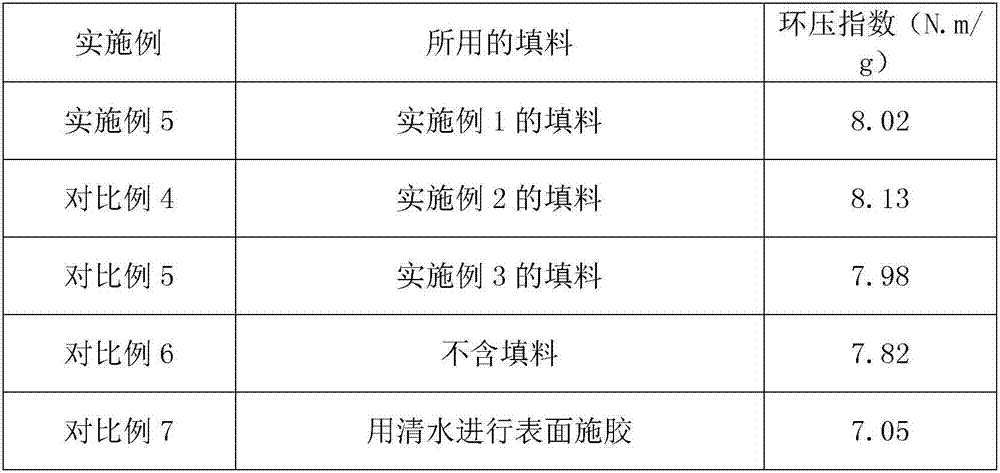

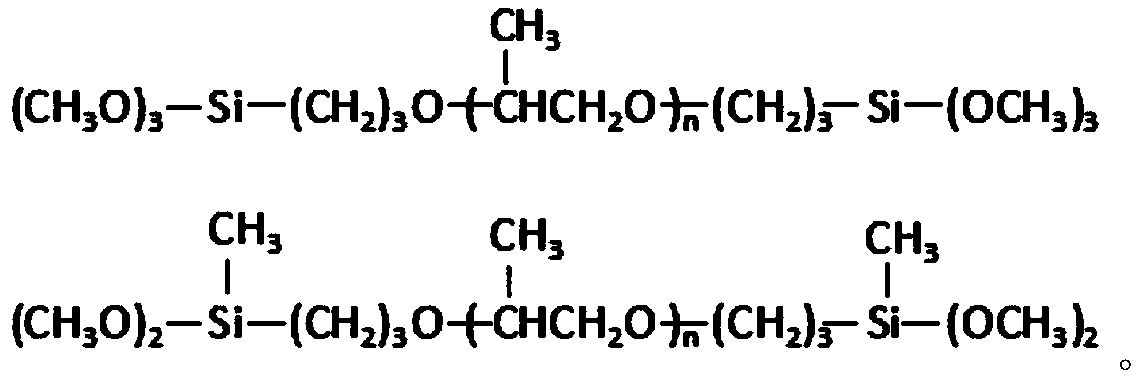

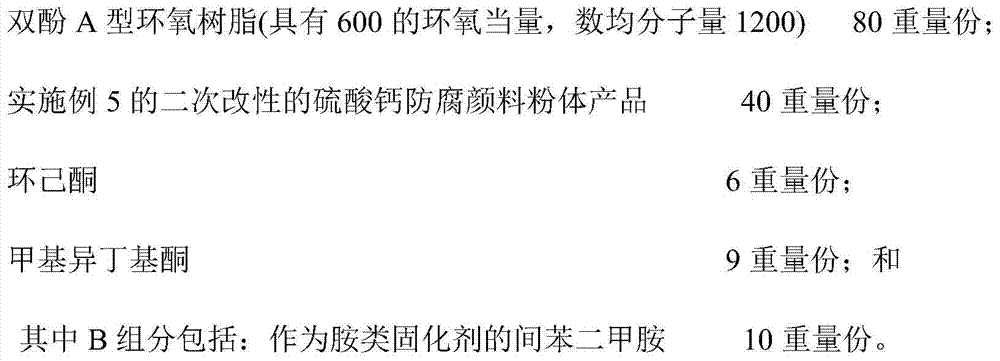

Modified calcium sulphate anticorrosive pigment as well as preparation method and application thereof

ActiveCN104945955AHigh temperature resistantWith acid and alkali corrosion resistanceAnti-corrosive paintsPigment treatment with organosilicon compoundsGas phaseBall mill

The invention discloses a modified calcium sulphate anticorrosive pigment as well as a preparation method and an application thereof. The preparation method comprises the following steps: preparing calcium sulphate extracted from industrial by-product gypsum into a suspension with a certain solid content, adding a modifier according to a certain mass percent, and then placing the modifier in a ball mill and uniformly mixing and grinding; drying the ground mixture for 3-6 hours at 80-150 DEG C, cooling the mixture and then grinding the mixture into a powder and crushing, wherein preferably, aminosilane-modified gas-phase silica is added during the grinding and crushing process. The calcium sulphate anticorrosive pigment disclosed by the invention is capable of effectively solving the pressure brought to an environment by the industrial by-product gypsum, and capable of improving the industrial by-product gypsum, wear resistance and corrosion resistance of a coating film in case of being mixed and used with other anticorrosive pigments; the pigment is good in dispersibility in resin, simple in production process, low in production cost, and capable of bringing good social and economic benefits.

Owner:HUNAN RUISHI SCI & TECH DEV

Starch based composite packing as well as preparation method and application thereof

InactiveCN106930141AHydrophilicCationicNon-fibrous pulp additionPaper/cardboardStarch granulePolymerization

The invention discloses starch based composite packing which is a compound of a core-shell structure, wherein starch granules are adopted as a core of the compound of the core-shell structure; a wrapping membrane which is grafted with the starch granules and comprises an acrylamide copolymer is adopted as a shell layer of the compound of the core-shell structure; the starch comprises raw starch or modified starch; the wrapping membrane shell layer with the acrylamide copolymer is prepared from monomers (a), (b) and (c) through polymerization.

Owner:GUANGDONG IND TECHN COLLEGE

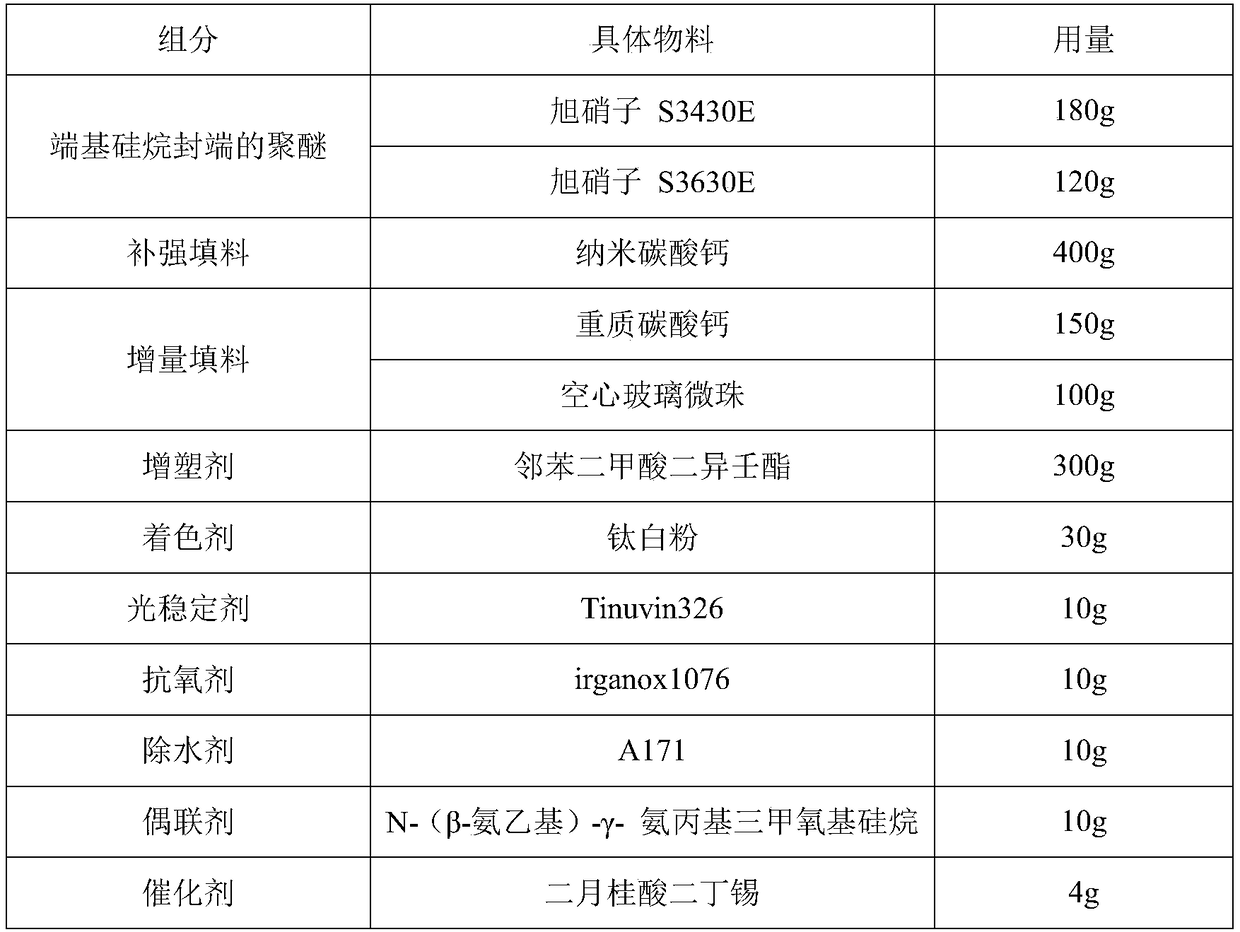

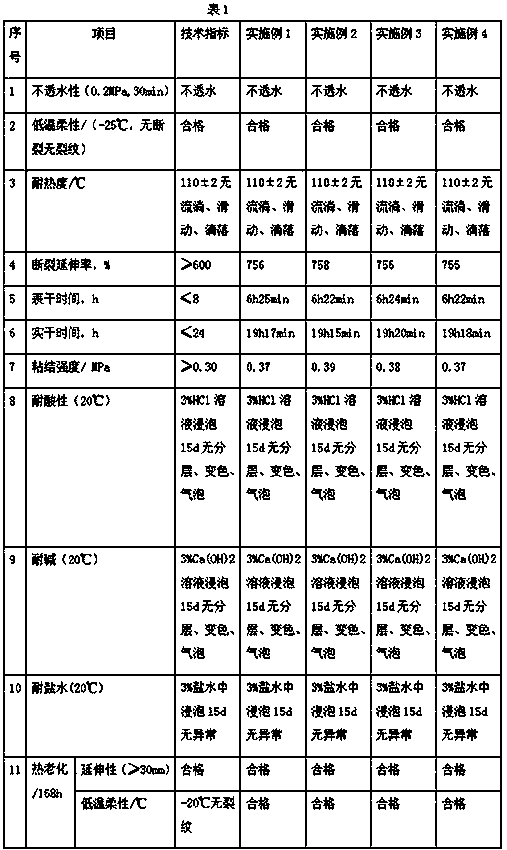

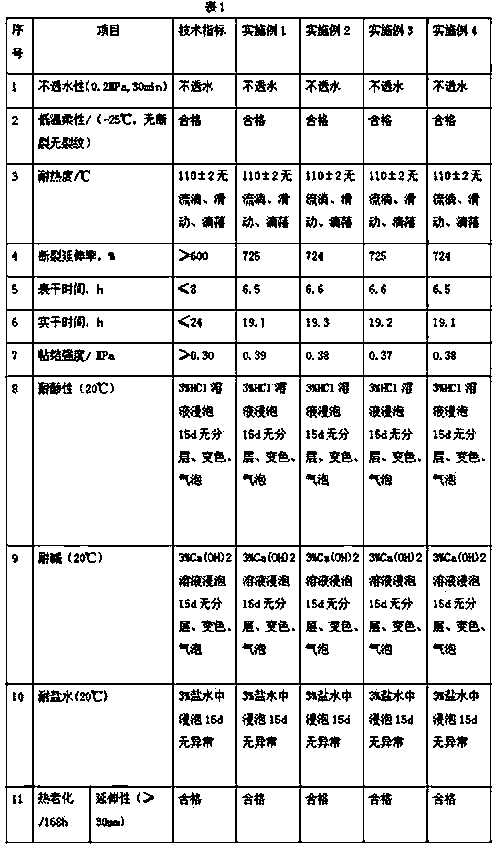

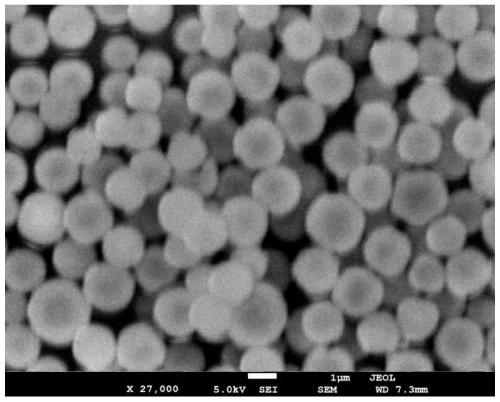

Stress relaxation type polyether sealant based on terminal silane modification and preparation method of polyether sealant

