Method for extracting rare earth and recovering fluorine resource from bastnaesite

A technology of bastnaesite and bastnaesite, which is applied in the field of rare earth hydrometallurgy, can solve the problems of reducing the profit margin of production enterprises, long production process, and high financial pressure, so as to reduce the cost of sewage treatment and simplify the production process , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

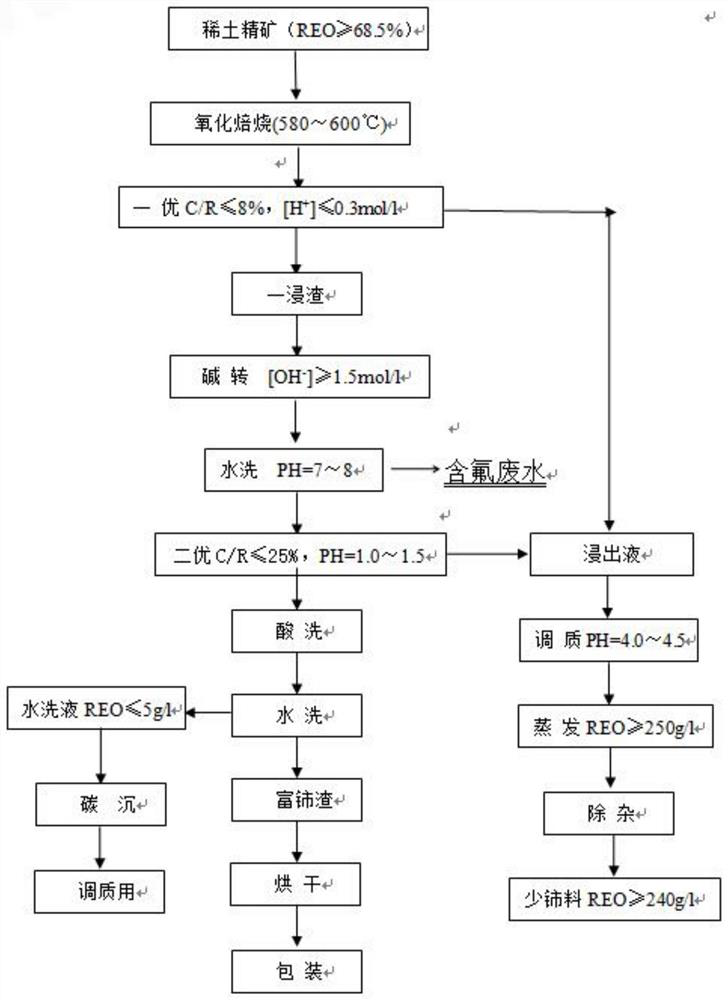

[0049] Such as figure 1 Shown, the existing common acid-base combined method is processed the production technology of bastnaesite, comprises the following steps:

[0050] S1. Oxidative roasting of rare earth concentrates (REO≥68.5%) at a roasting temperature of 580-600°C;

[0051] S2. The concentrated ore after roasting is leached with hydrochloric acid, and the acidity of the leachate is not more than 0.3mol / L. At this time, the cerium distribution C / R≤8% (CeO / REO) is obtained to obtain the leachate and the leach residue;

[0052] S3, carrying out alkaline conversion to the leaching residue, the concentration of NaOH is [OH - ]≥1.5mol / L to obtain alkali-converted slag, wash the alkali-converted slag with water, control the pH value between 7-8, and the washing solution is fluorine-containing wastewater;

[0053] S4, adding the washed alkali-turned slag into hydrochloric acid for pickling, the pH value of the hydrochloric acid is 1.0-1.5, and C / R≤25%;

[0054] S5, the solu...

