Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75 results about "Ethyl cyanoacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

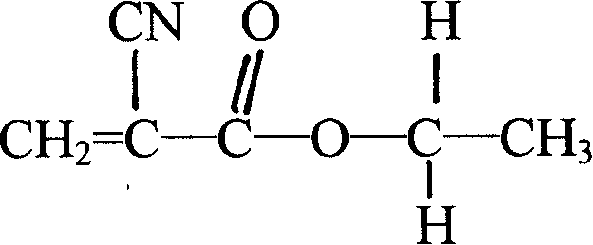

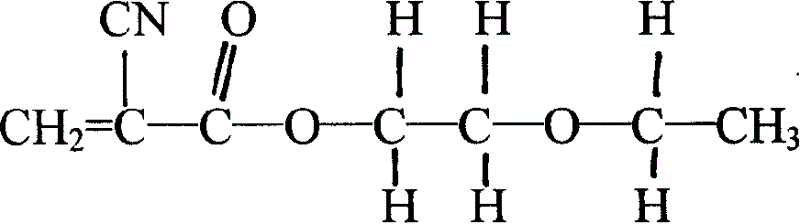

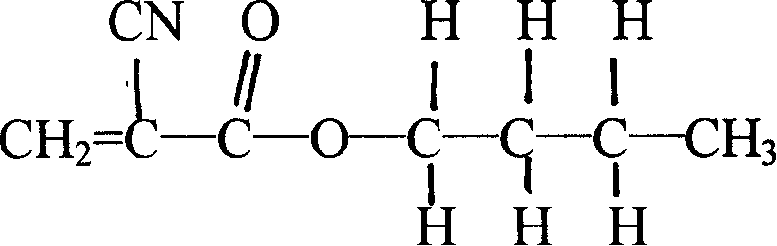

Ethyl cyanoacrylate (ECA), a cyanoacrylate ester, is an ethyl ester of 2-cyano-2-propenoic acid. It is a colorless liquid with low viscosity and a faint sweet smell in pure form. It is the main component of cyanoacrylate glues and can be encountered under many trade names. It is soluble in acetone, methyl ethyl ketone, nitromethane, and methylene chloride. ECA polymerizes rapidly in presence of moisture.

