Light- or heat-curing method and curable resin composition

A curing method and compound technology, applied in chemical instruments and methods, epoxy resin coatings, optics, etc., can solve problems such as sufficient thermal conductivity of resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0331] Example 1: Production of a cured film using a resin composition by irradiation of light (active energy rays) and evaluation of physical properties of the obtained cured film

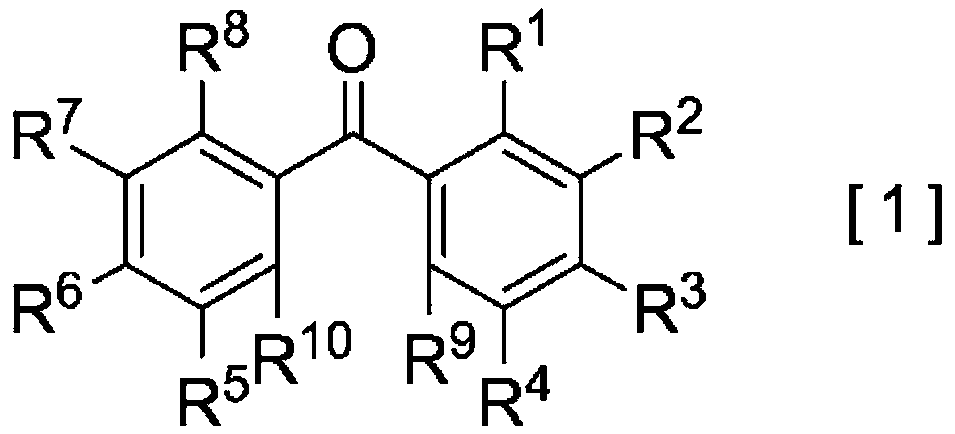

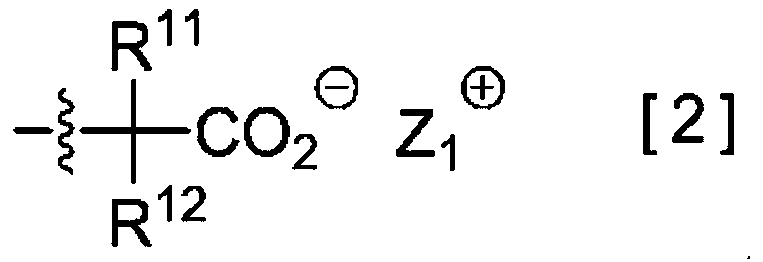

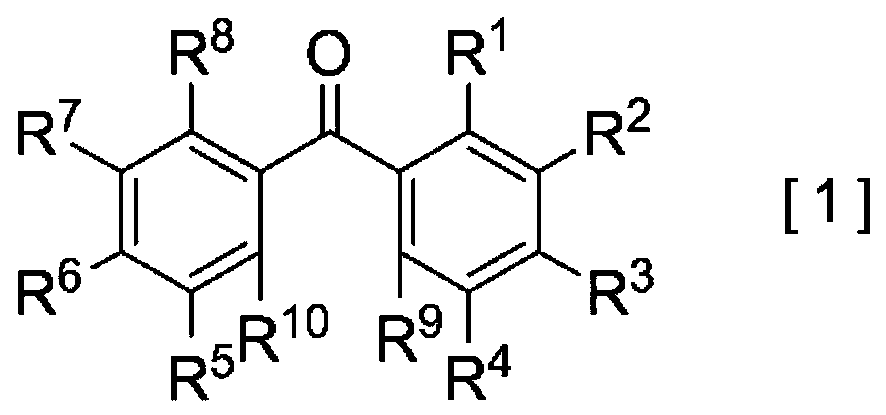

[0332] To 1,2-diisopropyl-4,4,5,5-tetramethylbiguanide 2-(3-benzoylphenyl) propionate [compound (A)], aluminum tri-sec-butoxide [ Add ion-exchanged water [water (D)] and carbitol acetate [ organic solvent] mixed solution and stirred for 30 minutes to prepare a sol solution. Next, the above-mentioned The sol liquid prepared in , was kneaded for 3 minutes at a rotational speed of 2000 rpm using a planetary mixer (THINKY CORPORATION "Awatori Rentaro AR-250") to prepare a resin composition. The obtained resin composition was coated on an aluminum plate to prepare a coating film, and after prebaking at 150° C., the coating film was prepared using “HLR-100-2” manufactured by SEN LIGHTS Co., Ltd. Irradiate light for 1 minute (active energy rays: surface illumination 254nm = 9mJ / cm 2 and 365nm=11mJ / cm...

Embodiment 2~5

[0371] Examples 2 to 5: Preparation of cured film using a resin composition added with a compound having two or more epoxy groups and evaluation of physical properties of the obtained cured film

[0372] In addition to adding a compound with two or more epoxy groups to the curing system of Example 1 or replacing the type of aluminum nitride used in Example 1, a cured film was produced in the same manner as in Example 1, and evaluated its many properties. Table 5 shows the usage-amount (molar amount) and evaluation result of each component. In addition, the names and places of purchase of components not used in Example 1 and Comparative Examples 1 to 3 among the components used in Examples 2 to 5 are shown below.

[0373] -(I) Filler-

[0374] Aluminum nitride (AlN) (manufactured by TOYO ALUMINUM K.K.; TFZ-A02P; average particle size 1.5 μm)

[0375] Aluminum nitride (AlN) (manufactured by TOYO ALUMINUM K.K.; TFZ-A15P; average particle diameter 15.0 μm)

[0376] -(J) Compou...

Embodiment 6~7

[0383] Examples 6-7: Production of a cured film using a resin composition added with a chelating agent and evaluation of physical properties of the obtained cured film

[0384] Methyl acetoacetate [chelating agent (F)] was added to aluminum tri-sec-butoxide [aluminum alkoxide (B)], and stirred until heat generation ceased. Next, add 1,2-diisopropyl-4,4,5,5-tetramethylbiguanide 2-(3-benzoylphenyl)propionate [compound (A)] and (3-mercapto Propyl) trimethoxysilane [silane coupling agent (C)], and then add a solution of ion-exchanged water [water (D)] and carbitol acetate [organic solvent], and stir for 30 minutes And prepare the sol solution. Next, the sol prepared above was added to a mixture of triallyl cyanurate [compound (H)], aluminum nitride [filler (I)] and carbitol acetate [organic solvent], And it kneaded for 3 minutes at 2000 rpm using the planetary mixer (THINKY CORPORATION "Awatori Rentaro AR-250"), and produced the resin composition. The obtained resin composition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com