Embodiment 2

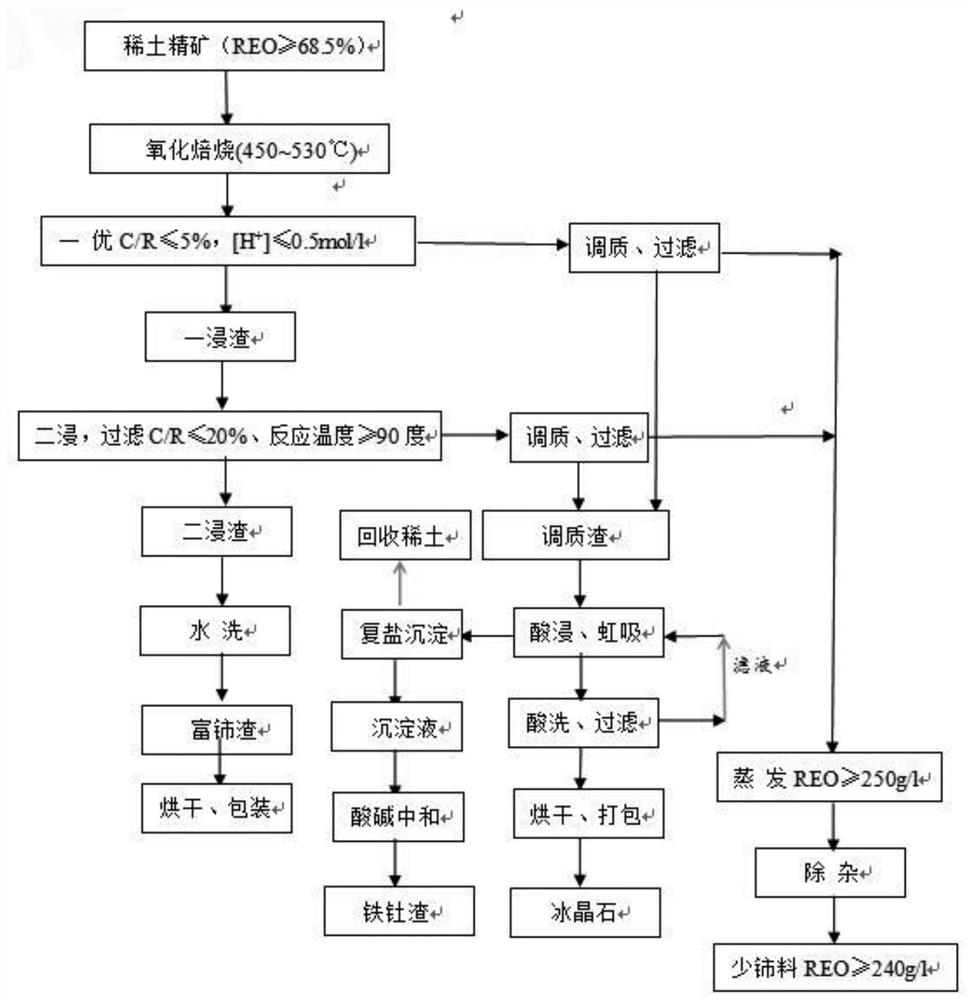

[0059] Such as figure 2 Shown, a kind of bastnaesite of the present invention extracts the method for rare earth, comprises the following steps:

[0060] S1. Carrying out oxidative roasting of the rare earth concentrate, the roasting temperature is 450-530°C, and the roasting time is 1-3 hours, to obtain the roasted product;

[0061] S2. Carry out hydrochloric acid leaching on the roasted product, the acidity of the acid solution is controlled at 0.3-0.8mol / L, the acidity of the whole reaction system is controlled below 0.5mol / L, the cerium partition C / R≤5%, and the primary leachate and primary leach residue;

[0062] S3. Add clear water to the primary leaching slag, stir and heat up to above 90°C, then add hydrochloric acid complexing agent, the amount of hydrochloric acid complexing agent added is 0.46-0.66 times the total weight of REO in the rare earth ore (here the weight of hydrochloric acid is equivalent to Industrial hydrochloric acid with a mass fraction of 31%), t...

example 1

[0070] A method for extracting rare earth from bastnaesite, comprising the following steps:

[0071] S1. Take the bastnaesite with REO grade of 67.25% and oxidize and roast it in a constant temperature muffle furnace at 530°C for 2.5 hours, and call the oxidized and roasted bastnaesite ore roasted ore. The fluorine content in the roasted ore At 8.54%, the REO content is 80.06%;

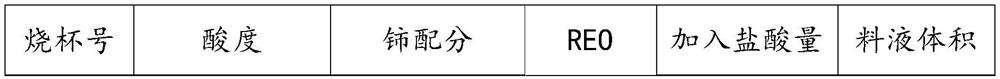

[0072] S2. Divide the oxidized and roasted bastnaesite into 5 groups according to a batch of 500g for testing; during the test, take 5 3000mL beakers, numbered 1-5 respectively, and control the acidity of the bottom water in each beaker to 0.3 -0.8mol / L, the acidity of the bottom water is shown in Table 1:

[0073] Table 1 Number 1-5 Bottom Water Acidity Table (The data shown is the concentration of hydrochloric acid)

[0074] Numbering number 1 number 2 number 3 No 4 Number 5 Acidity (mol / L) 0.36 0.45 0.55 0.64 0.77

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com