Anti-haze window screen based on electrospinning technology and preparation method thereof

An electrospinning technology and anti-smog technology, which is applied in the field of anti-smog window screens and its preparation, can solve the problems of inability to meet the needs of industrialized production, complicated filter material combination process, and hindering the protective effect, so as to achieve enhanced strength and enhanced combination effect, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

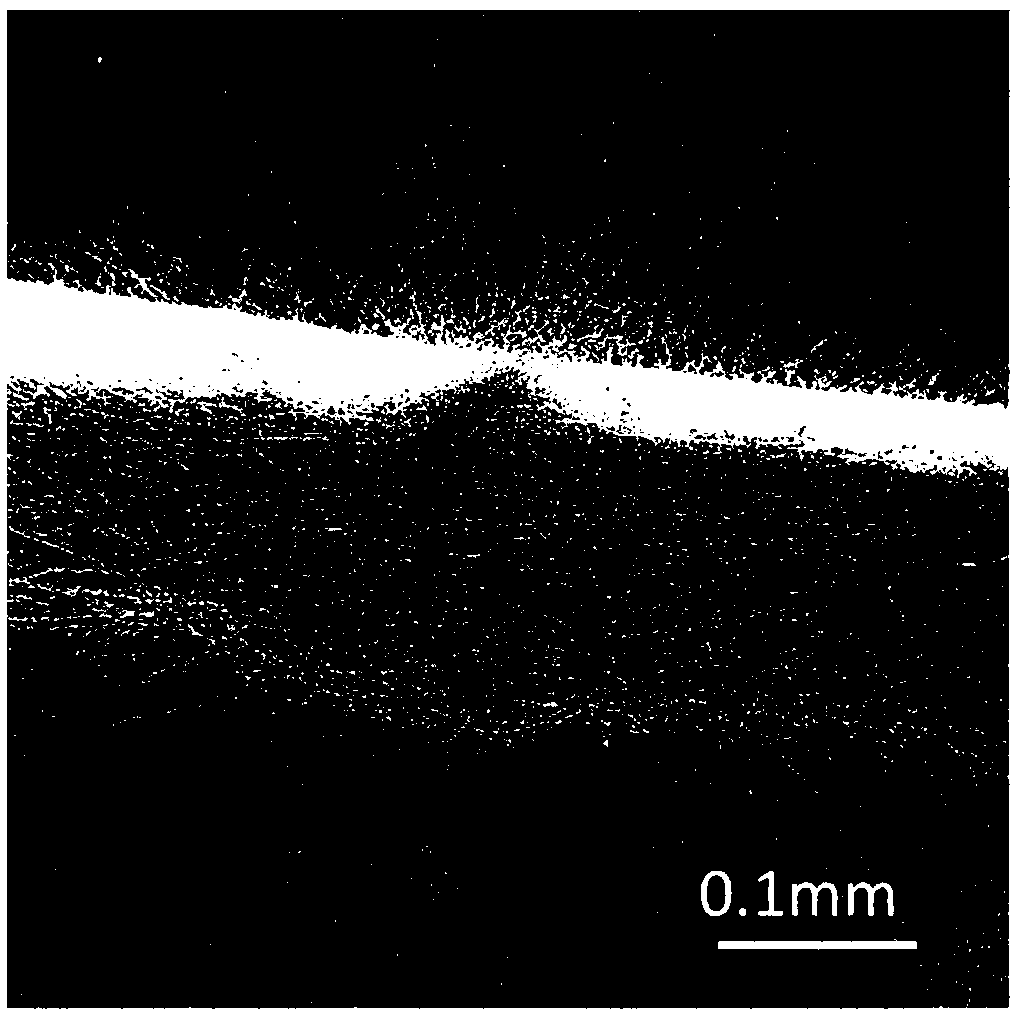

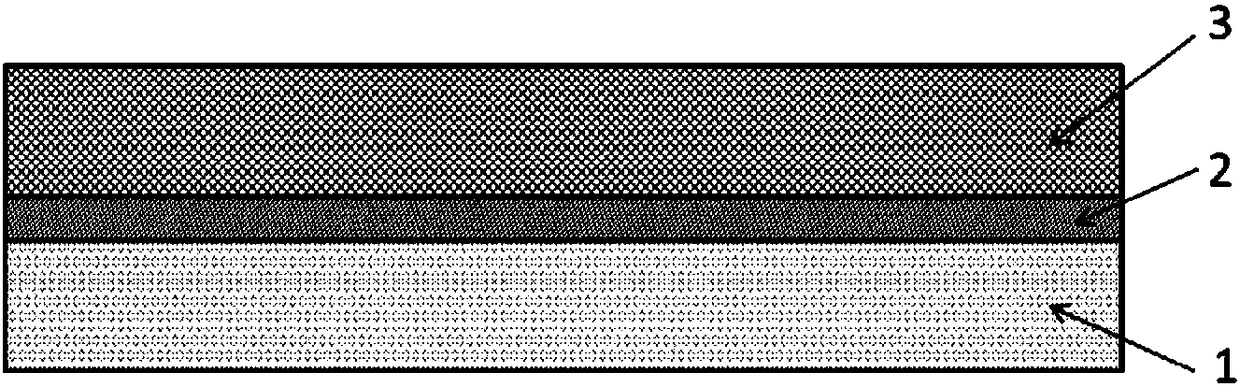

Image

Examples

preparation example Construction

[0030] The preparation method of the nano graphene used in the embodiment of the present invention comprises the following steps:

[0031] (a) Preparation of graphene oxide: in an ice-water bath at 0°C, sequentially add concentrated sulfuric acid and potassium permanganate with a mass fraction of 98% to expandable graphite, stir evenly at a temperature lower than 20°C, and place in a water bath Raise the temperature to 35°C and keep it for 1.5h; add ultrapure water to the obtained solution to dilute until the solution is brown, heat it in a water bath to 95°C, and keep it for 30-40min; add a 30% hydrogen peroxide solution to the solution to The solution turned khaki and cooled to room temperature; the obtained solution was suction filtered to obtain a yellow solid, which was acid-washed twice and then washed with deionized water until the washing liquid was neutral, and the solid was ultrasonically dispersed in ultrapure water Obtain a brown solution, freeze-dry after centrifu...

Embodiment 1

[0034] A preparation method of an anti-smog window screen based on electrospinning technology, comprising the following steps:

