Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

198results about How to "Increase profit margins" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

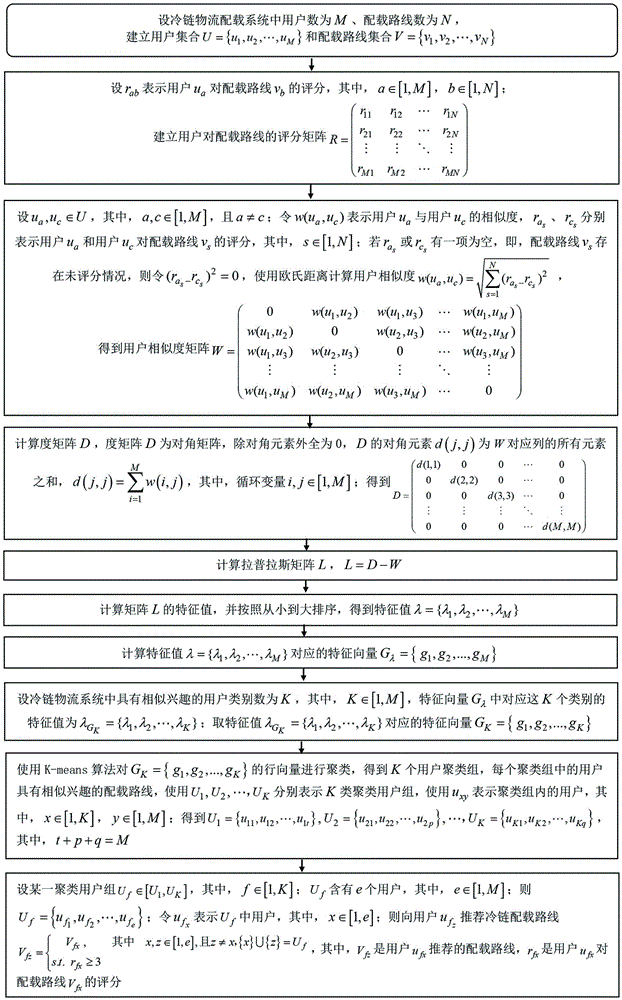

Cold-chain logistic stowage intelligent recommendation method based on spectral cl9ustering

InactiveCN105654267AReduce the no-load ratioIncrease profit marginsCharacter and pattern recognitionLogisticsCold chainRating matrix

The invention discloses a cold-chain logistic stowage intelligent recommendation method based on spectral clustering. Scores of users for a stowage line are conveyed through a cold chain for cold-chain logistic stowage intelligent recommending, a score matrix is built, the Euclidean distance is used for calculating the user similarity, a degree matrix is used for calculating a Laplacian matrix, feature vectors are obtained by calculating feature values of the orderly Laplacian matrix, a K-means algorithm is used for clustering the feature values to obtain a user group with the similar interesting stowage line, and a stowage line is recommended inside the user group with the similar interesting stowage line, so that cold-chain logistic stowage intelligent recommending is achieved, the cold-chain logistic vehicle non-load ratio is lowered, and the profit rate of cold-chain logistic transport vehicles is increased.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

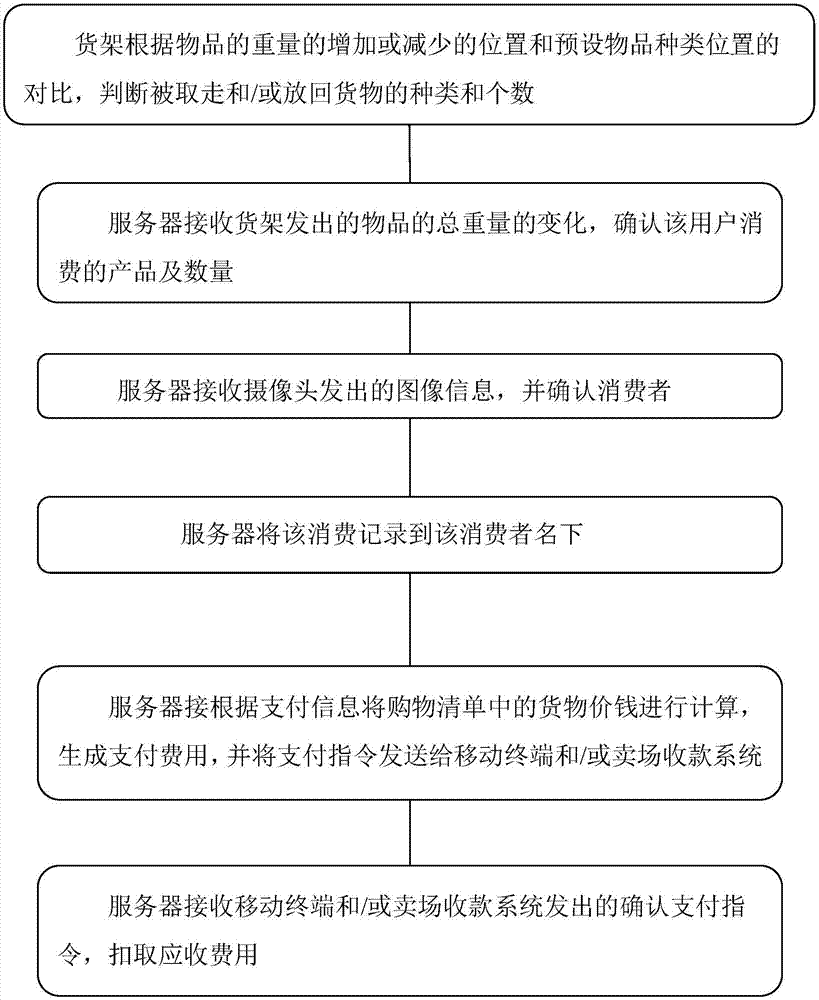

Intelligent shopping system

PendingCN107123006AReduce in quantityLow costCredit schemesIndividual entry/exit registersPaymentComputer module

The invention discloses an intelligent shopping system. The system comprises an access control, an intelligent shelf, a payment module, a video capture module, an electronic display screen module and a server, wherein the access control is used for acquiring user information and sending acquired user information to the server; the intelligent shelf is used for judging the type and number of taken or replaced articles according to change of weight of preset articles on the shelf and sending the type and number of the articles to the server to serve as goods information; the payment module is used for sending payment or payment confirmation information to the server through a communication module; each electronic display screen is defined separately and used for displaying content defined by the server; the server is used for receiving information, obtaining corresponding instructions and sending the instructions. With the adoption of the shopping system method, good identification or collection by workers is not required in the consumption process, the number of the workers is reduced, the cost is reduced, and the profit margin is increased.

Owner:杨智勇 +1

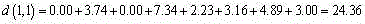

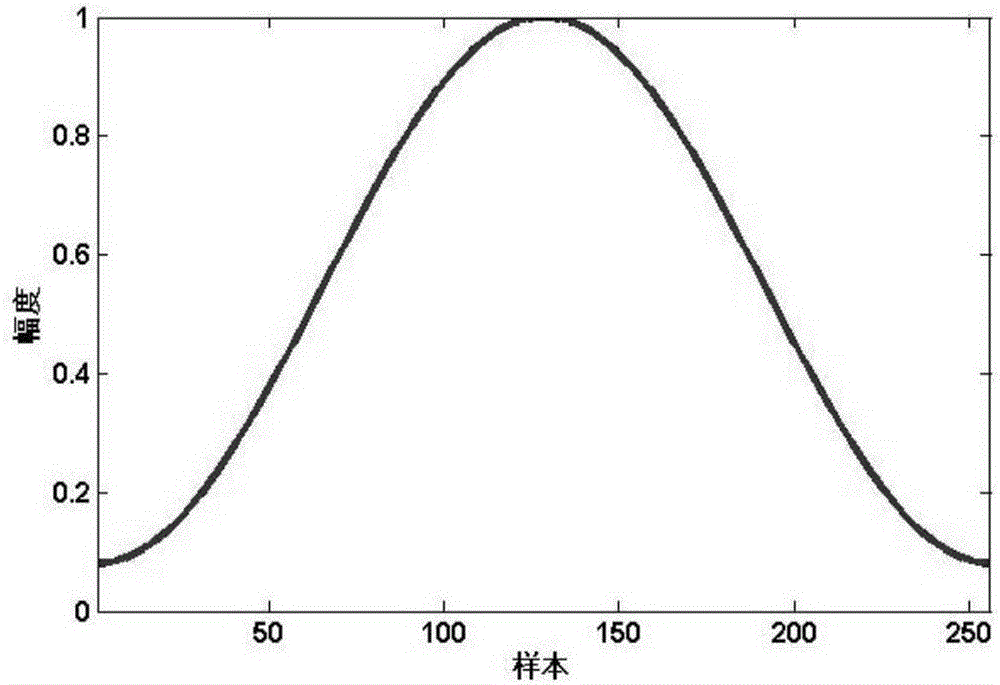

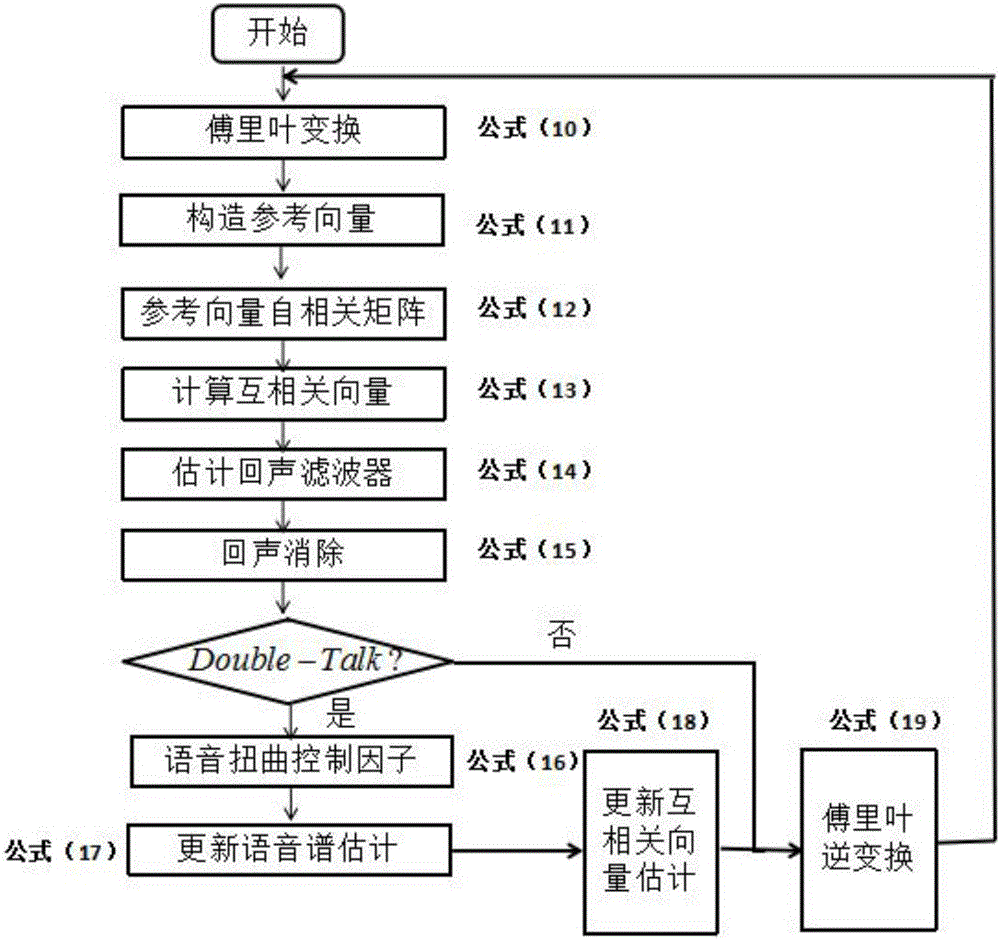

Double-talk detection and echo cancellation method based on zero-crossing rate

ActiveCN105825864AAdaptableImprove robustnessTwo-way loud-speaking telephone systemsTelevision conference systemsZero-crossing rateHarmonic structure

The invention discloses a double-talk detection and echo cancellation method based on zero-crossing rate, comprising the following steps: S1, zero-crossing rate calculation and double-talk monitoring: different echo cancellation strategies are adopted for double-talk and single-talk scenarios; S2, echo filter estimation and echo cancellation; there is difference between an echo signal collected by a microphone and a far-end signal because of room impulse response, and the echo component is eliminated from the signal collected by the microphone; and S3, recovery of a target speech harmonic structure. A harmonic structure analysis method is used to compensate for the missing harmonic components of near-end speech to further inhibit speech distortion. Compared with the traditional echo cancellation technology, double-end monitoring is realized based on the zero-crossing rate, and elimination of target speech is avoided. Based on the criterion of frequency-domain minimum mean square error, an echo cancellation filter converges rapidly. By adopting a frequency-domain parallel processing framework, the complexity is low. A speech distortion inhibition module is added, and the distortion degree of target speech is reduced.

Owner:深圳市雅今智慧科技有限公司

Automatic payment method

InactiveCN107301749AReduce in quantityLow costCharacter and pattern recognitionCash registersPaymentGoal recognition

The invention discloses an automatic payment method. According to the method, through image acquisition and target recognition and the increase or decrease of weight of scheduled objects on a shelf, user consumption is confirmed, and payment is carried out or confirmed. A server receives video information emitted by a camera. The server carried out target identification according to the received video information and marks identified targets. The server carries out target identification according to the received video information, marks the identified targets, and generates a corresponding shopping list. When the marked targets are taken and / or the objects are placed back, the shelf automatically identifies a number and category of the taken or returned objects through weight detection, the number and category are added into the shopping list and an object price is calculated, the money payment or payment confirmation is carried out with various money collection modes through identifying a payment instruction, the goods identification or payment by any staff in the middle is not needed, no customer is lost, the number of staff is reduced, the cost is reduced, and the profit rate is improved.