InactiveCN109233723AReduce internal stressEliminate the effects of shrinkageNon-macromolecular adhesive additivesPolyether adhesivesInternational standardAntioxidant

The invention belongs to the field of sealants and discloses a stress relaxation type polyether sealant for buildings based on terminal silane modification. The polyether sealant is mainly prepared from a terminal silane-capped polyether polymer, a plasticizer, a reinforcing filler, an increment filler, a silane coupling agent, a light stabilizer, an antioxidant, a dehydrant, a coloring agent anda catalyst. Generally, the stress relaxation performance and the elasticity recovery performance cannot be simultaneously realized, the silane modified sealant prepared by virtue of the preparation method has the stress relaxation property while meeting the elastic requirement, and the influence caused by the shrinkage of a building base material can be maximally eliminated under the stress relaxation effect even when the building base material is in a long-term stretching state; and in the premise that the elasticity recovery rate is more than 70% in an international standard GB / T14683-2017,the stress relaxation performance is provided for the sealant, so that the problems that the sealant is broken or the adhesion surface is damaged and the like caused due to the shrinkage of the building base material are effectively solved, and the application range of the sealant is broadened.

Owner:美好建筑装配科技有限公司

Polyurethane modified asphalt waterproof paint for buildings and production method thereof

InactiveCN108047949AGood storage stabilityImprove high temperature resistanceFireproof paintsAntifouling/underwater paintsBituminous waterproofingPolyvinyl alcohol

The invention relates to a polyurethane modified asphalt waterproof paint, which is composed of the following raw materials by weight: 25-30 parts of a polyurethane prepolymer; 70-75 parts of 90# petroleum asphalt; 40-60 parts of water; 20-25 parts of polychloroprene latex; 4-7 parts of an emulsifier; 2-4 parts of polyvinyl alcohol; 1-3 parts of a coupling agent; 1-2 parts of polypropylene glycol;3-5 parts of trihexyl o-acetylcitrate; 0.1-0.5 part of pentaerythritol ester of hydogenated rosin; 1-3 parts of polyacrylamide; and 10-15 parts of modified nano calcium carbonate. The polyurethane modified asphalt waterproof paint prepared by the method provided by the invention has good film compactness and high stability, a waterproof layer formed by the waterproof paint in a building has largebonding strength with a building base surface and good waterproof effect, moreover, after modification, the product has substantially improved water tolerance, aging resistance, acid and alkaline resistance and the like, has a simple making process, and overcomes the disadvantages of tedious making, poor film compactness, poor waterproofness and aging resistance in previous water emulsified asphalt paint.

Owner:GUANGXI WUXUAN JINPAI WATERPROOF MATERIAL SCI & TECH CO LTD

Modified asphalt waterproof paint for buildings and production method thereof

InactiveCN108047952AImprove physical performanceImprove waterproof performanceAnti-corrosive paintsBituminous coatingsBituminous waterproofingPolyvinyl alcohol

The invention relates to a modified asphalt waterproof paint for buildings. The modified asphalt waterproof paint is composed of the following raw materials by weight: 50-65 parts of 90# petroleum asphalt; 60-70 parts of water; 25-28 parts of styrene butadiene latex; 5-7 parts of an emulsifier; 2-4 parts of polyvinyl alcohol; 1-3 parts of a coupling agent; 5-7 parts of polyoxypropylene glycerol ether; 3-5 parts of triethyl citrate; 0.1-0.5 part of rosin glycerin ester; 1-3 parts of sodium polyacrylate; and 10-15 parts of modified nano calcium carbonate. The modified asphalt waterproof paint for buildings prepared by the method provided by the invention has good film compactness and high stability, can be used for buildings to form a waterproof layer, which has large bonding strength with the base surfaces of buildings and has good waterproof effect, moreover, after modification, the product has greatly improved water resistance, aging resistance, acid and alkali resistance and other properties, the making process is simple, and the modified asphalt waterproof paint overcomes the shortcomings of tedious making, poor film compactness, poor water resistance and aging resistance in previous water-emulsified asphalt paint.

Owner:GUANGXI WUXUAN JINPAI WATERPROOF MATERIAL SCI & TECH CO LTD

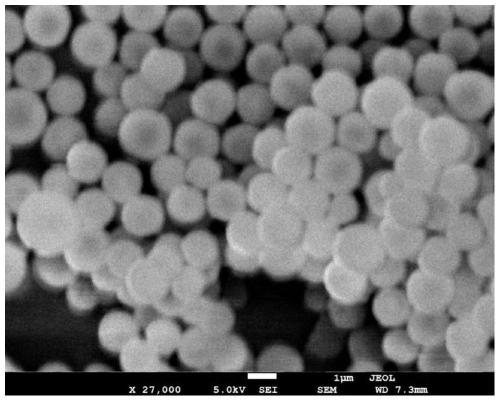

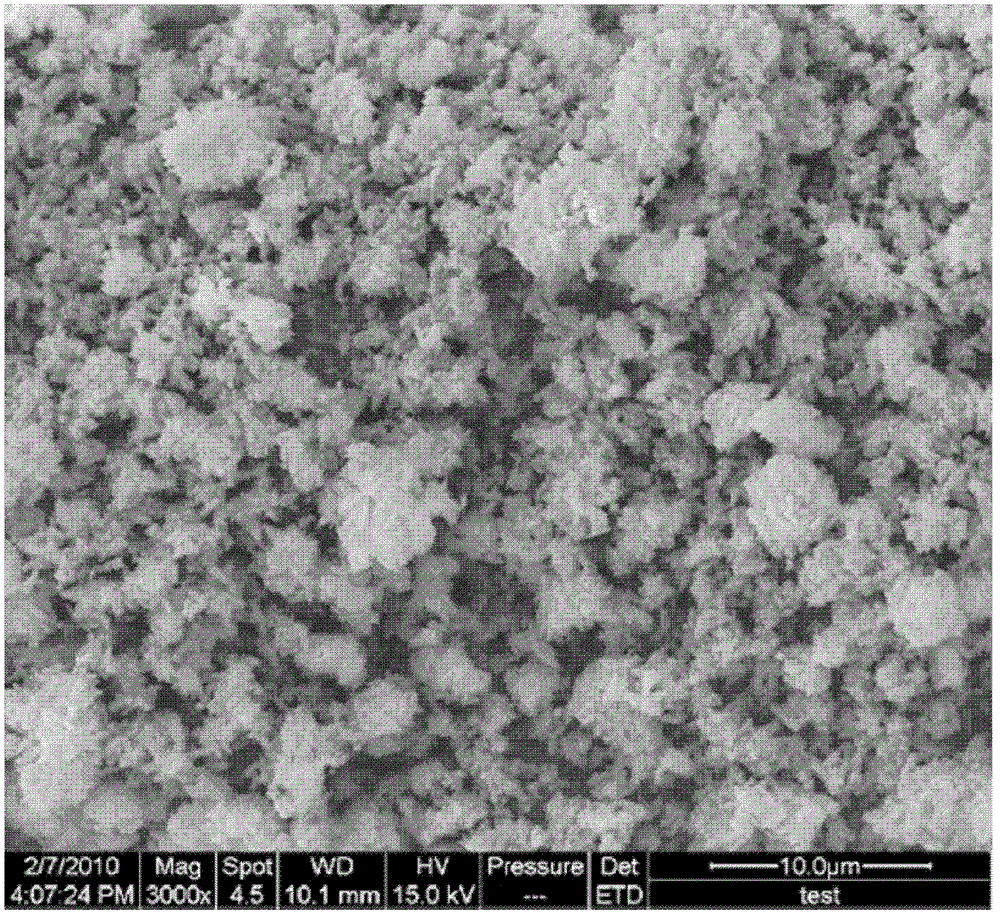

Modification method of ultrafine composite silica powder for high-end copper-clad plate

InactiveCN111303667AImprove heat resistanceImprove toughnessSilicaPigment treatment with organosilicon compoundsPhysical chemistryChloroform

The invention relates to a modification method of ultrafine composite silica powder for a high-end copper-clad plate, which comprises the following steps: 1, putting quartz fragments and quartz sand into a continuous running ball mill according to a mass ratio of 5: 1, taking alumina balls as grinding mediums, adjusting the induced air flux to be 10,000-15,000 cubic meters per hour, separating through a high-speed classifier to obtain large-particle silicon micropowder with non-uniform particle size distribution, and passing through a guarantee sieve to prepare angular silica powder coarse powder with the particle size of 1-3 microns, 2, pouring the 1-3-micron angular silica powder coarse powder into a reaction container and carrying out igniting, melting and spheroidizing, and 3, mixing the spheroidized silica powder, aminotriethoxysilane and hexamethyldisilazane in the step 2 in anhydrous chloroform according to a mass ratio of 1: 0.002-0.03: 0.01, reacting at 100-130 DEG C for 4-24hours, cooling, carrying out centrifugal separation, and carrying out vacuum drying to obtain the modified ultrafine silica powder. According to the invention, the compatibility of the silica powder and the phenolic resin is effectively enhanced in the processing process of the copper-clad plate.

Owner:江苏海格新材料有限公司

Anion environment-friendly coating and preparation method thereof

InactiveCN110330889AStrong weather resistanceGood for healthStarch dervative coatingsAntifouling/underwater paintsWeather resistanceSilicon dioxide

The invention discloses anion environment-friendly coating and a preparation method thereof. The anion environment-friendly coating comprises the following ingredients in parts by weight: 100-150 parts of fluorosilicon resin, 50-60 parts of amino resin, 40-50 parts of hydroxyalkyl starch, 15-30 parts of diatom ooze, 30-40 parts of plant extract, 50-60 parts of anion powder, 20-30 parts of nano-titanium dioxide, 30-40 parts of modified CNTs (carbon nano tubes), 20-30 parts of nano-silicon dioxide, 3-5 parts of amber sand, 15-25 parts of ceramic carbon balls, 1-2 parts of isopropyl triisostearoyltitanate and 1-2 parts of carboxymethylcellulose. The coating has the characteristics of being anti-aging, non-scaling and non-discoloring, being strong in weather resistance, being non-toxic and tasteless and being good in flatting and easy in construction, is resistant to washing, is non-toxic and harmless, is fresh in smell and has a health-care effect.

Owner:HENAN YUQIAN TECH TRANSFER CENT CO LTD

Glycidol polyether antibacterial powder coating

InactiveCN103102772AHigh glossImprove flatnessAntifouling/underwater paintsPaints with biocidesChemistryWeather resistance

The invention provides glycidol polyether antibacterial powder coating which consists of the following components in parts by mass: 60-70 parts of polyether resin, 4-6 parts of glycidol cyanate (TGIC), 8-12 parts of barium sulfate, 15-25 parts of titanium dioxide, 0.5-2 parts of leveling agent, 0.5-1 part of benzoin and 2-4 parts of antibacterial agent. The formula is prepared by a conventional coating preparation method. By adding polyether resin, the gloss, smoothness and the like of the pure epoxy powder are improved. After modification treatment of nonmetal mineral power, compatibility between inorganic substances and organic substances is enhanced, the dosage of filler is greatly increased, and the weather resistance, storage stability, corrosion resistance, mechanical strength and the like of the epoxy polyether powder are also improved at the same time.