Artificial Eyelash Hairs with Decorative Applique

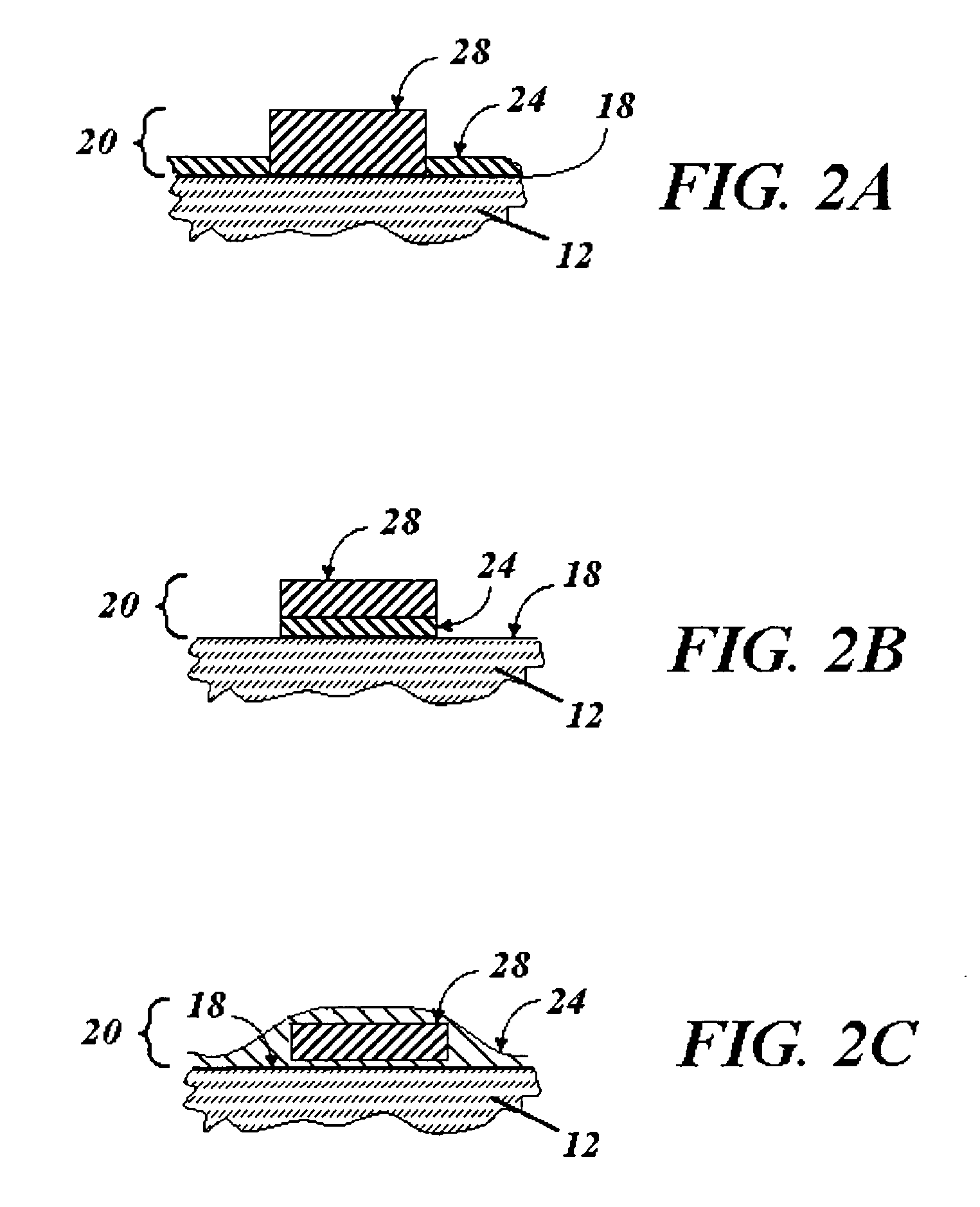

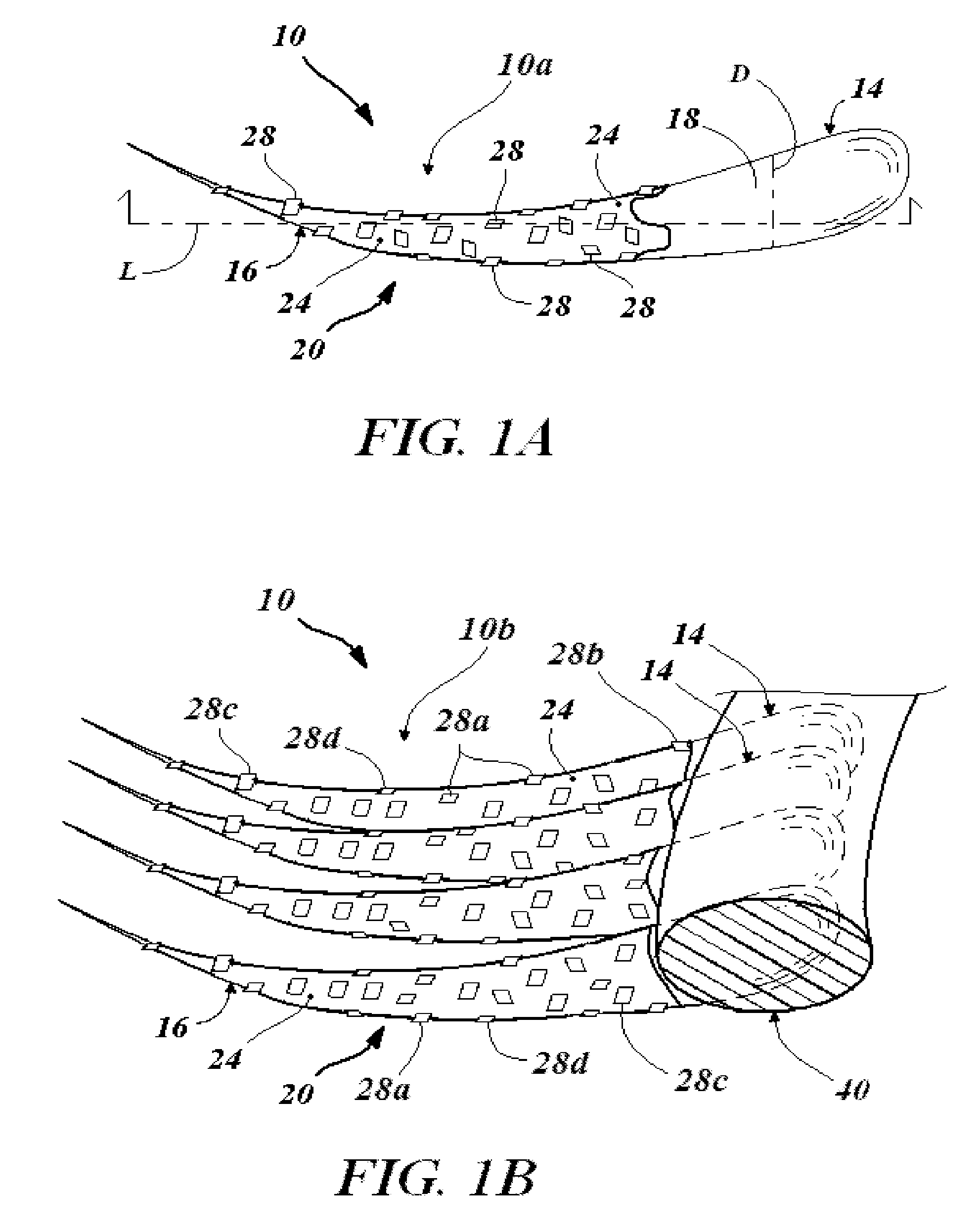

A decorative artificial eyelash hair (10) has an artificial eyelash hair (12) with a base portion (14), a tip portion (16) and an outer surface (18). A decorative applique (20) is adhered to at least a portion of the outer surface (18) of the artificial eyelash hair (12). The applique includes a decorative component (28) fixed to the outer surface (18) of the hair (12) by an adhesive (24). The decorative component (28) is made of very small, reflective particles adhered to the outer surface of the individual artificial eyelash hair. The reflective particles (28) were accomplished using plastic film and colored crystals of different colors, hues and reflectivity. The particles (28) were adhered to the individual artificial eyelash hairs (10) with an adhesive: ethoxy-ethyl cyanoacrylate. The decorative artificial eyelash hair (10) can be practiced as artificial eyelash single hair extensions (10a), or it can be practiced on the individual artificial eyelash hairs of an artificial eyelash set (10b).

Owner:NOVALASH

Eyelash Extension Hairs with Decorative Applique

A decorative artificial eyelash hair (10) has an artificial eyelash hair (12) with a base portion (14), a tip portion (16) and an outer surface (18). A decorative applique (20) is adhered to at least a portion of the outer surface (18) of the artificial eyelash hair (12). The applique includes a decorative component (28) fixed to the outer surface (18) of the hair (12) by an adhesive (24). The decorative component (28) is made of very small, reflective particles adhered to the outer surface of the individual artificial eyelash hair. The reflective particles (28) were accomplished using plastic film and colored crystals of different colors, hues and reflectivity. The particles (28) were adhered to the individual artificial eyelash hairs (10) with an adhesive: ethoxy-ethyl cyanoacrylate. The decorative artificial eyelash hair (10) can be practiced as artificial eyelash single hair extensions (10a), or it can be practiced on the individual artificial eyelash hairs of an artificial eyelash set (10b).

Owner:NAVARRO MARIA A +1

Medical adhesive used for adhering skin and viscus hemostasis, and its prepn. method

A medical adhesive for adhering skin and hemostasis of viscera is prepared from at least two organic compounds chosen from alpha-ethyl cyanoacrylate, alpha-ethoxyethyl cyanoacrylate, alpha-butyl cyanoacrylate and alpha-octyl cyanoacrylate through proportional mixing.

Owner:石平安

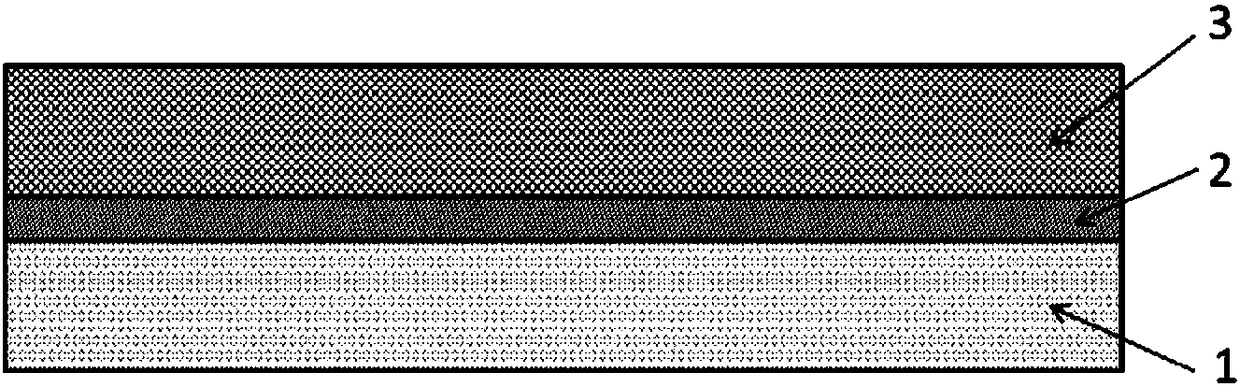

Anti-haze window screen based on electrospinning technology and preparation method thereof

ActiveCN108071332AThe overall thickness is thinHigh porosityDispersed particle filtrationInsect protectionParticulatesFiber

The invention discloses an anti-haze window screen based on an electrospinning technology and a preparation method thereof. The window screen is provided with a three-layer composite structure, a baselayer is a metal screen cloth, and a cyan ethyl acrylate viscous layer is compounded on the surface of the metal screen cloth in an electrostatic spray method. An intermediate layer is a nanofiber functional film directly electrospun on the surface of the metal screen cloth by electrospinning, and the nanofiber functional film is a nano-graphene / PVDF / PEO composite nanofiber film, a protective layer is compounded on the upper surface of the nanofiber functional film through a hot pressing method, and the protective layer is a nylon net. The window screen can filter outdoor air, effectively block dust and other particulate matter, and can ensure indoor and outdoor air circulation and indoor lighting. The preparation method is simple, suitable for large-scale production, and has a good application prospect.

Owner:聚纳达(青岛)科技有限公司

Guanine one-pot synthesis method

The invention discloses a synthesis method for guanine, which includes the following steps: carrying out a cyclization reaction of guanidine nitrate and ethyl cyanoacrylate to obtain the compound of 2, 4-diamino-6-hydroxypyrimidine in formamide solvent, adding sodium nitrite, formamide and concentrated formic acid in turn, and carrying out nitrosation and reduction reaction with reducing agent and cyclization reaction to obtain the final product. The invention is the use of ''one-pot'', and the raw materials are fat chain ethyl cyanoacrylate and guanidine nitrate, which are directly from market, cheap and easy to get, without need of separation and purification of pyrimidine intermediates. Guanine is prepared by one step through effective control of reaction conditions, feeding sequence and ratio. The product is purified through adjusting pH, which has high yield and is easy to operate.