Owner:杨智勇 +1

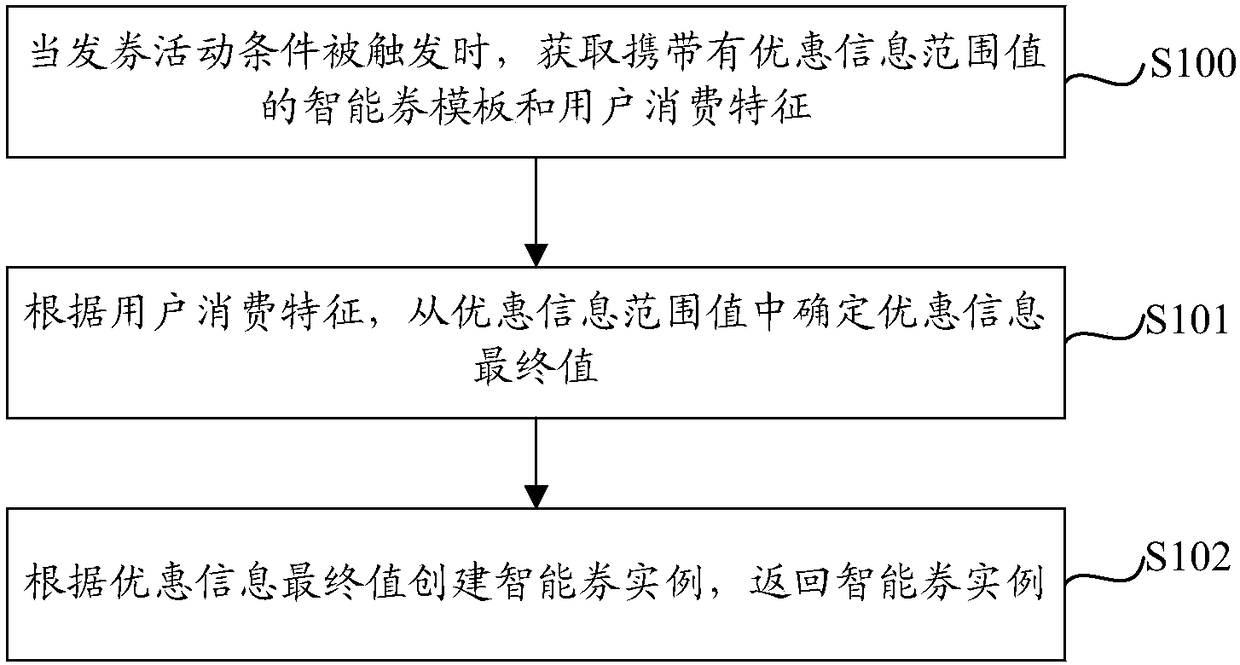

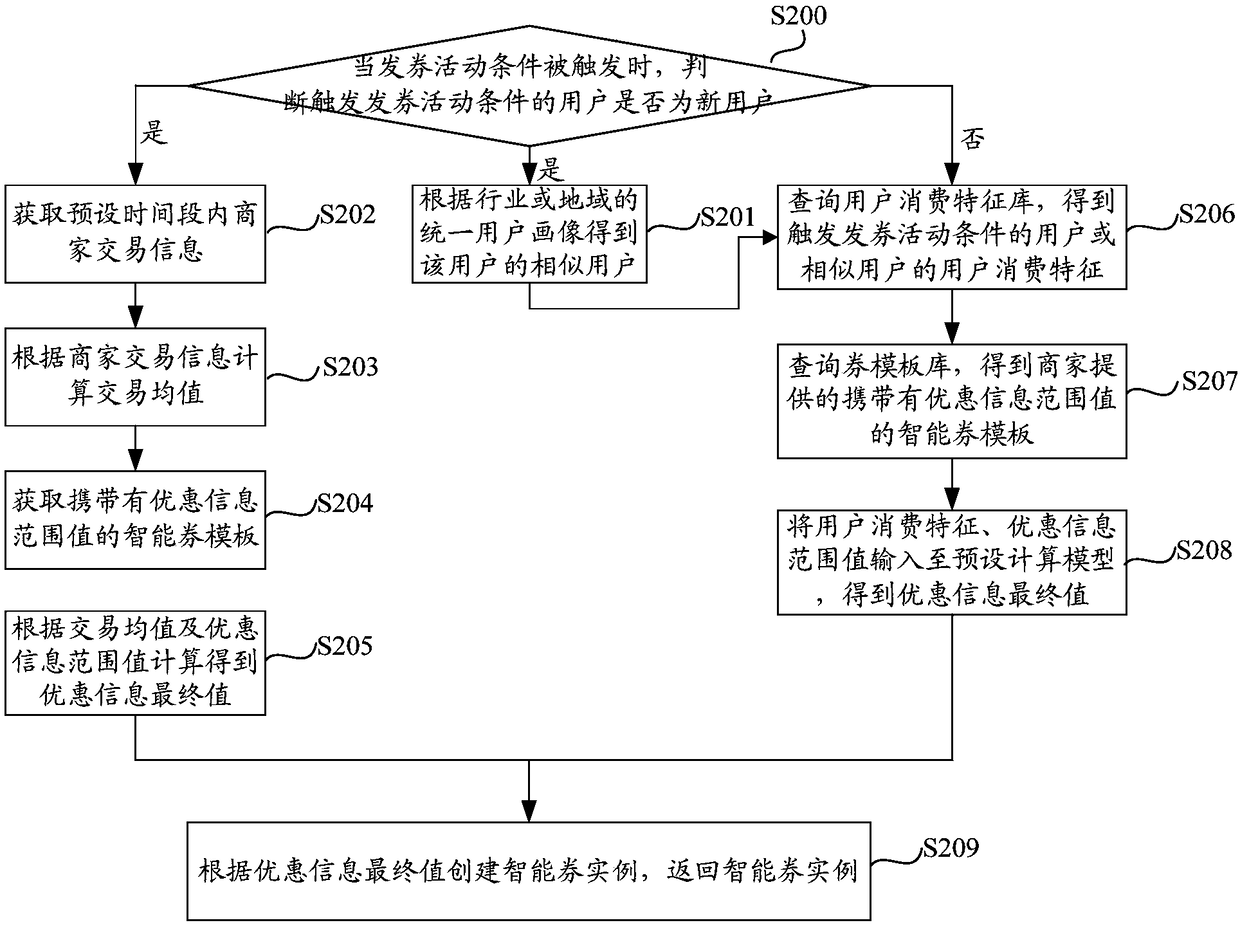

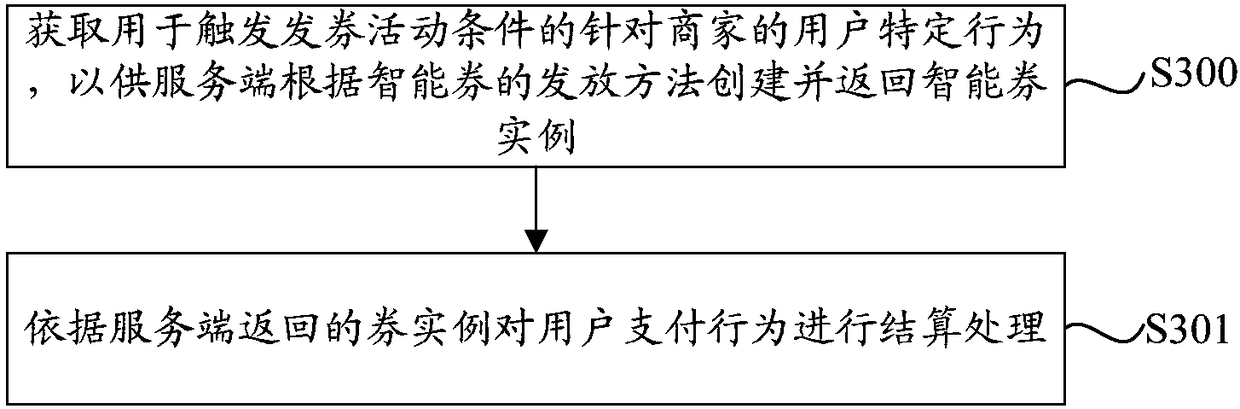

Smart coupon issuing method and device, and method and device for verification by employing smart coupon

The present invention discloses a smart coupon issuing method and device, and a method and a device for verification by employing a smart coupon. The smart coupon issuing method comprises the steps of: when a coupon issuing activity condition is triggered, obtaining a smart coupon template carrying a special offer range values and user consumption features; according to the user consumption features, determining a special offer final value from the special offer range value; creating a smart coupon example according to the special offer final value, and returning the smart coupon example. Based on the scheme provided by the embodiment, the special offer final value is calculated according to the user consumption features to achieve flexibly design the discount degree and / or usage thresholdof the smart coupon example, allow merchants to achieve the optimal marketing effect, reduce the unnecessary marketing expenditure of the merchants, further promote the user consumption and improve the merchant profit margin.

Owner:KOUBEI SHANGHAI INFORMATION TECH CO LTD

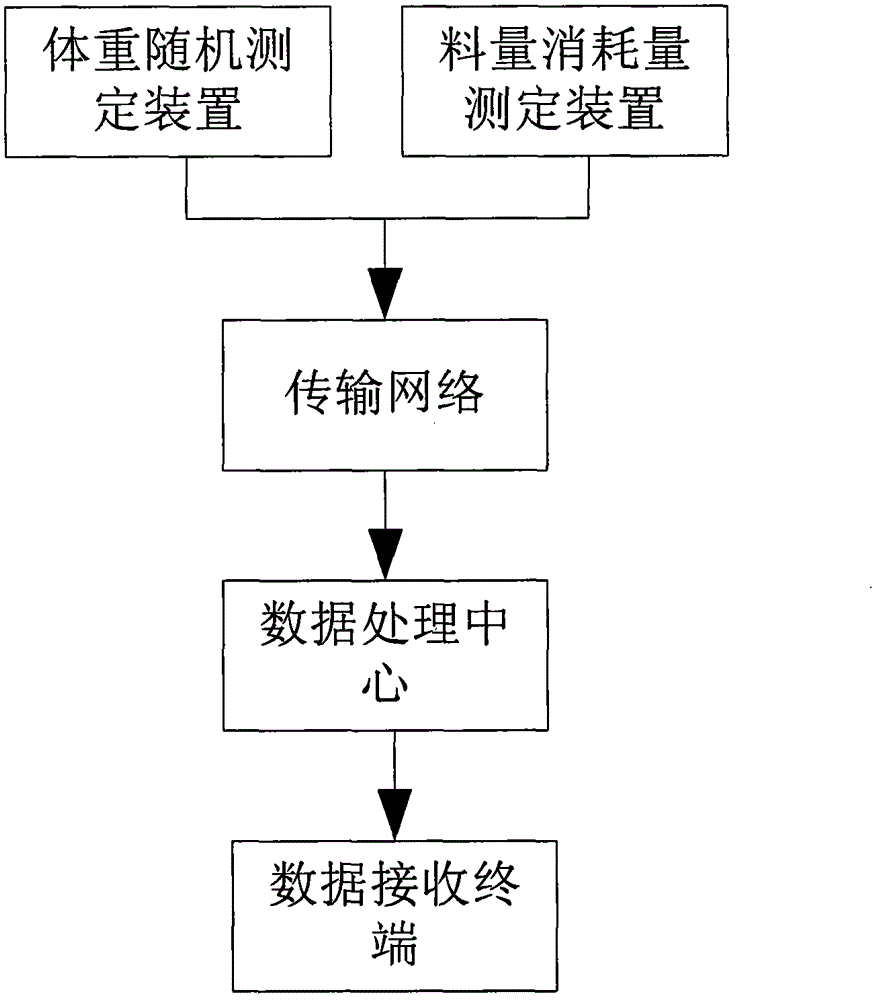

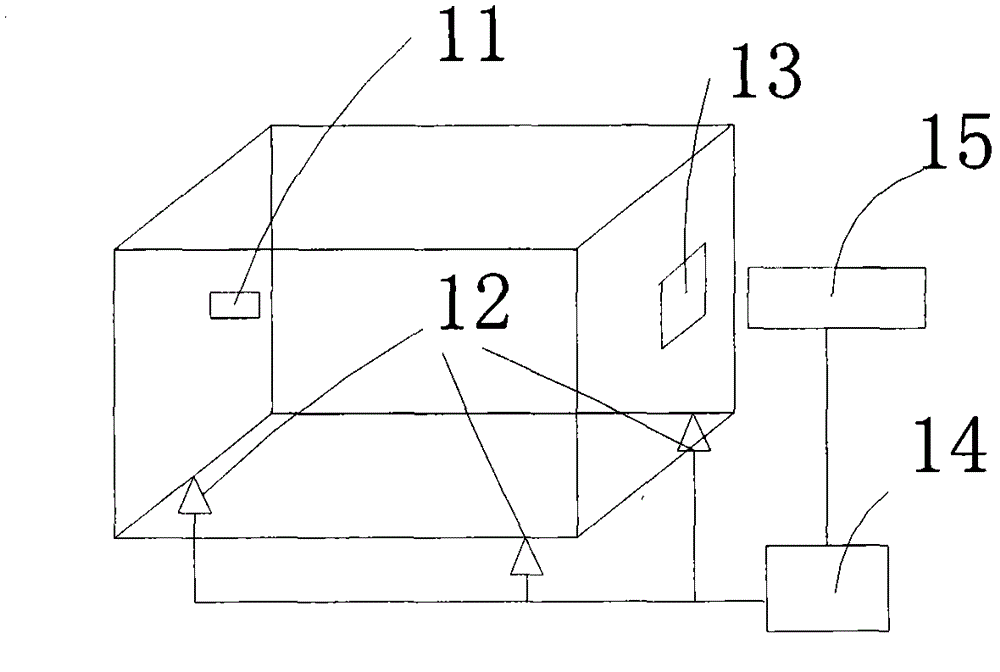

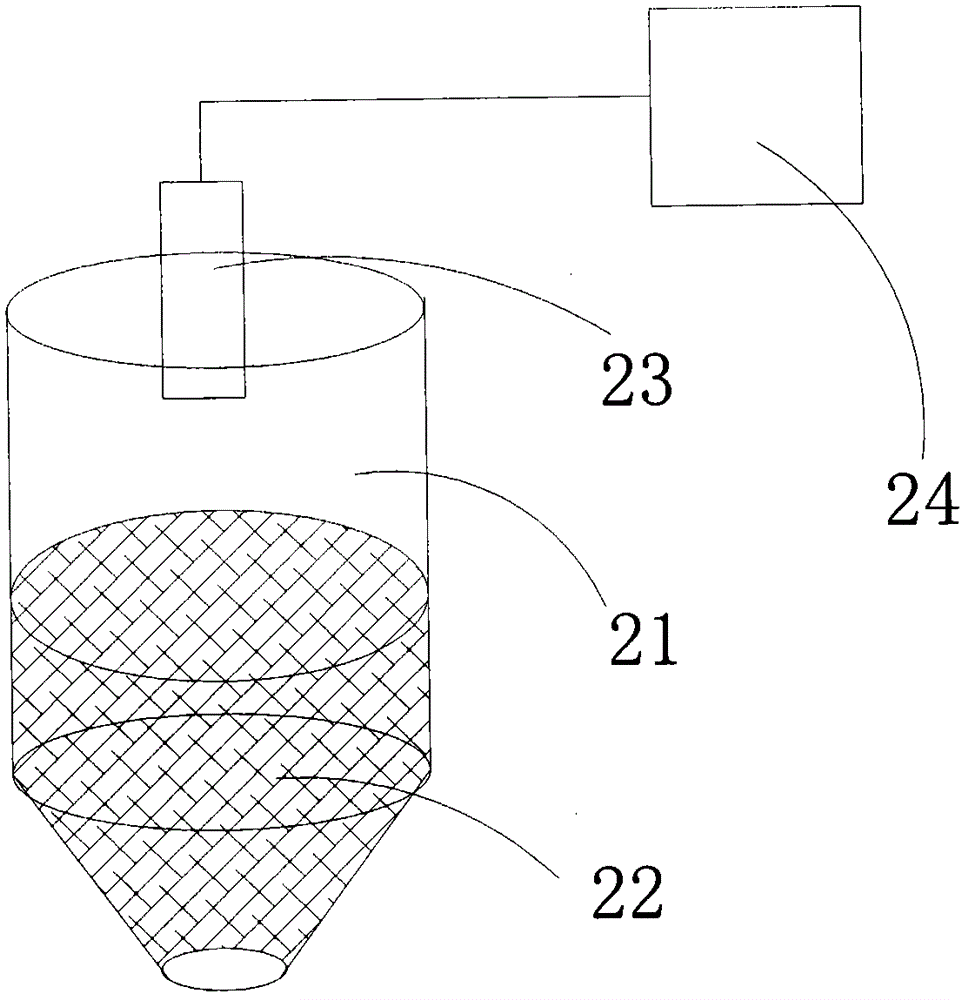

Intelligent intensive livestock and poultry monitoring system and intelligent intensive livestock and poultry monitoring method

ActiveCN104871999AEliminate blind breeding processImprove availability and reliabilityOther apparatusLivestockReal-time computing

The invention relates to an intelligent intensive livestock and poultry monitoring system and an intelligent intensive livestock and poultry monitoring method. The intelligent intensive livestock and poultry monitoring system comprises a weight random-measuring device and a feed consumption measuring device. The weight random-measuring device is used for measuring weight data of an animal group dynamically and intelligently in real time and acquiring a group parameter of an average daily gain according to daily group weight difference. The feed consumption measuring device is used for acquiring dynamic real-time feed consumption parameters. The weight random-measuring device and the feed consumption measuring device respectively send weight information and feed consumption information to a data processing unit through a transmission network, and the data processing unit sends processed data to a data receiving terminal. The intelligent intensive livestock and poultry monitoring system and the intelligent intensive livestock and poultry monitoring method are capable of measuring maximum marginal income and real-time variation tendency of marginal cost dynamically and intelligently in real time and are extremely high in reliability and practicability.