Owner:YIYANG XIANGRUI TECH

High heat-resistant high-strength PPE alloy material and preparation method thereof

InactiveCN108587109AHigh heat distortion temperatureHigh crystallinityGlass fiberHeat deflection temperature

Provided is a high heat-resistant high-strength PPE alloy material. The high heat-resistant high-strength PPE alloy material comprises the following components of: in percent by mass, 22-35% of PPE, 20-27% of PA6, 14-21% of PA46, 3% of a compatibilizer, 20-35% of glass fiber, 0.3% of a coupling agent, 0.2% of an antioxidant and 0.5% of a lubricant. The high heat-resistant high-strength PPE alloy material has the following advantages that: 1, by adding the component of PA46, the process is optimized, and the heat distortion temperature of the material is increased by 15-25 DEG C; 2, by introducing the compatibilizer, the compatibility is increased, the overall fluidity and mechanical properties are improved, and meanwhile a good appearance of the product is obtained; 3, excellent stabilityat high temperature and heat is achieved, excellent yellowing resistance and high-temperature degradation protection are achieved, thermal stability is improved, and high mechanical properties of thematerial can be maintained for a long period of time; 4, by adding the lubricant with high molecular weight and free of volatilization, the comprehensive performance of the PPE alloy material is muchbetter than that of spiro resin (CBT), dendronized polymer and other traditional resin with singular performance.

Owner:广东顺威赛特工程塑料开发有限公司

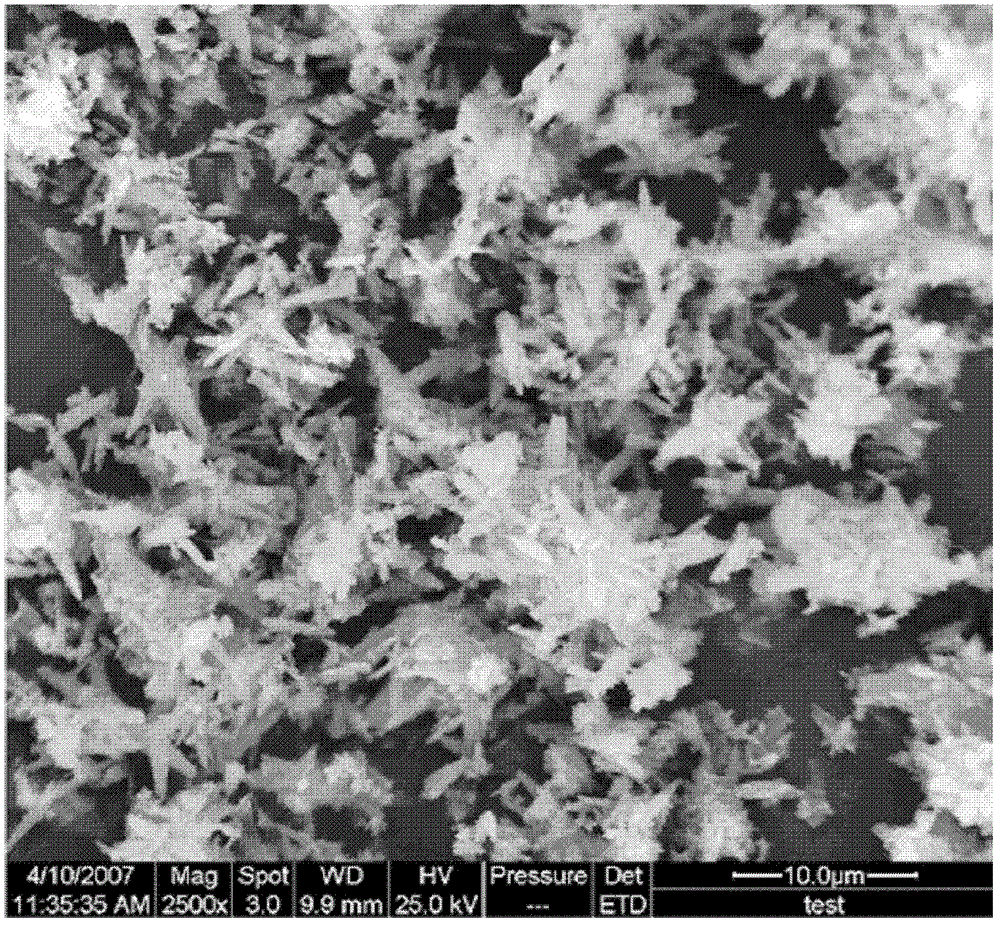

Modified barium sulfate for heavy anti-corrosion coating

InactiveCN111574853ABright colorIncrease the amount of fillerRubber derivative coatingsAnti-corrosive paintsModified carbonPhysical chemistry

The invention discloses modified barium sulfate for heavy anti-corrosion coating. The average particle size of the modified barium sulfate is smaller than 2.0 micrometers, the maximum particle size ofthe modified barium sulfate is smaller than 5 micrometers, and the content of the modified barium sulfate with the particle size being 2 micrometers is larger than 25%. The oil absorption amount is less than 10g / 100g, and the specific gravity is 4-4.5 g / cm < 3 >; and the pH value is 6-9. The modified barium carbonate is obtained by taking barium sulfate raw powder as a raw material and modifyingthe powder. The modified barium sulfate disclosed by the invention is used as a filler of a heavy anti-corrosion coating, so that the heavy anti-corrosion coating is fine, uniform and high in whiteness. And the strength, acid and alkali resistance, water resistance and the like of a paint film can be improved.

Owner:JIANGSU QUNXIN POWDER TECH CO LTD

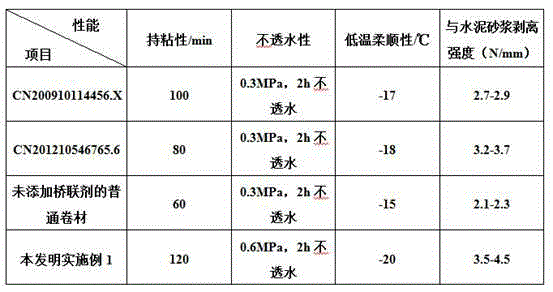

Aluminate asphalt cement waterproof bridging agent, waterproof product thereof and application thereof

InactiveCN105237801AQuality improvementMaintain stabilityNon-macromolecular adhesive additivesOther chemical processesCalcium silicateCalcium aluminates

The present invention discloses an aluminate asphalt cement waterproof bridging agent, a waterproof product thereof and an application thereof. One end of a structural formula of the aluminate asphalt cement waterproof bridging agent can be connected with arboxyl or esteryl to form relatively good chemical affinity; the other end of the aluminate asphalt cement waterproof bridging agent can be bonded with hydrated calcium silicate or calcium aluminate generated in a cement hydration process to form a chemical bond; and the chemical bond and the concrete generate chemical cross-linking reaction just like forming a bridge for tightly connecting the asphalt and the cement into an integer; chemical bond actions exist in relevant parts, and make reversible bonding effects after curing. The waterproof bridging agent can be made into a waterproof roll or prepared into waterproof paint, waterproof cream or a waterproof plugging agent. In a cement curing process, the waterproof bridging agent can permeate into pores of cement gel and the concrete, thereby achieving tight and firm fastening and reversible bonding effects as flesh and blood.

Owner:卢桂才

Flame retardant modified asphalt waterproof paint and production method thereof

InactiveCN108047951AHigh glossImprove the level ofFireproof paintsAntifouling/underwater paintsBituminous waterproofingSilanes

The invention relates to a flame retardant modified asphalt waterproof paint, which is prepared from the the following raw materials by weight: 50-65 parts of 90# petroleum asphalt; 60-70 parts of water; 22-26 parts of styrene butadiene latex; 4-6 parts of an emulsifier; 2-4 parts of polyvinyl alcohol; 2-5 parts of N-methyl-3-aminopropyl trimethoxy silane; 3-5 parts of a flame retardant; 5-7 partsof polyoxyethylene polyoxypropylene ether; 3-5 parts of triethyl citrate; 0.1-0.5 part of hydrogenated rosin glyceride; 1-3 parts of sodium polyacrylate; and 10-15 parts of modified nano calcium carbonate. The flame retardant modified asphalt waterproof paint prepared by the method provided by the invention has good film compactness and high stability, a waterproof layer formed by the waterproofpaint in a building has large bonding strength with a cement concrete base surface and good waterproof effect, moreover, after modification, the product has substantially improved flame retardance, water tolerance, aging resistance, acid and alkaline resistance and the like.

Owner:GUANGXI WUXUAN JINPAI WATERPROOF MATERIAL SCI & TECH CO LTD

Modified calcium carbonate filler and preparation method and application thereof in wet-strength paper

InactiveCN102660150BSimple processGuaranteed wet and dry strengthReinforcing agents additionInorganic compound additionPrecipitated calcium carbonatePolyamide

The invention discloses a preparation method and application of modified calcium carbonate for high-filling wet-strength paper. The preparation method comprises the following steps of: dispersing precipitated calcium carbonate in water, controlling the mass concentration between 20% and 50%, stirring, and then adding polyamide polyamine epichlorohydrin of the mass concentration of 0.2 to 2% obtained by being diluted with water, wherein the amount of the polyamide polyamine epichlorohydrin is 1 to 25% of the dry mass of the precipitated calcium carbonate; and stirring for 30 to 120 minutes at 150 to 500r / min, adding a low molecular weight cationic polyacrylamide enhancer with a molecular weight of 0.8 to 2 million, and stirring to obtain a modified calcium carbonate filler. The filler is used for producing the high-filling wet-strength paper, thereby obtaining better retention, dry strength, wet strength, and sizing degree. According to the preparation method and the application, the process is simple, the application is convenient, the problems that the high-filling wet-strength paper has poorer dry and wet strength, low filler retention and sizing impediment can be better solved, and the cost of production enterprises is reduced.