Owner:SHANGHAI INST OF PHARMA IND

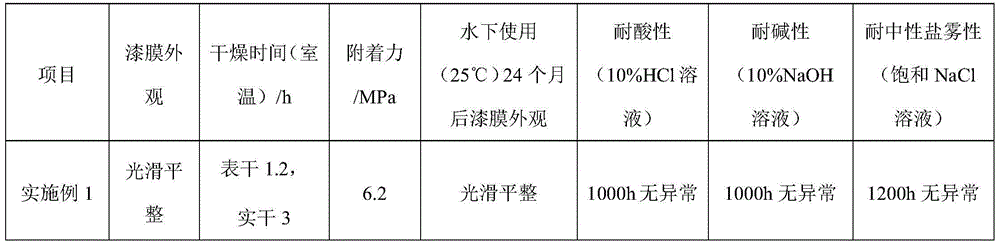

Anti-corrosive coating for aluminum electrolytic cells and preparation method thereof

InactiveCN104530791AStrong adhesionImprove water resistanceAnti-corrosive paintsPolyethylene glycolStearate

The invention discloses an anti-corrosive coating for aluminum electrolytic cells and a preparation method thereof. The anti-corrosive coating comprises the following components: polycarbonate, phenolic resin, barium stearate, a defoaming agent, 2-ethyl cyanoacrylate, ethylene-glycol-dimethacrylate, hexamine, carboxymethylcellulose, polyethylene glycol, polyvinylformal acetal, and polybor-organosiloxane. The preparation method comprises the following steps: uniformly mixing polycarbonate, phenolic resin, barium stearate, 2-ethyl cyanoacrylate, ethylene-glycol-dimethacrylate, carboxymethylcellulose and polyethylene glycol, adding the obtained mixture into a reaction kettle, heating for reacting under the condition of inert gas protection, cooling to 40-50 DEG C, adding a defoaming agent, hexamine and polyvinyl formal acetal, continuing to stir so as to obtain a mixture 2; and adding polybor-organosiloxane in the mixture 2, heating for reacting under vacuum conditions, and cooling to room temperature, so that the anti-corrosive coating is obtained. The anti-corrosive coating provided by the invention is excellent in properties and suitable for use.

