Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

211results about How to "Increase dust holding capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

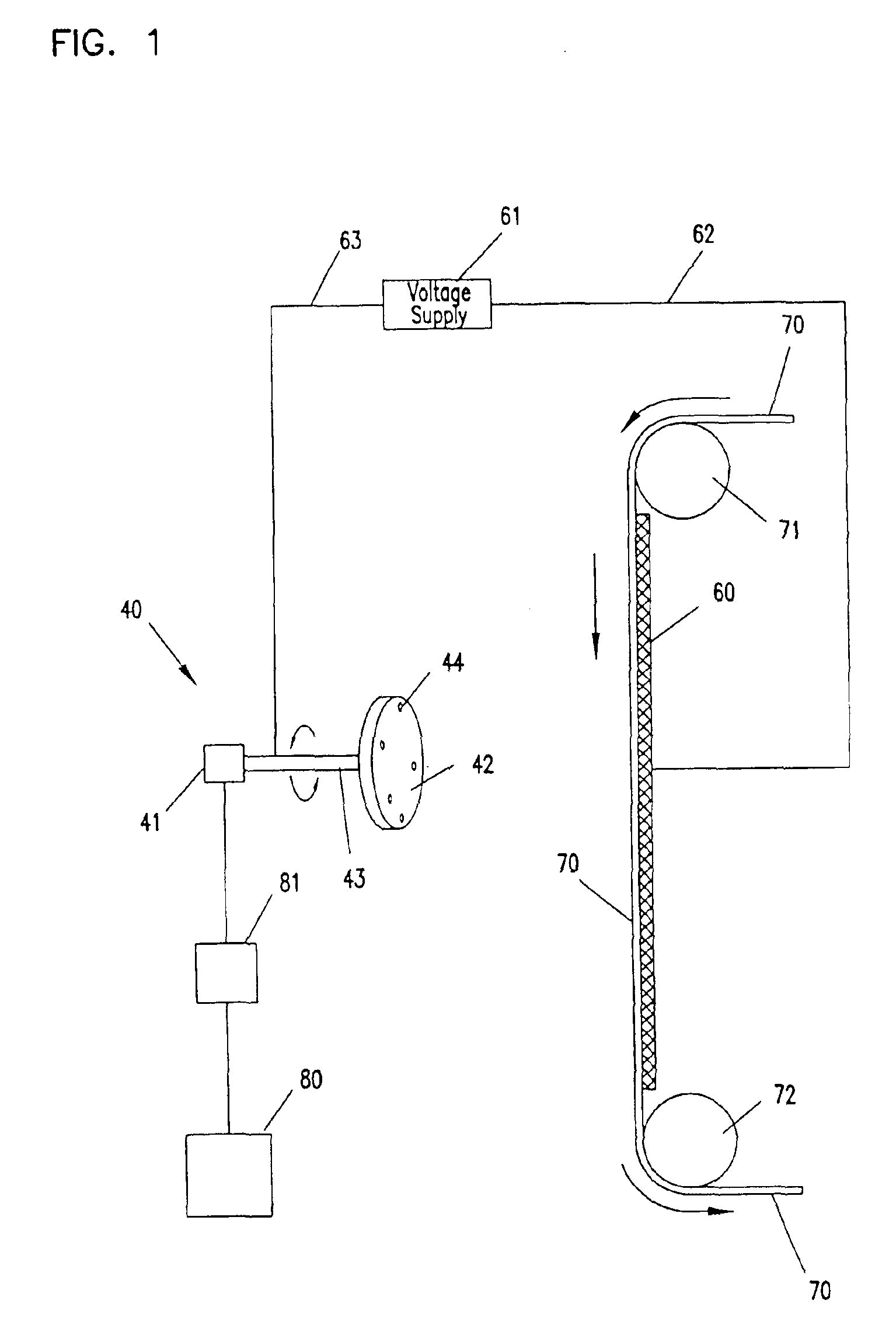

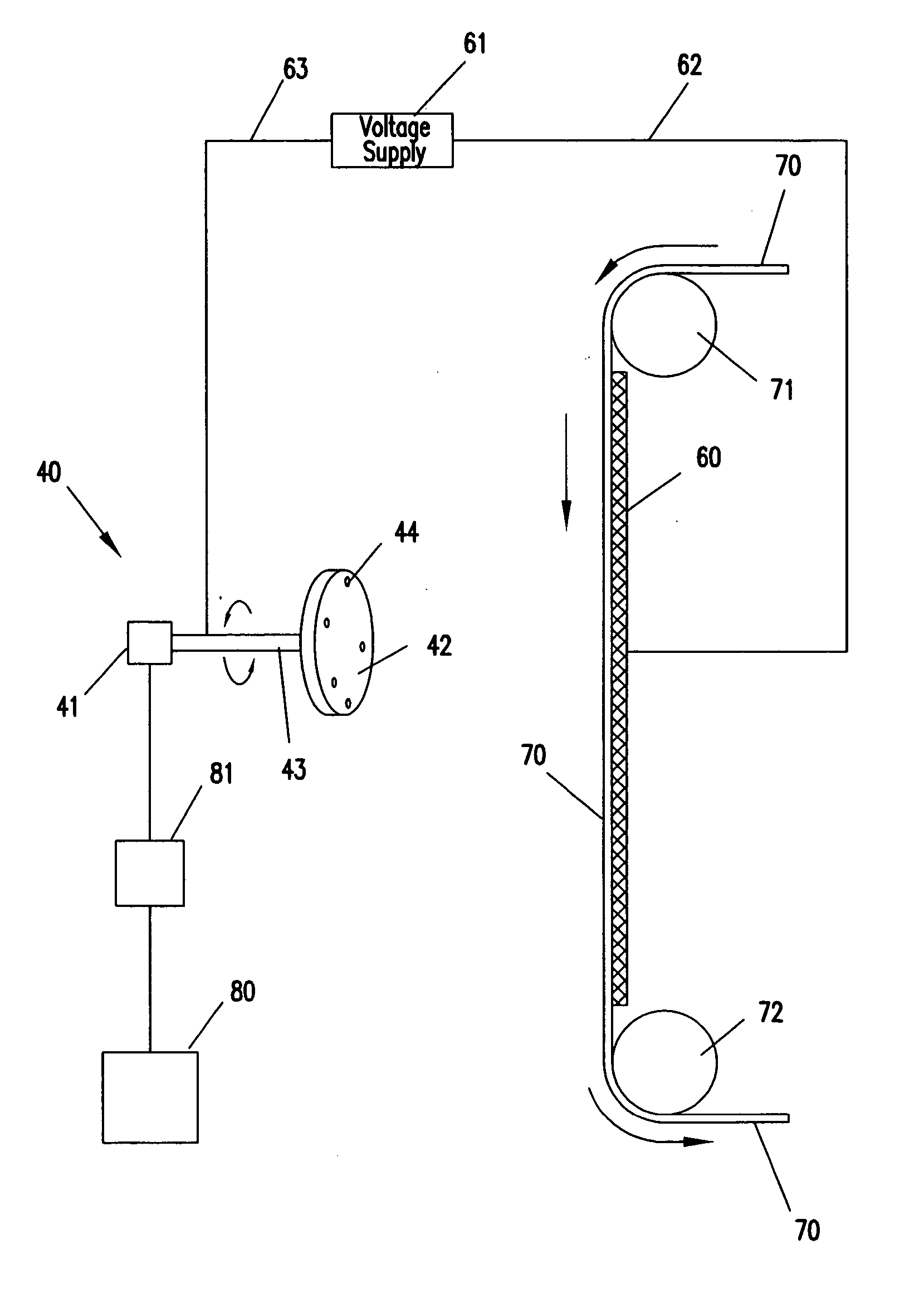