Owner:SOUTH CHINA UNIV OF TECH

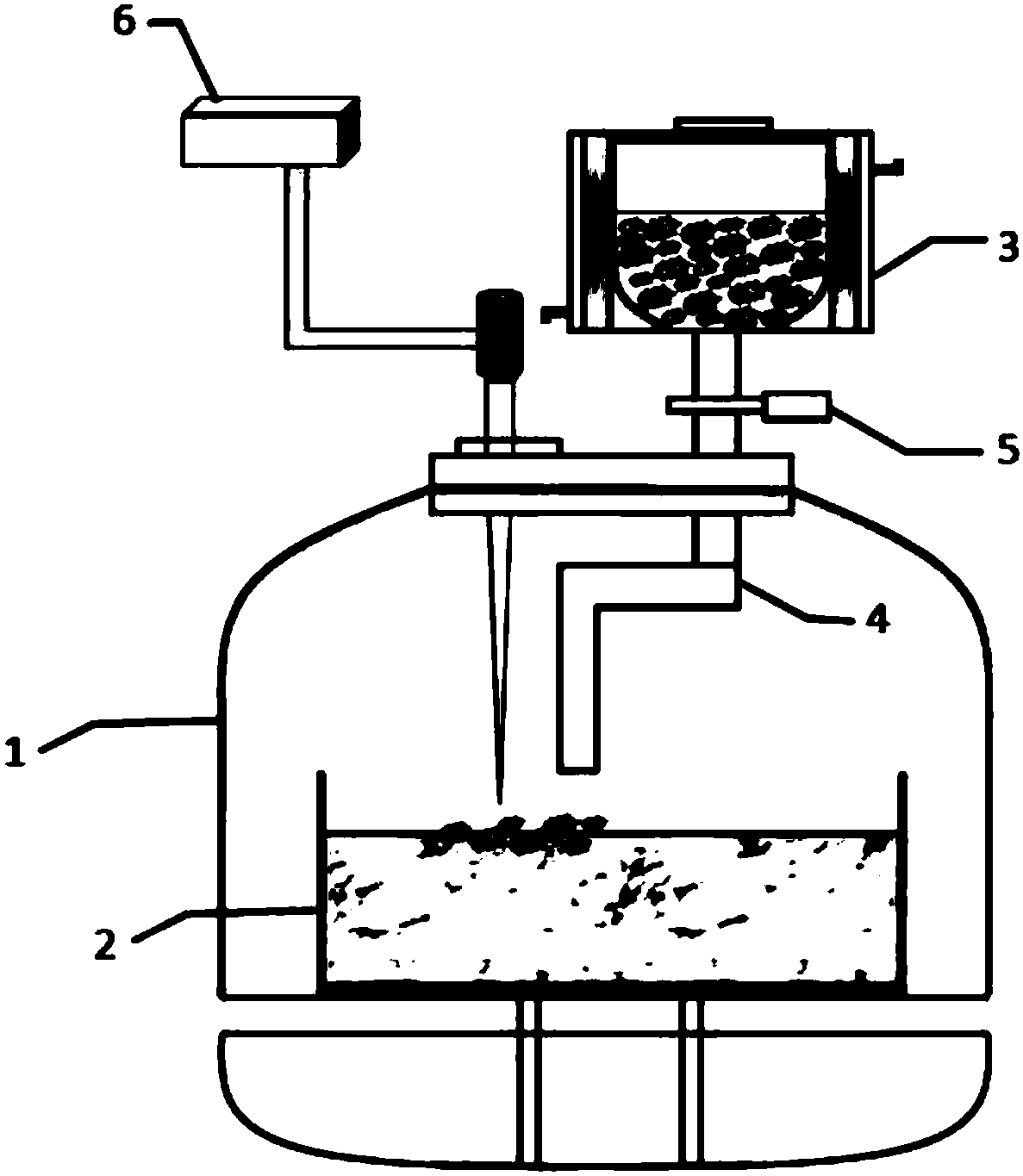

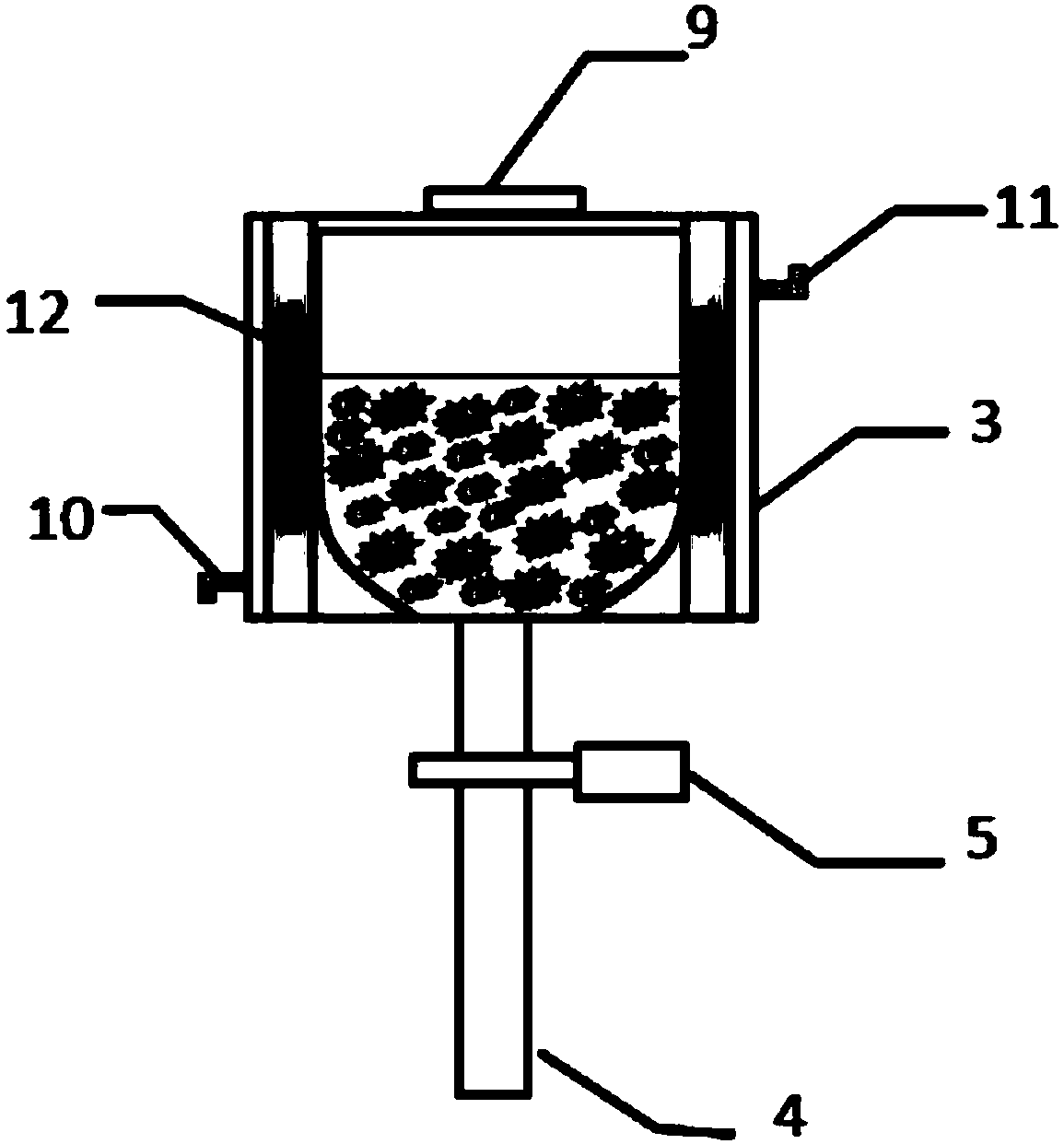

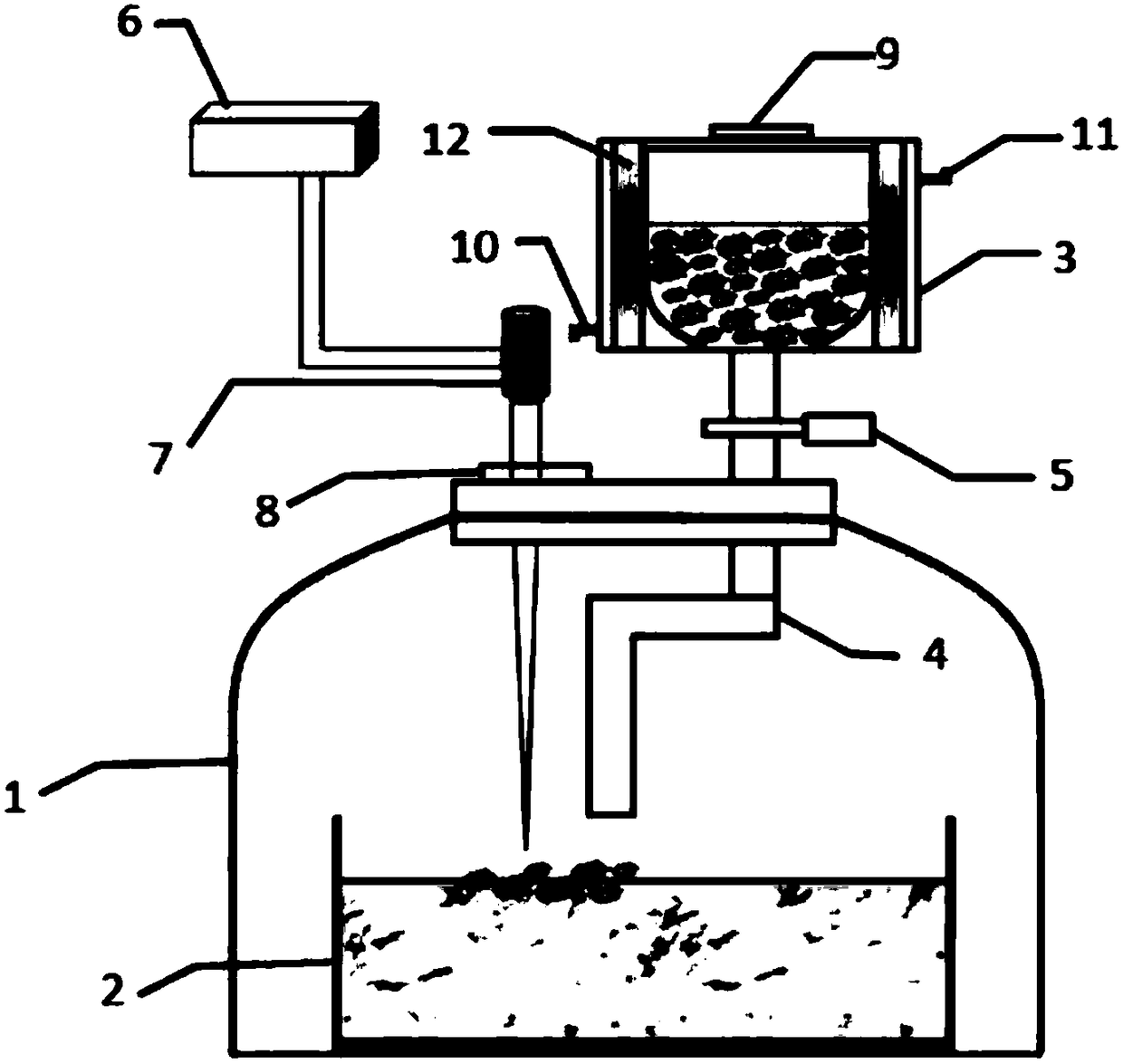

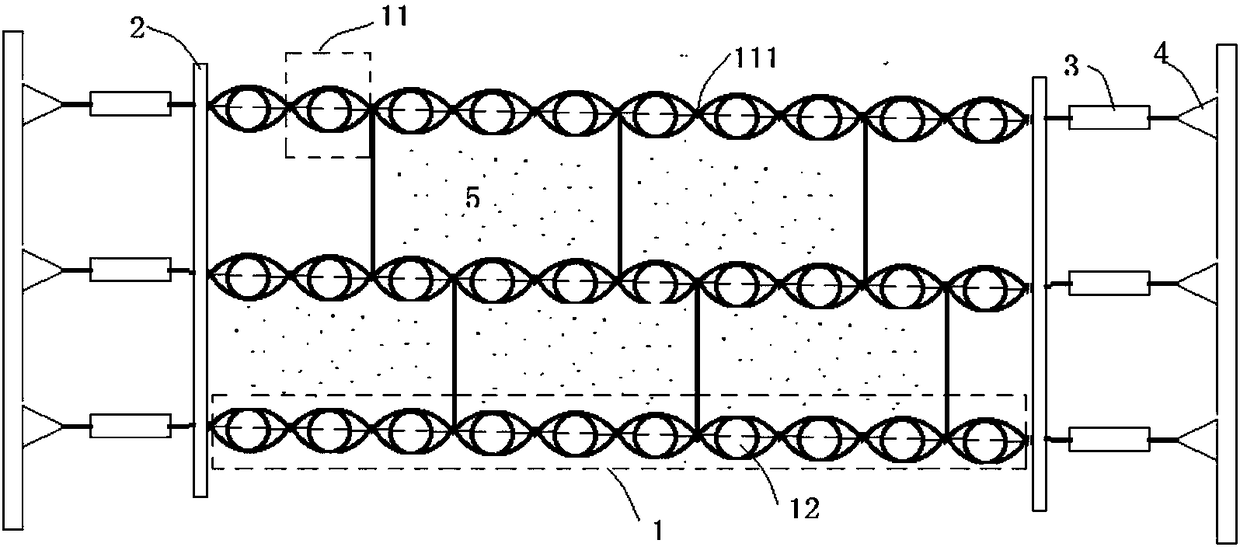

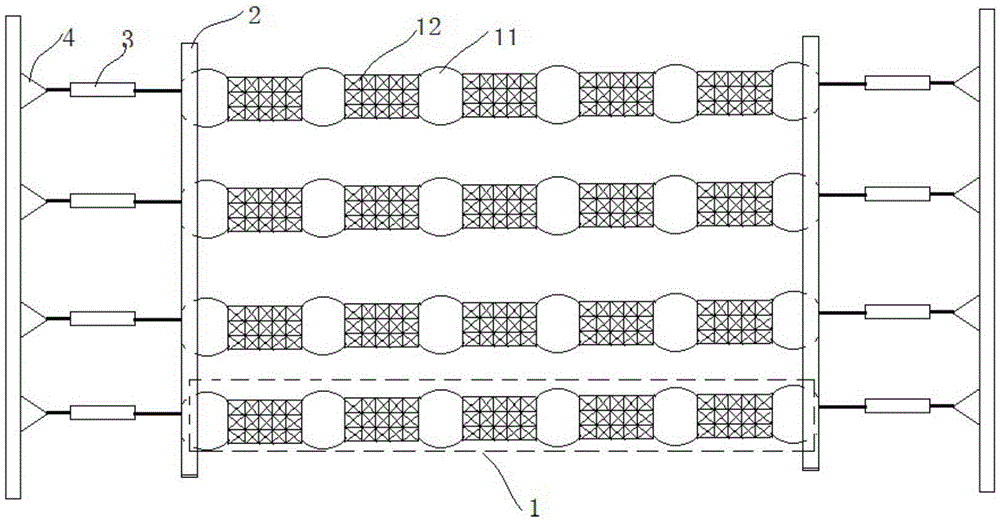

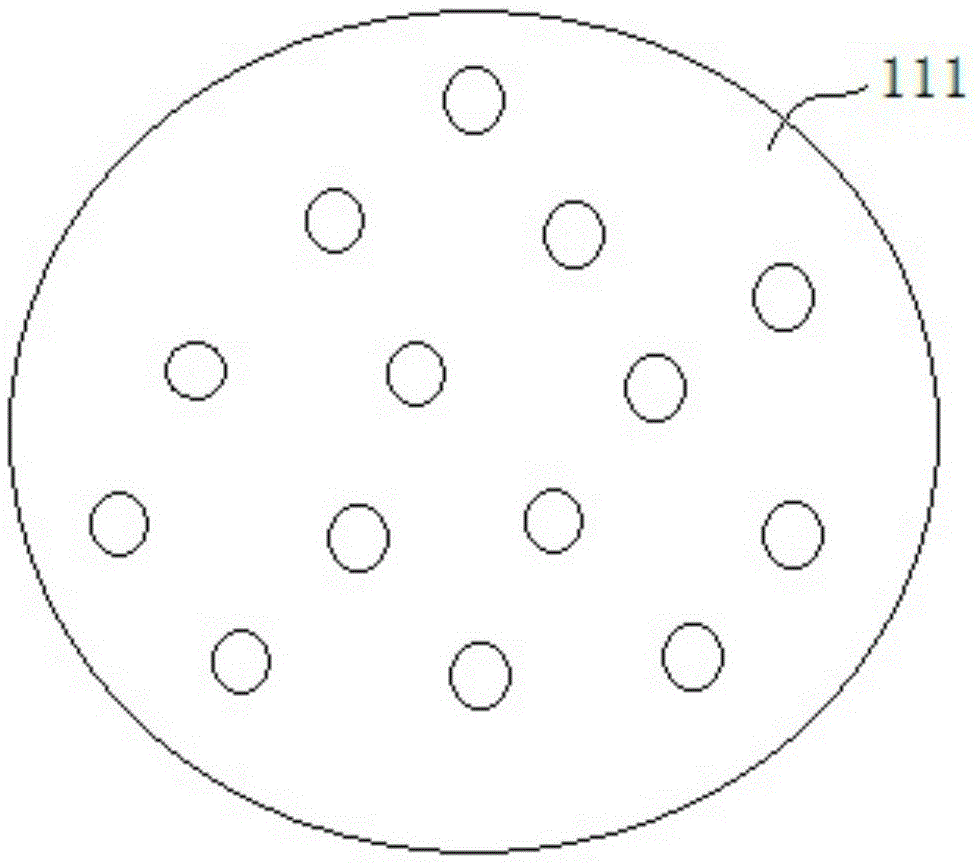

N-type polycrystalline silicon ingot casting device and ingot casting method

InactiveCN108221047AIncrease the amount of fillerImprove single productionPolycrystalline material growthSingle crystal growth detailsHigh power lasersIngot casting

The invention provides an N-type polycrystalline silicon ingot casting device which comprises an ingot casting furnace, wherein the ingot casting furnace is internally provided a crucible; a storage cabin for storing a silicon material is arranged at the top end of the ingot casting furnace; the storage cabin and the crucible are connected with a conveying tube; discharge of the silicon material inside the storage cabin is controlled by a discharge valve. The device is