Stress relaxation type polyether sealant based on terminal silane modification and preparation method of polyether sealant

A technology of end-group silane and sealant, applied in the field of sealant, can solve the problems of inability to solve the problem of internal stress of the substrate, slowly expanding joints, damage to the bonding surface, etc., to widen the scope of application, reduce internal stress, promote Effects of Stress Relief Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

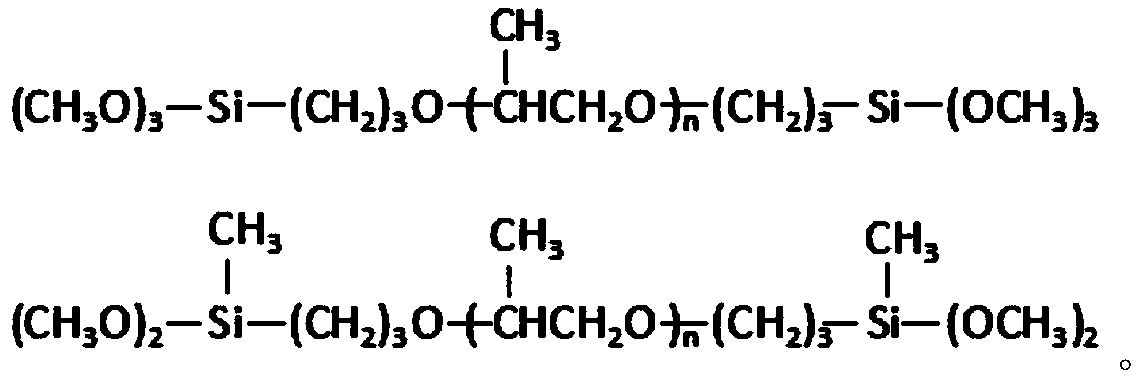

Method used

Image

Examples

Embodiment 1

[0039] A kind of stress relaxation type polyether building sealant based on terminal group silane modification, its preparation method comprises the following steps:

[0040] 100g of kaolin, 50g of heavy calcium carbonate and 450g of fumed silica were dried in a vacuum oven at 110-120°C and under vacuum for 6 hours, and the moisture in the filler was removed for subsequent use; 300g of terminal silane-capped polyether ( 180g KANEKAS203H+120g KANEKA MAX923) and the filler after dehydration were added to the stirring tank together, and 300g of diisononyl phthalate and 30g of titanium dioxide were added, stirred at a high speed at 120°C and vacuumed for 1.5h, and dispersed evenly to obtain Premix; lower the temperature of the stirring tank to normal temperature, gradually add 10g of light stabilizer (Tinuvin326), 10g of antioxidant (irganox1076) and 10g of water remover (A171), and continue to disperse at a high speed for 30min; keep at normal temperature, add 10g of N -(β-aminoe...

Embodiment 2

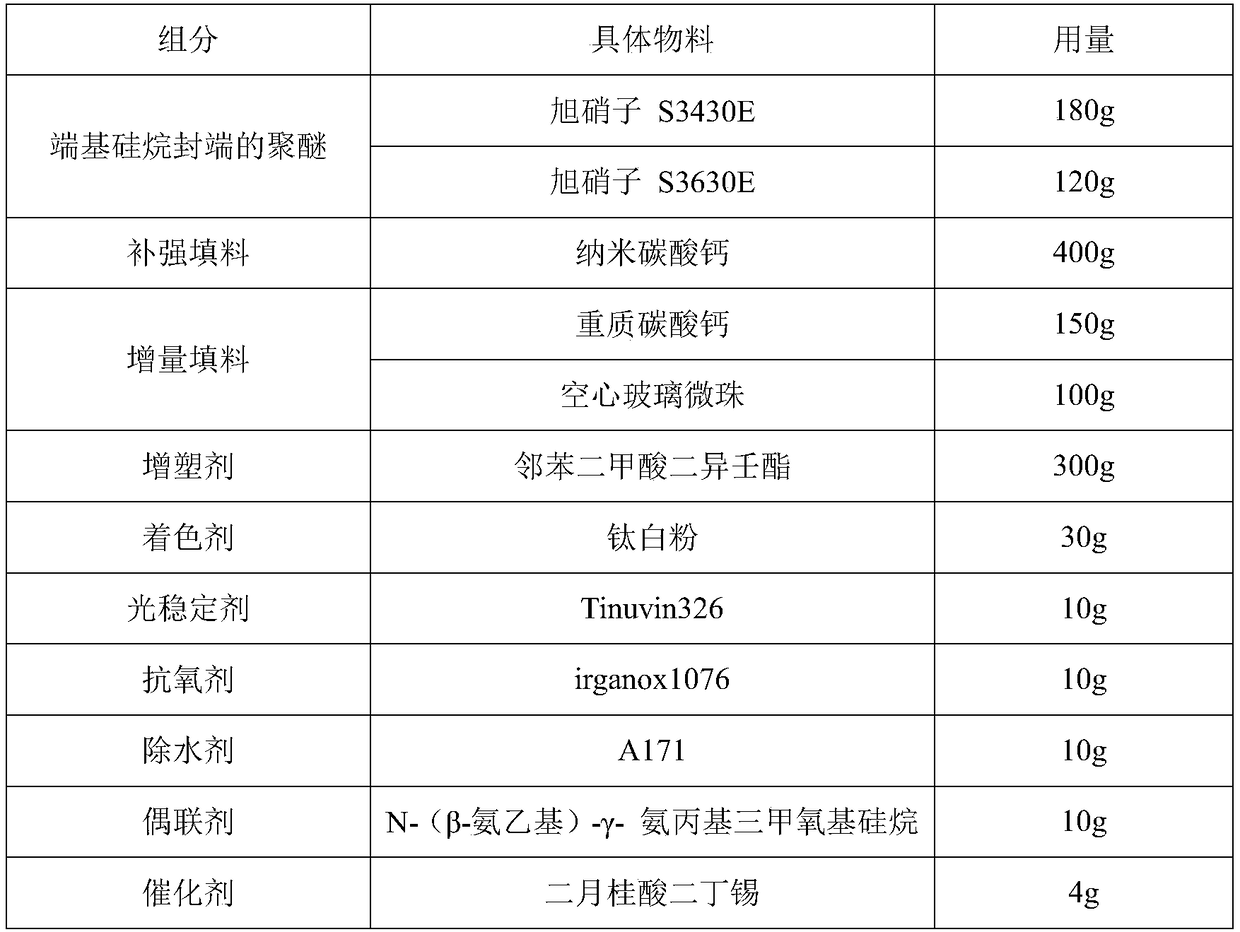

[0042] The preparation method of the stress-relieving polyether construction sealant based on terminal group silane modification described in Example 2 is roughly the same as that in Example 1, except that the formulation system used is shown in Table 1.

[0043] The mixture ratio of the stress relaxation type polyether construction sealant based on terminal silane modification described in Table 1 Example 2

[0044]

Embodiment 3

[0046] The preparation method of the stress-relieving polyether construction sealant based on terminal group silane modification described in Example 3 is roughly the same as that of Example 1, except that the formulation system used is shown in Table 1.

[0047] Table 2 The mix ratio of the stress-relieving polyether construction sealant based on terminal silane modification described in Example 3

[0048]

[0049] The performance test results of the obtained sealant are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com