N-type polycrystalline silicon ingot casting device and ingot casting method

A polysilicon, N-type technology, applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., can solve the problems of small segregation coefficient, uneven distribution, and inability to adjust the proportion of dopants in time, etc. , to achieve uniform control of dopant distribution, reduce segregation of dopant elements, and increase single-time production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

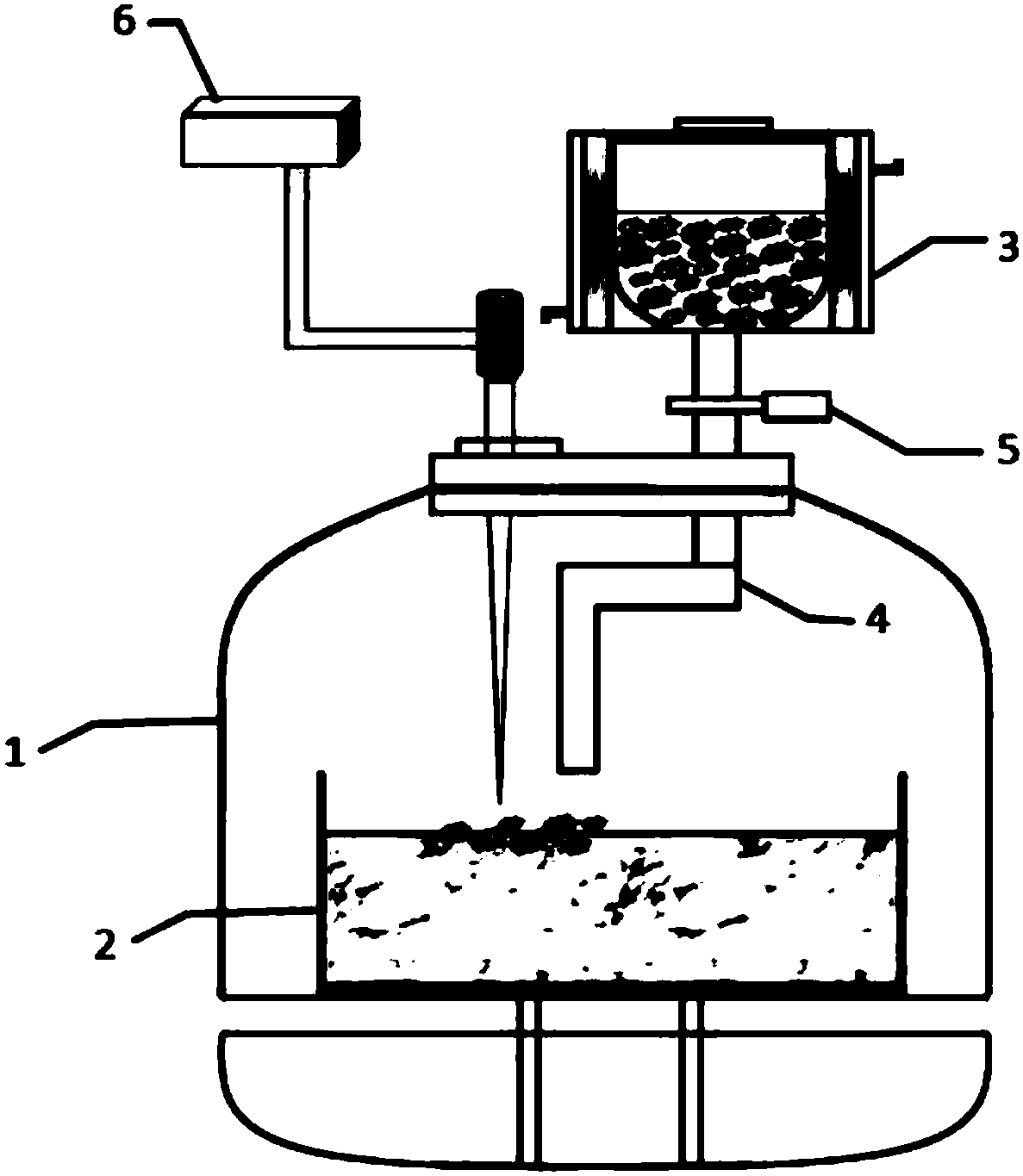