Owner:NANTONG RUIDA ELECTRONICS MATERIAL

Non-aqueous rapid setting drywall compound and method of use

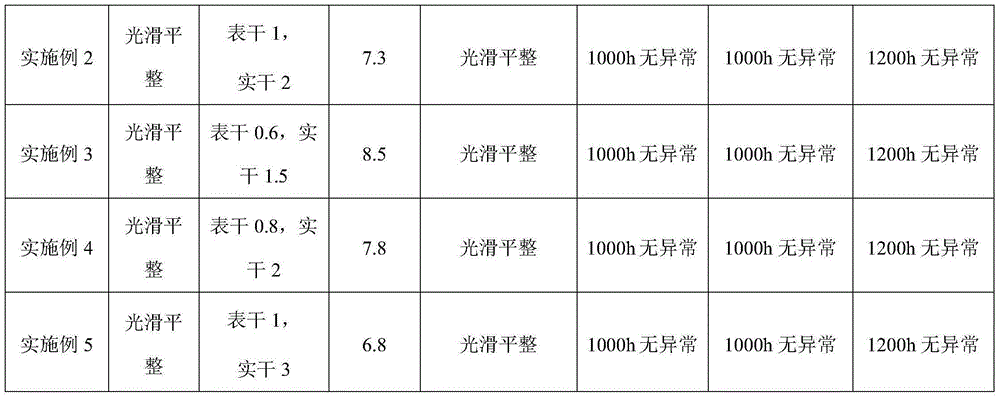

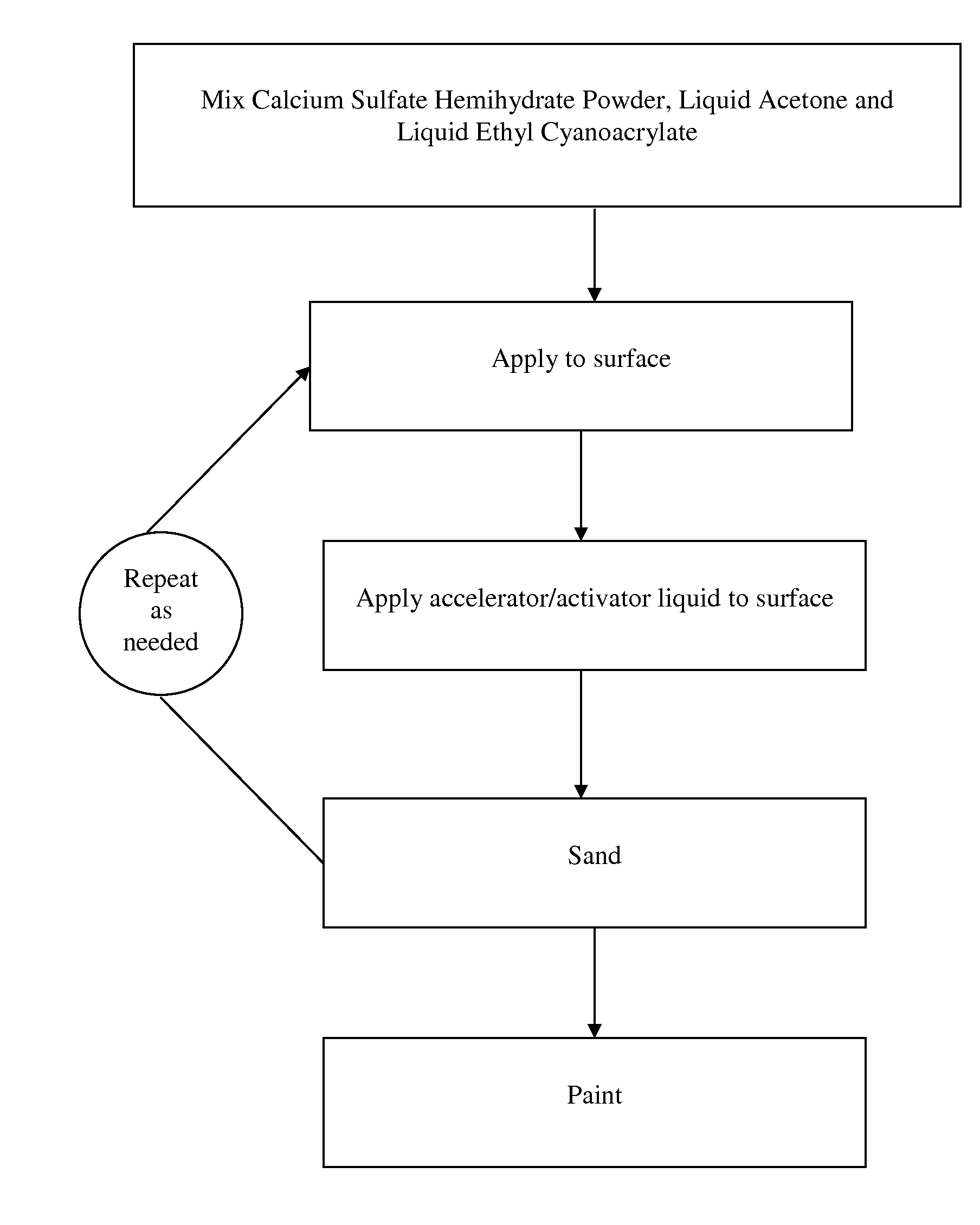

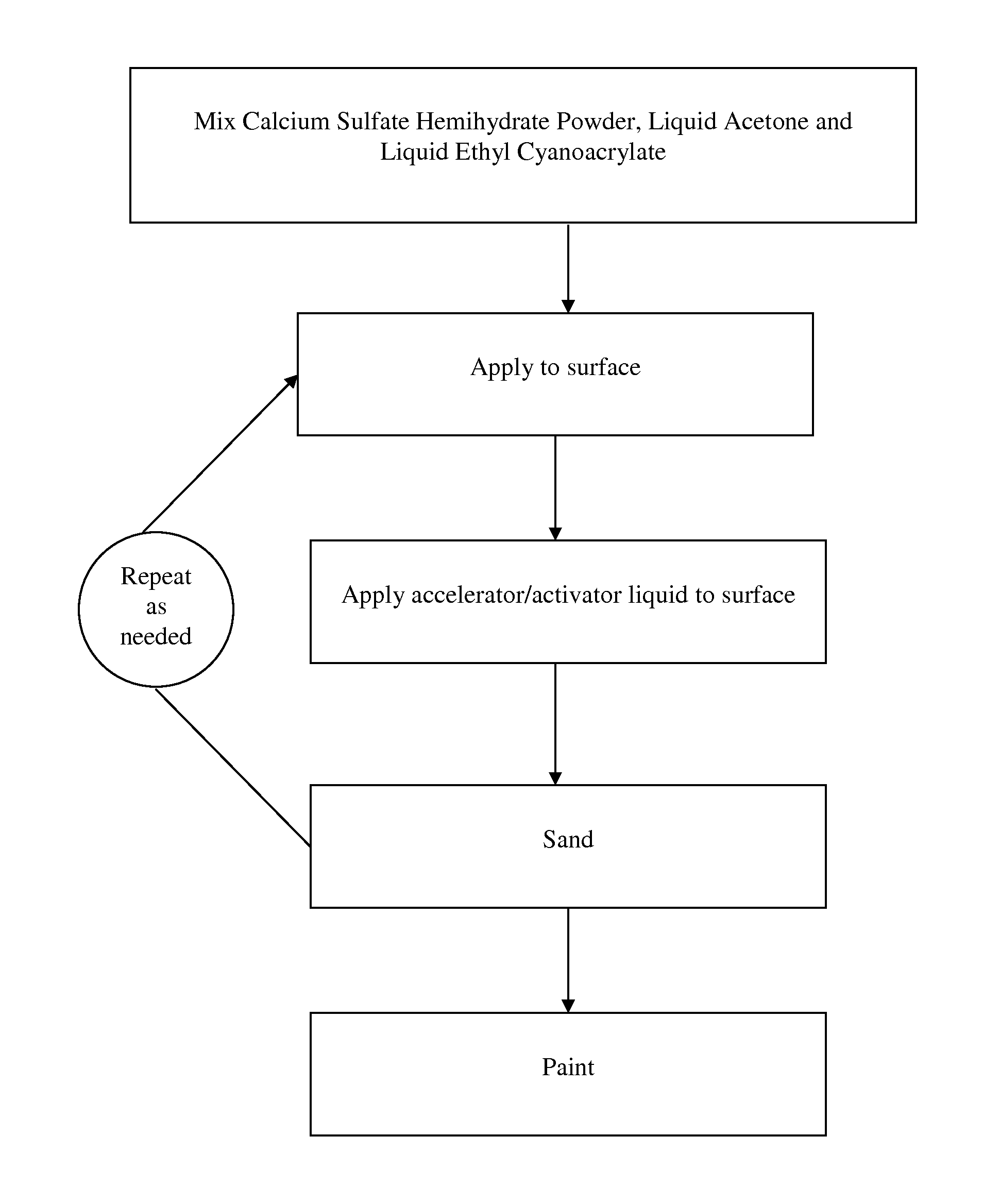

A non-aqueous drywall compound being the combination of a first component mixture of acetone, a non-aqueous liquid adhesive containing ethyl cyanoacrylate, and a powder containing calcium sulfate hemihydrate (plaster of Paris), the mixture being a pliable putty capable of adhering to gypsum wallboard or similar work surfaces. The second component of the drywall compound is an accelerator or activator containing acetone and toluene. The first component is applied to a defect in a work surface using a spreading tool and the second component is then applied to the exposed surface of the first component, such as by spraying or brushing, whereupon the drywall compound cures, hardens or sets within less than ten minutes to a state capable of being sanded into a smooth, hard surface and painted.

Owner:TRUDEAU WALTER

Polyethylene terephthalate composite material for 3D printing and preparation method thereof

The invention provides a polyethylene terephthalate composite material for 3D printing and a preparation method thereof. The preparation method of the composite material comprises the following steps of: dissolving polyethylene glycol into isopropanol; adding benzyl triethylamine bromide, and standing at room temperature; then sequentially adding benzoic anhydride and ethyl alpha-cyanoacrylate, and stirring at room temperature; then adding polyethylene terephthalate granules, heating, stirring, and cooling to room temperature to obtain the polyethylene terephthalate composite material for 3D printing, wherein the content of polyethylene terephthalate is 40%-50%, the content of ethyl alpha-cyanoacrylate is 5%-25%, the content of polyethylene glycol 4000 is 5%-20%, the content of isopropanol is 15%-30%, the content of benzyl triethylamine bromide is 1%-5%, and the content of benzoic anhydride is 1%-5%. The polyethylene terephthalate composite material prepared through the method provided by the invention can be used for 3D printing within a temperature range of 40-60 DEG C without plugging a spray head of a 3D printer.

Owner:TAICANG BIQI NEW MATERIAL RES & DEV

Instantaneous adhesive and preparation method thereof

InactiveCN103694903AShort gel timeImprove temperature resistanceNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveCelluloseAdhesive

The invention provides an instantaneous adhesive and a preparation method thereof. The instantaneous adhesive comprises the following component in parts by weight: 75-90 parts of 2-ethyl cyanoacrylate, 3-10 parts of methyl methacrylate, 5-10 parts of ethylene carbonate, 2-8 parts of hydroxypropyl cellulose acetate, 0.1-0.5 parts of sulfur dioxide, 0.5-1 part of hydroquinone and 0.1-0.4 parts of silica. The preparation method comprises the following steps: adding 2-ethyl cyanoacrylate, methyl methacrylate, ethylene carbonate, hydroxypropyl cellulose acetate and sulfur dioxide into a reaction kettle, uniformly mixing, heating and reacting for 1-2 hours at the temperature of 70-80 DEG C; adding the hydroquinone and silica into the reaction kettle, and performing reduced pressure distillation at the temperature of 170-180 DEG C. The instantaneous adhesive provided in the invention has the characteristics of short gel time, high temperature resistance and high water resistance and is suitable for popularization.

Owner:NANTONG REPAIR AIR CHEM BIOENG

Heat resistance instant dry adhesive and preparation method thereof

InactiveCN103666293AGel quicklyImprove adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesMeth-Adhesive

The invention discloses a heat resistance instant dry adhesive and a preparation method thereof. The heat resistance instant dry adhesive comprises the following components in parts by weight: 80 to 90 parts of ethyl cyanoacrylate, 2 to 8 parts of ethyl cyanoacrylate, 2 to 6 parts of silica, 0.3 to 1 part of nitrobenzene, 0.5 to 2 parts of polyethylene glycol, 0.5 to 1 part of hydroquinone, 5 to 10 parts of polyvinyl acetate, 0.1 to 0.5 part of methanesulfonic acid and 0.05 to 0.1 part of sulfur dioxide. The preparation method comprises the following steps: adding the ethyl cyanoacrylate, the ethyl cyanoacrylate, the nitrobenzene, the hydroquinone, the polyvinyl acetate, the silica, the polyethylene glycol, the methanesulfonic acid and the sulfur dioxide into a reaction kettle; sufficiently stirring and uniformly mixing; heating to a temperature of 70 to 80 DEG C and performing the reaction for 50 to 80 minutes to be a paste state. The heat resistance instant dry adhesive provided by the invention can be rapidly gelled and meanwhile, also can achieve a good binding effect under high temperature conditions of 80 DEG C and 120 DEG C.