characterized in that a high-power laser unit is arranged at the top end of the ingot casting furnace; the high-power laser unit is provided with a laser source; the laser source is adopted for radiation scanning on the silicon material fed into the crucible from the storage cabin; a vacuum air sucking valve and an inert gasinlet valve are respectively arranged outside the storage cabin; the storage cabin is further provided with a heating unit for preheating the silicon material inside the storage cabin. The inventionfurther discloses an ingot casting method with the device provided by the invention.

Owner:SUPER ENERGY MATERIALS

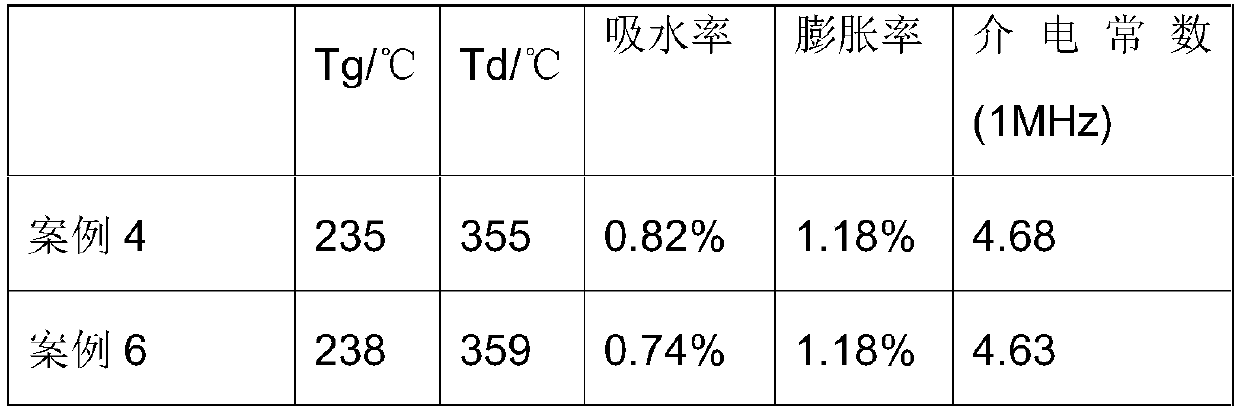

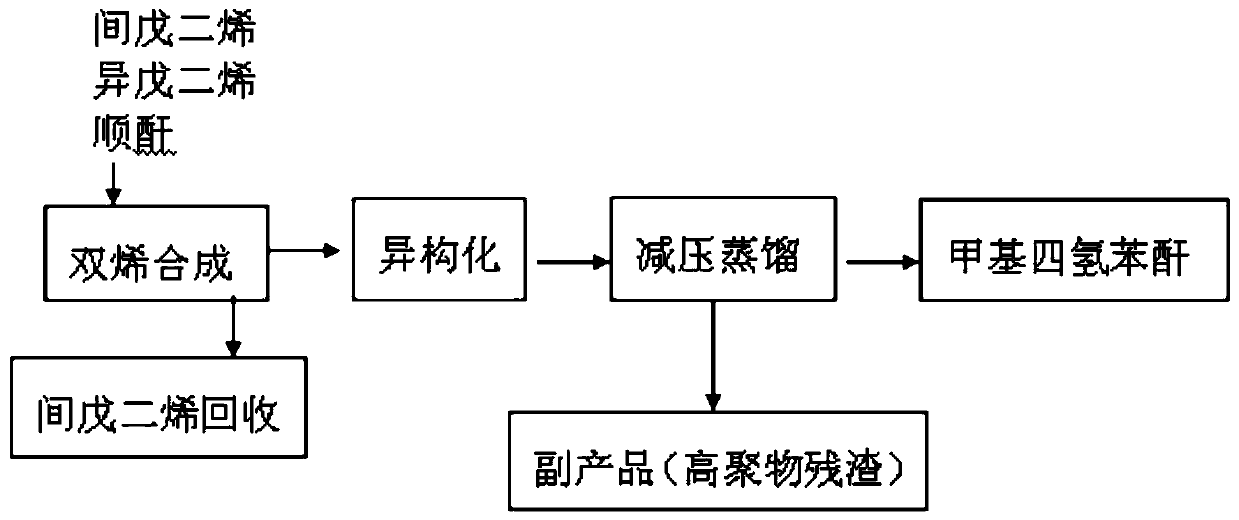

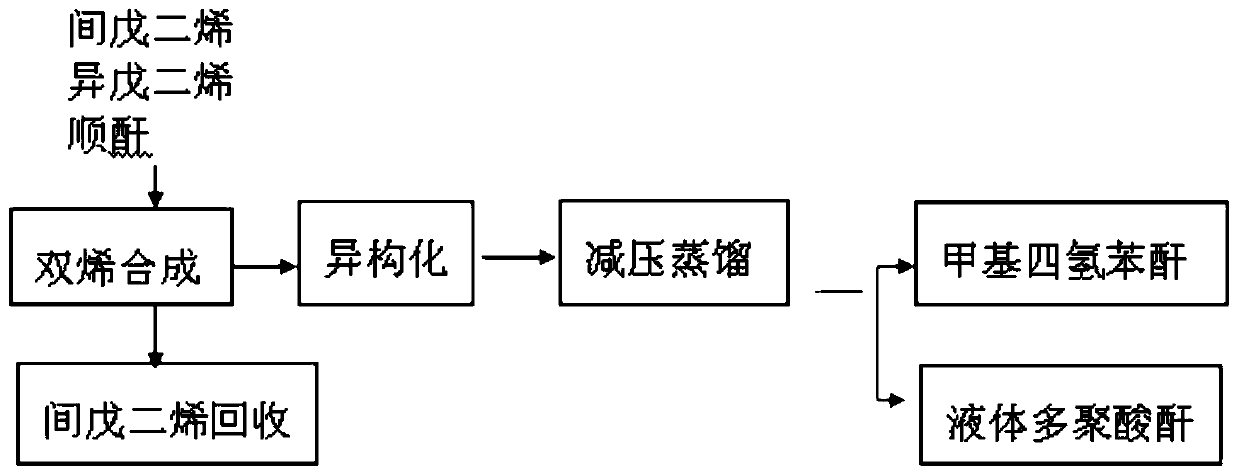

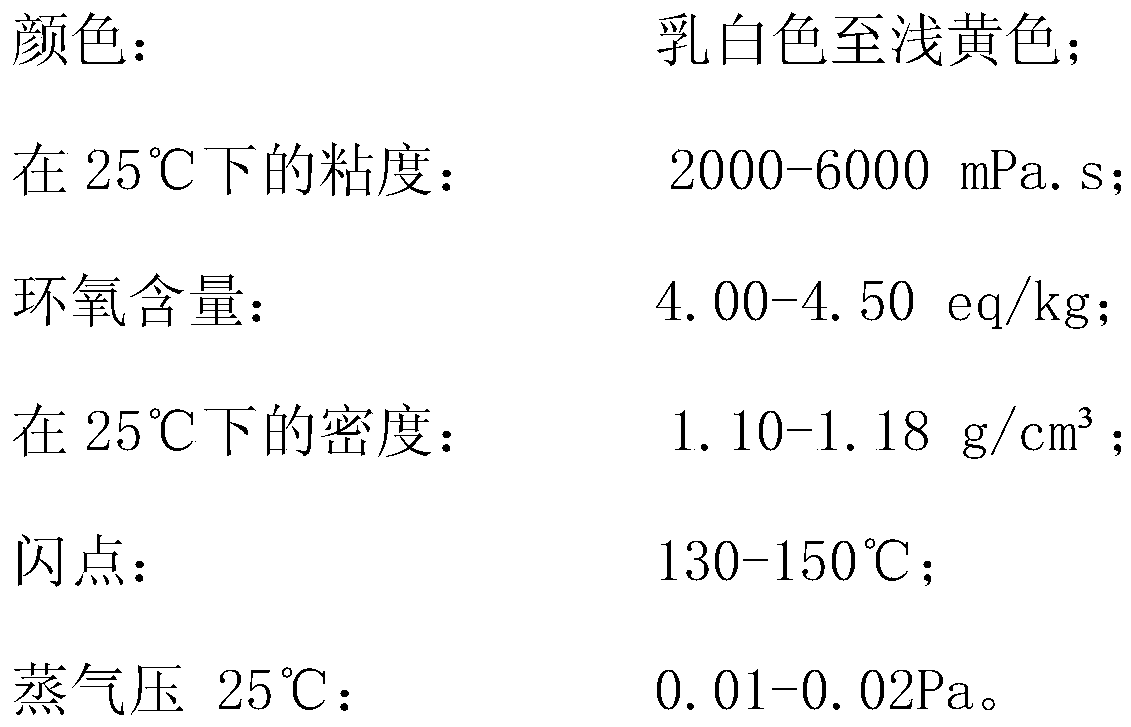

A kind of liquid polyacid anhydride, its preparation method and application

ActiveCN107298754BReduce environmental problemsIncrease profit marginsOrganic chemistryPolymer scienceOrganic chemistry

