Aluminate asphalt cement waterproof bridging agent, waterproof product thereof and application thereof

A bridging agent and aluminate technology, which is used in asphalt binders, asphalt coatings, adhesives, etc., can solve the problem that asphalt aging and weather resistance have not been significantly improved, and the chemical bonding of coupling agents has not been realized. There is no sense of direction and other problems, to achieve the effect of enhancing interface compatibility, low price, and improving processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0028] Embodiment 1-1, aluminate bridging agent waterproof membrane, the first layer of the waterproof membrane is a polyethylene film layer, the middle layer is an asphalt adhesive layer, and the lower layer is a barrier film protective layer, wherein the asphalt adhesive layer The ingredients and parts by weight are: 30-35 parts of asphalt, 15-16 parts of modifier, 2-4 parts of second-line oil refined in petrochemical production process, 0.1-0.5 parts by weight of aluminate waterproof bridging agent, The filler magnesium oxide is 3-4 parts, and the filler calcium carbonate powder is 40-45 parts. Production process: first heat the asphalt to 160-200 ℃, after reaching the molten state, add additives and waterproof bridging agent, stir and react for 0.5-2 hours, finally add appropriate amount of filler according to the performance of the waterproof membrane, and lay it on the plastic The surface of the film layer to obtain the product.

Embodiment 1-2

[0029] Embodiment 1-2, aluminate bridging agent waterproof membrane, the first layer of the waterproof membrane is a polyethylene film layer, the middle layer is an asphalt adhesive layer, and the lower layer is a barrier film protective layer, wherein the asphalt adhesive layer The ingredients and parts by weight are: 38-45 parts of asphalt, 17-18 parts of modifier, 5-7 parts of second-line oil refined in petrochemical production process, 7.0-9.0 parts by weight of aluminate waterproof bridging agent, The filler magnesium oxide is 5-6 parts, and the filler calcium carbonate powder is 48-53 parts. Production process: first heat the asphalt to 160-200 ℃, after reaching the molten state, add additives and waterproof bridging agent, stir and react for 0.5-2 hours, and finally add appropriate amount of filler according to the performance of the waterproof membrane, and lay it on the plastic The surface of the film layer to obtain the product.

Embodiment 1-3

[0030] Embodiment 1-3, aluminate bridging agent waterproof membrane, the first layer of the waterproof membrane is a polyethylene film layer, the middle layer is an asphalt adhesive layer, and the lower layer is an isolation film protective layer, wherein the asphalt adhesive layer The ingredients and parts by weight are: 46-50 parts by weight of asphalt, 19-20 parts of modifier, 8-10 parts of second-line oil refined in petrochemical production process, 12.0-15.0 parts by weight of aluminate waterproof bridging agent, The filler magnesium oxide is 7-8 parts, and the filler calcium carbonate powder is 55-60 parts. Production process: first heat the asphalt to 160-200 ℃, after reaching the molten state, add additives and waterproof bridging agent, stir and react for 0.5-2 hours, and finally add appropriate amount of filler according to the performance of the waterproof membrane, and lay it on the plastic The surface of the film layer to obtain the product.

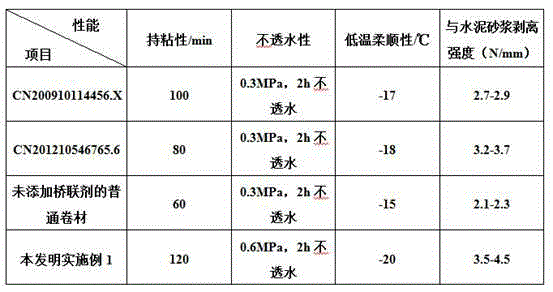

[0031] The made...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com