Owner:范石军

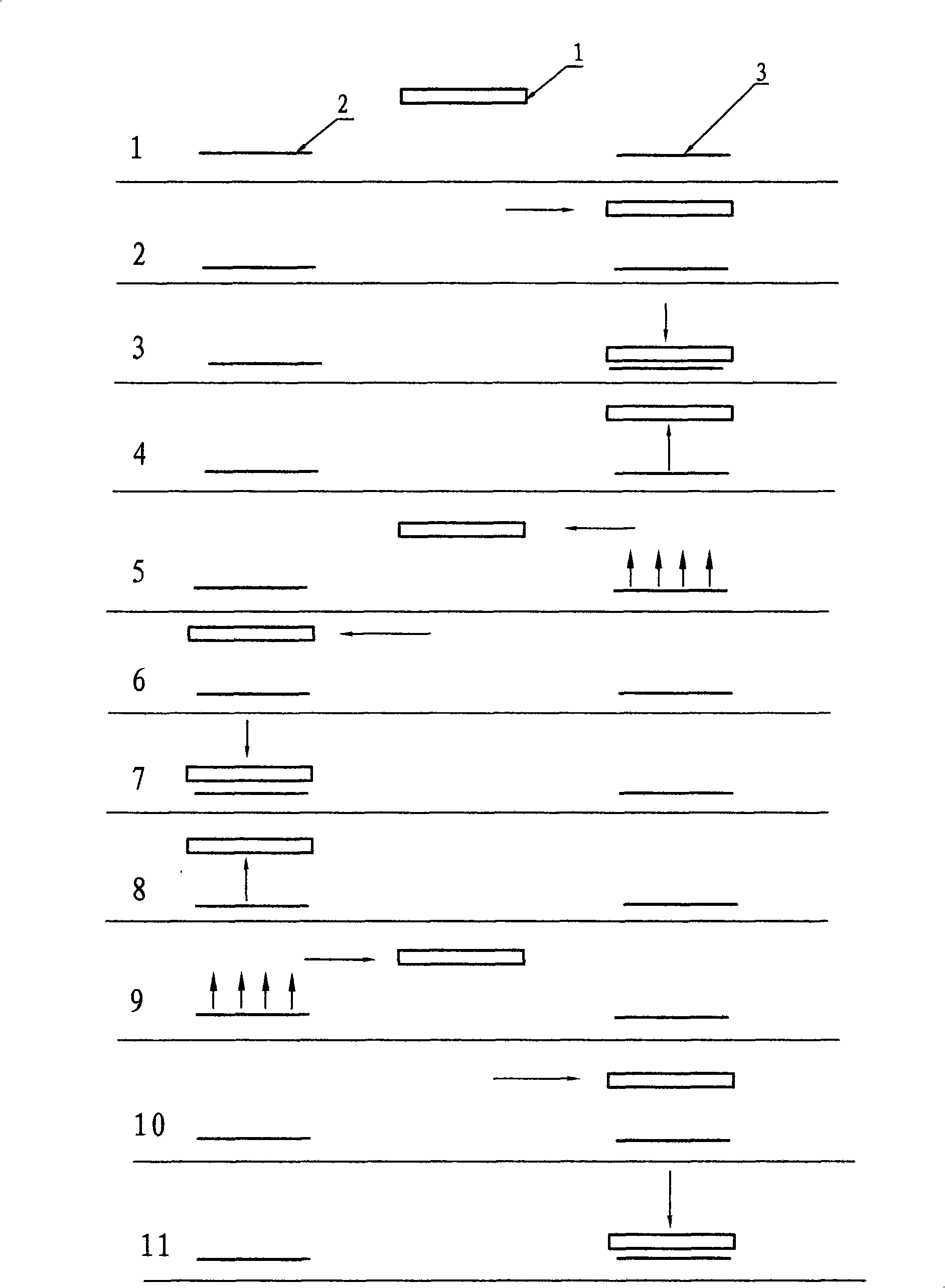

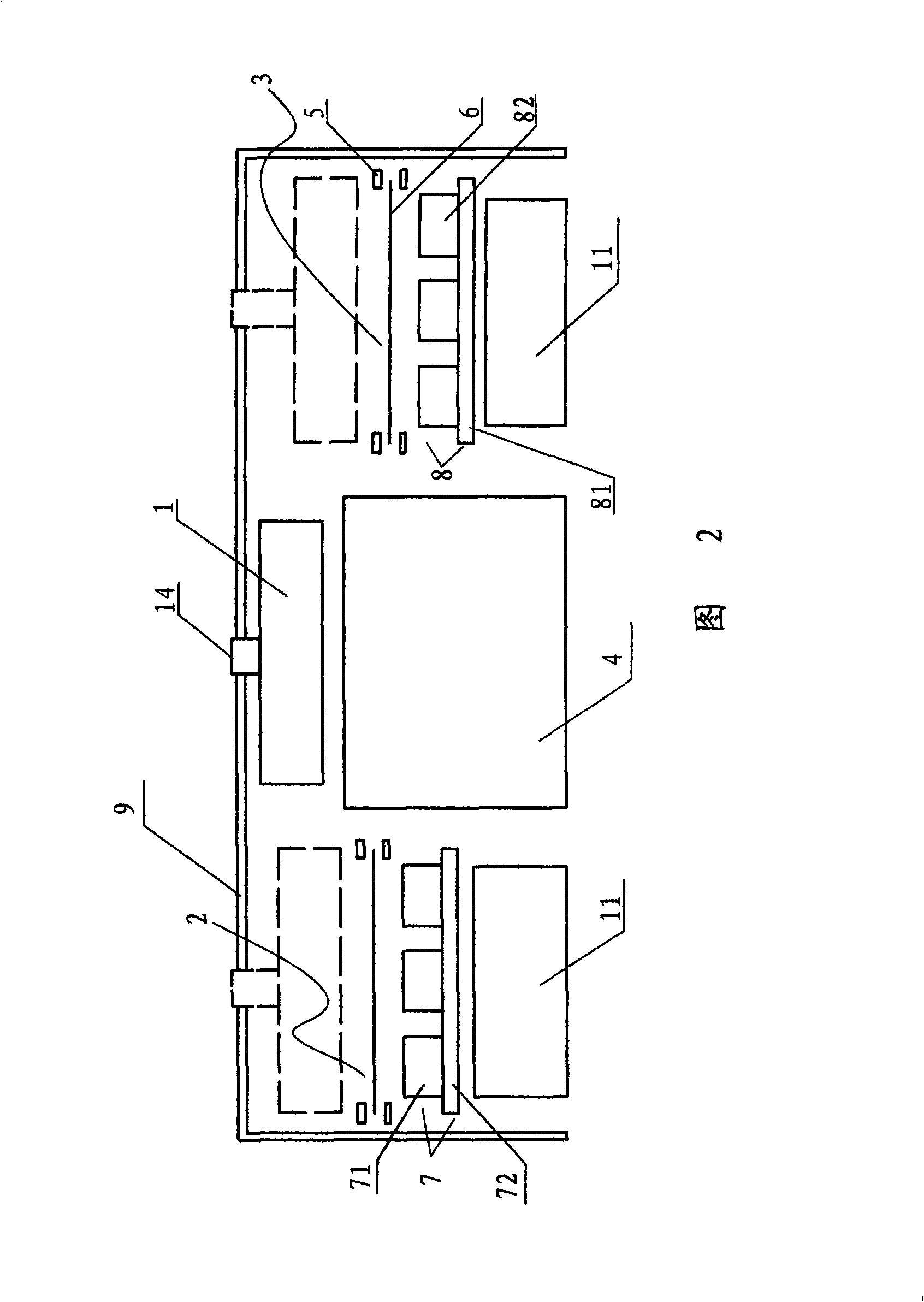

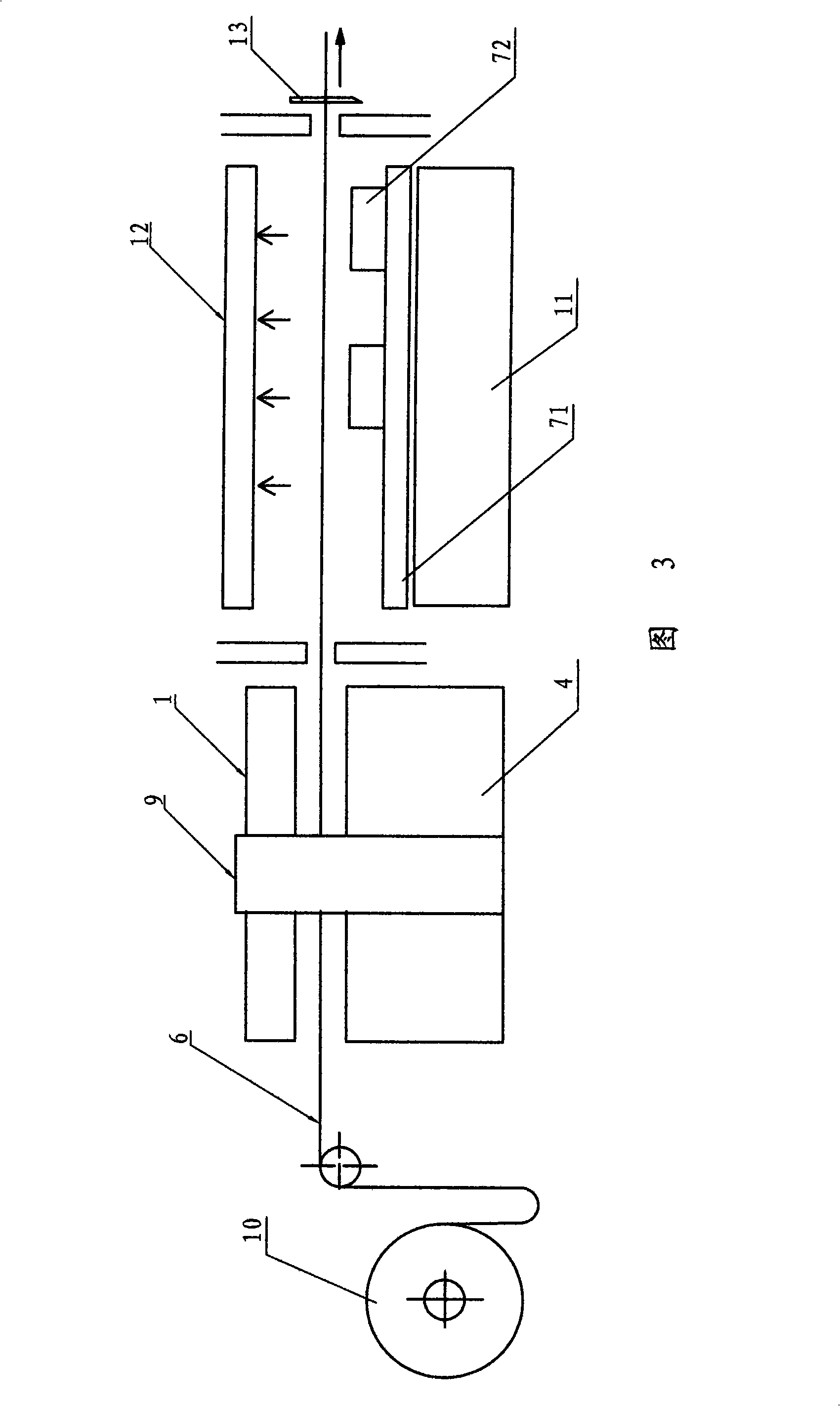

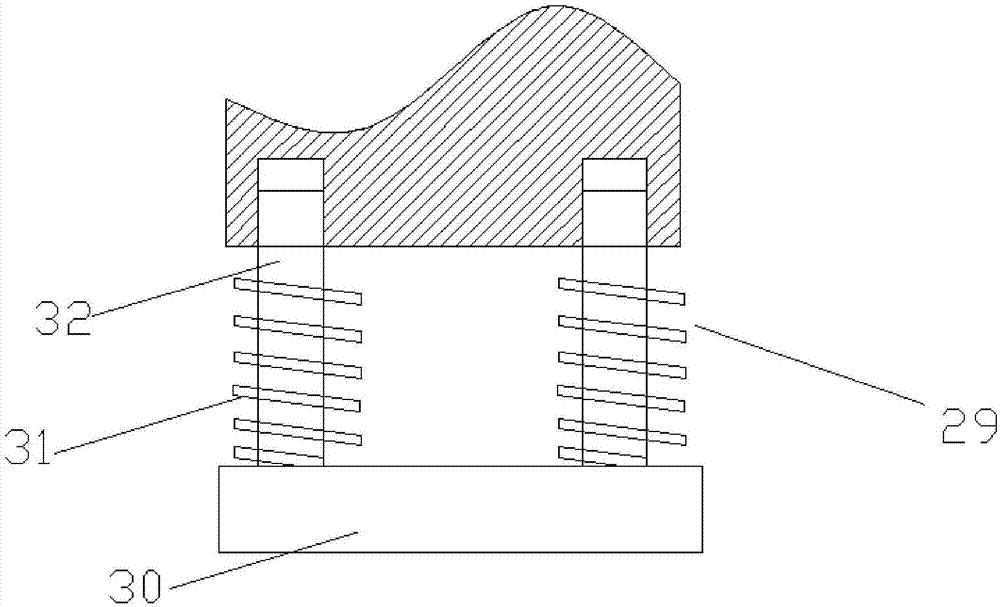

Efficient double-line suction plastic production method and device

The invention provides a high-efficiency dual-line plastic suction production method, comprising the steps as follows: 1) a bidirectional movable plastic suction heating furnace is arranged; the left side and the right side right below the plastic suction heating furnace are respectively provided with a set of vacuum forming processing line; 2) the plastic suction heating furnace is moved to the initial position and electrified to a given temperature, and the temperature is kept; 3) after the plastic suction heating furnace is transversely moved to one side right above the hot forming working position of the vacuum forming processing line, the plastic suction heating furnace vertically runs downwards to a given height H1 and remained for the time t1 so as to heat the material on the side of the processing line hot forming working position; 4) after the prearranged heating time t1 is reached, the plastic suction heating furnace runs upwards vertically and recovers transversely, and stops for a time t3; 5) the plastic suction heating furnace is moved to another processing line, runs downwards vertically by a height H2 and stops for a time t2; 6) the plastic suction heating furnace runs upwards vertically, transversely recovers and stops for a time t4; 7) the step 3) to step 6) are repeated. The invention also discloses a device which realizes the method of the invention.

Owner:DONGGUAN FUCAI PACKAGING PROD

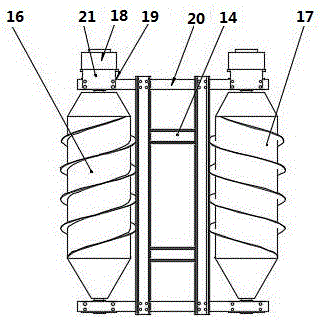

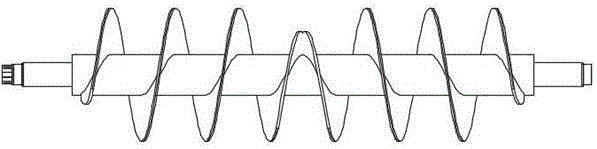

Efficient environmentally friendly automatic grinding machine for grinding ceramic raw materials

InactiveCN107876163AAvoid wastingAvoid noiseDispersed particle filtrationDirt cleaningElectric machineryIndustrial engineering

The invention discloses an efficient environmentally friendly automatic grinding machine for grinding ceramic raw materials. The efficient environmentally friendly automatic grinding machine comprisesa grinding machine body and supporting columns, and the supporting columns are located on the lower portion of the grinding machine body; a regrinding feeding opening and a feeding inlet are formed in the left and the right of the upper side of the machine body, a screw rod shaft is vertically arranged in the center of the interior of the grinding machine body, and grinding tools are correspondingly arranged on the left side and the right side on the outer wall of the screw rod shaft; and the top end of the screw rod shaft extends out of the outer side of the grinding machine body and is connected with a motor, baffles are vertically arranged around the interior of the grinding machine body, a screen net connected with a vibration device is arranged in the middle section of the interior of the grinding machine body, and the lower portion of the screen net is connected with a discharging opening. According to the efficient environmentally friendly automatic grinding machine for grinding the ceramic raw materials, automatic feeding and regrinding of the materials which are not completely grinded can be achieved, the grinding effect is good, the efficiency is high, automatic discharging and quantitative collecting can be achieved, dust generated in the grinding and discharging process can be collected, the environment is protected, and the raw materials are saved.

Owner:WUXI HUIOU CERAMIC CO LTD

Monascus selenium-rich millet powder and preparation method thereof

InactiveCN101816391AIt has the functions of lowering blood pressure, lowering blood sugar, anti-cancer and anti-cancerIncrease profit marginsFood preparationLovastatinSugar

The invention relates to monascus selenium-rich millet powder, which is fermented by using monascus as a fermentation strain and selenium-rich millet as fermentation substrate. The invention also provides a preparation method of the monascus selenium-rich millet powder. The monascus selenium-rich millet powder of the invention contains rich lovastatin and organic selenium. And monascus selenium-rich millet cakes made by using the millet powder have the functions of reducing blood fat, sugar and pressure and resisting and preventing cancers and are good products of homologous food and medicine.

Owner:FENYANG CITY KANGYUANFA FOOD DEV

Low temperature proanthocyanidin extracting process from grape seed

The present invention relates to the extraction of proanthocyanidin from plant material, and is especially the low temperature extraction of proanthocyanidin from grape seed. Grape seed as material is extracted with the mixed solution of methanol, normal butyl alcohol and hydrochloric acid; concentrated hydrochloric acid is added to reach the acid concentration of 0.1-0.8 wt%; and through filtering, recovering methanol and normal butyl alcohol, extraction with chloroform and normal butyl alcohol, recovering chloroform and normal butyl alcohol, low temperature deposition of the water solution at -20 deg.c to 0 deg.c and drying, the product is obtained. The present invention has the advantages of low organic solvent consumption, low cost, high safety, high product purity and yield, and simple technological process suitable for industrial production.