[0035] (1) Configure the precursor spinning solution: add nano-graphene to the mixed solvent of dimethylformamide (DMF) and acetone, and in the mixed solvent, N,N-dimethylformamide (DMF) and acetone The volume ratio of the solution is 1:1, and it is treated with an ultrasonic breaker for 2 hours, so that the nano-graphene is uniformly dispersed in the solvent to make a 0.05wt% nano-graphene dispersion, and it is added to the nano-graphene dispersion under heating and stirring in a water bath at 60 ° C. PVDF, stirred for 8 hours until the mixed solution was evenly clarified; then added PEO to the solution and continued to stir for 12 hours to obtain a homogeneous and transparent precursor spinning solution with suitable viscosity. The content of PVDF in the resulting precursor spinning solution was 15wt%, and the content of PEO was 0.8wt%;

[0036] (...

Embodiment 2

[0042] A preparation method of an anti-smog window screen based on electrospinning technology, comprising the following steps:

[0043] (1) Configure the precursor spinning solution: add nano-graphene to the mixed solvent of dimethylformamide (DMF) and acetone, and in the mixed solvent, N,N-dimethylformamide (DMF) and acetone The volume ratio of the solution is 1:1, and it is processed with an ultrasonic breaker for 3 hours, so that the nano-graphene is uniformly dispersed in the solvent to make a 0.25wt% nano-graphene dispersion, and it is added to the nano-graphene dispersion under heating and stirring in a water bath at 60 ° C. PVDF, stirred for 8 hours until the mixed solution was evenly clarified; then added PEO to the solution and continued to stir for 12 hours to obtain a homogeneous and transparent precursor spinning solution with suitable viscosity. The content of PVDF in the resulting precursor spinning solution was 19wt%, and the content of PEO was 0.6wt%;

[0044]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com