A kind of liquid polyacid anhydride, its preparation method and application

A technology of polyacid anhydride and liquid acid anhydride, applied in the direction of organic chemistry, etc., to achieve the effect of high filler content, lower energy consumption and zero investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of liquid polyanhydride:

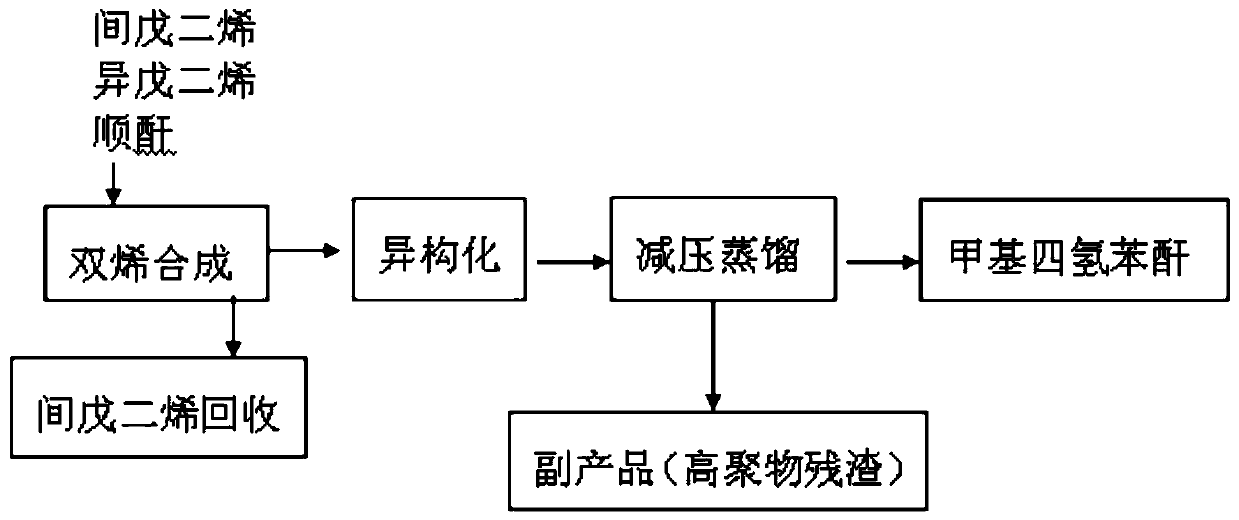

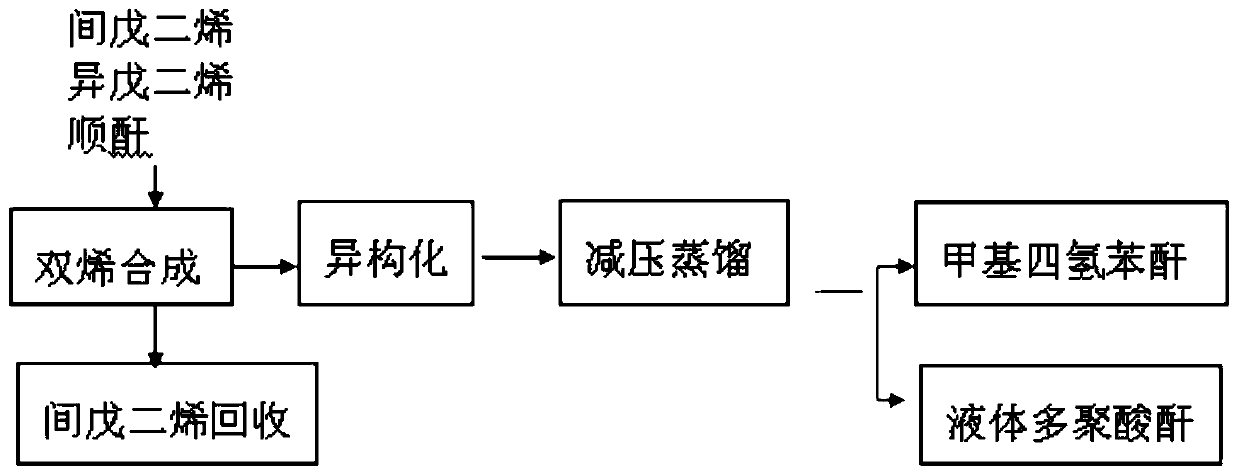

[0039] Process basis of the present invention figure 2 Schematic diagram of the production process of liquid polymeric anhydride, when the yield of methyl tetrahydrophthalic anhydride is controlled to 83% of the normal output, the vacuum distillation is stopped, the rear fraction process and the redistillation process are cancelled, and about 7% of the former fraction and the remainder are directly injected into the In the vacuum distillation kettle, stir for 30 minutes and directly filter and transfer to the finished product kettle, after cooling, pack it and name it as liquid polyanhydride LLQ1010. In the production process, except for less than 0.05% insoluble and infusible residue, no methyl tetrahydrophthalic anhydride polymer residue is precipitated.