Owner:沈阳中科药业有限责任公司

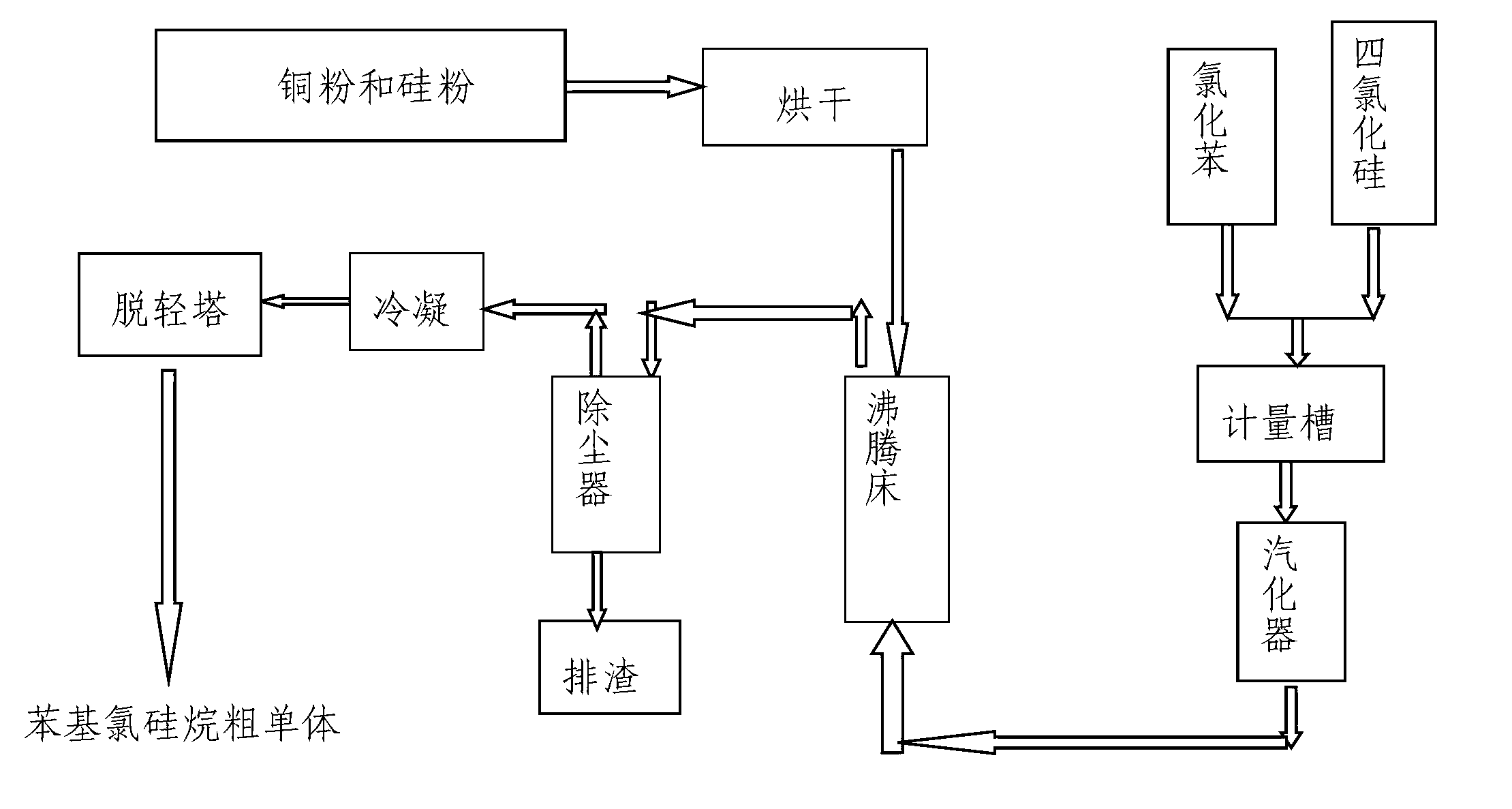

Preparation method of phenyl chlorosilane

ActiveCN102936261ALow costSimple processGroup 4/14 element organic compoundsPtru catalystDichlorosilane

The invention provides a preparation method of phenyl chlorosilane. The preparation method comprises the following steps: (1) a mixture of 4-8 parts by weight of benzene chloride and 0-1 part by weight of silicon tetrachloride is added into a reactor; (2) a contact is added into the reactor; and (3) the temperature of the reactor is controlled at 510-530 DEG C, and a reaction is carried out. According to the method provided by the invention, the addition of silicon tetrachloride as a co-catalyst is eliminated, such that catalyst cost is reduced, and processes are simplified. The yield of high-economic-value diphenyl dichlorosilane in a product is improved, and product economic value is improved. With the method provided by the invention, the benefit of phenyl crude monomer can be improved by approximately 15,000 Yuan / ton, such that the yield of high-added-value product is improved, and device profit margin is improved.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

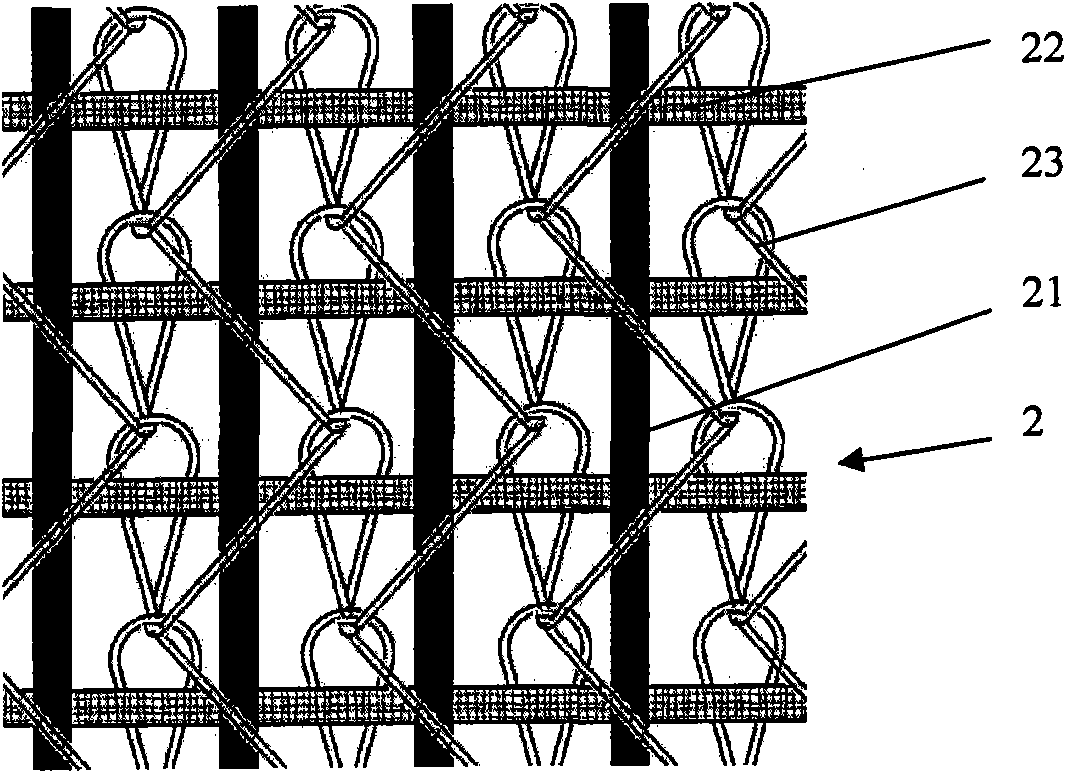

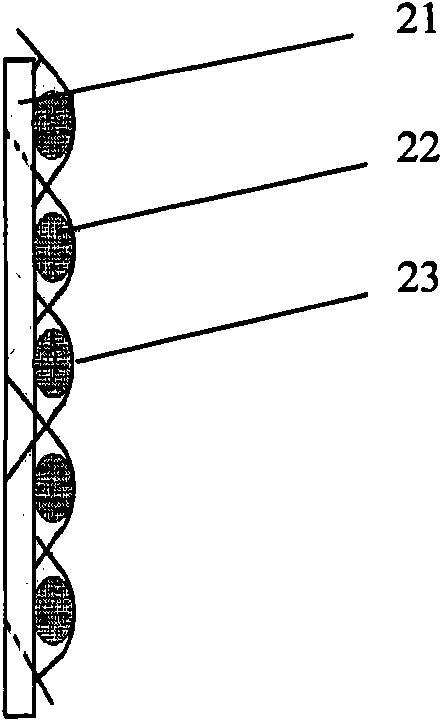

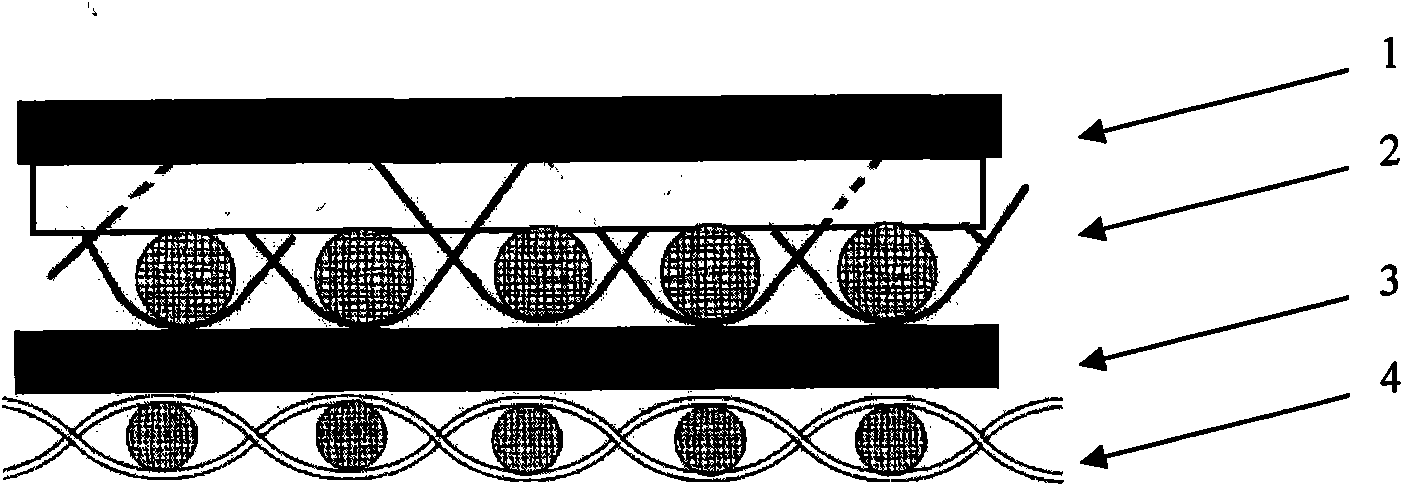

Conveyer belt taking warp-knitted bi-axial fabric as framework and manufacturing method thereof

InactiveCN101830335AHigh strength requirementsThere is no up and down staggered mutual pressure phenomenonConveyorsSynthetic resin layered productsSurface layerPolyvinyl chloride

The invention relates to a conveyer belt taking a warp-knitted bi-axial fabric as a framework and a manufacturing method thereof. The conveyer belt sequentially comprises a woven fabric, a polyvinyl chloride laminated layer, the warp-knitted bi-axial fabric and a polyvinyl chloride surface layer from bottom to top. The manufacturing method comprises the following steps of: finalizing the design of the woven fabric, carrying out primary coat, and coating polyvinyl chloride paste resin to form the laminated layer; finalizing the design of the warp-knitted bi-axial fabric, jointing with the woven fabric of the bottom layer; and carrying out surface layer coating on the warp-knitted bi-axial fabric to form the conveyer belt structure of a double-framework double- polyvinyl chloride layer. The utilization rate of the intensity of warp in the warp-knitted bi-axial fabric reaches the highest, and the warp is always in a straight state and does not have creep relaxation. Self-cementing between the PVC (polyvinyl chloride) surface layer and the PVC laminated layer can be formed, the primary coat process is left out, the racking strength is greatly enhanced, the requirements on roll diameter and tension length of a conveyer are reduced, the service life is improved, and the cost is 40% lower than the woven fabric.

Owner:SHANGHAI YONGLI BELTING +1

Bio-refinery method for co-producing multiple products by using lignocellulose as raw material

InactiveCN106191135AIncrease added valueHigh carbon contentBiofuelsFermentationActivated carbonSolid acid

The invention provides a bio-refinery method for co-producing multiple products by using lignocellulose as a raw material. The bio-refinery method comprises the steps that raw materials are pretreated by adopting a formic acid water solution the mass concentration of 50-80%, effective separation of cellulose, hemicellulose and lignin in the raw materials is achieved, further the cellulose is converted into ethanol, the lignin is converted into active carbon and solid acid, and the hemicellulose is converted into furfural. The bio-refinery method can achieve the diversity and high value conversion of the raw materials, remarkably improves the economical efficiency of the process, and the formic acid can be recycled and has remarkable environmental benefits.

Owner:TSINGHUA INNOVATION CENT IN DONGGUAN +1

Polyester fully-drawn slub yarn and preparation method thereof

InactiveCN102828278AGood orientationEnsure productivityNew-spun product collectionFilament forming substance formingPolyesterBreaking strength

The invention discloses a polyester fully-drawn slub yarn and a preparation method thereof. On the basis of not changing the conventional FDY (fully-drawn yarn) production device, the polyester fully-drawn slub yarn is produced by using a one-step method implemented through adding a polymethyl methacrylate additive (mass percentage: 0.5-3.0%) into a polyester chip and then carrying out drawing on an obtained mixture at a drawing speed of 4600-5000m / min. The radial fineness ratio of the obtained slub yarn is 1.20-1.60 / l, the length of a thick section of the slub yarn is 15-40mm, and the slub density is 5-15 / m; and the breaking strength is 2.70-3.40 cN / dtex, and the breaking elongation is 40-80%. The polyester fully-drawn slub yarn prepared by using the technical scheme of the invention has the characteristics of high output, low cost, good quality, stable performance, high added values of products, and obvious price-performance advantages, and achieves the purposes of energy conservation, emission reduction, environmental protection, clean production and benefit incensement.

Owner:SUZHOU UNIV

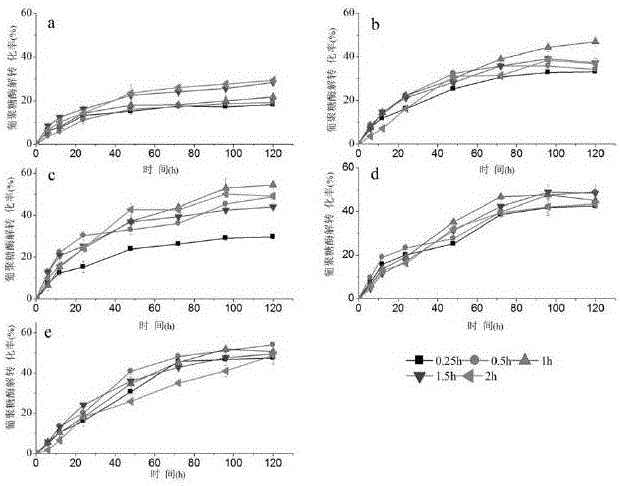

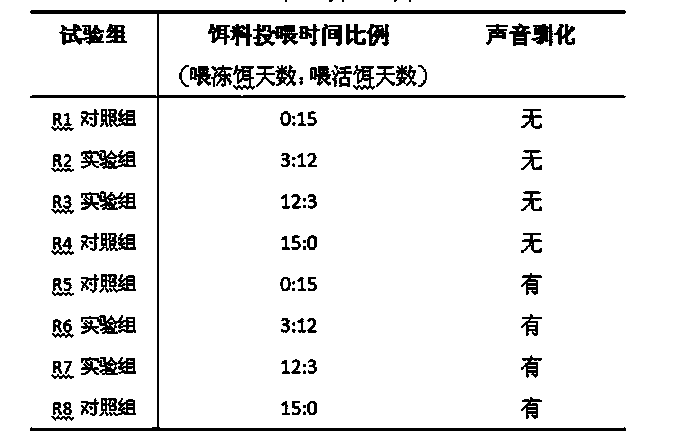

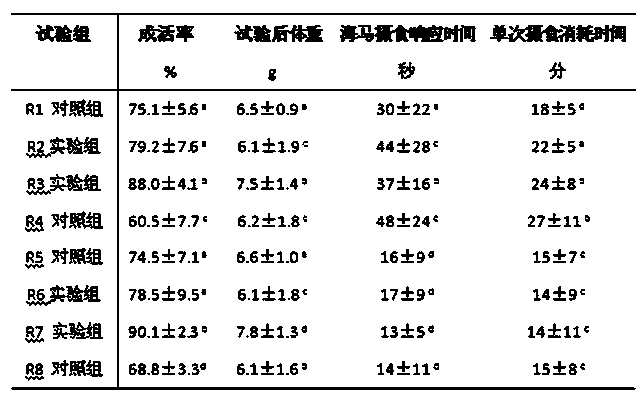

Optimized feeding method for adult stage of sea horses

ActiveCN103430880AMeet the nutritional needs of rapid growthReinforcement feeding behaviorClimate change adaptationPisciculture and aquariaFisheryZoology

The invention discloses an optimized feeding method for the adult stage (2 to 6 months old) of sea horses, which includes the reasonable arrangement and optimization of a sea horse culture environment, feed types, feeding time, feeding amount, a feeding method and a feed processing method. When the feeding method is adopted, the survival rate and growing rate of sea horses at the growing stage are remarkably increased, meanwhile, the feed coefficient is decreased, the overall sea horse culture efficiency can be increased ultimately, and the degree of ecological pollution can be decreased.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Polycarboxylate-type water reducer monomer polyether and preparation method for midbody thereof

The invention discloses a polycarboxylate-type water reducer monomer polyether and a preparation method for a midbody thereof. The preparation method for the polycarboxylate-type water reducer monomer polyether midbody, provided by the invention, comprises the steps of mixing an enol initiator with water content of less than 0.05% with a catalyst and reacting under the temperature of below 35 DEG C and under a nitrogen bubbling condition, wherein stirring is not required in the mixing and reaction processes of the enol initiator and the catalyst. According to the preparation method for the polycarboxylate-type water reducer monomer polyether midbody, provided by the invention, the content of the side reactant can be obviously reduced, the damage to the device can be reduced, the production process is safe, the operation method is simple and convenient and the prepared polycarboxylate-type water reducer monomer polyether contains few impurities.