Owner:广州仑利奇合成树脂有限公司

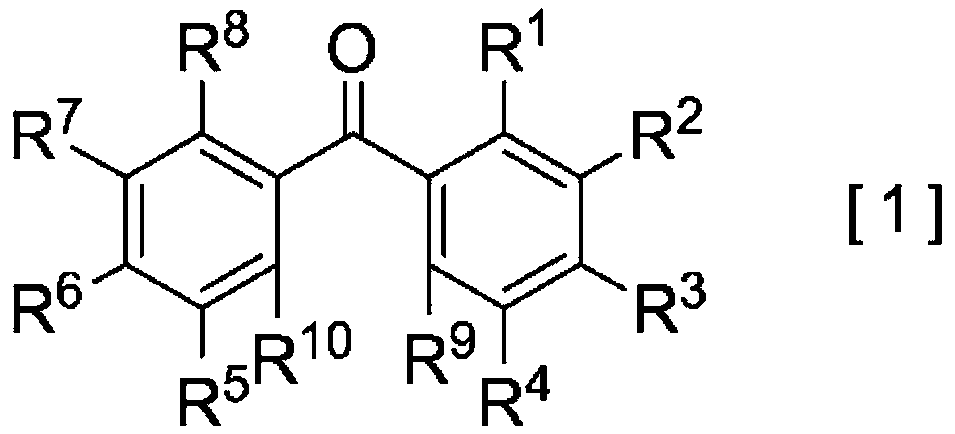

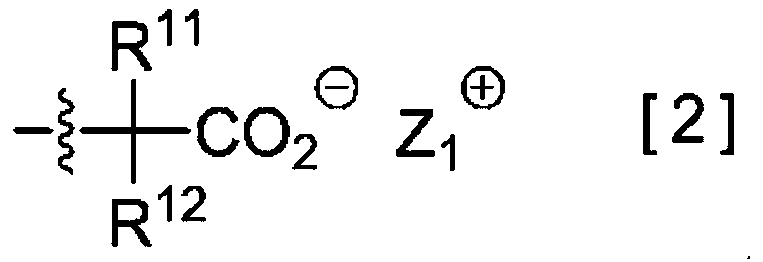

Light- or heat-curing method and curable resin composition

ActiveCN110678500AIncrease the amount of fillerGood storage stabilityPrinted circuit aspectsHeat-exchange elementsPolymer scienceLight irradiation

The purpose of the present invention is to provide a light- or heat-curing method whereby a cured material (crosslinked material / resin) can be obtained even when a large amount of a filler is included, and to provide a curable resin composition used in the curing method. The present invention relates to a light- or heat-curing method and a curable resin composition used in the curing method, the curing method including: a step 1 for obtaining a condensate having Si-O-Al and / or Si-O-Si constituent units, obtained from a silane derived from a silane coupling agent having a mercapto group and aluminum derived from (E) an aluminum alkoxide, from (A) a compound comprising a salt of a carboxylic acid and an amine and having a carbonyl group for generating a radical and a carboxylate group for decarboxylating and generating a base by light irradiation or heating, (B) an aluminum alkoxide, (C) a silane coupling agent having a mercapto group, and (D) water; and a step 2 for reacting the condensate (E), (H) a compound having two or more polymerizable unsaturated groups, and (I) a filler under a condition of light irradiation or heating.

