double sided adhesive tape

A double-sided adhesive tape and adhesive layer technology, applied in the direction of adhesive types, ester copolymer adhesives, film/sheet adhesives, etc., can solve the problem of difficult to obtain waterproof, uneven tracking Resilience (deterioration of height difference followability, water resistance problems, etc., to achieve the effect of excellent re-peelability and thin total thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0201] In a reaction vessel with a condenser tube, a nitrogen inlet tube, a thermometer, a dropping funnel, and a stirring device, add 69 parts by weight of toluene, 163 parts by weight of ethyl acetate as a solvent, 80 parts by weight of butyl acrylate, 2-ethyl acrylic acid 20 parts by weight of hexyl ester, 3 parts by weight of acrylic acid, 5 parts by weight of vinyl acetate, 0.1 part by weight of 2-hydroxyethyl acrylate, and 0.2 parts by weight of 2,2-azobisisobutyronitrile as initiators, in a nitrogen stream Polymerization was carried out at 60° C. for 6 hours to obtain a solution of an acrylic polymer.

[0202] In this solution, 30 parts by weight of a polymerized rosin ester resin (softening point: 123°C) and 1.5 parts by weight (in terms of solid content) of an isocyanate crosslinking agent (trade name " Coronet L", manufactured by Nippon Polyurethane Industry Co., Ltd.) to obtain an acrylic adhesive composition.

[0203] This acrylic pressure-sensitive adhesive compo...

Embodiment 2

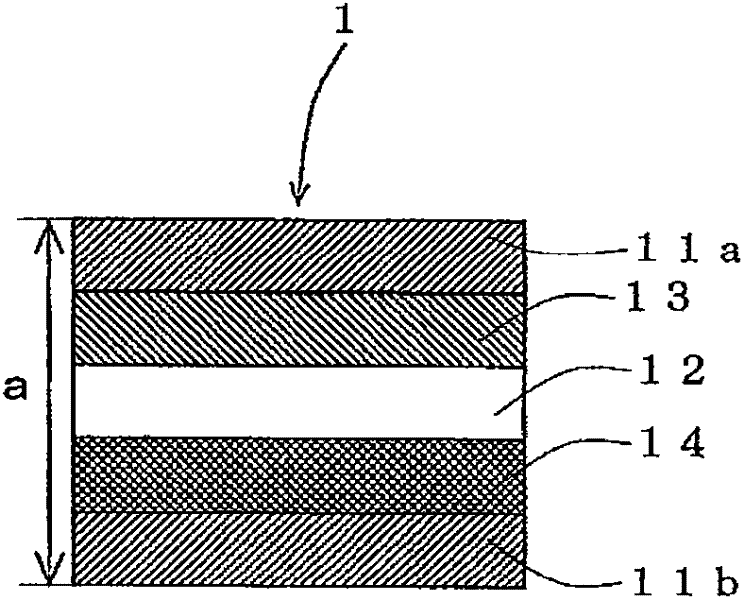

[0206] In addition to using a PET base material (non-bubble structure, thickness: 12 μm, trade name “Lumira S-10#12”, manufactured by Toray Co., Ltd.) instead of a PET base material (bubble-free structure, thickness: 5 μm, trade name “Lumira-S-10#12”) #5AF53 ", manufactured by Toray Co., Ltd.), in the same manner as in Example 1, an adhesive layer (adhesive layer on the surface layer on the side of the foam layer) / foam layer / adhesive layer / reinforcing layer / double-sided adhesive tape (total thickness: 187 μm) of the adhesive layer (adhesive layer of the reinforcing layer side surface layer).

Embodiment 3

[0208] In addition to using a foam (trade name "ボラ一ラ XL-HN#03001Wシヨヨリクロ", manufactured by Sekisui Chemical Industry Co., Ltd., thickness: 100 μm, average cell diameter: 163 μm, density: 0.34 g / cc) as the foam, And use PET base material (non-bubble structure, thickness: 25 μ m, trade name " ルミラ-S-10#25 ", manufactured by Toray Co., Ltd.) instead of PET base material (no-bubble structure, thickness: 5 μm, trade name "ルミラ-S-10#25", trade name "ルミラ-S-10#25" #5AF53 ", manufactured by Toray Co., Ltd.), in the same manner as in Example 1, an adhesive layer (adhesive layer on the surface layer on the side of the foam layer) / foam layer / adhesive layer / reinforcing layer / double-sided adhesive tape (total thickness: 200 μm) of the adhesive layer (adhesive layer of the reinforcing layer side surface layer).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com