Owner:SHANGHAI DONGDA CHEM

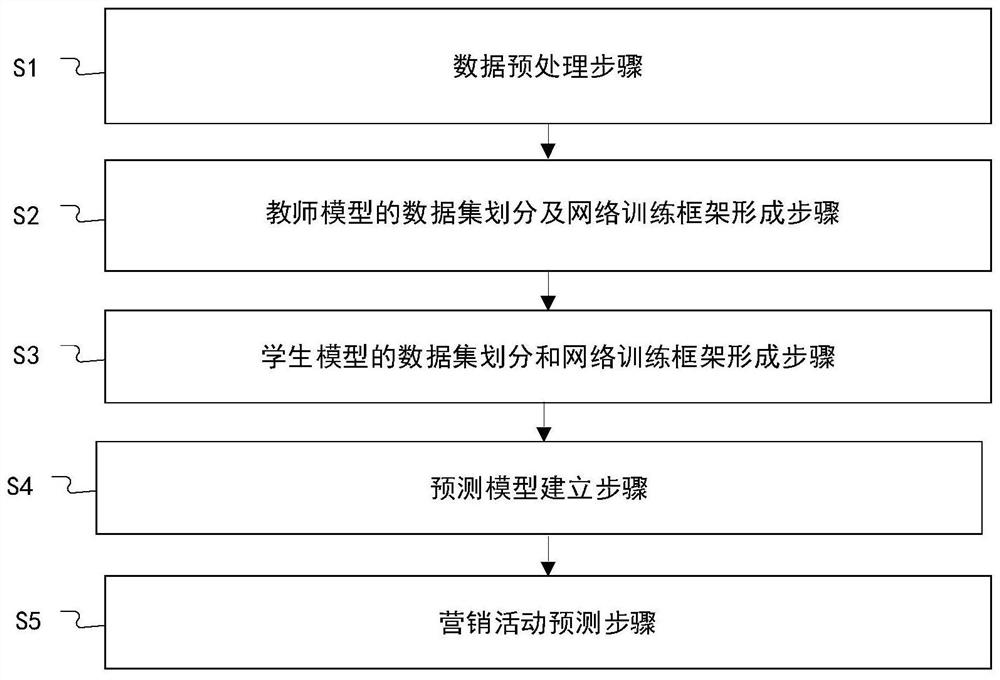

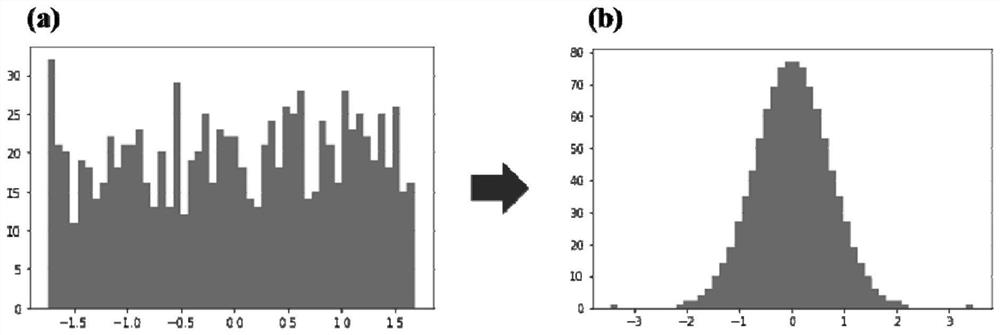

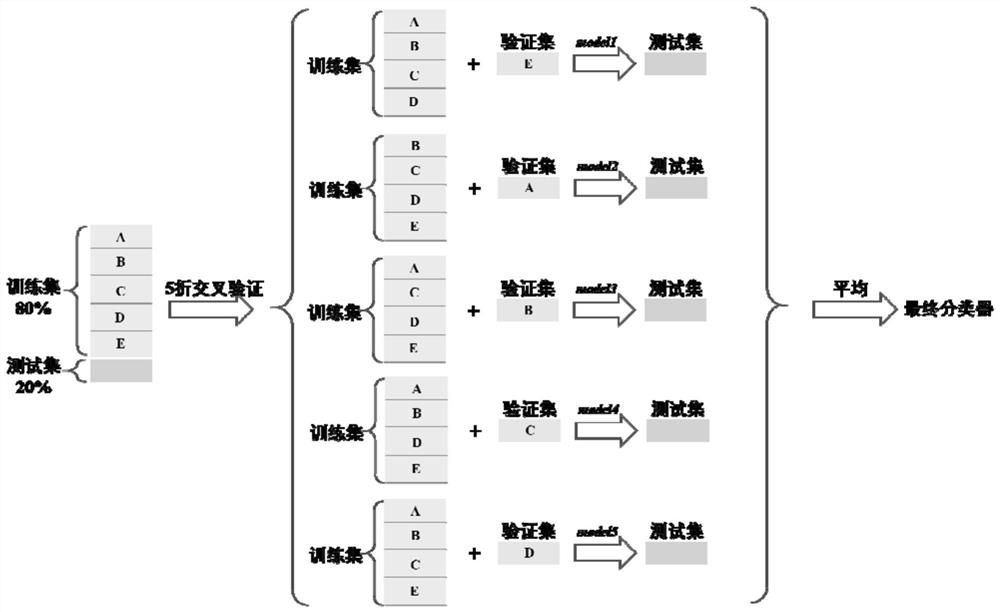

Marketing activity prediction model structure and prediction method based on knowledge distillation

PendingCN112967088AImprove robustnessImprove accuracyAdvertisementsCharacter and pattern recognitionData setPredictive methods

The invention discloses a marketing activity prediction method based on knowledge distillation. The method comprises the steps of data preprocessing, data set division and network training framework formation of a teacher model, data set division and network training framework formation of a student model, prediction model establishment, marketing activity prediction and the like. The method includes following steps: firstly, constructing a relatively complex teacher model Net-T with a residual neural network as a core, and then establishing a student model Net-S formed by a simple neural network; weighting a soft label obtained by training a teacher model Net-T at a high temperature and a hard label obtained by training a student model Net-S at the same temperature to obtain a total loss function of knowledge distillation; by taking the total loss function as a target function of a student model Net-S during actual deployment, training to obtain a final neural network model, and performing prediction, wherein the result shows that the hybrid model effectively expands the application of deep learning to advertisement calculation and recommendation system algorithms, so that the method significantly improves the accuracy of user click prediction.

Owner:上海数鸣人工智能科技有限公司

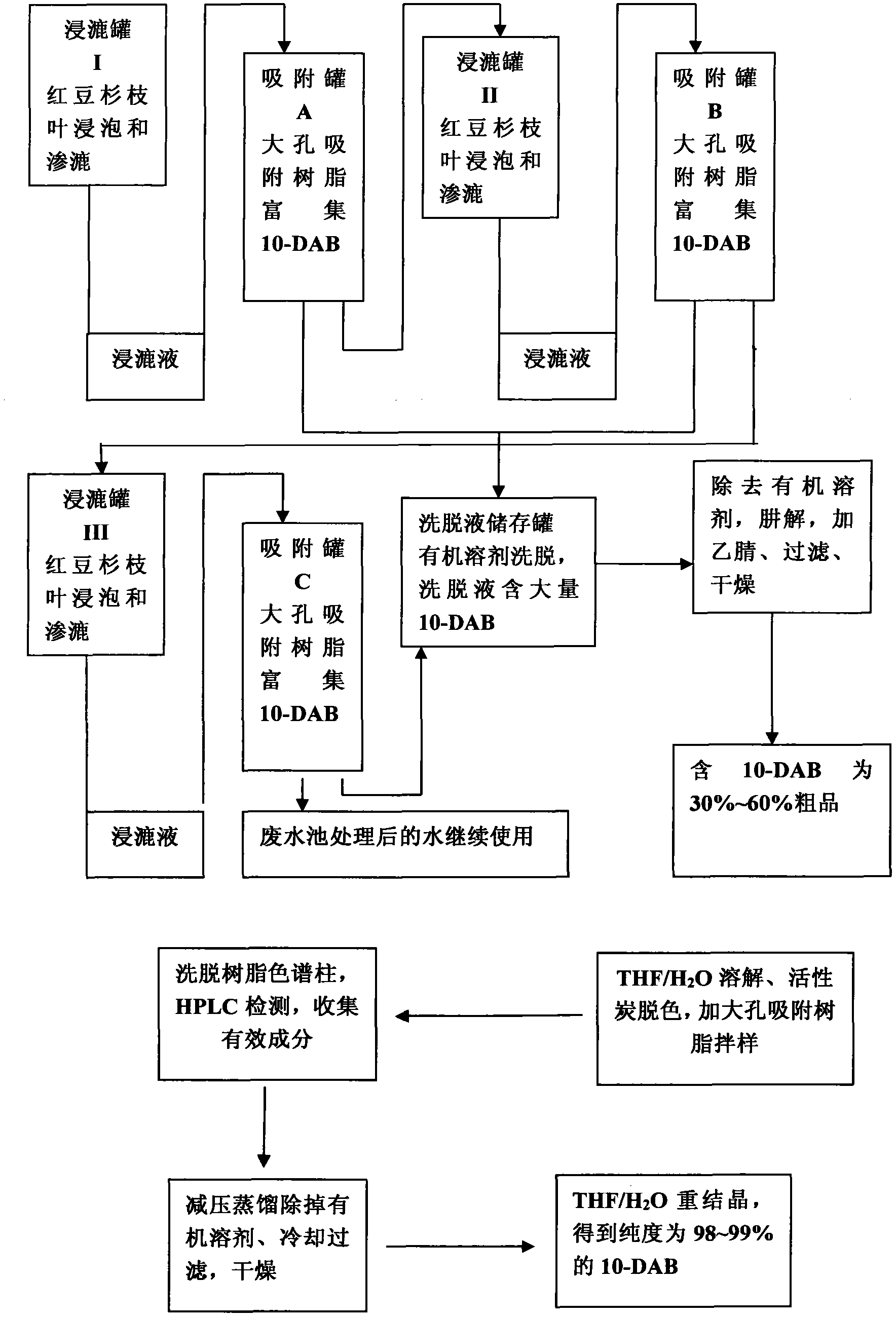

Method for extracting 10-DAB from taxus chinensis according to continuous leaching adsorption enrichment method

ActiveCN103508984ALess investmentEmission reductionOrganic chemistryOrganic solventEnrichment methods

The invention relates to a method for extracting 10-DAB from taxus chinensis according to a continuous leaching adsorption enrichment method. According to the method, the leaching extraction technology and the macroporous resin adsorption technology are combined; the method comprises the following steps: dissolving 10-DAB-related components in taxus chinensis leaves into water through the leaching with weak acidic water, obtaining an oily product after the completion of the resin enrichment and the hydrazinolysis, adding acetonitrile, stirring, and precipitating a solid to obtain a crude 10-DAB product; using a resin chromatographic column to perform purification and recrystallization on the crude 10-DAB product to obtain a pure 10-DAB product with the purity of higher than 98%. Through the adoption of the method, the 10-DAB extraction rate from high-10-DAB-content leaves can be higher than 90%, the 10-DAB extraction rate from low-10-DAB-content leaves can be higher than 75%,and with the 10-DAB converted from the hydrazinolysis, the 10-DAB extraction rate reaches 150-300%; the method has relatively low requirements on equipment, can reduce discharge of an organic solvent, is small in investment, enables the 10-DAB productivity of dried taxus chinensis leaves with relatively low 10-DAB content to reach 0.08-0.15% that can not be obtained by adopting the traditional technology.

Owner:云南罗瑞生物科技有限公司

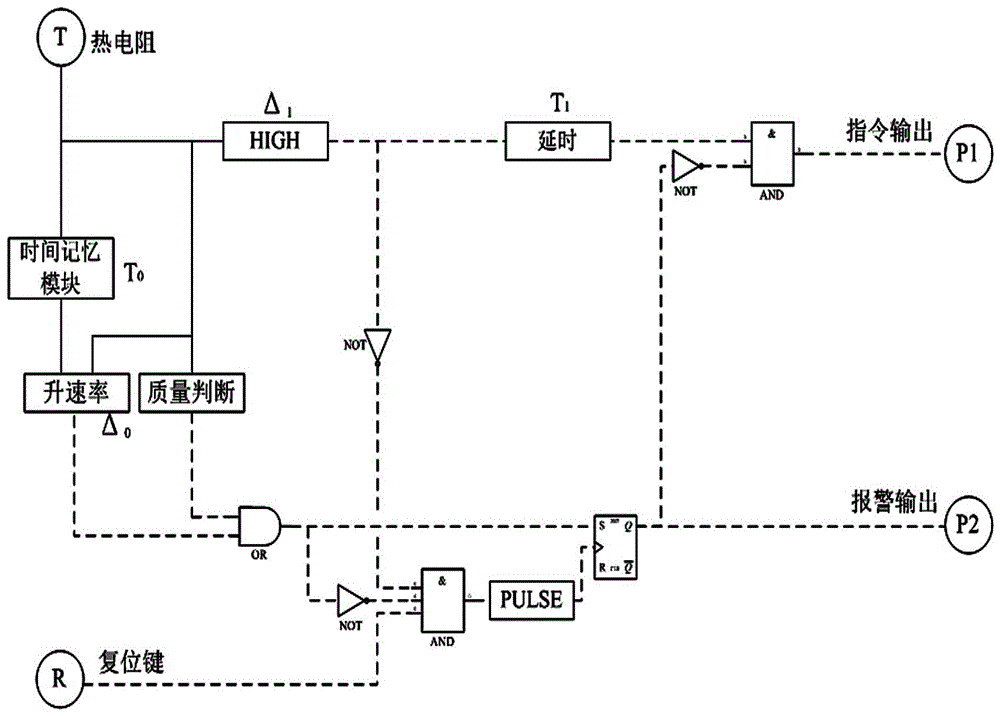

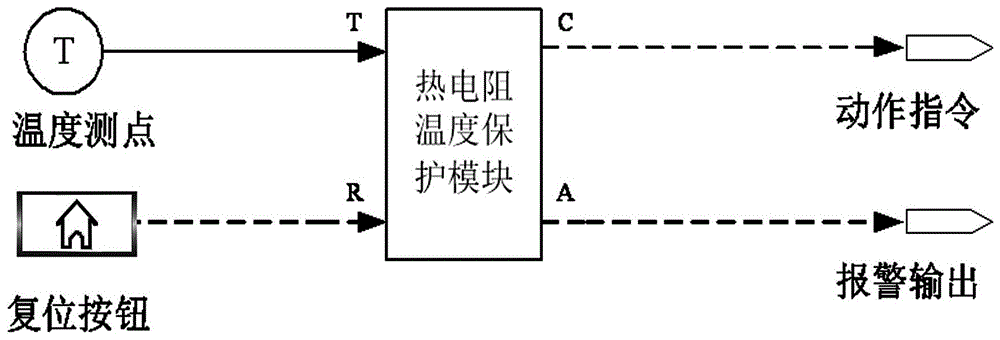

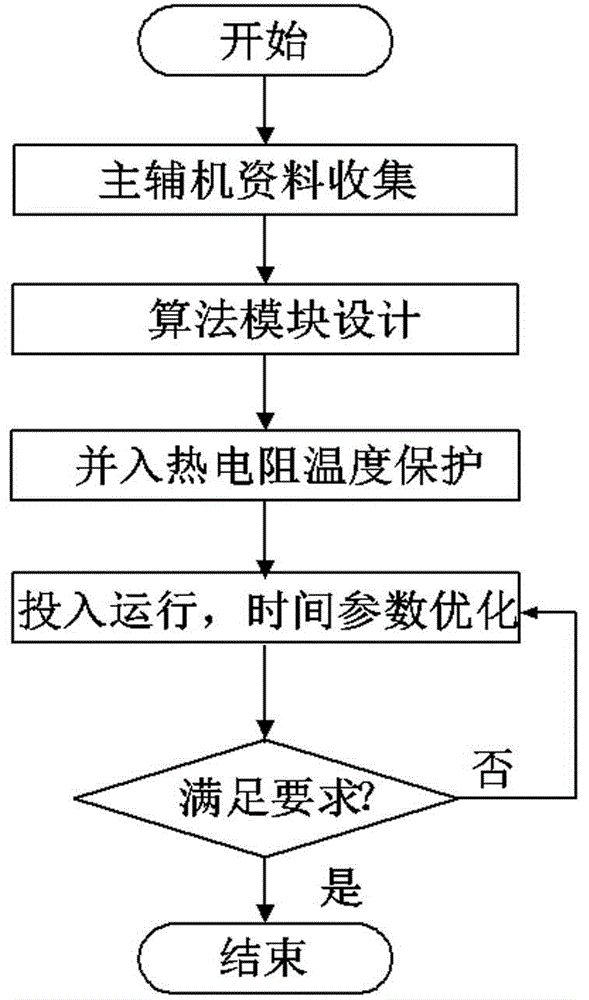

Method for preventing thermal resistor protection failure of thermal power plant DCS

InactiveCN106502229AWith a clear purposePerfect process method systemTotal factory controlProgramme total factory controlAutomatic controlEngineering

The invention belongs to the technical field of thermal generator unit automatic control, especially relates to a method for preventing thermal resistor protection failure of a thermal power plant DCS (Distributed Control System), and specifically relates to a method for preventing thermal resistor temperature protection failure of a thermal generator set. The method can be used to reform a thermal generator unit thermal resistor temperature protection system so as to improve the ability of the unit thermal process protection system to prevent misoperation. A thermal resistor temperature protection system of main and auxiliary equipment of a thermal power plant is taken as an optimized design object, false signals produced due to open circuit or virtual connection of a thermal resistor signal line are shielded, and the phenomenon that the temperature signal of the thermal resistor rises too fast and causes equipment mis-tripping is prevented. The method has the distinctive characteristics of simple field debugging process and easy project implementation. The reliability of the unit DCS thermal process protection system is improved effectively. The occurrence probability of misoperation events is reduced. The occurrence of unit tripping and equipment damage accidents is reduced. The number of non-stop times of the unit is reduced. The cost is lowered. The profit margin is improved. The method is of importance significance to improving the operation safety and economy of thermal generator units.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +1

Process for preparing biomass fuel by using rural town domestic waste and agricultural and forestry waste

ActiveCN108435754ALess investmentLow costSolid waste disposalExcrement fertilisersLiquid wasteSludge

The invention discloses a process for preparing biomass fuel by using rural town domestic waste and agricultural and forestry waste. The process comprises the steps of step one, waste leachate treatment and foul smell deodorization; step two, waste screening, sorting and coarse crushing; step three, non-organic matter magnetic separation, winnowing and fine crushing; step four, agricultural and forestry waste crushing and screening; step five, stirring of waste combustible materials, agricultural and forestry waste, sludge and water, compression molding, airing and biomass fuel obtaining; andstep six, waste organic matter adding of livestock and poultry manure, and organic fertilizer obtaining. According to the process, the biomass fuel can be directly used in a boiler, and the problem that the livestock and poultry manure pollutes the environment in a livestock farm is solved through the organic fertilizer; for the construction of waste treatment plants, the investment is small, thecost is low, and implementation is easy; the agricultural and forestry waste is collected with paying performed, so that the income of farmers is increased, and the pollution is reduced; the profit rate is high, and operating can last without government subsidy; the waste gas, the waste liquid and the waste residue are subjected to the environmental protection treatment so that new pollution can be avoided.