Owner:FUJIFILM WAKO PURE CHEM CORP

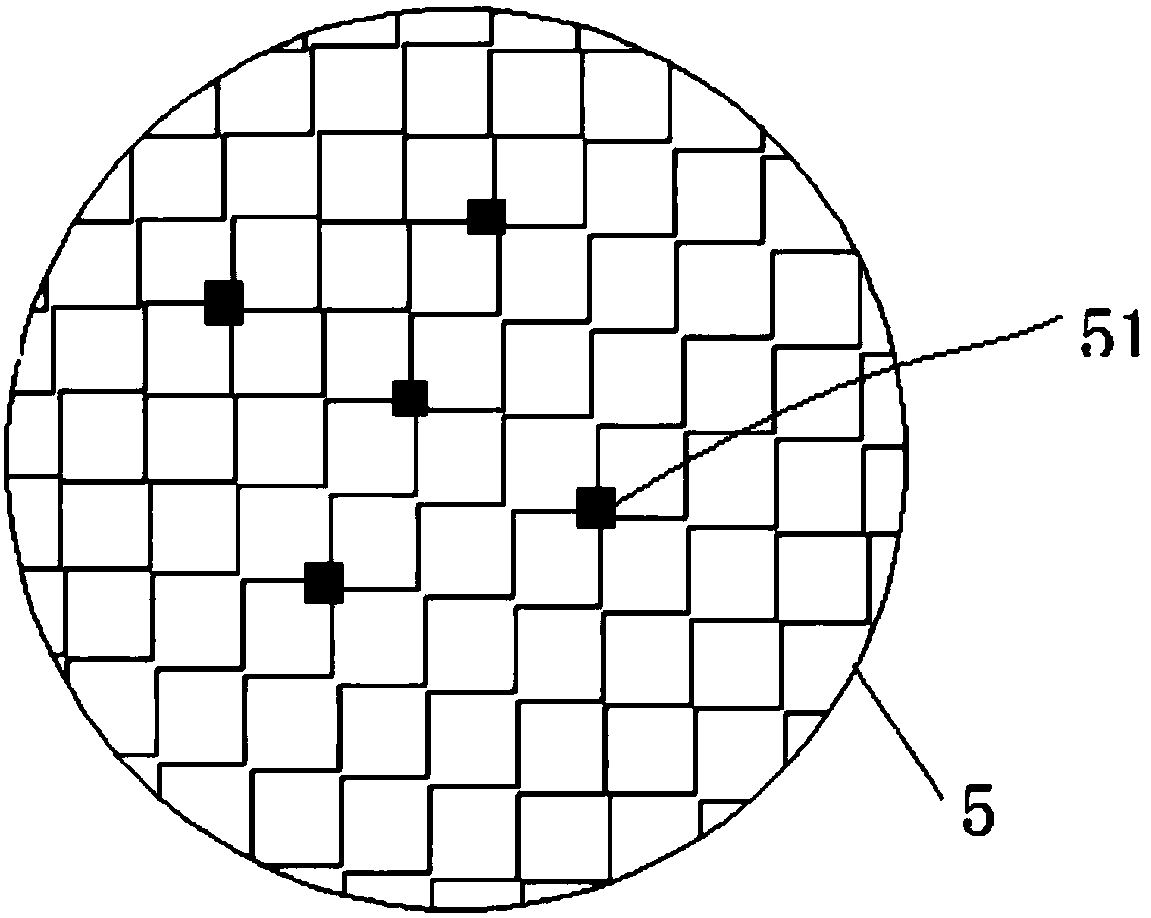

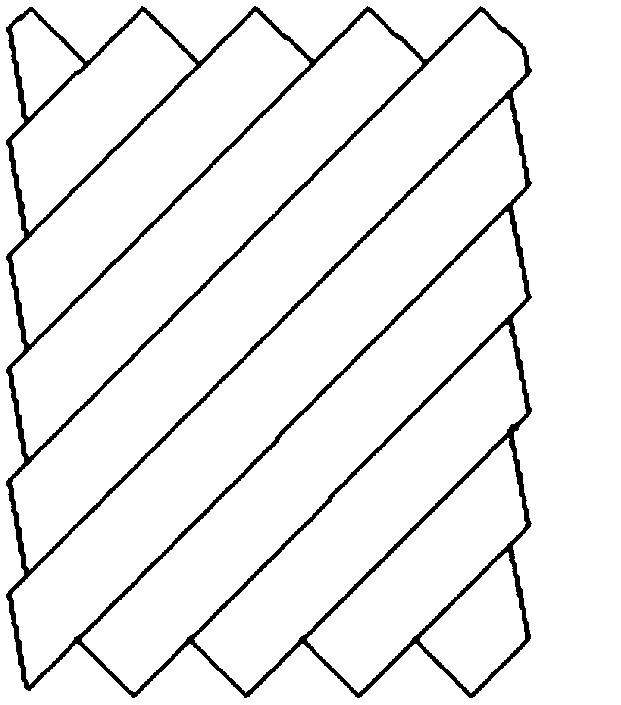

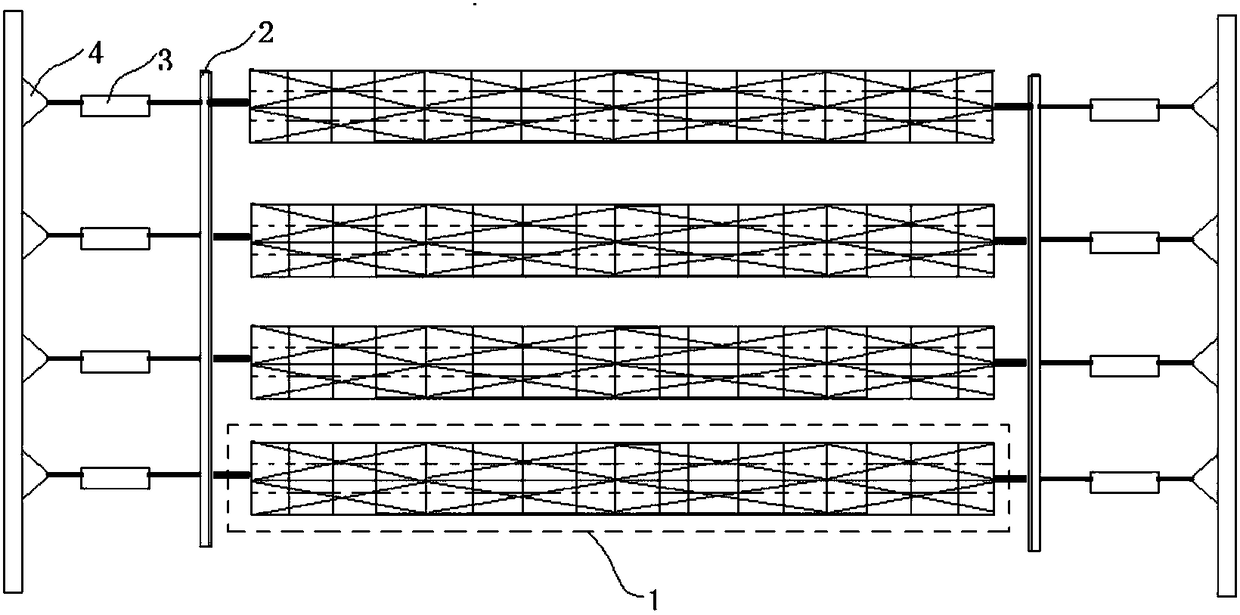

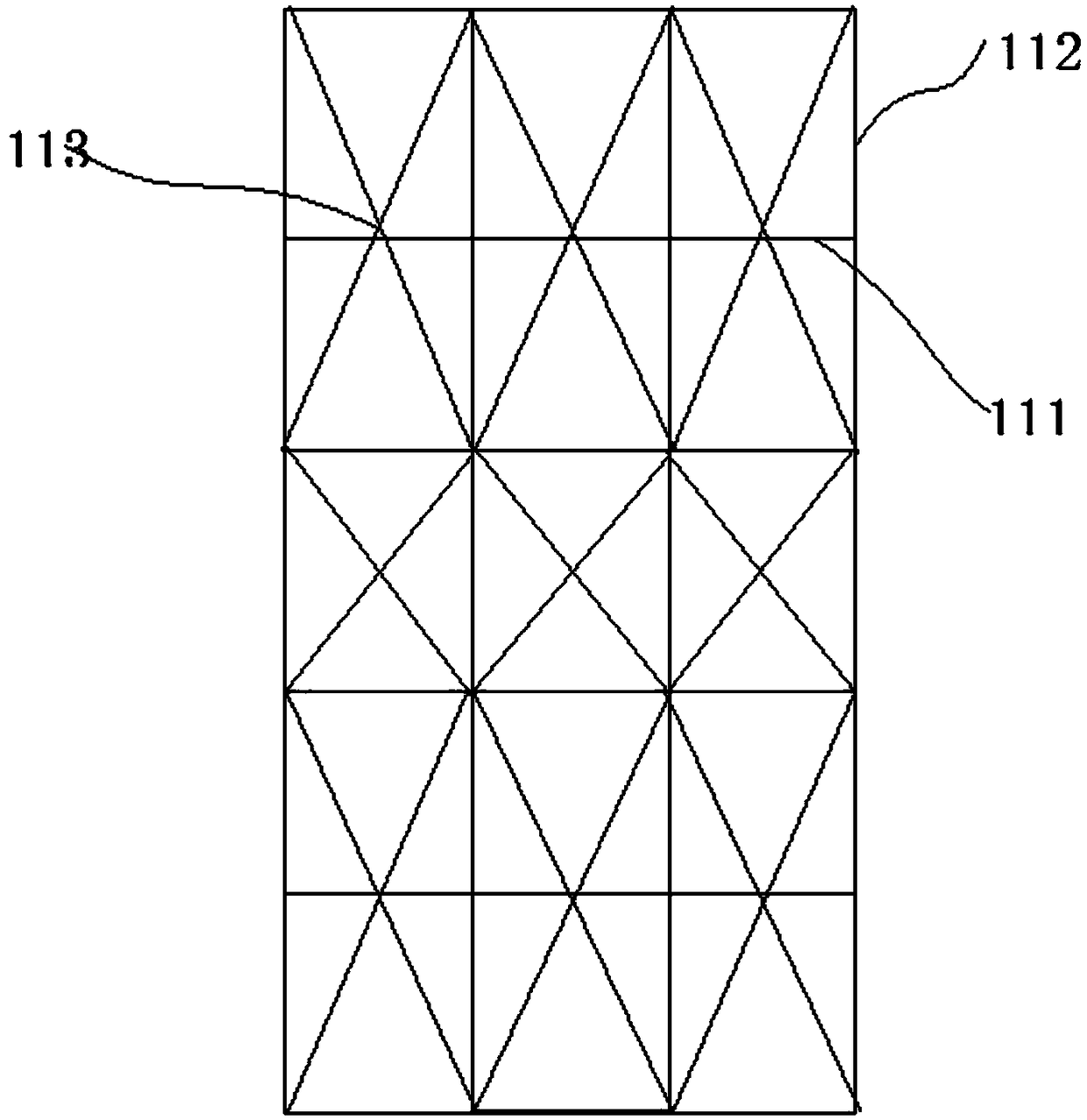

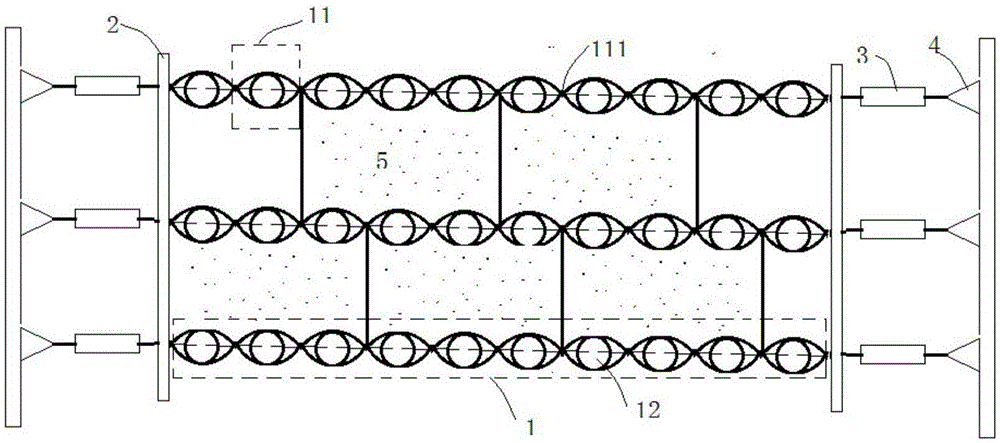

Combined bundle packing device for water treatment

ActiveCN105565484BEasy to replaceEasy to handleWater treatment compoundsSustainable biological treatmentFiberWater treatment

The invention discloses a combined binding packing device for water treatment. The combined binding packing device comprises fiber strips which are arranged in parallel and used for fixing packing, fixed frames located at the two ends of the fiber strips, tension mechanisms connected with the fixed frames and fixed components which are fixedly connected with the tension mechanisms and pre-buried in pond walls. Each fiber strip is of a braided structure and comprises a plurality of crossed units. A spherical fiber frame is arranged in the middle section of each crossed unit and fixedly connected with the corresponding fiber strip through a steel wire rope. Reinforcing pillars are arranged between the crossed units.

Owner:SUZHOU ZHILVE INTELLECTUAL PROPERTY OPERATION CO LTD

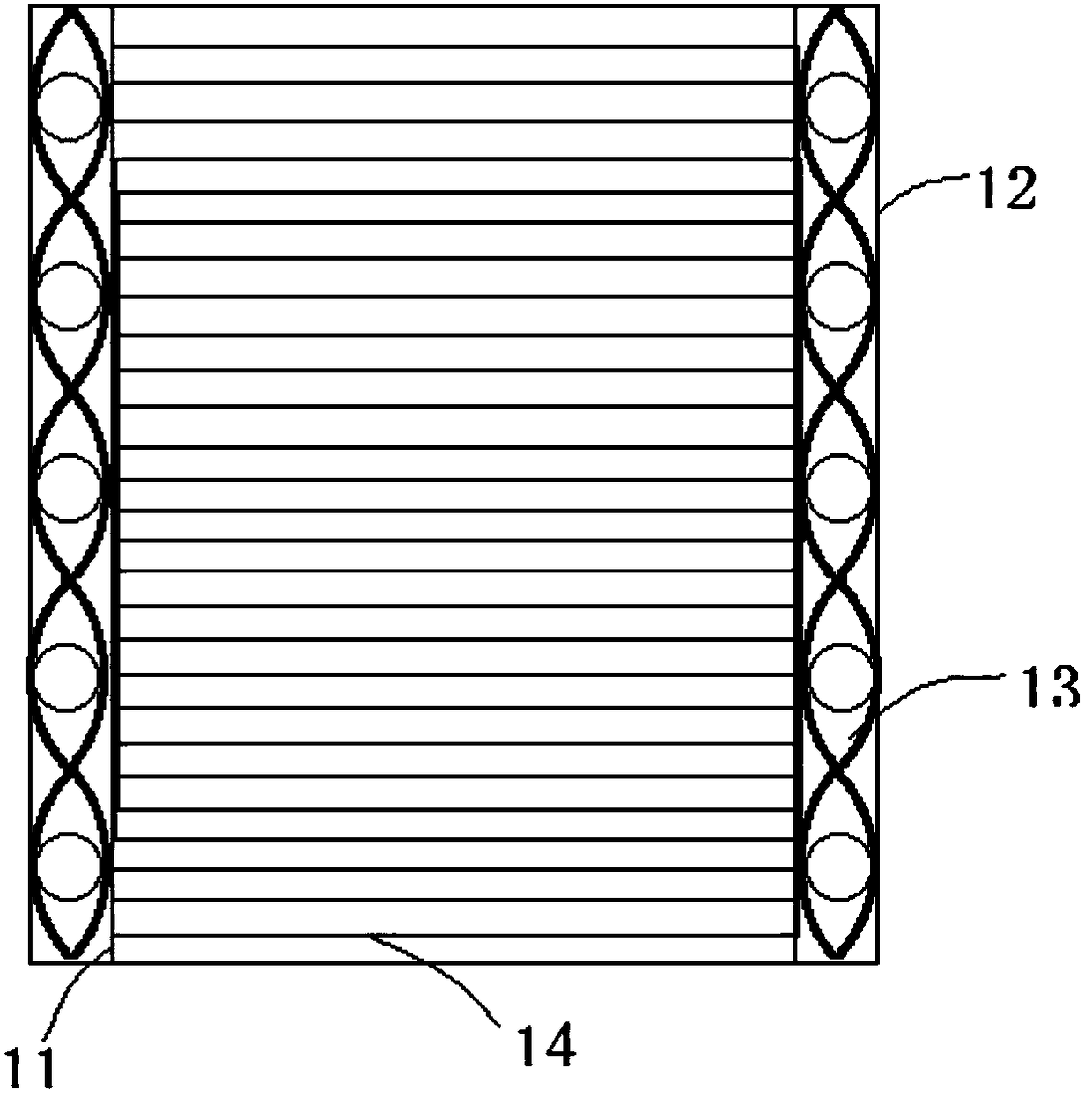

Packing mechanism for sewage treatment

InactiveCN105565476AIncrease the amount of fillerGood processing effectTreatment using aerobic processesSustainable biological treatmentFiberEngineering

The invention discloses a packing mechanism for sewage treatment. The packing mechanism comprises packing units which are arranged in parallel and used for fixing packing, fixed frames located at the two ends of each packing unit, tension mechanisms connected with the fixed frames and fixed components which are fixedly connected with the tension mechanisms and pre-buried in pond walls. Each fixed frame is buckled to the two ends of the corresponding packing unit and is of a symmetrical structure capable of being opened and closed. Each packing unit comprises a first packing unit part and a second packing unit part, wherein the first packing unit part is a packing ball composed of fibers, the second packing unit part is a columnar packing column composed of net-shaped fibers, the top end of the packing column is connected with the bottom end of the packing ball, and both the first packing unit part and the second packing unit part are of hollow structures.

Owner:TAICANG DONGNENG ENVIRONMENTAL PROTECTION EQUIP

Floating body material and manufacturing technique thereof

Owner:SECOND INST OF OCEANOGRAPHY MNR

Bundled packing device for sewage treatment

ActiveCN105565474BEasy to replaceIncrease the amount of fillerSustainable biological treatmentBiological water/sewage treatmentFiberEngineering

Owner:SUZHOU ZHILVE INTELLECTUAL PROPERTY OPERATION CO LTD

PVC profiles added with vinyl chloride-acrylate copolymer resin and preparation method

The invention relates to a PVC (Poly Vinyl Chloride) profile added with a chloroethylene-acrylate copolymer resin and a preparation method thereof, and belongs to the technical application of the chloroethylene-acrylate copolymer resin in PVC resin processing. According to the invention, the common PVC resin is modified by using the special properties of the chloroethylene-acrylate copolymer resin such as internal plasticization property, excellent processability and tenacity; the processing formulation by weight is as follows: 100 parts of PVC resin, 5-10 parts of chloroethylene-acrylate copolymer resin, 1-5 parts of heat stabilizer, 5-20 parts of filler and 3-6 parts of other additives. In the processing process of the PVC profile, the chloroethylene-acrylate copolymer resin is used for substituting for processing modifiers ACR (Acrylic Rubber) and CPE (Chlorinated Polyethylene), and a specific mixing process is adopted so as to achieve the synergistic effect of the chloroethylene-acrylate copolymer resin with inorganic particles, and consequently, the processing temperature of the PVC profile is reduced and the mechanical properties of the PVC profile are improved.

Owner:XINJIANG TIANYE GRP

Combined binding packing device for water treatment

ActiveCN105565484AImprove the effect of sewage treatmentIncrease the amount of fillerWater treatment compoundsSustainable biological treatmentFixed frameWire rope

The invention discloses a combined binding packing device for water treatment. The combined binding packing device comprises fiber strips which are arranged in parallel and used for fixing packing, fixed frames located at the two ends of the fiber strips, tension mechanisms connected with the fixed frames and fixed components which are fixedly connected with the tension mechanisms and pre-buried in pond walls. Each fiber strip is of a braided structure and comprises a plurality of crossed units. A spherical fiber frame is arranged in the middle section of each crossed unit and fixedly connected with the corresponding fiber strip through a steel wire rope. Reinforcing pillars are arranged between the crossed units.

