Modified calcium carbonate filler and preparation method and application thereof in wet-strength paper

A technology of calcium carbonate filler and wet-strength paper, which is applied in the directions of fibrous filler, reinforcing agent addition, inorganic compound addition, etc., can solve the problems of inability to meet wet-strength paper, reduce paper dry strength and wet strength, etc., and improve the surface of paper. performance and optical properties, increasing the ash content of paper, increasing the effect of filler content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

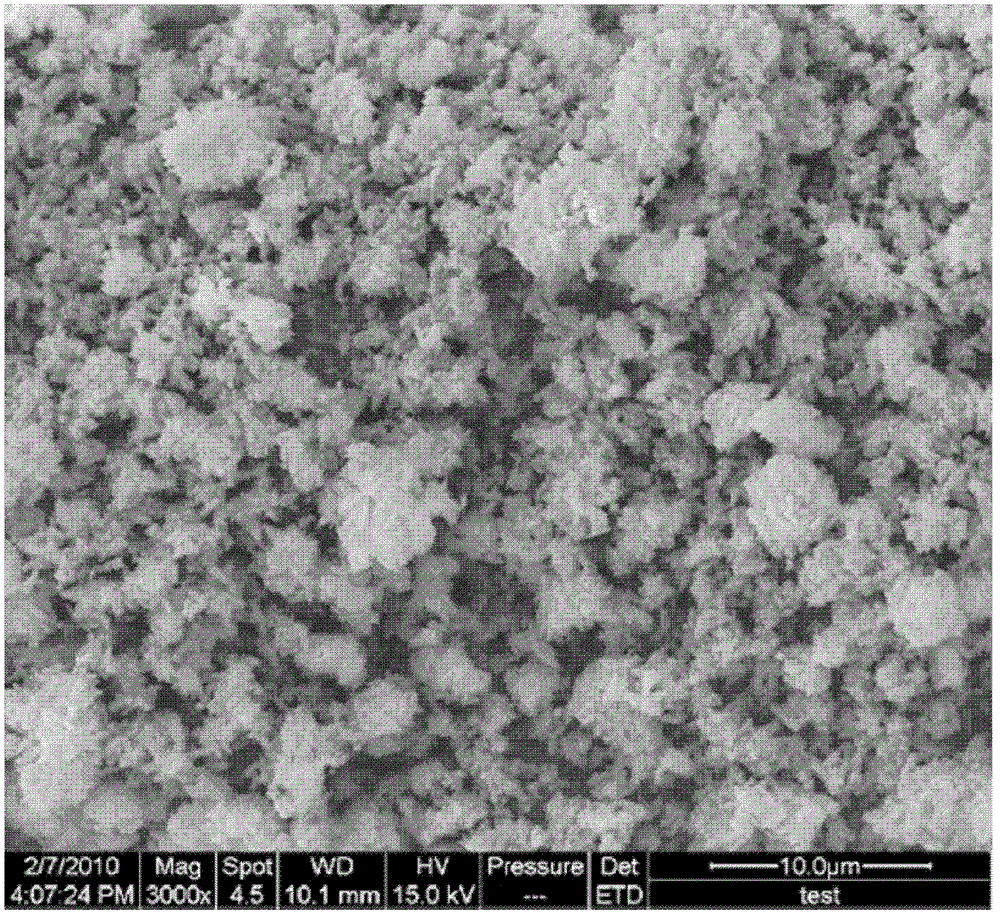

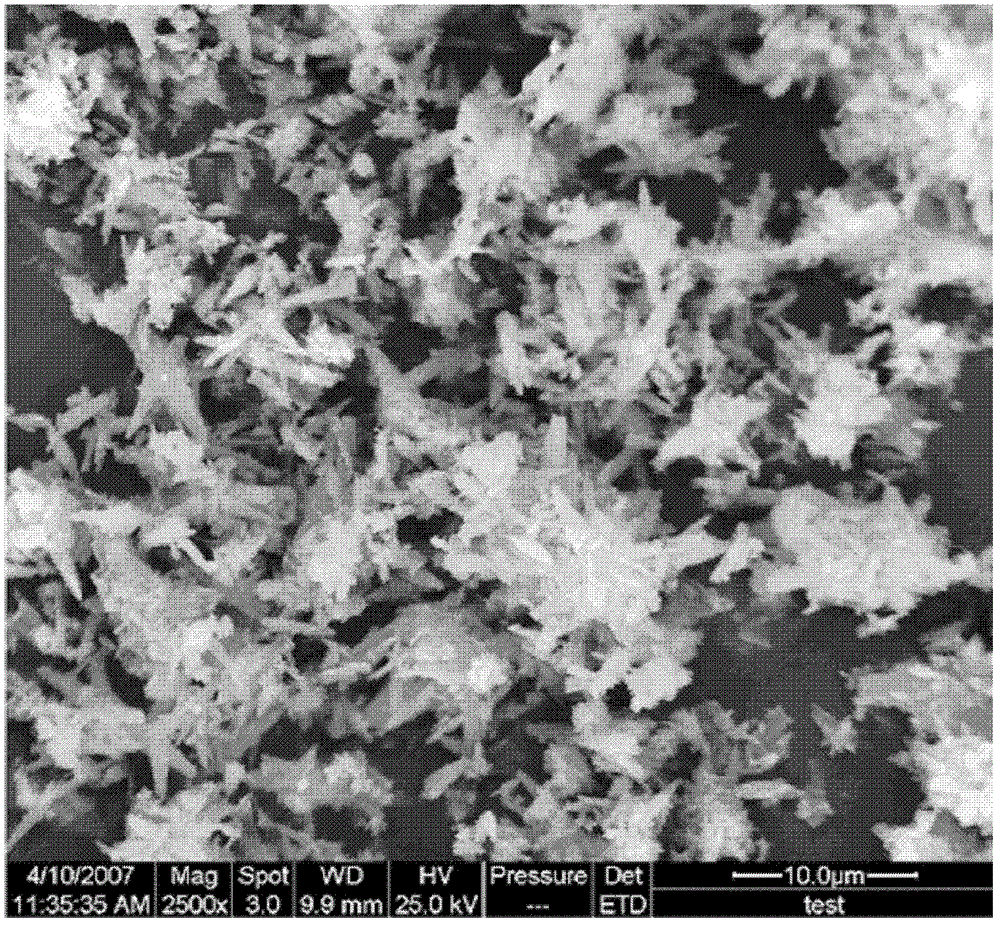

Image

Examples

Embodiment 1

[0026] First disperse the precipitated calcium carbonate in water, the concentration is 50% (mass percentage), then add PAE (polyamide polyamine epichlorohydrin) diluted with water to 0.5% concentration, the amount of PAE is relative to the absolute dry weight of the precipitated calcium carbonate Stir for 90 minutes under the condition of 500r / min, and then add a low molecular weight cationic polyacrylamide reinforcing agent with a molecular weight of 800,000. Minutes, the modified calcium carbonate filler is prepared, placed in the storage tank, and stirred at 300r / min for later use.

Embodiment 2