Owner:于继林

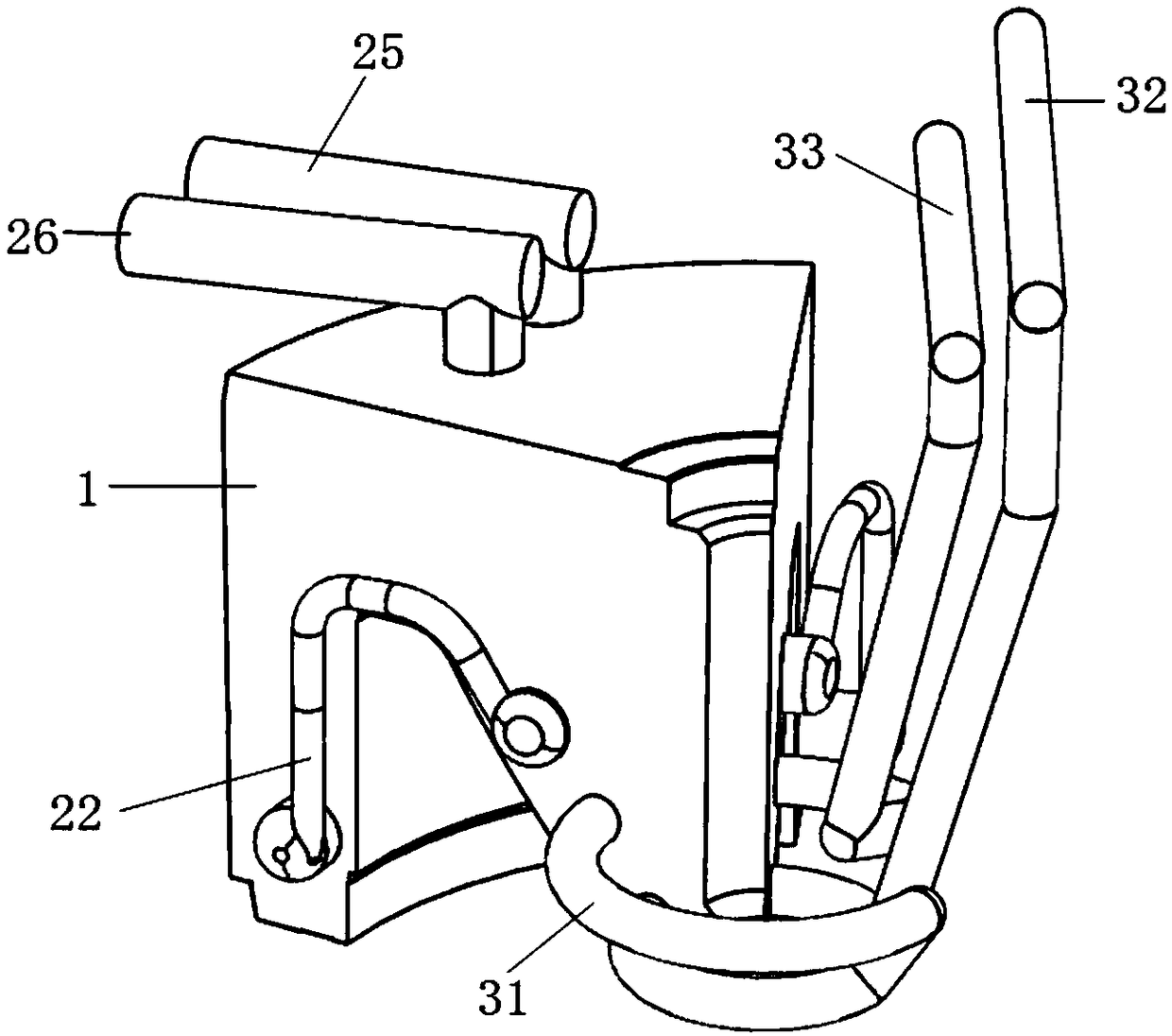

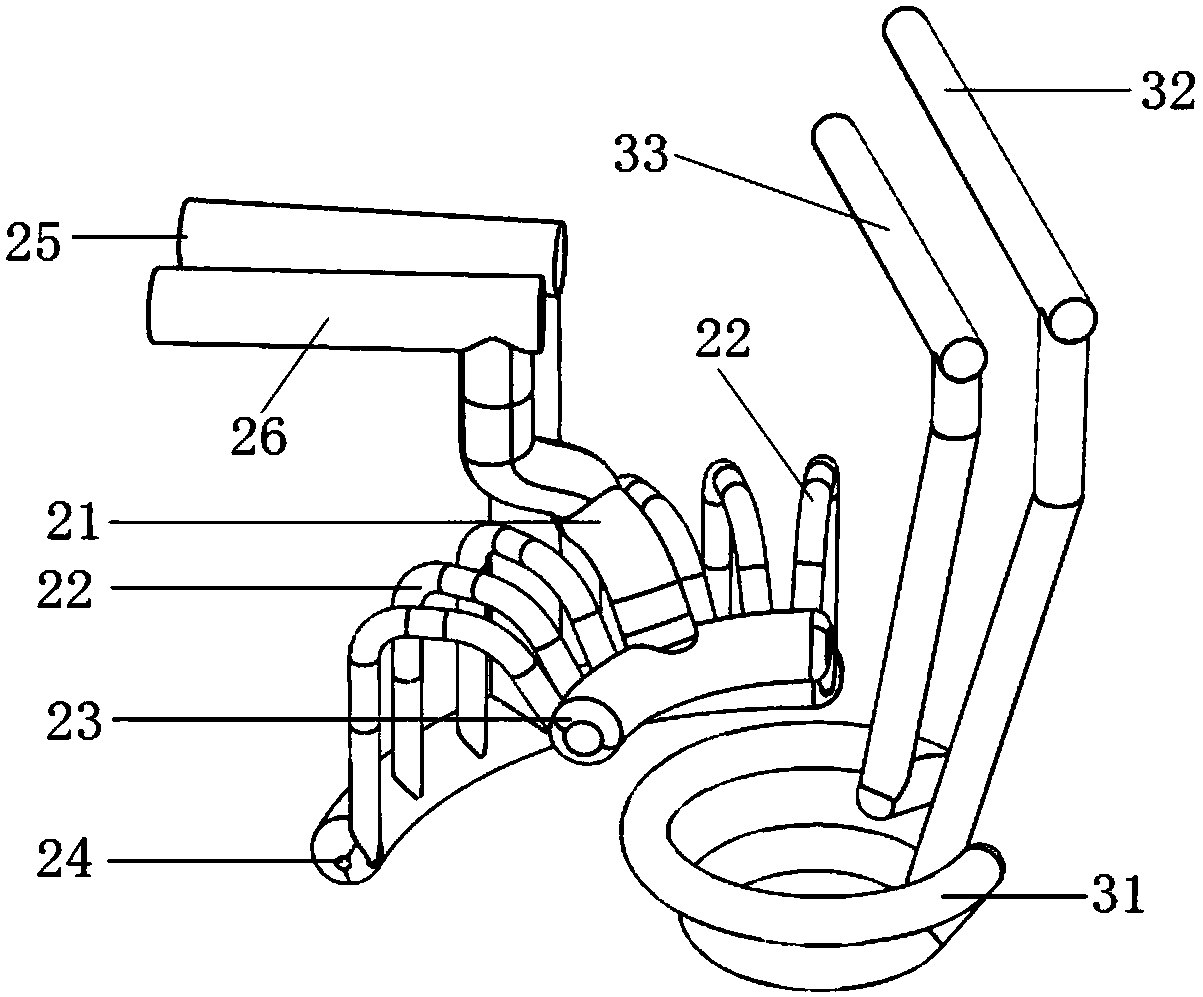

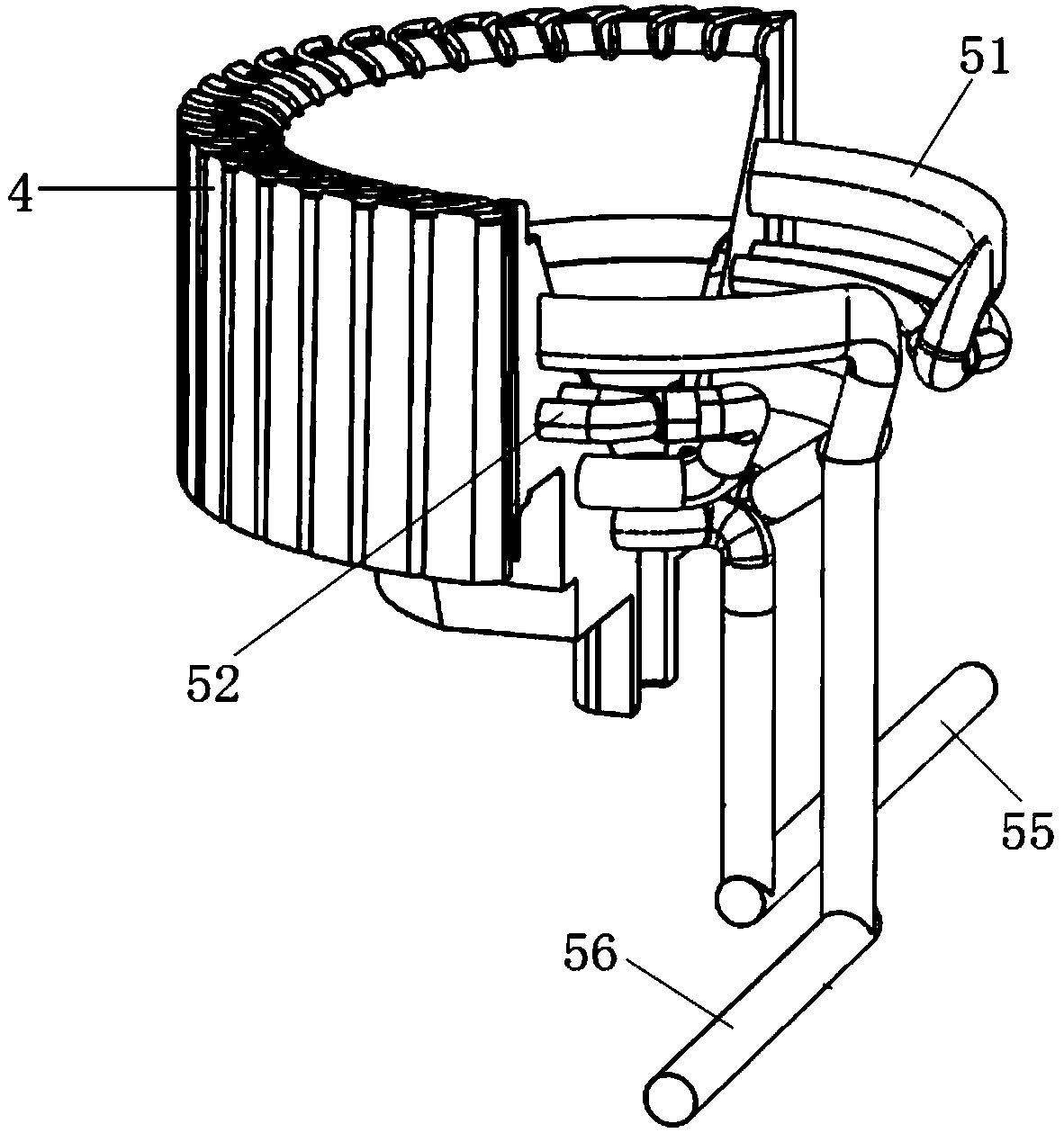

Plastic impeller mold shape follow-up waterway cooling system

PendingCN108501336AOptimized shape and shunt diameterImprove cooling effectDomestic articlesImpellerEngineering

The invention discloses a shape follow-up waterway cooling system in the technical field of plastic impeller mold cooling. The shape follow-up waterway cooling system comprises a mold cavity and a mold core. A shape follow-up connection waterway, a shape follow-up distribution waterway, an inner side arc-shaped waterway, an outer side arc-shaped waterway and a spiral annular waterway are all arranged in the mold cavity. The mold cavity outer side arc-shaped waterway is arranged on the outer side of the mold cavity. The mold cavity inner side arc-shaped waterway and the spiral annular waterwayare arranged on the inner side of the mold cavity. An outer side water outlet pipeline is connected with the inner side arc-shaped waterway through the shape follow-up connection waterway. A mold coreupper side annular waterway, a mold core parallel-connection waterway and a mold core lower side annular waterway are arranged in the mold core sequentially from top to bottom. In the shape follow-upwaterway cooling system, the waterways can be distributed in a mold kernel evenly, in this way, the best product forming temperature can be ensured, the product injection molding period of about 60-70 seconds in a traditional cooling scheme can be shortened to about 40-50 seconds through even regulation of mold temperature, and the defect rate caused by uneven product cooling can also be lowered.

