Adhesive sheet

An adhesive sheet and bonding technology, applied in the direction of adhesives, pressure-sensitive films/sheets, film/sheet-like adhesives, etc. problem, to achieve the effect of excellent exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

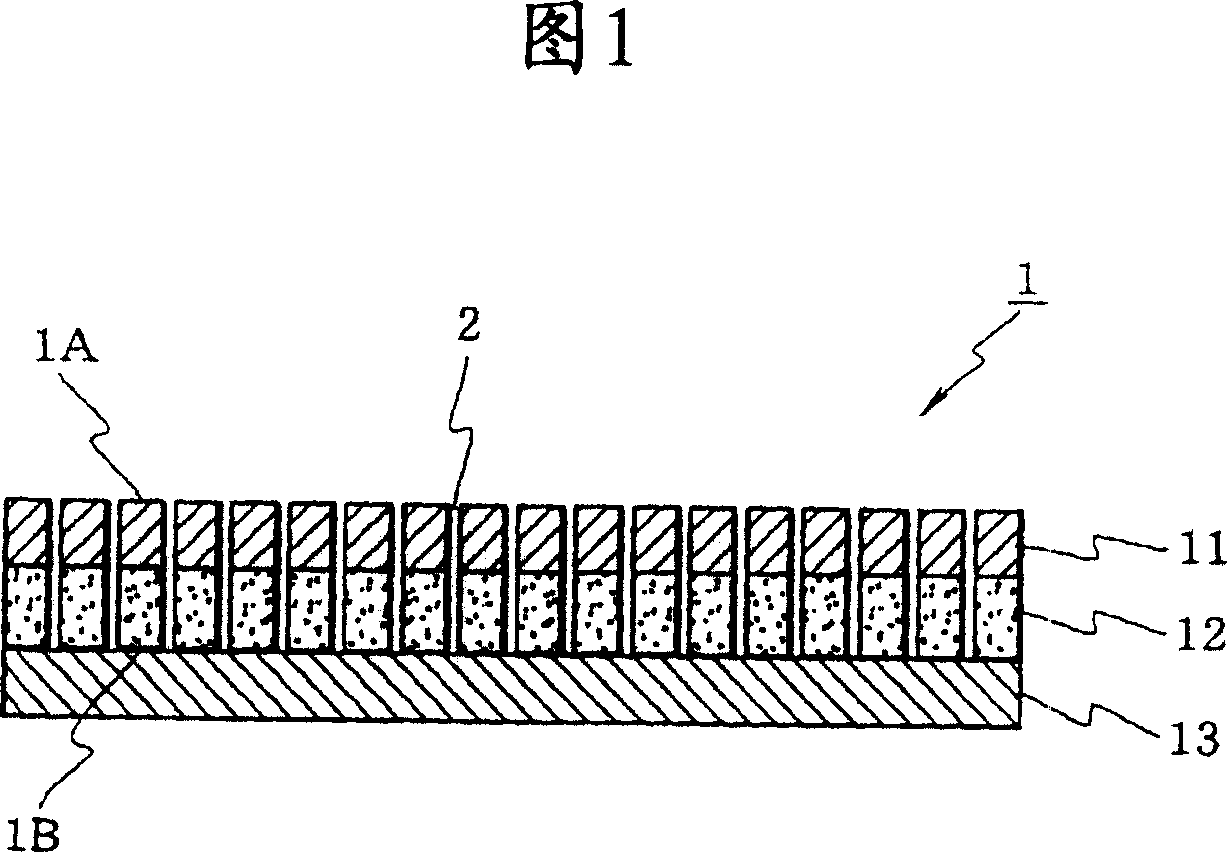

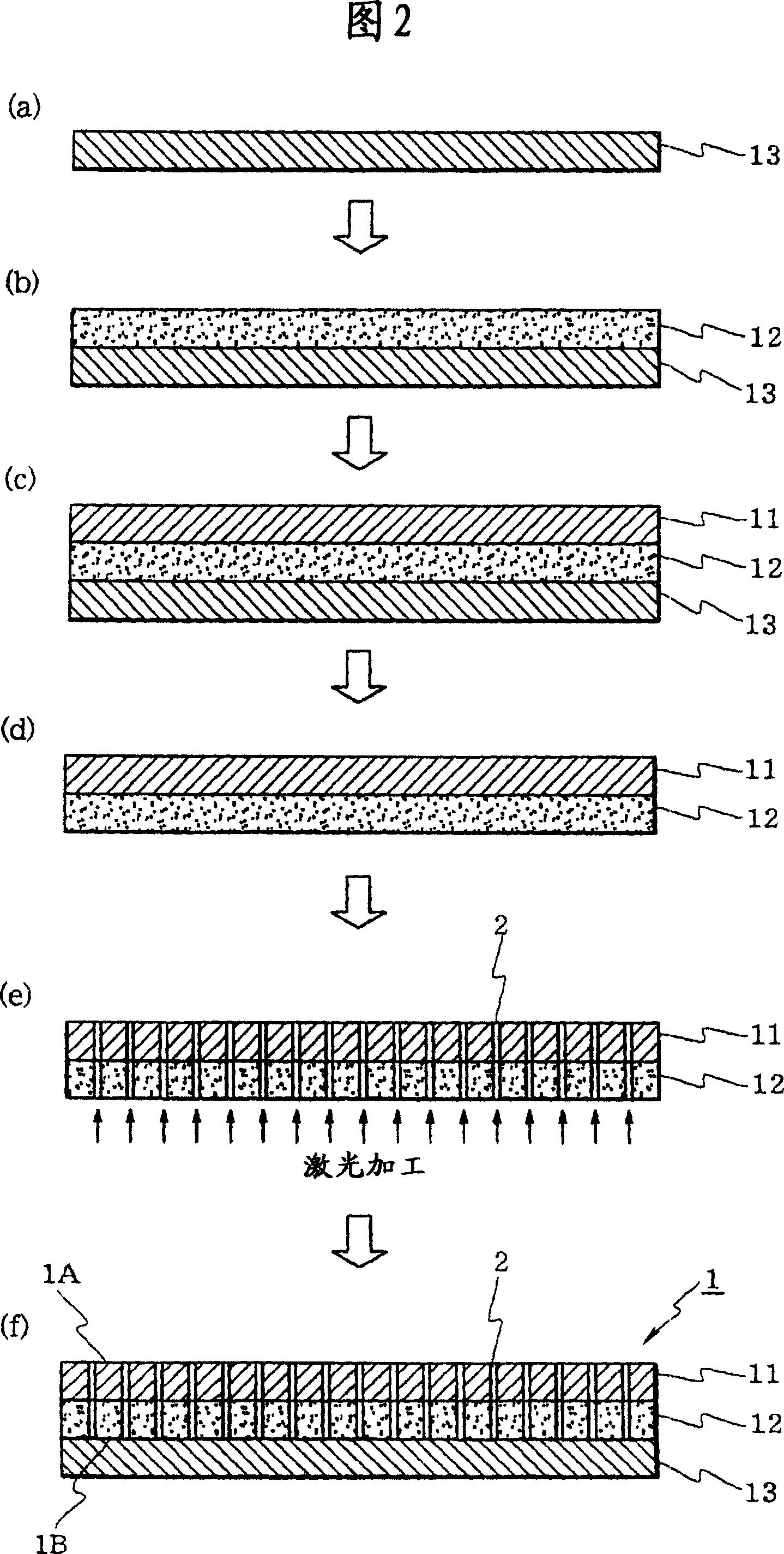

[0064]The peeling surface of a release material (manufactured by Lintec Corporation, FPM-11, thickness: 175 μm) that laminated wood-free paper on both sides with polyethylene resin and coated with a silicone-based release agent on one side Above, a coating agent of an acrylic solvent-based adhesive (manufactured by Lintec, MF) was applied with a knife coater so that the thickness after drying was 30 μm, and dried at 90° C. for 1 minute. A black opaque substrate (thickness: 100 μm) made of polyvinyl chloride resin was pressure-bonded to the adhesive layer thus formed to obtain a laminate having a three-layer structure.

[0065] Peel off the release material from the laminate, and irradiate the laminate with CO from the adhesive layer side. 2 Laser, 2,500 pcs / 100cm 2 The pore density of 1.00000000000000000000000000000000 formed through-holes with a pore diameter of about 50 μm in the substrate surface and a pore diameter of about 90 μm in the bonding surface. Thereafter, the p...

Embodiment 2

[0068] In addition to replacing CO 2 The laser was irradiated with a UV-YAG laser, and an adhesive sheet was produced in the same manner as in Example 1, except that the through-hole diameter on the substrate surface was about 30 μm, and the hole diameter on the adhesive surface was about 45 μm. Thereafter, the storage modulus and loss tangent of the adhesive layer of the obtained adhesive sheet were measured in the same manner as in Example 1. The results are shown in Table 1.

Embodiment 3

[0070] In addition to using an acrylic solvent-based adhesive (manufactured by LINTEC, PK) as an adhesive, and setting the pore diameter on the substrate surface of the through hole to about 30 μm, and the pore diameter on the bonding surface to about 80 μm, An adhesive sheet was produced in the same manner as in Example 1. Thereafter, the storage modulus and loss tangent of the adhesive layer of the obtained adhesive sheet were measured in the same manner as in Example 1. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com