Owner:NANTONG REPAIR AIR CHEM BIOENG

Anti-stripping cyanoacrylate adhesive and preparation method thereof

ActiveCN105315933AImprove impact resistanceImprove anti-stripping performanceNon-macromolecular adhesive additivesProtein adhesivesEthyl cyanoacrylateGelatin

The invention discloses an anti-stripping cyanoacrylate adhesive. The anti-stripping cyanoacrylate adhesive is prepared from, by weight, 30-50 parts of alpha-ethyl cyanoacrylate, 0.5-4 parts of EVA, 2-5 parts of beta-propiolactone, 0.5-1 part of modified titanium oxide, 8-12 parts of gelatin, 5-10 parts of polyacrylate, 2-8 parts of galactomannan, 3-8 parts of hydroxyethyl cellulose and 1-1.5 parts of coupling agent. The invention further discloses a preparation method of the anti-stripping cyanoacrylate adhesive. The anti-stripping cyanoacrylate adhesive is high in curing speed, good in water resistance, high in impact resistance, large in bonding strength, good in anti-stripping performance, small in use amount, free of toxicity and beneficial to environmental protection.

Owner:ZHEJIANG TIME NEW MATERIAL

Preparation method of hydrotalcite composite material for repairing soil of farmland with copper ions exceeding standard

ActiveCN105170104AAvoid secondary pollutionLow densityAgriculture tools and machinesOther chemical processesCakingEnvironmental chemistry

The invention belongs to the field of soil repairing materials and relates to a preparation method of a hydrotalcite composite material for repairing soil of farmland with copper ions exceeding the standard. According to the preparation method, modified hydrotalcite is composited into holes of ammoniated bagasse, and the preparation method comprises specific processes such as cleaning of bagasse, ammoniation of the bagasse, modification of hydrotalcite, preparation of the composite material and the like. The bagasse and hydrotalcite composite material prepared with the method has the advantages as follows: (1) the hydrotalcite is fixed in the bagasse by the aid of ethyl cyanoacrylate, the characteristics of low density and large specific surface area of the bagasse can be realized, and the advantage that the modified hydrotalcite has high adsorption capacity for the heavy metal copper ions can also be utilized; (2) compared with hydrotalcite powder, the composite material solves problems of agglomeration of the hydrotalcite powder and reduction of adsorption capacity for the copper ions and can also solve the problem of secondary soil pollution due to the fact that the hydrotalcite adsorbing the copper ions is difficult to recover; (3) compared with the bagasse, the composite material has the advantage that the copper ion saturated adsorption amount of the soil repairing material is substantially increased.

Owner:TAICANG BIQI NEW MATERIAL RES & DEV

Silver conductive adhesive as well as preparation method and application thereof

InactiveCN102040916ARapid responseLow viscosityNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveEthyl cyanoacrylateEpoxy

The invention provides a silver conductive adhesive, comprising a basic resin, a curing agent, a curing accelerator and a conductive material, wherein the basic resin is epoxy resin, the curing agent is binary aliphatic ether amine and versamid, the curing accelerator is 2,4,6-tri-(dimethylaminomethyl)-phenol, and the conductive material is silver powder. The silver conductive adhesive is characterized by furthering comprising alpha-cyan ethyl acrylate and polyether. The invention further provides a preparation method and application of the silver conductive adhesive. The silver conductive adhesive prepared in the invention can be completely cured within 5-15min at room temperature (25 DEG C) and has good cohesiveness and conductivity.

Owner:BYD CO LTD

Preparation method for nano particle-modified polypropylene composite sheet

ActiveCN106003973AImprove mechanical propertiesImprove heat resistanceSynthetic resin layered productsLaminationDodecylsulfonic acidMechanical property

The invention discloses a preparation method for a nano particle-modified polypropylene composite sheet. The preparation method comprises the following steps: adding a modifying composition into a first extruding machine, and extruding at 90 to 120 DEG C to obtain a modified thin film; adding a polypropylene composition into a second extruding machine, and extruding at 220 to 240 DEG C to obtain a polypropylene foamed sheet; compounding the modified thin film and the polypropylene foamed sheet to obtain the nano particle-modified polypropylene composite sheet, wherein the modifying composition consists of ethyl cyanoacrylate, phenyl benzoate, sodium dodecyl sulphate, nano porous nickel oxide and tributyl phosphate; the polypropylene composition consists of homo-polypropylene, N-acyl-N-methyl glucamine, nanosilicon dioxide of which the surface is coupled with triethylamine, and a foaming agent. According to the preparation method, the compositions are molten by adopting simple extruding machines and are extruded to obtain a main body and a modifying body material; a composite plastic sheet is prepared by utilizing a multilayer compounding manufacturing method; the operation is easy and convenient; the produced composite sheet has the characteristics of good heat resistance, mechanical properties and the like.

Owner:JIN BAOLI TECH SUZHOU

Medical adhesive and preparation method thereof

InactiveCN110420347AEasy to prepareEasy to operateSurgical adhesivesPharmaceutical delivery mechanismEthyl cyanoacrylateOrganic solvent

The invention provides a medical adhesive, and further discloses a preparation and using method of the medical adhesive. The medical adhesive is characterized by being prepared from the following rawmaterials in parts by weight: 35-45 parts of copolymers of ethyl cyanoacrylate / S-allyl-D-cysteine / 2,3,5,4-tetrahydroxy stilbene glucoside / N-acryloxysuccinimide, 30-50 parts of cyanovinyl modified quaternized chitosan, 3-6 parts of Chinese herbal medicine concentrate, 0.3-1 part of pectic acid, 20-30 parts of an organic solvent, and 1-3 parts of an initiator. The medical adhesive has excellent comprehensive performance, a good adhesive tissue effect, high adhesive strength, low biological toxicity, excellent adhesion durability and a good antibacterial effect, and can effectively inhibit formaldehyde production.

Owner:湖南博隽生物医药有限公司

Method for producing alpha-cyanoacrylate adhesive by continuous feeding

ActiveCN112375500AReduce production energy consumptionHigh yieldTransportation and packagingMixersPolymer scienceDepolymerization

The invention relates to a method for producing an alpha-cyanoacrylate adhesive by continuous feeding, which comprises the following steps: pumping ethyl cyanoacetate and an organic solvent into a first mixer by a feeding pump respectively, conducting uniform mixing, and preheating the mixed material 1 by a heat exchanger to obtain a preheated material 1; and converging and mixing the preheated material 1 with formaldehyde and a basic catalyst entering through a feeding pump in a second mixer to obtain a mixed material 2, performing primary polycondensation reaction on the mixed material 2, and then performing polycondensation reaction to obtain an ethyl alpha-cyanoacrylate prepolymer with centralized molecular weight distribution. The method provided by the invention maintains a constantmolar ratio of ethyl cyanoacetate to formaldehyde in the reaction process. According to the invention, continuous feeding of raw materials in the synthesis stage of the ethyl alpha-cyanoacrylate prepolymer is realized, the homogeneity of the polymerization degree of the ethyl alpha-cyanoacrylate prepolymer is improved, the depolymerization temperature range of the ethyl alpha-cyanoacrylate prepolymer is reduced, the energy consumption in the production process is reduced, and the yield and the production efficiency of the product are improved.