Owner:上海迪质特信息科技有限公司

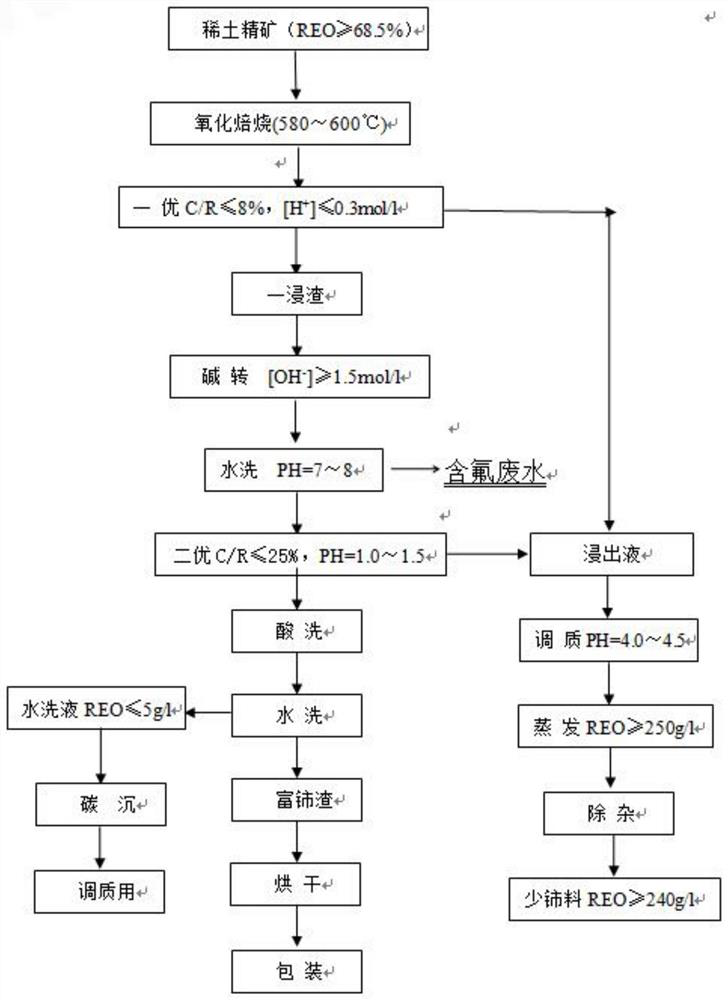

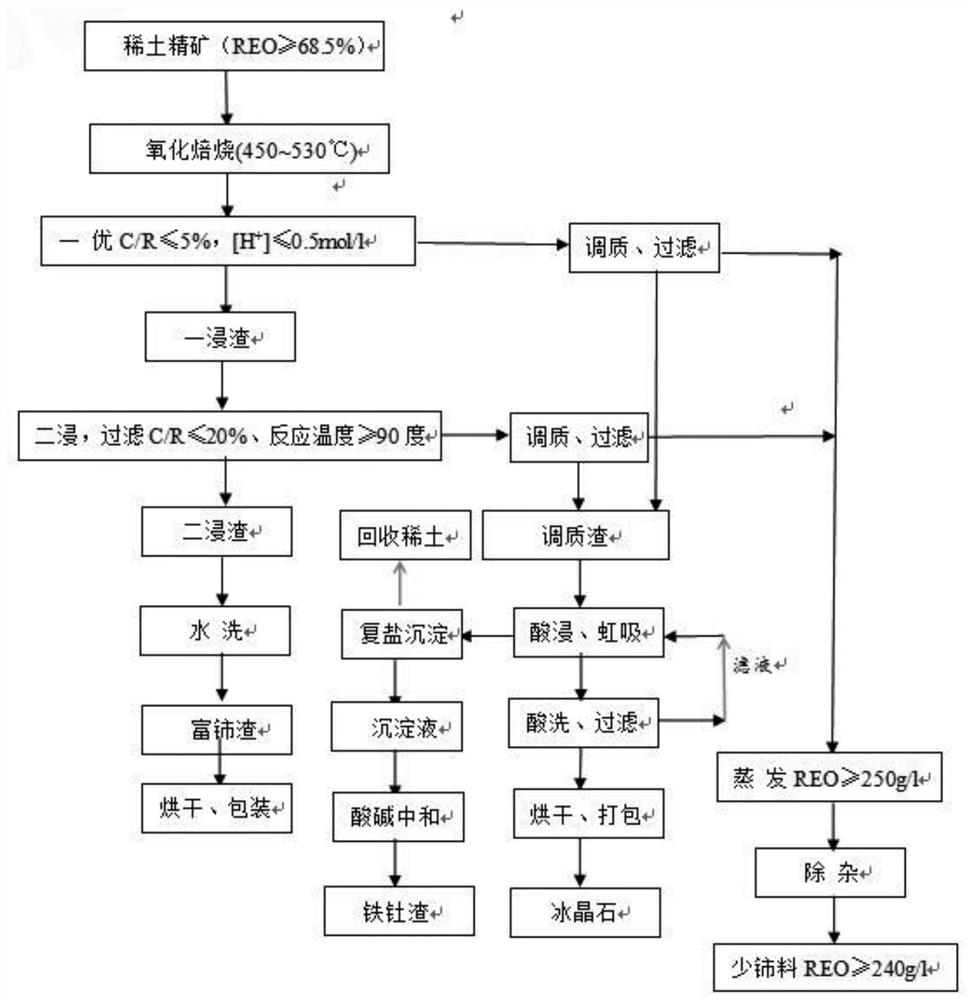

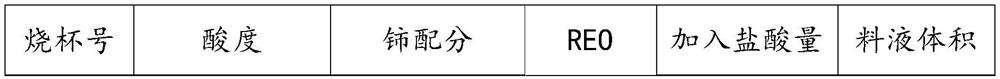

Method for extracting rare earth and recovering fluorine resource from bastnaesite

ActiveCN113667841AEfficient recyclingSave energyRare earth metal sulfatesAluminium fluoridesPregnant leach solutionSewage treatment

The invention discloses a method for extracting rare earth and recycling fluorine resources from bastnaesite. The method comprises the following steps that S1, oxidizing roasting is carried out on rare earth concentrate, and then hydrochloric acid leaching is carried out to obtain primary leaching liquid and primary leaching residues; S2, clear water and a hydrochloric acid complexing agent are added into the primary leaching residues, and secondary leaching residues and secondary leaching liquid are obtained after filtering; S3, quenching and tempering and filtering treatment are carried out on the primary leaching liquid and the secondary leaching liquid, and quenched and tempered residues are obtained; and S4, the quenched and tempered residues are dissolved by using hydrochloric acid, filtering and separating are carried out to obtain filter residues, chlorohydric acid pickling is carried out on the filter residues for multiple times, and then drying and packaging are carried out. According to the method, the fluorine resources are recovered by adding the hydrochloric acid complexing agent and the like, alkali conversion is not needed, energy is greatly saved, the production process is simplified, the product cryolite with high added value is formed, due to the fact that high-salt wastewater is not generated, a high-salt recovery system is not needed, the sewage treatment cost is greatly reduced, and the defects in the prior art are overcome.

Owner:四川省冕宁县方兴稀土有限公司

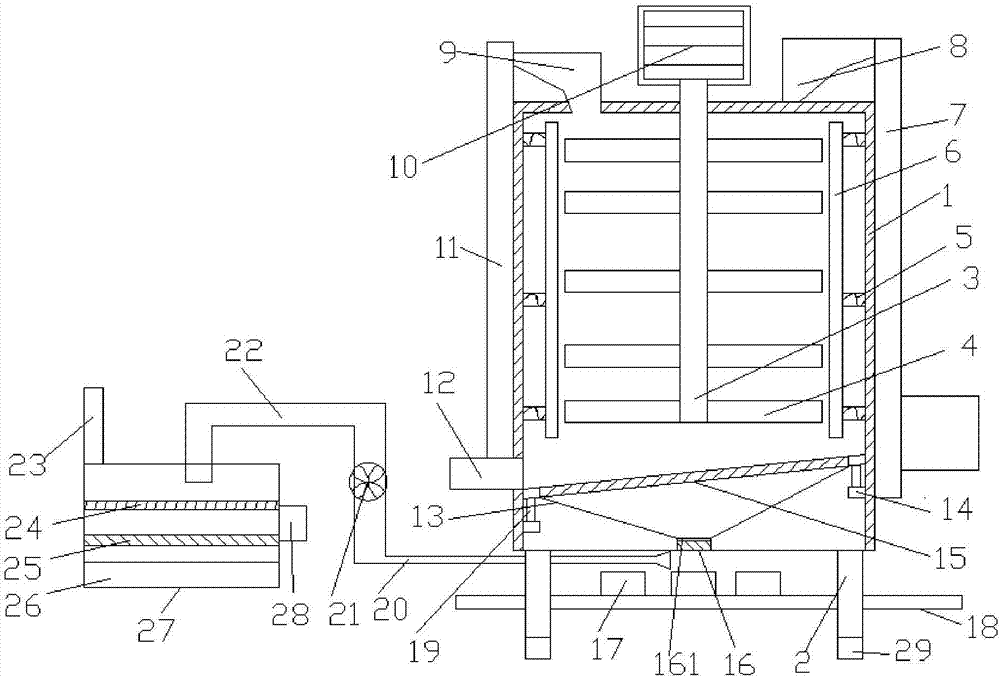

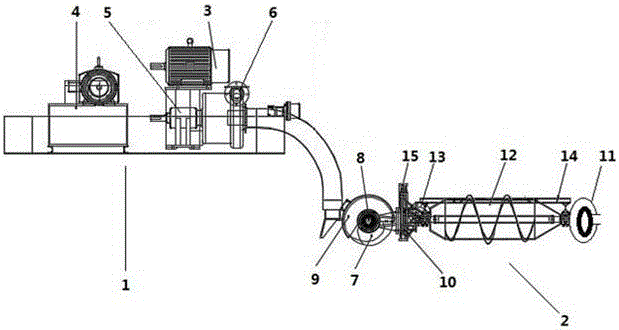

Automatic underwater silt remover

InactiveCN106545042AEasy to controlLow powerMechanical machines/dredgersUnderwater explosionControl system

The invention relates to an automatic underwater silt remover, and belongs to the field of underwater silt removing. The automatic underwater silt remover is composed of two portions including a water portion (1) and an underwater portion (2); the water portion (1) and the underwater portion (2) are in telescopic flexible connection; the water portion (1) comprises a silt pump (3), a hydraulic station (4), a small air pump (5), a winch (6) and a control system; the underwater portion (2) comprises a material collection transfer device (7), a material collection motor (8), a material collection protection cover (9), a material collection lifting device (10), a material collection device (11) and a propeller (12); the material collection device (7) is hinged to the propeller (12), and the propeller (12) is of a hollow structure. The problems that in the prior art, silt removing is not thorough, and the silt removing depth is limited are solved, and the silt remover is mainly applied to large deep underwater silt removing work.

Owner:NUCLEAR IND YANTAI TONCIN IND GRP CO LTD

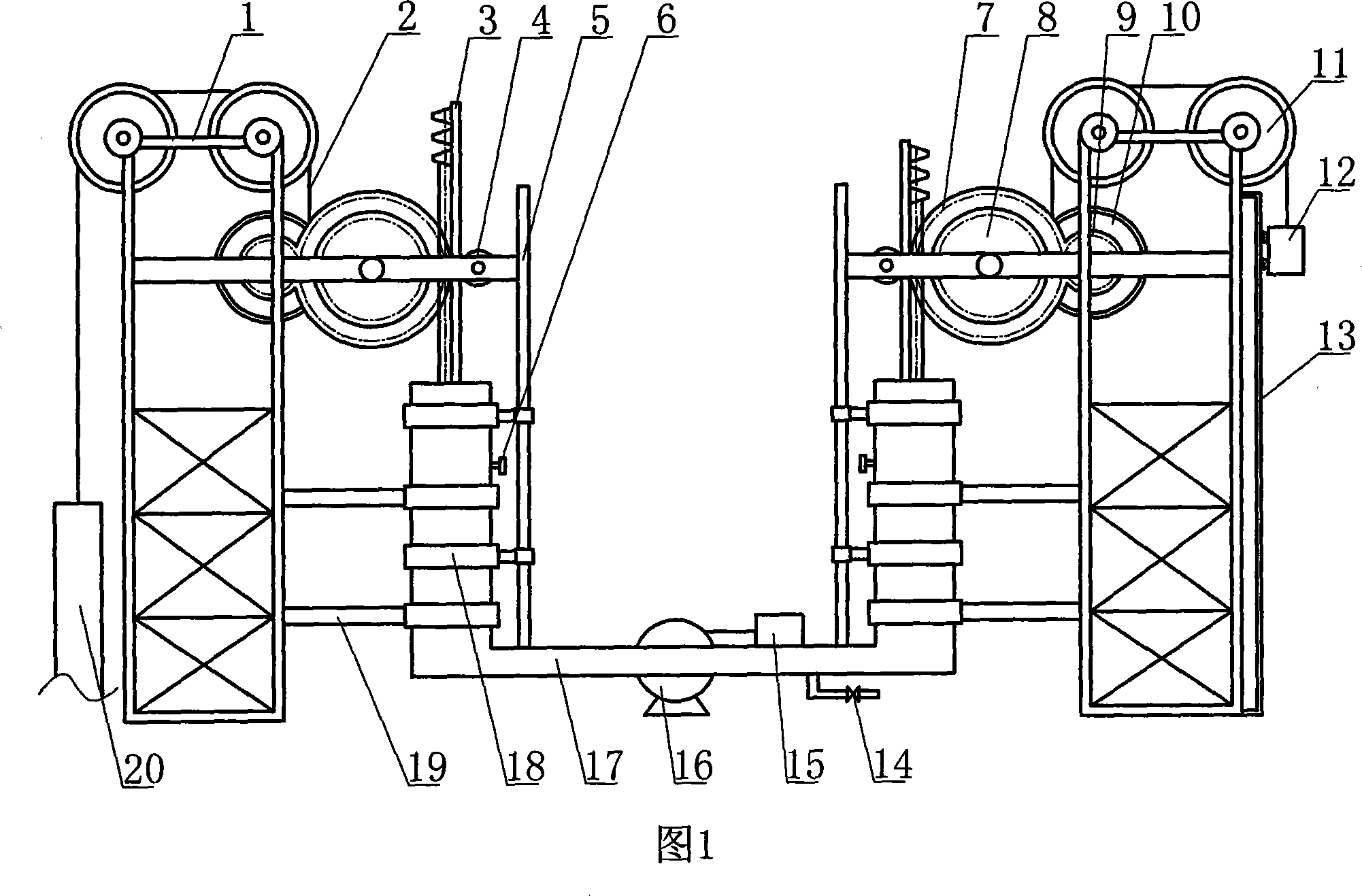

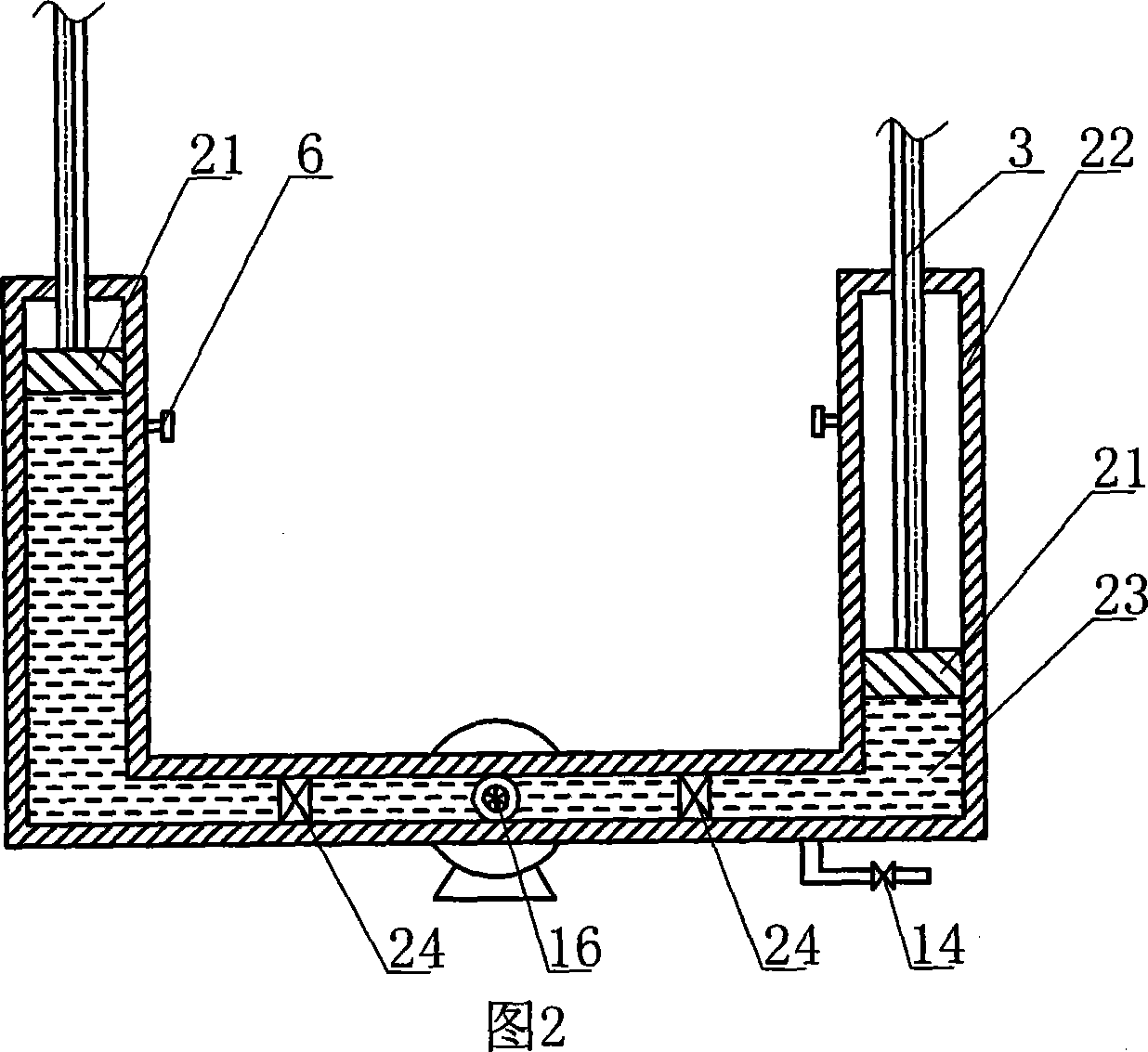

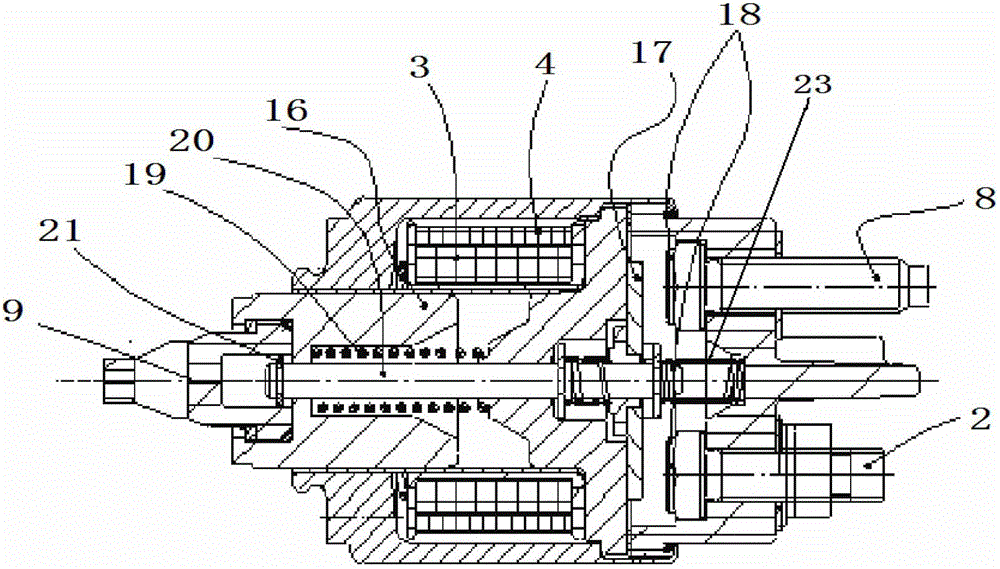

Stroke adjustable energy-saving hydraulic pumping unit

InactiveCN101078340AAdjustable strokeAdjustable stroke timesFluid removalFluid gearingsPunchingHydraulic pump

The invention relates to an energy-saving hydraulic oil pumping unit with adjustable stroke used in oil field, comprising frame, gear group, hydraulic transmission mechanism, rack, head sheave, suspended-weight rope and oil pumping bar. Two frames are set at two sides of hydraulic transmission mechanism symmetrically. A gear group and two head sheaves are set on each frame. Two gear groups are mated with racks set at two ends of hydraulic transmission mechanism respectively. The gear group draws the oil pumping bar through the suspended-weight rope and the head sheave. Thereinto, the hydraulic transmission mechanism comprises communicating vessel, piston and hydraulic pump. A hydraulic pump is fixed in the communicating vessel and two pistons are set in cavities at two ends of communicating vessel respectively. Driving liquid is poured between two pistons in cavities of communicating vessel. The invention is provided with simple structure, scientific and reasonable design, adjustable stroke and punching time, convenient maintenance, dismounting and use, safe operation, high liquid production volume, little energy consumption and low operating cost. It is also provided with higher innovation.

