Reverse-impact forced-power-failure type electromagnetic switch

A technology of forced power-off and electromagnetic switch, applied in electromagnetic relays, electromagnetic relay details, circuits, etc., can solve the problem of heat aging of battery +30 terminal wiring harness, damage to engine commutator and armature, and damage to battery feed and other problems, to avoid the adhesion of static and dynamic contacts, reduce the failure rate, and improve the profit margin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

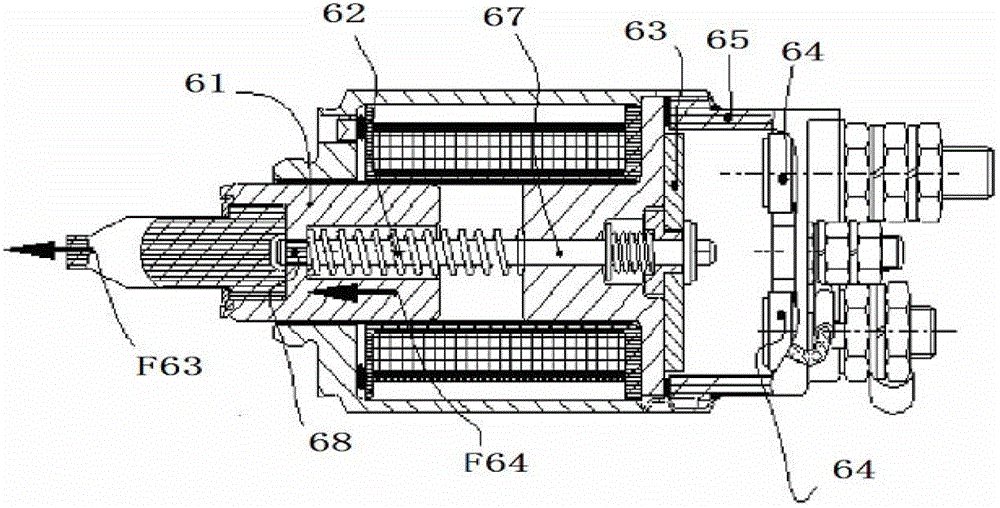

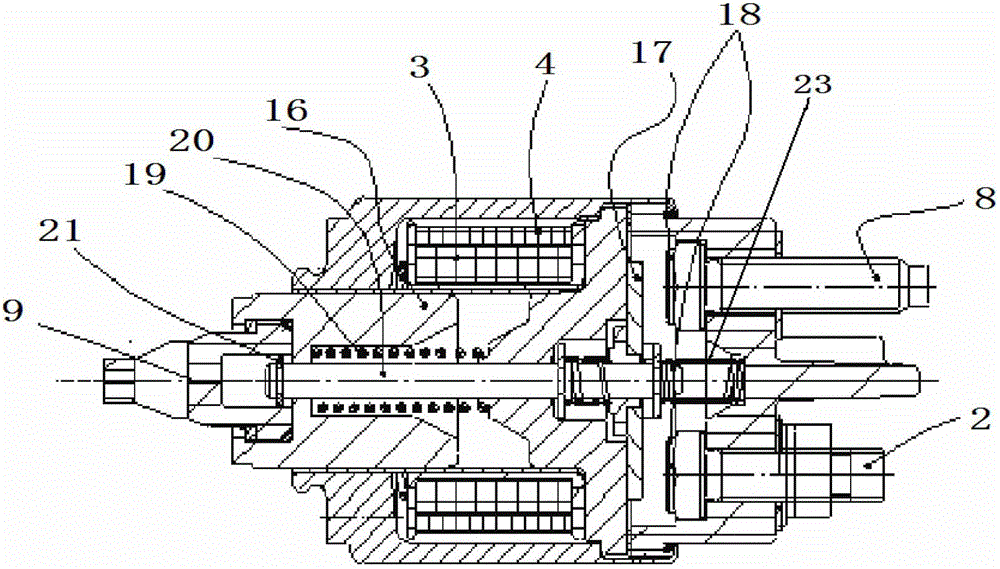

[0029] image 3 It is a schematic diagram of the electromagnetic switch of the present invention, as shown in the figure: a kind of anti-impact forced power-off electromagnetic switch, comprising a moving iron core 16, a suction coil 3 and a holding coil 4 arranged outside the moving iron core 16 successively, connected Rod 20, hook 9, movable contact 17 and static contact 18 that can be connected with the movable contact, the center of the moving iron core 16 is provided with a step-shaped inner hole that is thin in the middle and thick at both ends, and the hook 9 is connected with the moving iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com