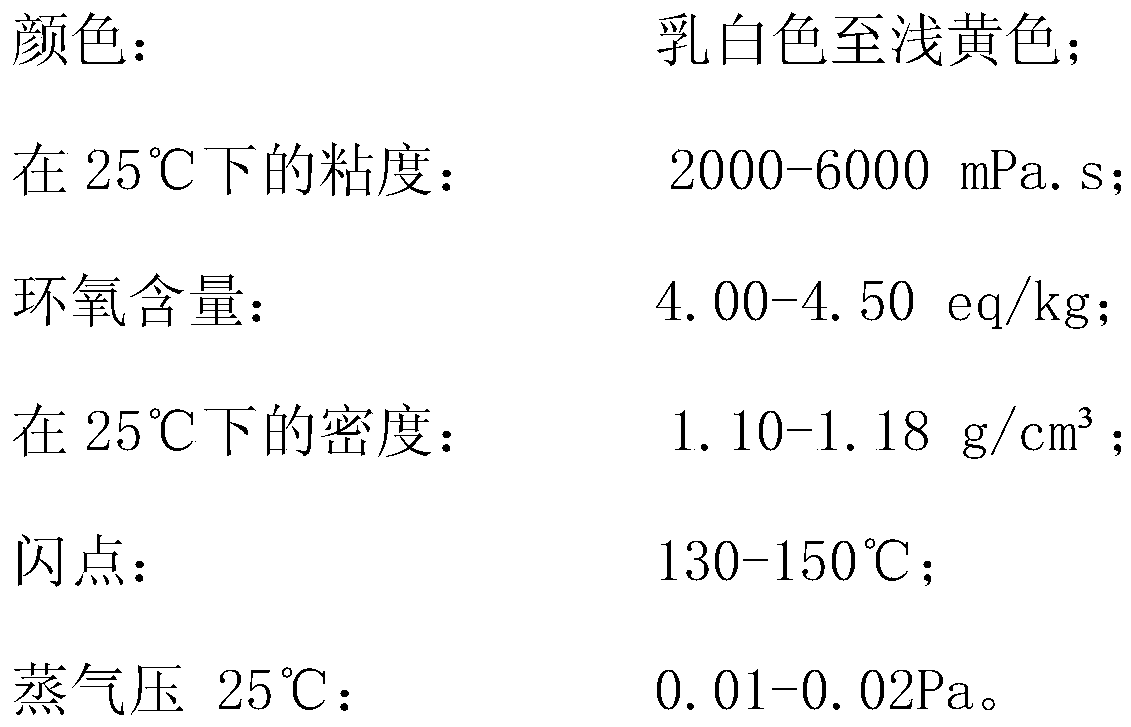

[0040] Product technology refers to the following:

[0041] Acid value (490mg / KOH / g),

[0042] Anhydride group content (38%)

[0043] Viscosity (2100mPa.s).

Embodiment 2

[0045] Preparation of a low-viscosity APG epoxy resin pouring system:

[0046] At room temperature, add 3% liquid polyanhydride into 97% bisphenol A epoxy resin DY 128, heat up to 150°C while stirring, and keep the temperature for reaction for 3 hours. After the reaction is finished, cool to room temperature to 80°C, add 15% epoxy reactive diluent C by weight of the above composition 12-14 Alcohol glycidyl ether (AGE) was stirred for 30 minutes, filtered and packaged. The liquid polyanhydride modified epoxy resin with a viscosity of about 4500mPa.s was prepared. At 110°C, react 60% toughened acid anhydride (LLQ 1225) and 40% liquid polyanhydride for 2 hours, cool to 60°C after the reaction is completed, add 0.8% accelerator dimethyl benzylamine (BDMA), stir After 30 minutes, filter and pack to prepare a pre-accelerated modified polyanhydride curing agent with a viscosity of about 1500mPa.s. Mix the low-viscosity liquid polyanhydride-modified epoxy resin prepared above, the p...

Embodiment 3

[0048] Preparation of a low-viscosity APG epoxy resin pouring system:

[0049] At room temperature, add 5% liquid polyanhydride into 95% bisphenol A epoxy resin DY 128, heat up to 140°C while stirring, and keep the temperature for reaction for 2 hours, and cool down to 80°C quickly after the reaction is completed. Add 15% reactive diluent LLQ 8040 to the weight of the above composition, filter and pack. A liquid polyanhydride-modified epoxy resin with a viscosity of about 4000 mPa.s was prepared. At 80°C, react 70% toughened acid anhydride (LLQ1225) and 30% liquid polymeric anhydride for 2 hours, cool to 60°C after the reaction is completed, add 0.7% accelerator dimethyl benzylamine (BDMA), and stir for 30 Minutes, filter and pack to prepare a pre-accelerated modified polyanhydride curing agent with a viscosity of about 250mPa.s. Mix the low-viscosity liquid polyanhydride-modified epoxy resin prepared above, the pre-accelerated modified polyanhydride curing agent and 400-mes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com