Owner:丁长良

Method for enhancing nitration reaction rate of 2,5-dichloronitrobenzene

InactiveCN104230716AEasy to separate, recycle and reuseSolve pollutionNitro compound preparationReaction rateNitration

The invention discloses a method for enhancing nitration reaction rate of 2,5-dichloronitrobenzene, which is characterized by adding a nano solid acid catalyst ZrO2 / SO4<2-> into a reaction kettle filled with paradichlorobenzene and dropwisely adding nitric acid to perform nitration reaction. The catalyst ZrO2 / SO4<2-> used in the method is a green solid acid catalyst, and is used instead of concentrated sulfuric acid to solve the problem of secondary environmental pollution of waste acids; the catalyst ZrO2 / SO4<2-> has more efficient nitration reaction catalysis capacity, and is easy to separate and recycle; the method has the advantages of controllable temperature and small basic heat output of reaction, is beneficial to enhancing the product yield, does not need to treat the waste acids, does not generate oxidation and other side reactions, has high catalytic activity, and is a green nitration method which is easy for recovery and recycling; the yield of the prepared 2,5-dichloronitrobenzene is above 99%; the solid acid catalyst ZrO2 / SO4<2-> does not need waste acid treatment, does not generate oxidation and other side reactions and is recyclable; and the product has high purity, and the content is above 99.8%.

Owner:XIAMEN UNIV +1

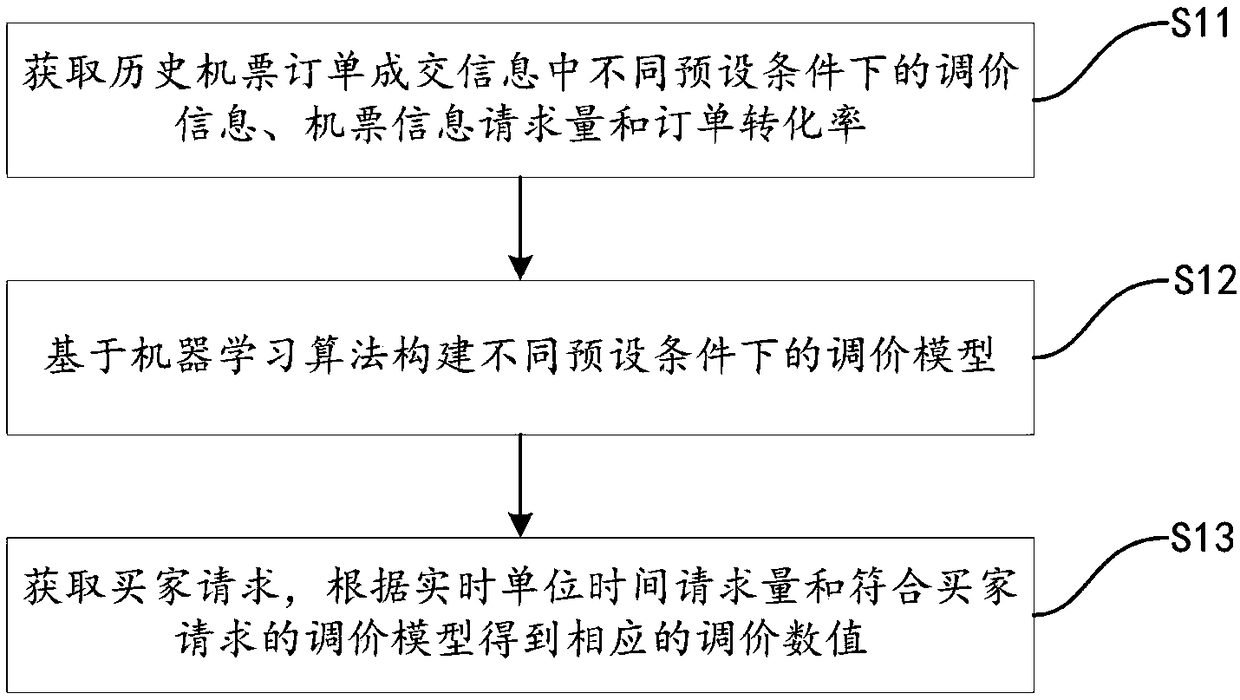

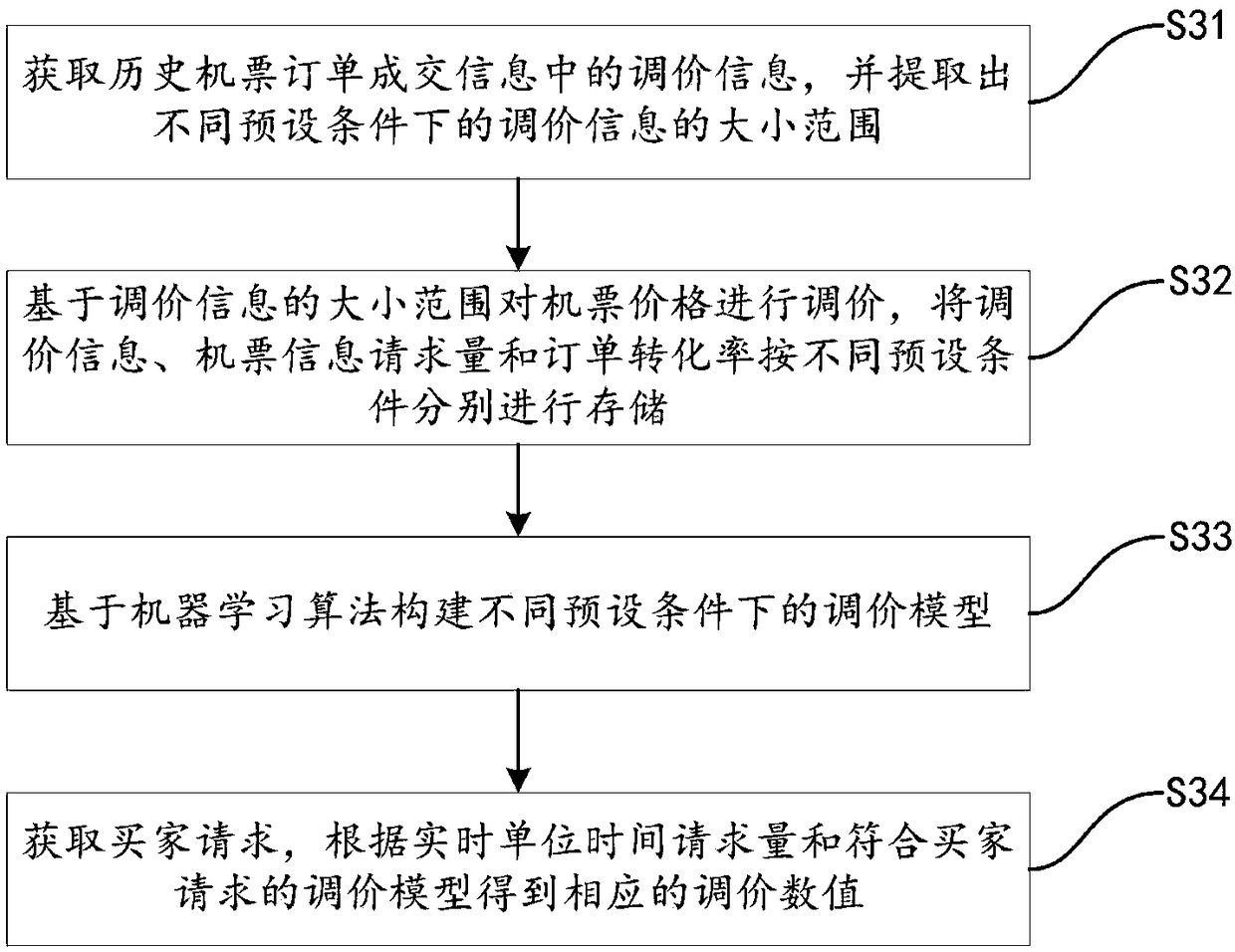

Air ticket order dynamic price adjusting method and system

PendingCN108830635AIncrease profit marginsMarket predictionsReservationsComputer scienceTicket price

The invention relates to an air ticket order dynamic price adjusting method and system. The price adjusting method comprises: obtaining price adjusting information , air ticket information request quantity and order conversion rate under different preset conditions in history air ticket order closing information; constructing a price adjustment model under different preset conditions based on a machine learning algorithm; acquiring requests of buyers, and according to the real-time unit time request quantity and the price adjustment model according to the requests of the buyers, obtaining corresponding price adjustment values. The embodiment of the invention constructs the corresponding price adjustment model through the big data analysis and the machine learning algorithm, so that the model can obtain the order conversion rate corresponding to different price adjustment information, and the most suitable price adjustment values are given according to the current request quantity. Therefore, real-time dynamic adjustment of the air ticket price can be realized and the profit margin is improved.

Owner:MARCO POLO TRAVEL TECH CO LTD

Vehicle and ship freight concealed quotation system and method

The invention discloses a vehicle and ship freight concealed quotation system and method. The system comprises a server module, a delivery information module, a concealed bid module, a GPS real-time tracking module, an insurance purchasing module, an invoice purchasing module, an evaluation module and a B / S query module. By use of the vehicle and ship freight concealed quotation system and method, enormous freight source information or vehicle and ship information can be easily obtained, freight owners and vehicle and ship owners are in direct contact, intermediate links are reduced, the logistics cost is decreased, malicious competition can be reduced, and market order is maintained.

Owner:HANGZHOU SHIFU INFORMATION TECH CO LTD

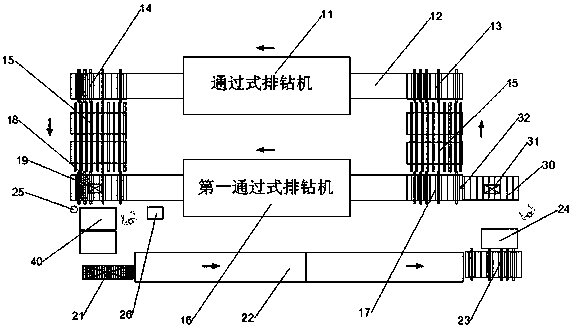

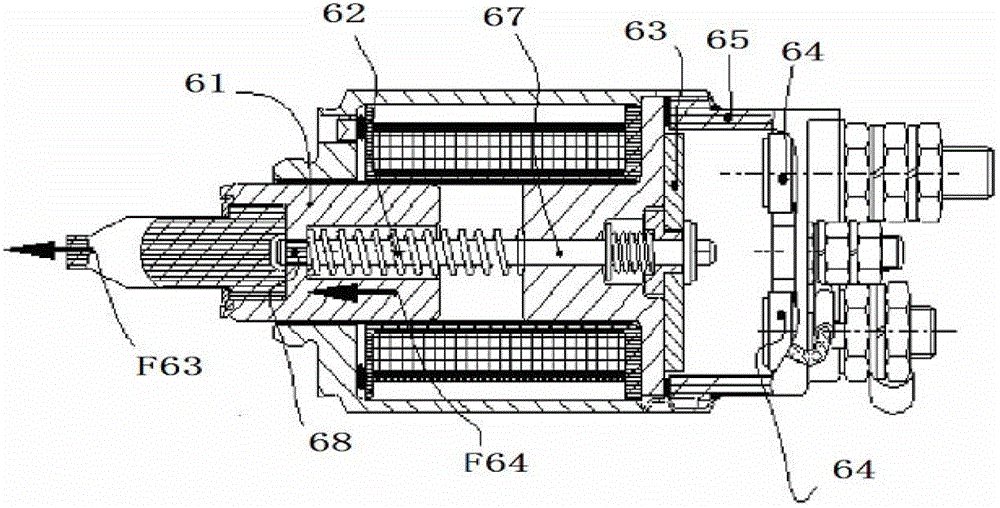

Passing type gang drill online production system and production method thereof

PendingCN109227771AStable productionEfficient productionStationary drilling machinesElectricityControl system

The invention provides a passing type gang drill online production system and a production method thereof. The passing type gang drill online production system is electrically connected with a controlsystem and comprises a plate gang drill part, an unpowered roller, a plate receiving platform and a plate rotation part; the unpowered roller and the plate receiving platform are respectively arranged on a feeding end and a discharging end of the plate gang drill part; the plate rotation part is arranged on one side of the plate gang drill part; the plate gang drill part comprises a plurality ofparallel gang drill devices; a cache region is formed on the feeding end of each gang drill device; the discharging end of each gang drill device is connected with a discharging jacking transplantingdevice; a feeding jacking transplanting device is externally connected with the cache region; a narrow-band translation device is arranged between feeding and discharging jacking transplanting deviceswhich are parallel and adjacent to each other; a fixed scanner is arranged above the unpowered roller; a laser sensor is arranged under the feeding end of the plate gang drill part; the plate rotation part comprises a plate turning device, a plate conveying device, a jacking transplanting device, a rotation plate-receiving plate, an indicator and a barcode printer; the plate turning device, the plate conveying device, the jacking transplanting device and the rotation plate-receiving plate are connected with each other in turn; the indicator and the barcode printer are respectively arranged onthe two sides of the plate receiving platform. The passing type gang drill online production system is capable of reducing labor cost and increasing production efficiency.

Owner:南京我乐家居智能制造有限公司

Reverse-impact forced-power-failure type electromagnetic switch

ActiveCN102881515AAvoid sticky failuresLow failure rateElectromagnetic relay detailsFault rateElectrical and Electronics engineering

The invention discloses a reverse-impact forced-power-failure type electromagnetic switch. The reverse-impact forced-power-failure type electromagnetic switch comprises a movable iron core, a sucking and pulling coil and a holding coil, a connecting rod, a hook, a movable contact and a static contact, wherein the sucking and pulling coil and the holding coil are arranged outside the movable iron core in sequence; the static contact can be connected with the movable contact; a stepped inner hole which is thin at the middle part and thick at two ends is arranged at the middle part of the movable iron core; the hook is connected with the movable iron core; the tail end of the hook is provided with a groove communicated with the inner hole of the movable iron core; the tail end of the connecting rod is arranged in the groove of the hook, and a rod body extends out of the inner hole of the movable iron core; and the tail end of the connecting rod is provided with a washer, and the initial end of the connecting rod is connected with the movable contact. The reverse-impact forced-power-failure type electromagnetic switch disclosed by the invention has the advantages that the occurrence of faults of adhesion of the electromagnetic switch can be avoided, further the fault rate of a whole starter is reduced and a zero-kilometer PPM value and a after-sale PPM value of an engine company are reduced.

Owner:马勒电驱动(太仓)有限公司

6N high-purity cobalt ingot casting method

ActiveCN109371255AChanging the effect of high purity reductionImprove surface qualityIngot castingWater cooling

The invention discloses a 6N high-purity cobalt ingot casting method, and belongs to the field of high-purity metal ingots casting. In the technology, electron beam is utilized for smelting, and through technological innovations in a water cooling crucible, smelting temperature parameters, feeding, and ingot casting, 4n5 cobalt plate is cleaned, high-vacuum smelted and purified, therefore that theinternal of the ingot material is pore-fee, the surface of the ingot material is free of cracks, and the total content of impurities meets the requirement of mass production of 6N and above high-purity cobalt ingots .

Owner:JINCHUAN GROUP LIMITED +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com