A kind of oily conductive silver paste and preparation method thereof

A conductive silver paste, oily technology, applied in the direction of cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problem of large volume resistance of silver paste, and achieve favorable and process operation, volatility The effect of small, large amount of filler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

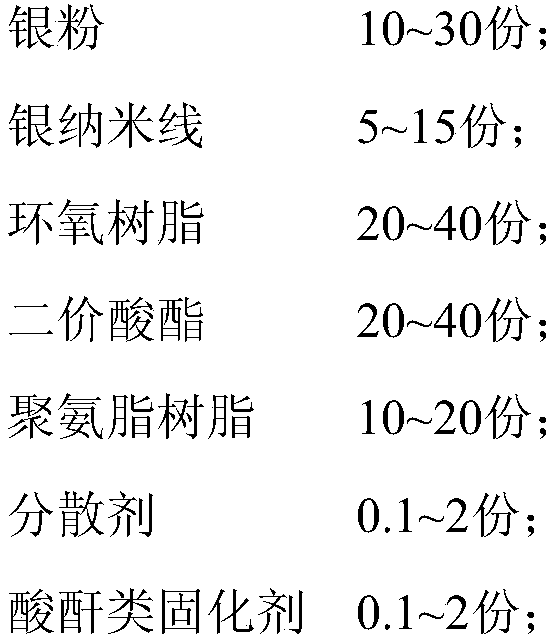

Method used

Image

Examples

Embodiment 1

[0026] The oily conductive silver paste of the present embodiment is prepared according to the following steps:

[0027] a, 40g epoxy resin and 20g dibasic acid ester are mixed 30min in high shear machine, obtain mixed solution A;

[0028] b. Add 10g of silver nanowires and 2g of dispersant carboxymethylpropyl cellulose into the mixed solution A, and perform vacuum defoaming and mixing in a vacuum mixer to obtain the mixed solution B;

[0029] c. Stir 30g of silver powder and 20g of polyurethane resin in a vacuum mixer for 30 minutes to obtain a mixture C; wherein the silver powder is formed by mixing 10g of flake silver powder and 20g of spherical silver powder.

[0030] d. Add 1 g of phthalic anhydride to the mixture C, stir in a vacuum mixer for 30 minutes, and then filter through a 250-mesh mesh cloth to obtain an oily conductive silver paste.

Embodiment 2~7

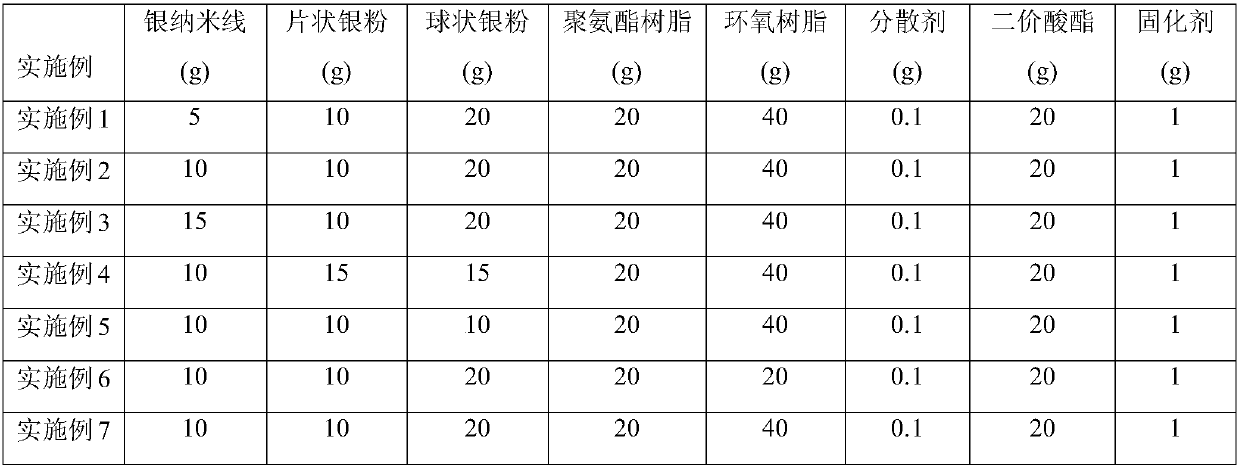

[0032] After adjusting the raw materials and their quality in Example 1 according to Table 1, carry out Examples 2-7 in the same manner.

[0033] Wherein, the curing agent used in Examples 2-6 is phthalic anhydride, and the curing agent used in Example 7 is trimellitic anhydride.

[0034] The raw material composition of each embodiment conductive silver paste of table 1

[0035]

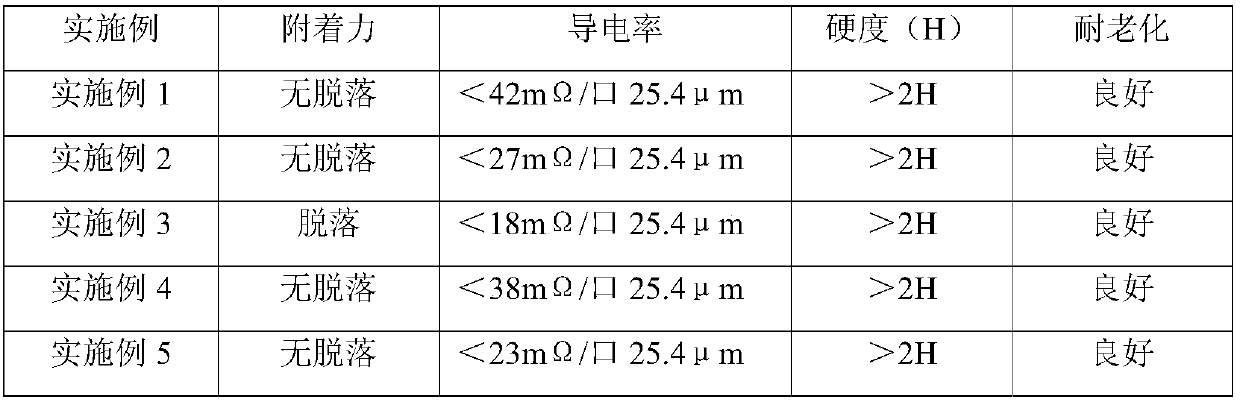

[0036] The conductive silver paste prepared by the above-mentioned embodiment is carried out performance test:

[0037] Electrical performance test: use a square resistance meter to test the resistance;

[0038] Adhesion test: 3M600 tape is used to pull vertically, and it does not fall off after two consecutive pulls;

[0039] Hardness Testing;

[0040] Aging resistance test: Set the temperature at 65°C, humidity at 90% RH, and hold time at 96 hours. The test resistance change before and after aging resistance is defined as good within 10%, and it is defined as poor if it exceeds.

[0041] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com