Owner:山东禹王和天下新材料有限公司

Composite medical pressure-sensitive adhesive and preparation method thereof

InactiveCN104877578APromote healingHigh medical valueNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveMedicinal herbsAdhesive

The invention provides a composite medical pressure-sensitive adhesive and a preparation method thereof. The composite medical pressure-sensitive adhesive comprises the following components: alpha-cyan ethyl acrylate, dibutyl phthalate, methacrylic acid, alginate, a cissampelos pareira extract and sweetgum resin, wherein the cissampelos pareira extract is extracted by adding water into a crude cissampelos pareira material to extract, concentrating, adding ethanol until the volume concentration of ethanol is 40-60%, filtering to obtain the supernate, and by recycling the ethanol until the volume concentration of the ethanol is less than 2-5%. The preparation method comprises the following steps: mixing and smelting alpha-cyan ethyl acrylate, dibutyl phthalate and methacrylic acid in an open mill, adding alginate, the cissampelos pareira extract and the sweetgum resin, continuously smelting until the components are uniformly dispersed, and vulcanizing by using a press vulcanizer, thereby obtaining the composite medical pressure-sensitive adhesive of requested thickness. Compared with the prior art, the composite medical pressure-sensitive adhesive has the advantages of good mechanical property, good biocompatibility, good injury heal promotion effect and the like.

Owner:SUZHOU BEC BIOLOGICAL TECH

Antibacterial and antiviral composite material for automobile steering wheel

PendingCN112898661APromote decompositionImprove antibacterial propertiesEthyl cyanoacrylateDiphenyl phosphate

The invention discloses an antibacterial and antiviral composite material for an automobile steering wheel. The antibacterial and antiviral composite material is prepared from the following raw materials: polyethylene resin, polylactic resin, mica powder, alpha-ethyl cyanoacrylate, ethylene bis stearamide, diphenyl phosphate and an antibacterial agent. The antibacterial and antiviral composite material for the automobile steering wheel has good mechanical properties, antibacterial and antiviral properties and scratch resistance.

Owner:宇豪(马鞍山)科技有限公司

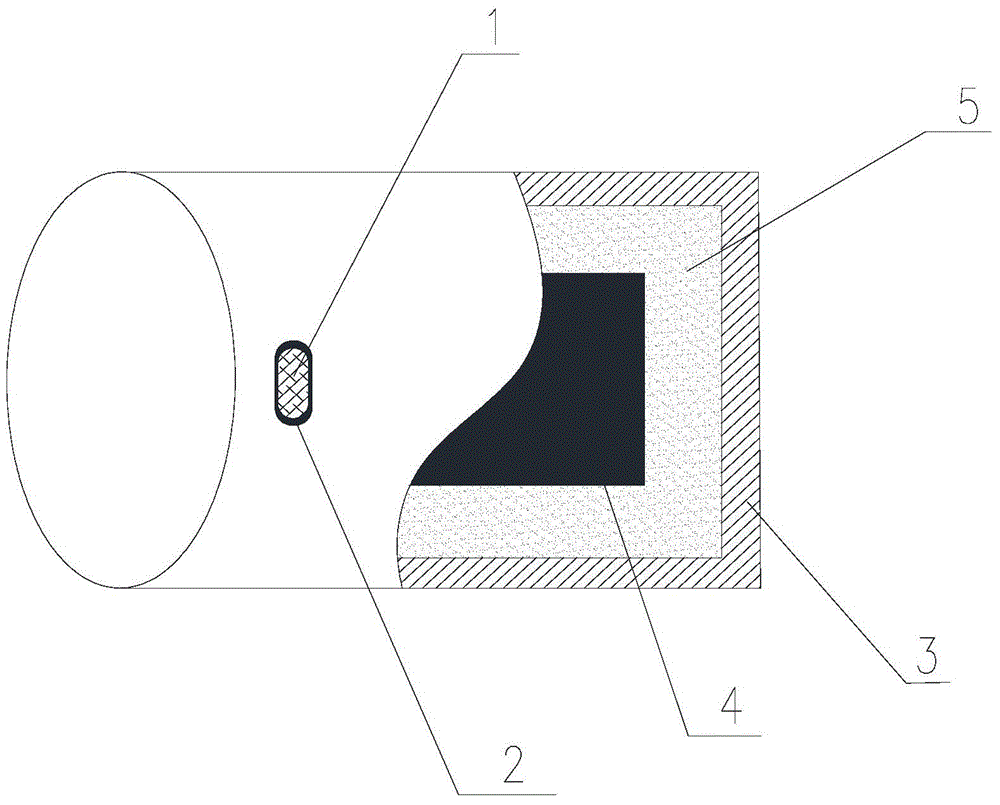

Production device for ethyl alpha-cyanoacrylate

InactiveCN108238979ALow reaction temperatureDelayed reaction timeCarboxylic acid nitrile preparationOrganic compound preparationEthyl acetateStorage tank

The invention discloses a production device for ethyl alpha-cyanoacrylate. The production device mainly includes a storage tank (F101), a storage tank (F102), a storage tank (F103), a storage tank (F104), a raw material pump (J101), a raw material pump (J102), a raw material pump (J103), a raw material pump (J104), a reaction kettle (D101), a delivery pump (J105), a water separator (L101), a condenser (C101), a condenser (C102), a condenser (C103), a cracking kettle (D102), a storage tank (F105), a buffer tank (F106), a vacuum pump (J106), a rectification tower (E101), a non-boiling-range product receiving tank (F107), and a finished-product receiving tank (F108), wherein the storage tank (F101) is used to store ethyl cyanoacetate, the storage tank (F102) is used to store dichloroethane, the storage tank (F103) is used to store formaldehyde, the storage tank (F104) is used to store dibutyl phthalate, the storage tank (F105) is used to store a crude product, and the storage tank (F104)has a cone bottom height of 470-475mm.

Owner:成都麦克贝恩科技有限公司

Instant dry adhesive and preparation method thereof

InactiveCN113773758AImprove impact resistanceEnhanced resistance to peelingNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveEthyl cyanoacrylatePolymer science

The invention provides an instant-dry adhesive and a preparation method thereof. The instant-dry adhesive is prepared from the following raw materials in parts by weight: 55 to 80 parts of alpha-ethyl cyanoacrylate, 10 to 40 parts of thickening agent, 1 to 3 parts of organic solvent, 0.5 to 5 parts of graphene and 0.5 to 5 parts of carbon nano tube. The invention also provides a preparation method of the instant-dry adhesive. The instant-dry adhesive has the advantages of being high in water resistance, impact resistance, high temperature resistance and corrosion resistance, and also has good binding power during construction in a water medium.

Owner:深圳市燊凝科技有限公司

Antibacterial coating

InactiveCN104356699AHas natural antibacterial ingredientsImprove antibacterial propertiesAntifouling/underwater paintsAlkali metal silicate coatingsSODIUM METAPHOSPHATESodium phosphates

The invention relates to an antibacterial coating which comprises the following raw materials in parts by weight: water glass, alpha-ethyl cyanoacrylate, titanium dioxide, talcum powder, cylindrin, di-tert-butyl peroxide, glyoxal, sodium hexametaphosphate, sodium chloride, sodium sulfate, ethylene glycol, borax, furocoumarin and bamboo leaf phenolic ketone. The coating contains natural antibacterial components, is lasting in antibacterial effect, strong in adhesive power and good in mould forming property, and can be widely applied to the surfaces of various objects.

