Anti-corrosive coating for aluminum electrolytic cells and preparation method thereof

An anti-corrosion coating, aluminum electrolytic cell technology, applied in anti-corrosion coatings, coatings and other directions, can solve the problem of anti-corrosion coating adhesion, water resistance and poor acid and alkali resistance, tank shutdown overhaul, aluminum electrolytic cell protection can not function for a long time, etc. problem, to achieve the effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

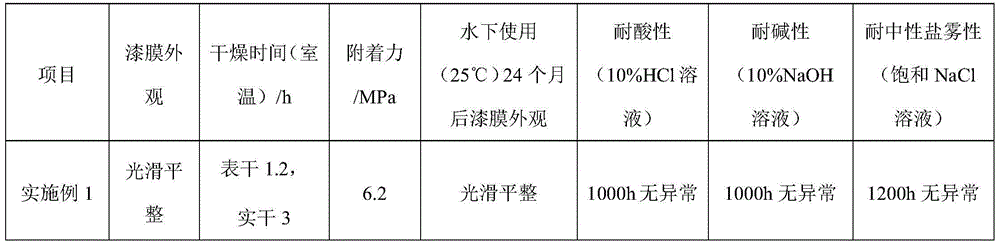

Embodiment 1

[0021] An anticorrosion coating for an aluminum electrolytic cell, comprising: 10 parts of polycarbonate, 5 parts of phenolic resin, 2 parts of barium stearate, 0.2 part of silicone defoamer, 5 parts of ethyl 2-cyanoacrylate by weight components Parts, 3 parts of ethylene glycol dimethacrylate, 0.2 part of hexamethylenetetramine, 0.8 part of carboxymethyl cellulose, 8002 parts of polyethylene glycol, 5 parts of polyvinyl formal, polyboron silicone 1 part of oxane.

[0022] The preparation method of the anticorrosion coating for the aluminum electrolytic cell comprises the following steps:

[0023] Step 1, polycarbonate, phenolic resin, barium stearate, ethyl 2-cyanoacrylate, ethylene glycol dimethacrylate, carboxymethyl cellulose and polyethylene glycol 800 are mixed uniformly, specifically as follows: Stir at 150 rpm for 30 minutes to obtain mixture 1;

[0024] Step 2: Add mixture 1 to the reaction kettle, raise the temperature to 80°C under nitrogen protection, stir for 40...

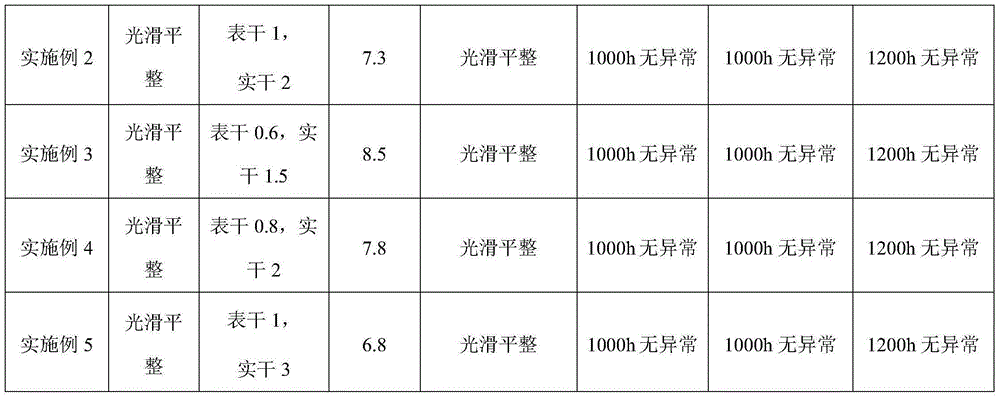

Embodiment 2

[0027] An anticorrosion coating for an aluminum electrolytic cell, comprising by weight components: 13 parts of polycarbonate, 7 parts of phenolic resin, 3 parts of barium stearate, 0.4 part of silicone defoamer, 6 parts of ethyl 2-cyanoacrylate 5 parts of ethylene glycol dimethacrylate, 0.3 parts of hexamethylenetetramine, 1 part of carboxymethyl cellulose, 8003 parts of polyethylene glycol, 7 parts of polyvinyl formal, polyboron silicone 2 parts of oxane.

[0028] The preparation method of the anticorrosion coating for the aluminum electrolytic cell comprises the following steps:

[0029] Step 1, polycarbonate, phenolic resin, barium stearate, ethyl 2-cyanoacrylate, ethylene glycol dimethacrylate, carboxymethyl cellulose and polyethylene glycol 800 are mixed uniformly, specifically as follows: Stir at 150 rpm for 30 minutes to obtain mixture 1;

[0030] Step 2: Add mixture 1 to the reaction kettle, raise the temperature to 80°C under the protection of inert gas, stir for 4...

Embodiment 3

[0033] An anti-corrosion coating for an aluminum electrolytic cell, comprising by weight components: 15 parts of polycarbonate, 8 parts of phenolic resin, 4 parts of barium stearate, 0.5 part of silicone defoamer, 7 parts of ethyl 2-cyanoacrylate 6 parts, 6 parts of ethylene glycol dimethacrylate, 0.4 parts of hexamethylenetetramine, 1.3 parts of carboxymethyl cellulose, 8004 parts of polyethylene glycol, 8 parts of polyvinyl formal, polyboron silicone 3 parts of oxane.

[0034] The preparation method of the anticorrosion coating for the aluminum electrolytic cell comprises the following steps:

[0035] Step 1, polycarbonate, phenolic resin, barium stearate, ethyl 2-cyanoacrylate, ethylene glycol dimethacrylate, carboxymethyl cellulose and polyethylene glycol 800 are mixed uniformly, specifically as follows: Stir at 170 rpm for 40 minutes to obtain mixture 1;

[0036] Step 2: Add mixture 1 to the reaction kettle, raise the temperature to 85°C under the protection of inert ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com