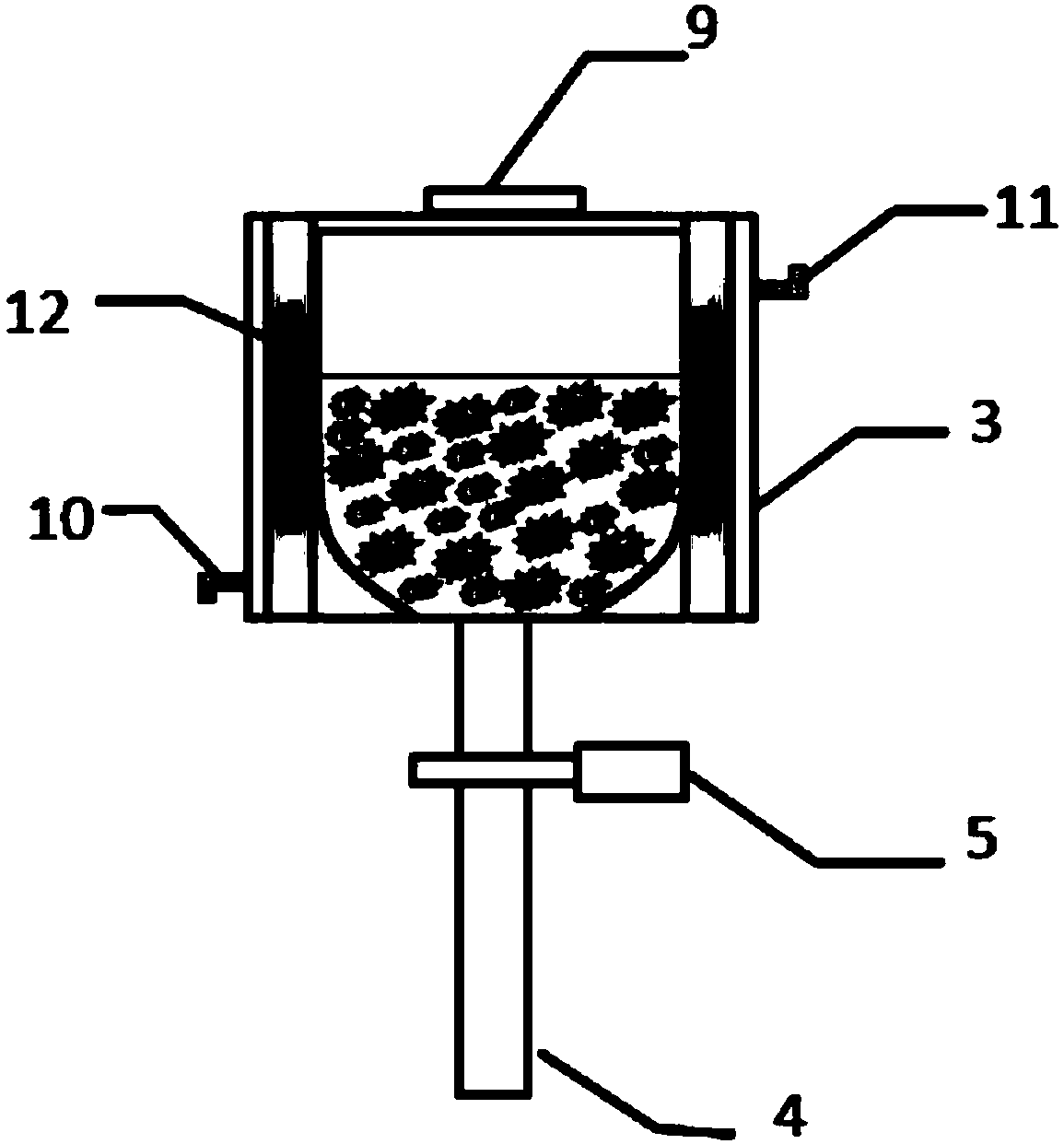

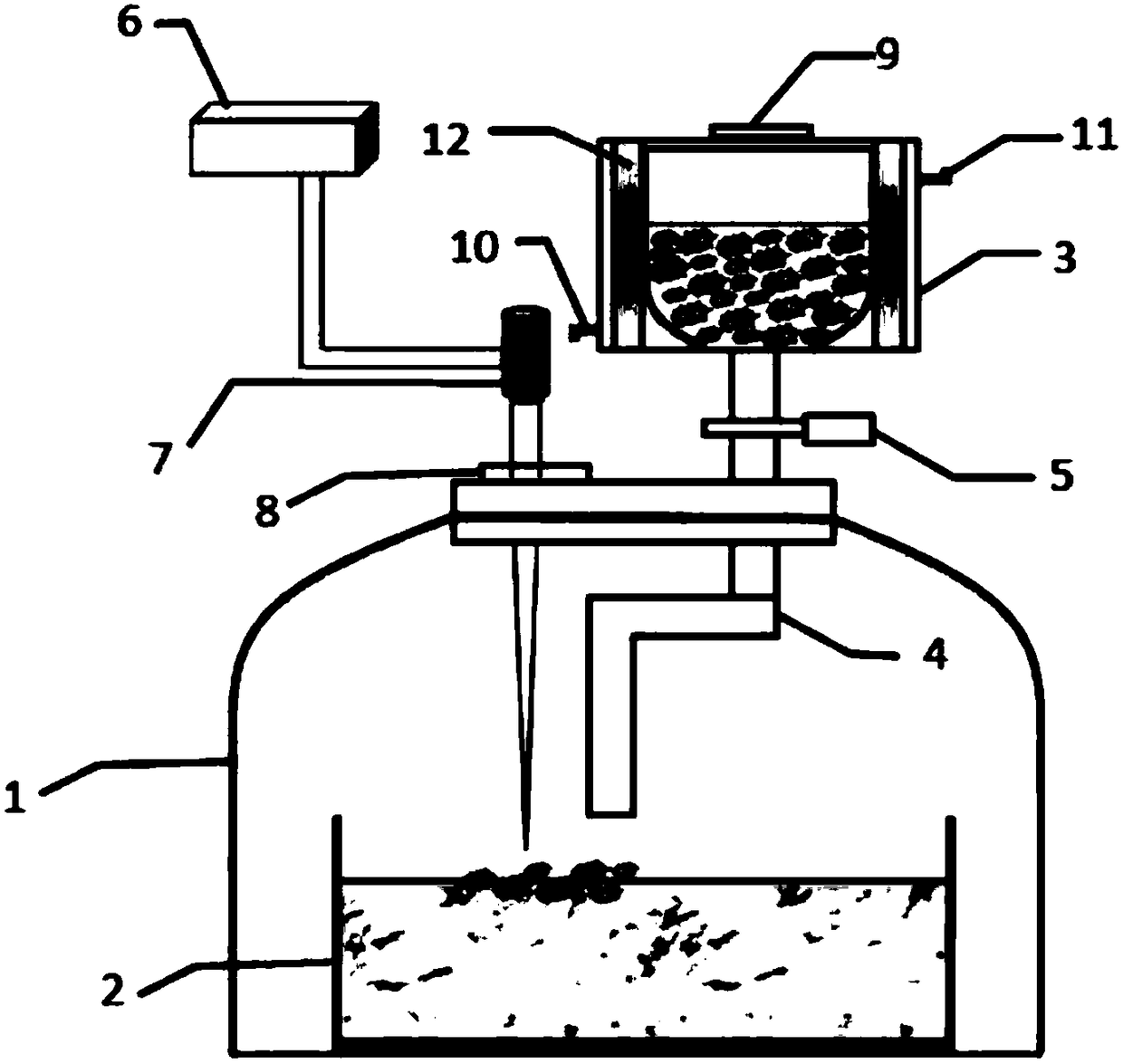

[0017] The present invention proposes an N-type polysilicon ingot casting device and ingot casting method. In order to fully illustrate the inventive concept of the present invention, the specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0018] see figure 1 and figure 2 , the N-type polysilicon ingot casting device of the present invention comprises: an ingot casting furnace 1, a crucible 2 is arranged in the ingot casting furnace 1, the crucible 2 can be a silicon nitride crucible, a quartz crucible or a crucible of other materials, and the top of the ingot casting furnace 1 There is a storage bin 3, which is used to place silicon materials. The top of the storage bin 3 is provided with a feeding port 9, and a heating unit 12 is provided outside. The upper and lower sides of the bin body are respectively equipped with vacuum pumping valves 10 and inert gas inlets. Gas valve 11, storage bin 3 and crucible 2 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com