Owner:QINGDAO TONGSHENGTONG RUBBER & PLASTIC

Adhesive for lithium ion batteries and preparation method of adhesive for lithium ion batteries

ActiveCN105810948AImprove applicabilityImprove toughnessCell electrodesSecondary cellsAdhesiveLithium-ion battery

The invention discloses an adhesive for lithium ion batteries and a preparation method of the adhesive for the lithium ion batteries. The adhesive is prepared from 2-cyanoacrylates, cyanoethyl ethylenediamine, citric acid, polyethyleneimine, a modified polyacrylate mixture, a coupling agent and an initiator. The preparation method includes: adding the 2-cyanoacrylates, the cyanoethyl ethylenediamine, the citric acid, the polyethyleneimine and the modified polyacrylate mixture into a reaction kettle, well mixing, heating to 60-70 DEG C, adding the coupling agent and the initiator, heating to 80-85 DEG C under inert gas protection, reacting for 40-60min, and cooling to the room temperature to obtain the adhesive. The adhesive for the lithium ion batteries is excellent in usability and further meets utilization requirements.

Owner:JIANGSU SHENSU ELECTRONICS TECH CO LTD

Building insulation coating and its preparing method

InactiveCN104725912AImprove insulation effectExcellent other physical and chemical propertiesCoatingsSarcosineEthyl acetate

The invention discloses building insulation coating. The building insulation coating comprises diatomite, light calcium carbonate, bentonite, ethylene carbonate, 2-cyanoacrylate, triethyleneglycolmonoethylether, hydroxypropyl methyl cellulose, N-oleo sarcosine octadecyl amine, silicon dioxide, and ethyl acetate. The preparing method includes: adding the diatomite, the bentonite, the hydroxypropyl methyl cellulose, the N-oleo sarcosine octadecyl amine and the silicon dioxide into water, performing periodic heating and stirring, drying mixed liquid to obtain solid, crushing the solid, adding the crushed solid into mixed liquid of the ethylene carbonate, the 2-cyanoacrylate and the ethyl acetate, performing heating and stirring in a reflow device, and allowing cooling to room temperature after reflowing; adding the remaining components, and performing stirring at the room temperature before grinding so as to obtain the building insulation coating. The building insulation coating has good thermal insulation, good impact strength and good other physical and chemical characteristics and is widely applicable to the field of coating insulation.

Owner:李孟平

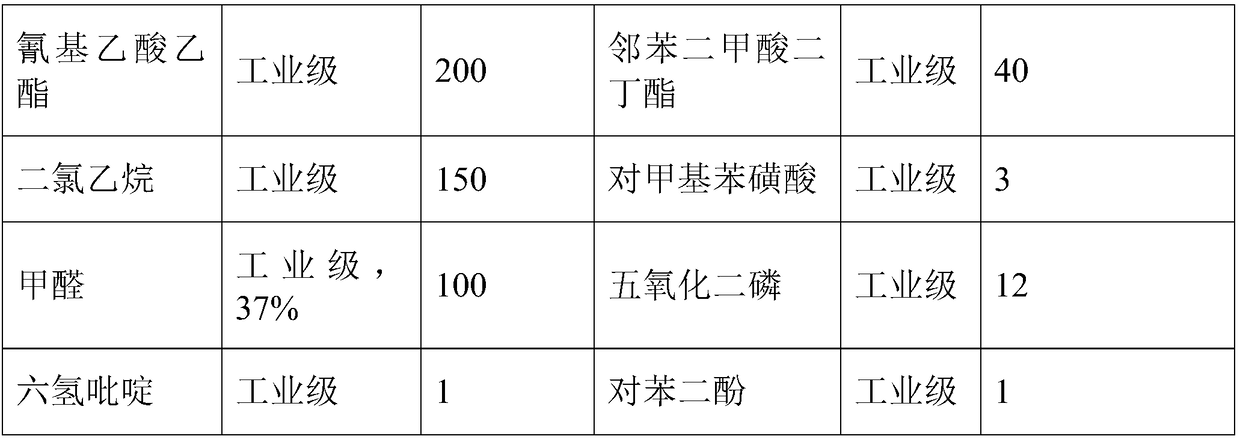

Polylactic acid composite material for 3D (three-dimensional) printing and preparation method thereof

The invention provides a polylactic acid composite material for 3D (three-dimensional) printing and a preparation method thereof. The preparation method of the composite material comprises the following steps: dissolving N-vinyl pyrrolidone in 2-butanone; adding benzoyl peroxide; then, sequentially adding p-methylbenzene sulfonic acid and alpha-ethyl cyanoacrylate; then adding polylactic acid granules; heating and stirring; and cooling to room temperature, wherein the content of polylactic acid is 40-50%, the content of alpha-ethyl cyanoacrylate is 10-20%, the content of N-vinyl pyrrolidone is 10-20%, the content of 2-butanone is 20-30%, the content of benzoyl peroxide is 1-2% and the content of p-methylbenzene sulfonic acid is 1-5%. The composite material provided by the invention is simple in preparation process, and the prepared composite material can be used for 3D printing in a temperature range of 0-40 DEG C without blocking a nozzle of a 3D printer, so that the defect that high-molecular polymers need to be melted under a high temperature condition for conventional 3D printing using a polylactic acid consumable is overcome.

Owner:TAICANG BIQI NEW MATERIAL RES & DEV

Surface treatment method for wooden mold

ActiveCN107442381AOsmotic binding idealHigh hardnessPretreated surfacesPolyester coatingsWater basedEthyl cyanoacrylate

The invention discloses a surface treatment method for a wooden mold, and belongs to the technical field of mold treatment. The surface treatment method is characterized by comprising the steps of 1) polishing the surface of the formed mold, then applying a layer of alpha-ethyl cyanoacrylate under the temperature condition of 20 DEG c-40 DEG c and carrying out drying; and 2) then applying water-based paint for woodware on the mold and then carrying out drying so as to complete the treatment. According to the treatment method, in the treatment process, the alpha-ethyl cyanoacrylate is firstly applied, then the water-based paint is applied after drying, and therefore the purposes of greatly improving the hardness, the wear resistance and the waterproof performance can be achieved at the same time.

Owner:山东华成中德传动设备有限公司

Heat resistance instant dry adhesive and preparation method thereof

InactiveCN103666293BGel quicklyImprove adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesMeth-Adhesive

The invention discloses a heat resistance instant dry adhesive and a preparation method thereof. The heat resistance instant dry adhesive comprises the following components in parts by weight: 80 to 90 parts of ethyl cyanoacrylate, 2 to 8 parts of ethyl cyanoacrylate, 2 to 6 parts of silica, 0.3 to 1 part of nitrobenzene, 0.5 to 2 parts of polyethylene glycol, 0.5 to 1 part of hydroquinone, 5 to 10 parts of polyvinyl acetate, 0.1 to 0.5 part of methanesulfonic acid and 0.05 to 0.1 part of sulfur dioxide. The preparation method comprises the following steps: adding the ethyl cyanoacrylate, the ethyl cyanoacrylate, the nitrobenzene, the hydroquinone, the polyvinyl acetate, the silica, the polyethylene glycol, the methanesulfonic acid and the sulfur dioxide into a reaction kettle; sufficiently stirring and uniformly mixing; heating to a temperature of 70 to 80 DEG C and performing the reaction for 50 to 80 minutes to be a paste state. The heat resistance instant dry adhesive provided by the invention can be rapidly gelled and meanwhile, also can achieve a good binding effect under high temperature conditions of 80 DEG C and 120 DEG C.