Owner:SUZHOU ZHILVE INTELLECTUAL PROPERTY OPERATION CO LTD

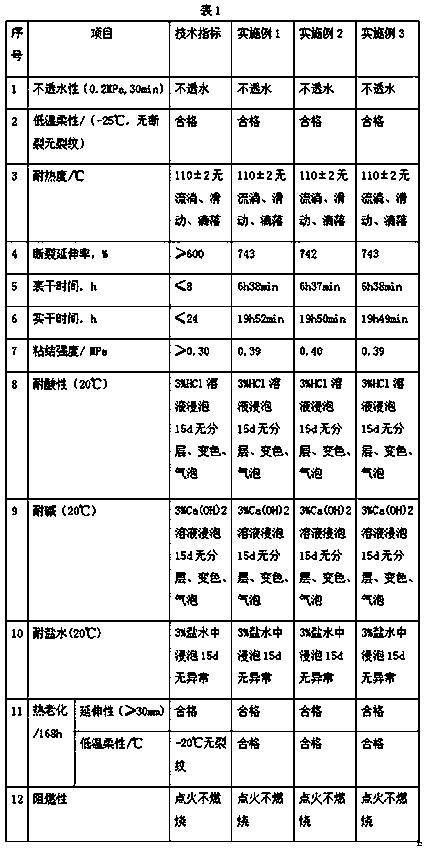

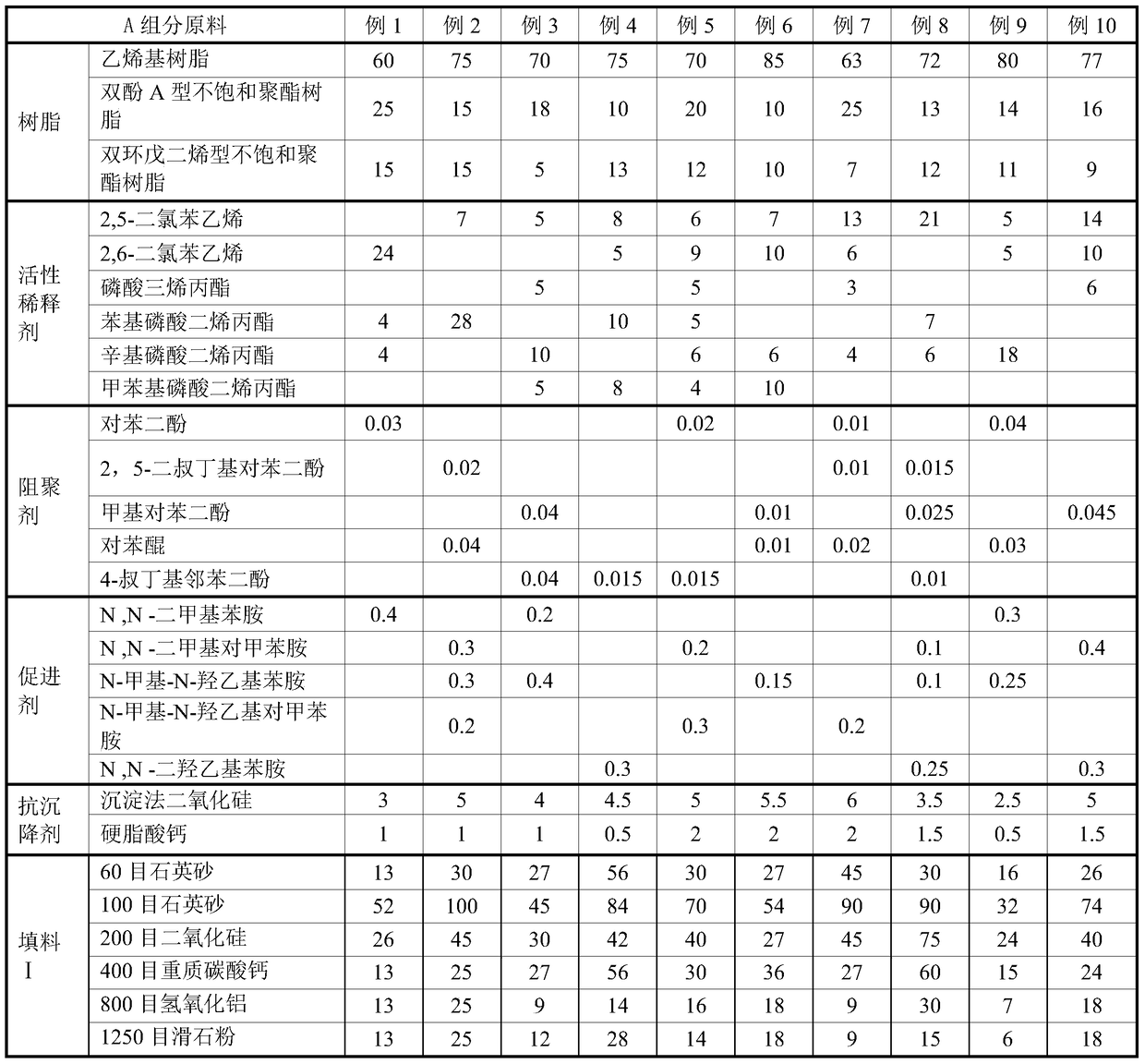

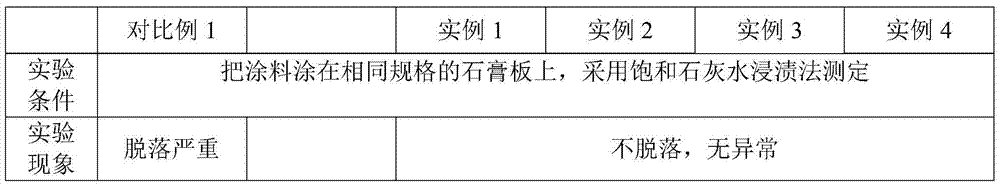

A kind of flame retardant vinyl planting glue

ActiveCN105441004BImprove mechanical propertiesGood chemical propertiesNon-macromolecular adhesive additivesModified epoxy resin adhesivesAdhesiveVinyl ester

The invention discloses a flame-retardant vinyl type anchor adhesive. The flame-retardant vinyl type anchor adhesive comprises a component A and a component B, wherein the component A comprises, in parts by weight, 60-85 parts of vinyl ester resin, 10-25 parts of bisphenol A type unsaturated polyester resin, 5-15 parts of dicyclopentadiene type unsaturated polyester resin, 25-35 parts of a reactive diluent and 100-300 parts of filler I; the reactive diluent is a mixture of a chlorine-containing reactive diluent and a phosphorus-containing reactive diluent; the component B comprises, in parts by weight, 5-15 parts of a curing agent, 35-50 parts of a blender and 35-60 parts of filler II; after the component A and the component B are mixed, the curing agent accounts for 0.6%-1.6% of the total weight of the mixture. The flame-retardant vinyl type anchor adhesive has flame retardance, high strength as well as excellent mechanical properties, chemical properties and anti-settling performance, and the cost is reduced.

Owner:江苏大力士云石护理材料有限公司

A kind of modified calcium sulfate anticorrosion pigment and its preparation method and application

ActiveCN104945955BHigh temperature resistantWith acid and alkali corrosion resistanceAnti-corrosive paintsPigment treatment with organosilicon compoundsSulfateFumed silica

Owner:HUNAN RUISHI SCI & TECH DEV

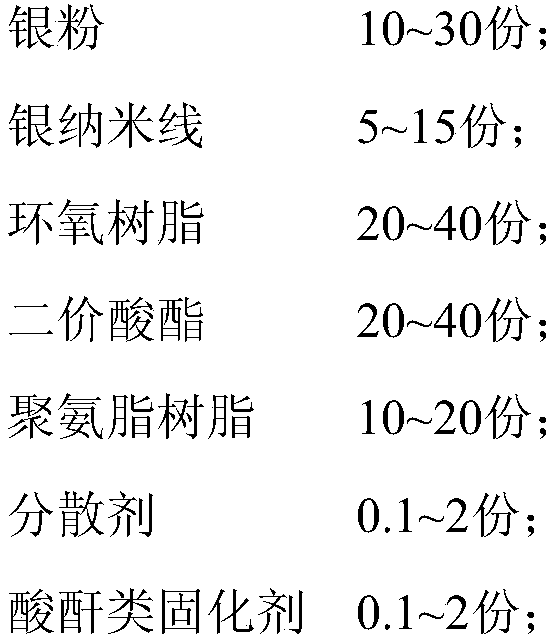

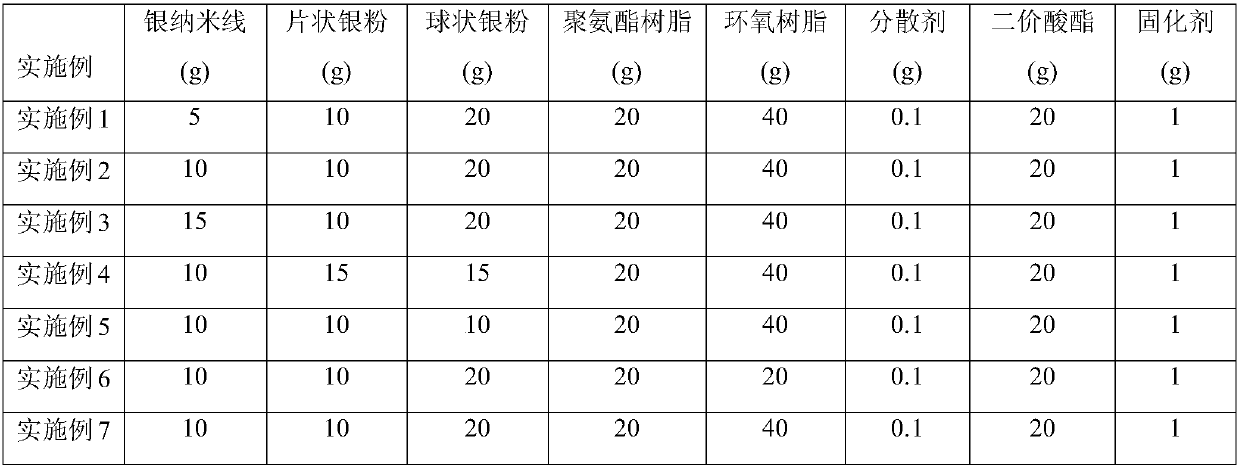

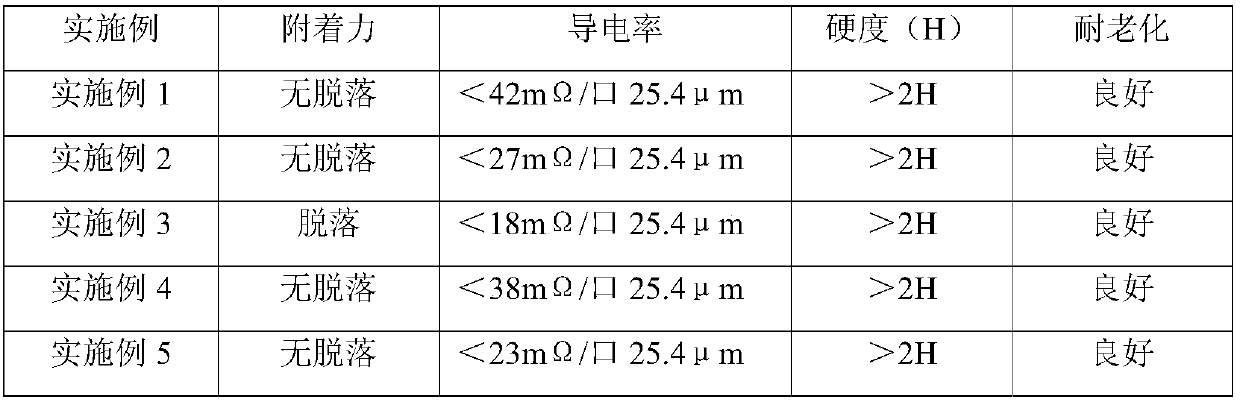

A kind of oily conductive silver paste and preparation method thereof

ActiveCN106098147BReduce usageImprove conductivityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteEpoxy

The invention discloses an oily conductive silver paste and a preparation method therefor. The silver paste comprises the following raw materials by weight: 10-30 parts of silver powder, 5-15 parts of silver nanowires, 20-40 parts of epoxy resin, 20-40 parts of dibasic esters, 10-20 parts of polyurethane, 0.1-2 parts of dispersing agent and 0.1-2 parts of anhydride-type curing agent, wherein the silver powder is formed by the mixing of flake-shaped silver powder and spherical silver powder according to a ratio: 1: 1-5. The conductive silver paste is formed by the complex formulation of silver powder and silver nanowires, reduces the consumption of conductive filling materials, improves the conductive performance of the material, reduces the consumption of silver, and reduced the production cost.

Owner:合肥微晶材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com