[0029] First the precipitated calcium carbonate is dispersed in water, the concentration is 40% (mass percentage), then add PAE (polyamide polyamine epichlorohydrin) diluted to 0.8% concentration with water, the consumption is 20% (relative to the precipitated calcium carbonate absolute Dry mass ratio), stirred at 300r / min for 80 minutes, then added a low-molecular-weight cationic polyacrylamide reinforcing agent with a molecular weight of 1.2 million, in an amount of 0.6% relative to the dry mass of precipitated calcium carbonate, and stirred at 200r / min for 30 minutes. The prepared modified calcium carbonate is placed in a storage tank and stirred at 300r / min for subsequent use.

Embodiment 3

[0031] First the precipitated calcium carbonate is dispersed in water, the concentration is 20% (mass percentage), then add PAE (polyamide polyamine epichlorohydrin) diluted to 2% concentration with water, the consumption is 25% (relative to the precipitated calcium carbonate absolute Dry mass ratio), stirring at 150r / min for 60 minutes, then adding a low molecular weight cationic polyacrylamide reinforcing agent with a molecular weight of 1.8 million, in an amount of 0.8% relative to the dry mass of precipitated calcium carbonate, stirring at 200r / min for 30 minutes. The prepared modified calcium carbonate is placed in a storage tank and stirred at 300r / min for subsequent use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com