Owner:NANTONG REPAIR AIR CHEM BIOENG

Self-lubricating ultrasonic sound guide pad and preparation method thereof

ActiveCN114163944APaste firmlyLow costFilm/foil adhesivesEchographic/ultrasound-imaging preparationsAlkanePolymer science

The invention provides a self-lubricating ultrasonic sound conducting pad and a preparation method thereof. The preparation method of the self-lubricating ultrasonic sound conducting pad comprises the following steps: coating a first surface of a viscous hydrogel layer with an adhesive; an adhesive is smeared on the second surface of the smooth hydrogel layer; bonding the first surface of the viscous hydrogel layer coated with the adhesive with the second surface of the slippery hydrogel layer coated with the adhesive to obtain the self-lubricating ultrasonic sound guide pad; wherein the adhesive comprises an adhesive and a dispersion, the adhesive comprises any one or a combination of more of polyurethane, 2-ethylhexyl acrylate, methyl cyanoacrylate, octyl cyanoacrylate or ethyl cyanoacrylate, and the dispersion comprises an alkene alkane organic matter.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Waterproof glue for wood doors and windows and preparation method thereof

InactiveCN106433494AImprove waterproof performanceImprove crack resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyvinyl alcoholAdhesive

The invention discloses waterproof glue for wood doors and windows. The waterproof glue is prepared from the following materials in parts by weight: 42-45 parts of neoprene, 16-20 parts of castor oil, 7-15 parts of nanometer silicon, 5-8 parts of sodium nitrite, 7-12 parts of ethyl acetate, 6-10 parts of toluene diisocynate, 9-15 parts of ethyl cyanoacrylate, 6-10 parts of lignosulfonate, 4-8 parts of titanium dioxide, 12-16 parts of epoxy acrylate, 13-18 parts of polyvinyl acetal adhesive, 10-15 parts of dibutyl phthalate, 12-15 parts of asbestos powder, 5-10 parts of dibasic lead phthalate, 2-6 parts of dihydropyridine, 4-7 parts of metallic soap, 4-9 parts of p-phenylenediamine, 11-16 parts of glycerol trioleate and 6-8 parts of calcium propionate. The waterproof glue for wood doors and windows has good waterproof effects, good anti-crack effects and strong adhesive force.

Owner:ANHUI KATA DOOR & WINDOW

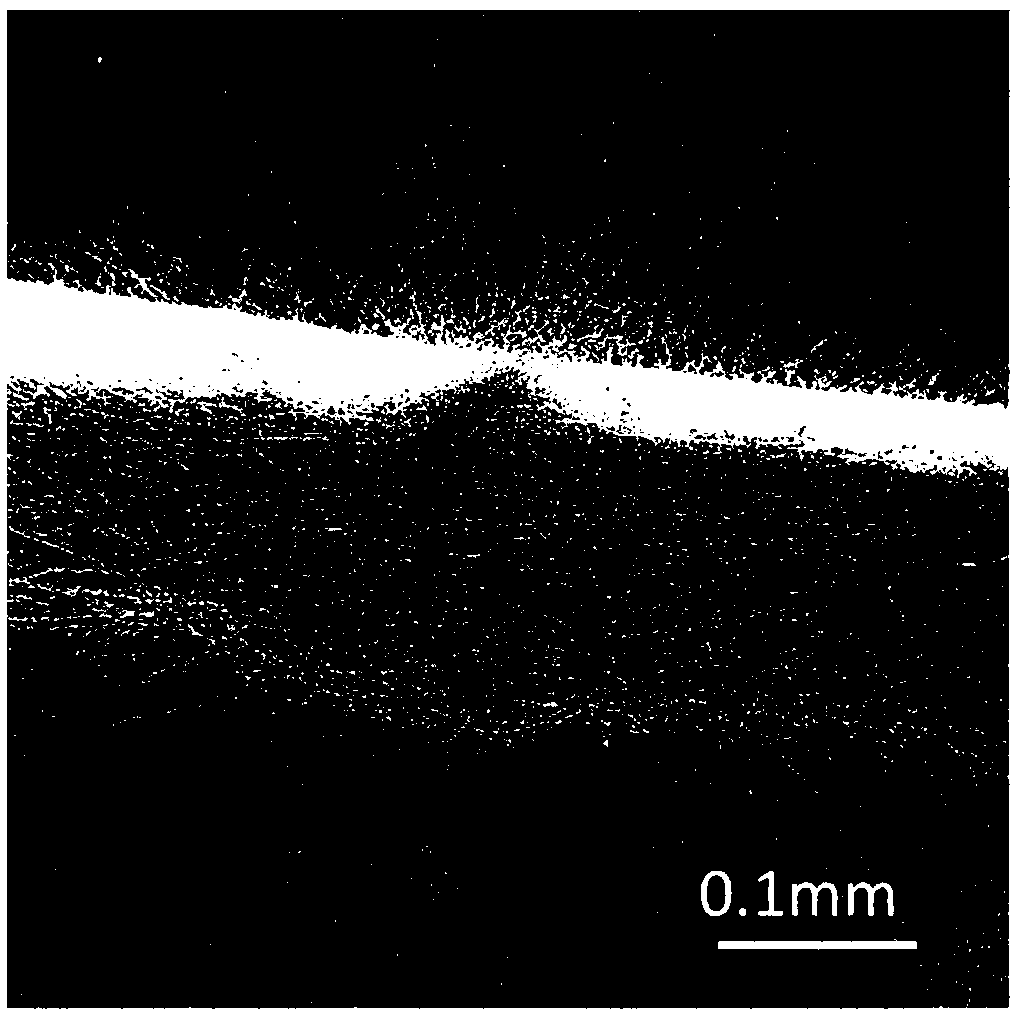

Sample preparation method and mold for peel strength test on coated fabric

ActiveCN107389399ASolve the shortcomings that cannot reflect the real strengthPreparing sample for investigationEthyl cyanoacrylateAdhesive

The invention discloses a sample preparation method and a sample preparation mold for a peel strength test on coated fabric. An adhesive adopted in a gluing and conglutination step in a sample preparation process is a single-componnet moisture-cured adhesive; ethyl cyanoacrylate is contained in the single-componnet moisture-cured adhesive; the compaction and the curing are carried out by adopting a sample preparation compaction mold in a compaction and curing step in the sample preparation process; the sample preparation compaction mold comprises a base and a gland which can be put together in a covering manner; multiple compaction grooves which are arranged in parallel are processed in the upper surface of the base; the tops of the compaction grooves are open; certain end surfaces of the compaction grooves are open; the lower surface of the gland is provided with multiple press heads correspondingly matched with the compaction grooves in a one-to-one correspondence manner. The sample preparation method provided by the invention can effectively keep the peel strength of a coating changeless, can be further used for the test, is applicable to the preparation of a test sample for the T-shaped peel strength of most coated fabric, and is especially applicable to PU (Polyurethane) and PVC (Polyvinyl Chloride) coated fabric.

Owner:中央军委后勤保障部建筑工程研究所

Method for sealing tenon on instrument shell

ActiveCN103980823AImprove reliabilityFast curingAdhesive processes with surface pretreatmentOrganic non-macromolecular adhesiveWaxEthyl cyanoacrylate

The invention provides a method for sealing a tenon on an instrument shell. According to the method, a quick dry adhesive with Alpha-ethyl cyanoacrylate as a main component is applied into a gap between a flight parameter recorder shell and the tenon so as to achieve the aims of sealing and preventing liquid wax from flowing out. After the method is adopted, even if burning happens, since an adhesive layer in the gap is rapidly carbonized to form a solid blockage, the sealing function does not fail, so that electronic elements are effectively protected; the adhesive layer is not corroded when being soaked in seawater, therefore the protection time is prolonged and consequently the precious time is prolonged for search and rescue work.

Owner:SHAANXI BAOCHENG AVIATION INSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com