Modified calcium sulphate anticorrosive pigment as well as preparation method and application thereof

A technology of anti-corrosion pigment and calcium sulfate, applied in anti-corrosion coatings, inorganic pigment treatment, chemical instruments and methods, etc., can solve problems such as poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

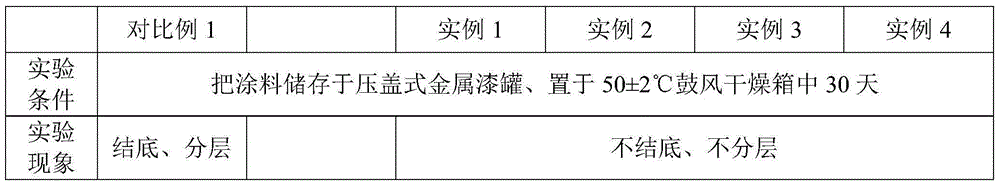

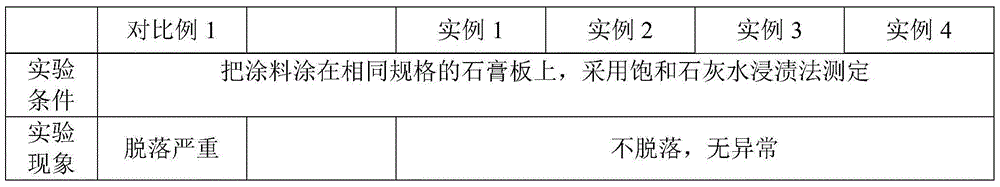

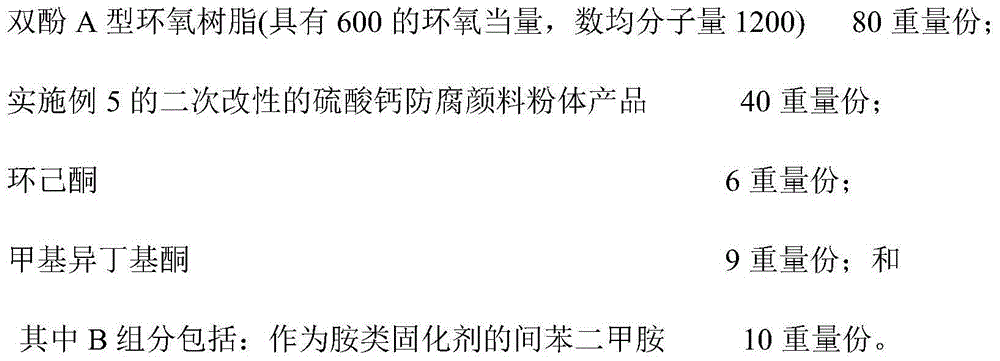

Examples

Embodiment 1

[0054] Phosphogypsum extracted from phosphogypsum has a purity of 95%, a whiteness of 95% ISO, a particle size of 150 μm, and a density of 2.5 g / cm 3 , 50g of calcium sulfate with a refractive index of 1.6, slowly added to the aqueous dispersion containing 2% silane coupling agent KH5501.0g under stirring, and the solid content of the suspension was adjusted to 60%, adjusted with 0.5mol / L HCl solution The pH of the suspension is between 5 and 7, stirred at a speed of 4000r / min for 20 minutes and then transferred to a small ball mill; the grinding medium is ceramic beads with a diameter of 1cm, 2cm, and 3cm at a ratio of 1:1:1. 3:1, adjust the voltage of the ball mill to 150V, and grind the mixture for 180 minutes; transfer the ground suspension and ceramic beads to a blast drying oven for drying at 105°C for 5 hours; finally put the dried mixture into the ball mill again Grind into powder. The whiteness of the powder is 95% ISO.

Embodiment 2

[0056] The purity extracted from desulfurized gypsum is 99%, the whiteness is 95% ISO, the particle size is 200μm, and the density is 2.6g / cm 3 , 50g of calcium sulfate with a refractive index of 1.7 was slowly added under stirring to the aqueous dispersion containing 1% silane coupling agent KH5700.5g and 2% titanate coupling agent 1020.5g, and the solid content of the suspension was adjusted to 65%, use 0.5mol / L HCl solution to adjust the pH of the suspension between 5 and 7, stir at a speed of 3000r / min for 15min and then transfer to a ball mill; the grinding medium is 1:1:1 and the diameter is 1cm , 2cm, 3cm ceramic beads, the ratio of ball to material is 5:1, the voltage of the ball mill is adjusted to 200V, and the mixture is ground for 150min; the suspension and ceramic beads after grinding are transferred to a blast drying oven for drying, and dried at 105°C for 4 hours ; Finally, put the dried mixture into the ball mill again and grind it into powder. Whiteness is 95...

Embodiment 3

[0058] The purity extracted from desulfurized gypsum is 99%, the whiteness is 96% ISO, the particle size is 200μm, and the density is 2.6g / cm 3 , 50g of calcium sulfate with a refractive index of 1.7, slowly added to the water dispersion containing 2% silane coupling agent DL6021.5g under stirring, adjusted the solid content of the suspension to 50%, adjusted with 0.5mol / L HCl solution The pH of the suspension is between 5 and 7, stirred at a speed of 4000r / min for 20 minutes and then transferred to a ball mill; the grinding medium is ceramic beads with a diameter of 1cm, 2cm, and 3cm at a ratio of 1:1:1, and the ball-to-material ratio is 3 : 1. Adjust the voltage of the ball mill to 150V, and grind the mixture for 180 minutes; transfer the ground suspension and ceramic beads to a blast drying oven for drying at 105°C for 6 hours; finally put the dried mixture into the ball mill again Grind into powder. The whiteness of the powder is 96% ISO.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com