A kind of high wear-resisting and anti-stripping electrostatic spinning nanofiber composite filter material and its spinning method

An electrospinning and nanofiber technology, which is applied in the field of high wear-resistant and anti-stripping electrospun nanofiber composite filter materials and its spinning, can solve the problem of non-stripping resistance of the substrate and nanofiber layer, poor wear resistance, and low strength. problem, to achieve excellent anti-peeling performance, excellent performance, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

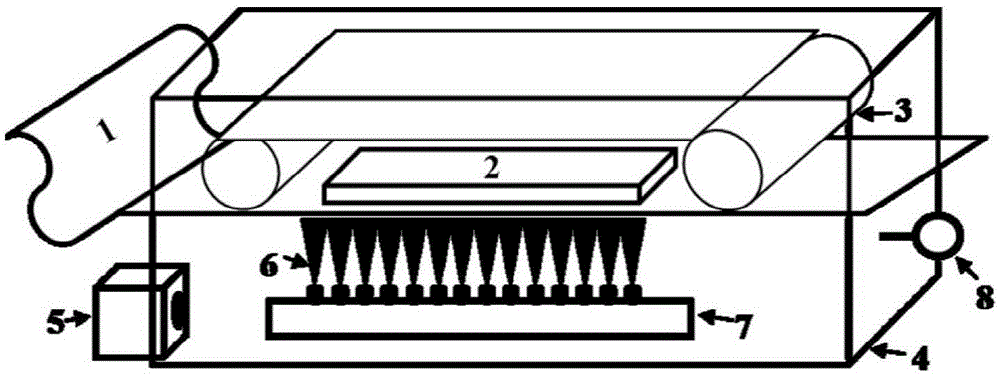

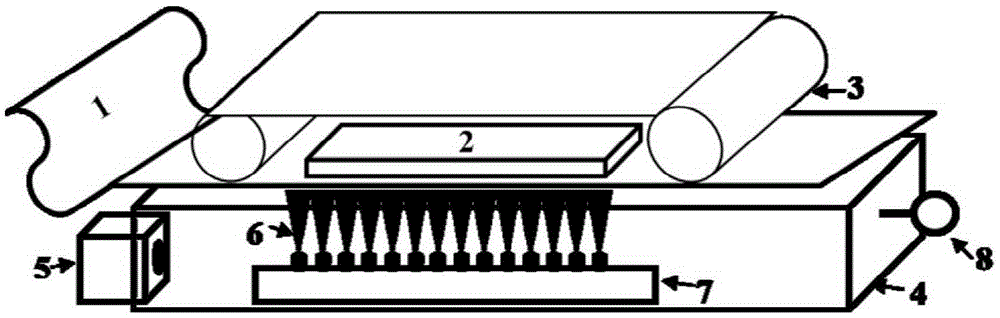

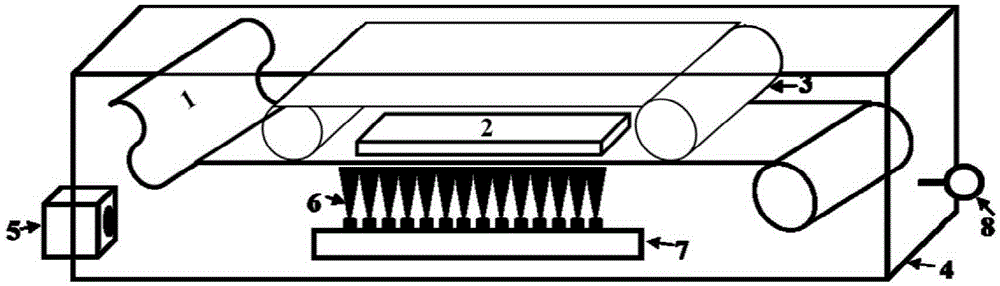

Image

Examples

Embodiment 1

[0047] A high wear-resistant and anti-stripping electrostatic spinning nanofiber composite filter material and its spinning method, the specific steps are:

[0048] Step 1: The polyacrylonitrile powder and the polysulfone resin particles were placed in a vacuum oven at 70°C for 1.5 hours and a vacuum oven at 110°C for 2.5 hours, respectively.

[0049] The second step: dissolve the dried polyacrylonitrile powder in the DMF solution, place the solution on a magnetic stirrer and stir for 15 hours respectively to form a homogeneous solution; in the homogeneous solution, the mass of polyacrylonitrile The fraction is 30%; while polysulfone resin particles are dissolved in DMF solution, the solution is placed on a magnetic stirrer and stirred for 15 hours to form a homogeneous solution; in the homogeneous solution, the mass fraction of polysulfone is 35% %

[0050] Step 3: Draw a certain amount of DMF solvent into a 10mL needle tube, and then electrostatically spray it onto the rece...

Embodiment 2

[0053] A high wear-resistant and anti-stripping electrostatic spinning nanofiber composite filter material and its spinning method, the specific steps are:

[0054] Step 1: Place the polyethylene oxide powder and polyurethane particles in a vacuum oven at 70°C for 1.5 hours and in a vacuum oven at 110°C for 2.5 hours, respectively.

[0055]The second step: dissolve the dried polyethylene oxide powder in the DMAc solution, place the solution on a magnetic stirrer and stir for 15 hours respectively to form a homogeneous solution; in the homogeneous solution, the mass of polyethylene oxide Fraction is 28%; Polyurethane particle is dissolved in DMF solution simultaneously, and described solution is placed on magnetic stirrer and stirs 15 hours respectively, forms homogeneous solution; In described homogeneous solution, the massfraction of polyurethane is 30%

[0056] Step 3: Draw a certain amount of DMAc solvent into a 10mL needle tube, and electrostatically spray it onto the rece...

Embodiment 3

[0059] A high wear-resistant and anti-stripping electrostatic spinning nanofiber composite filter material and its spinning method, the specific steps are:

[0060] Step 1: Place the polycaprolactone particles and the polyethersulfone particles in a vacuum oven at 40°C for 3.5 hours and in a vacuum oven at 150°C for 1.0 hour, respectively.

[0061] Second step: dissolve the dried polycaprolactone particles in acetone, place the solution on a magnetic stirrer and stir for 10 hours respectively to form a homogeneous solution; in the homogeneous solution, polycaprolactone The mass fraction is 20%; while the polyethersulfone particles are dissolved in the NMP solution, the solution is placed on a magnetic stirrer and stirred for 15 hours to form a homogeneous solution; in the homogeneous solution, the mass fraction of polyethersulfone 40%

[0062] Step 3: Draw a certain amount of acetone solvent into a 10mL needle tube, and electrostatically spray it onto the receiving substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| stiffness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com