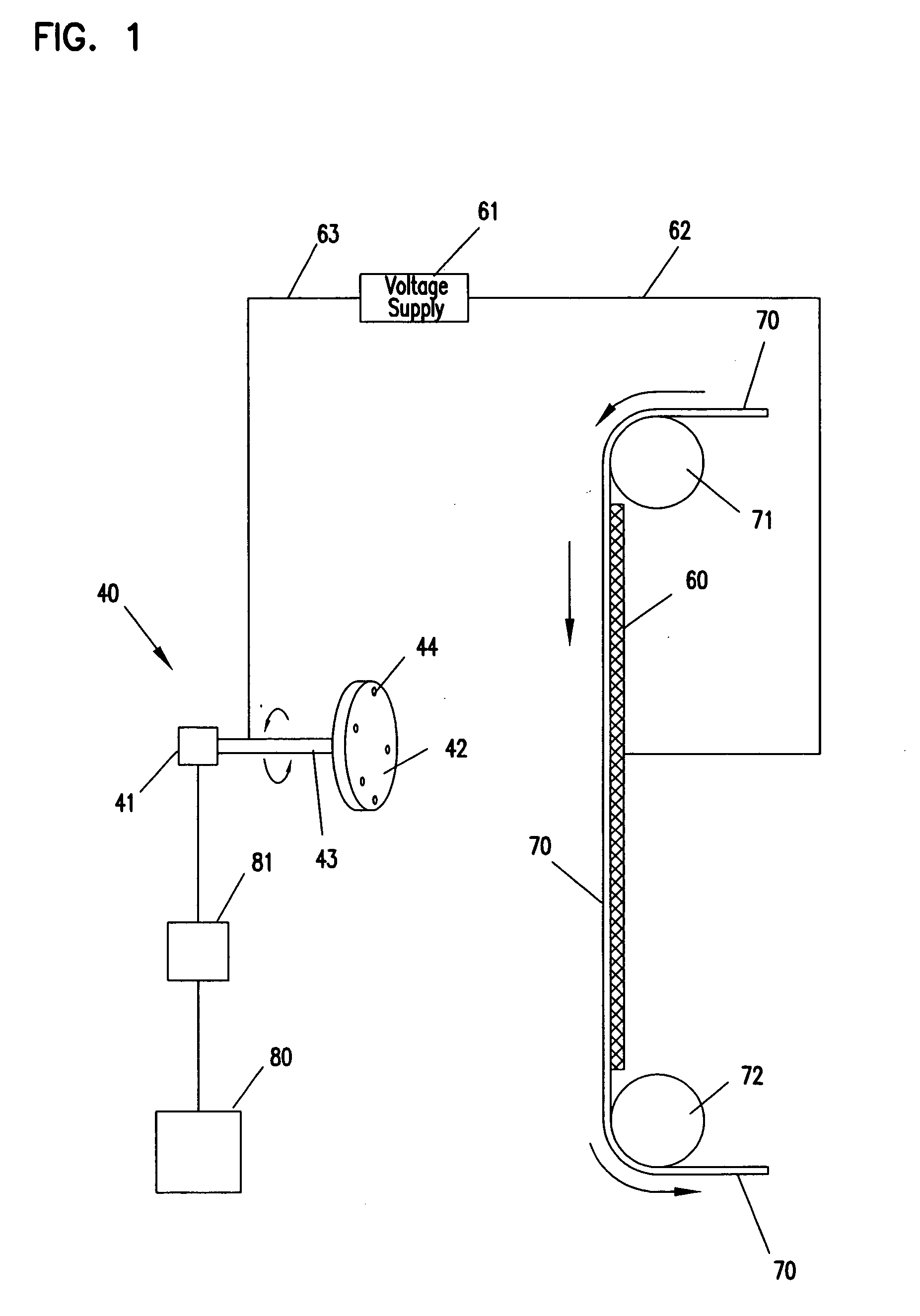

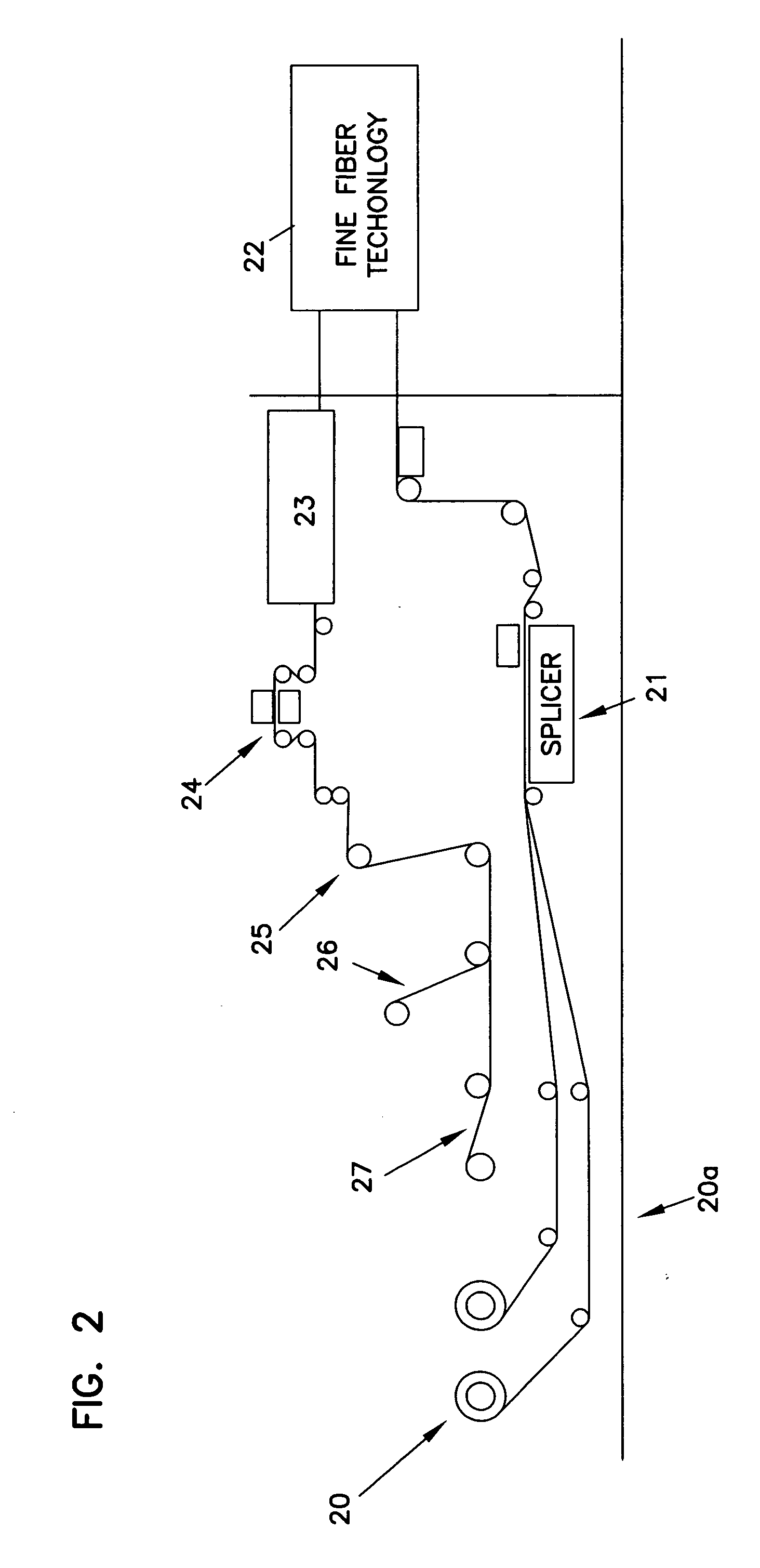

Polymer, polymer microfiber, polymer nanofiber and applications including filter structures

InactiveUS6924028B2Simple materialSubstantial surface loadingCombination devicesMaterial nanotechnologyPolymer scienceNanofiber

Disclosed are improved polymer materials. Also disclosed are fine fiber materials that can be made from the improved polymeric materials in the form of microfiber and nanofiber structures. The microfiber and nanofiber structures can be used in a variety of useful applications including the formation of filter materials.

Owner:DONALDSON CO INC

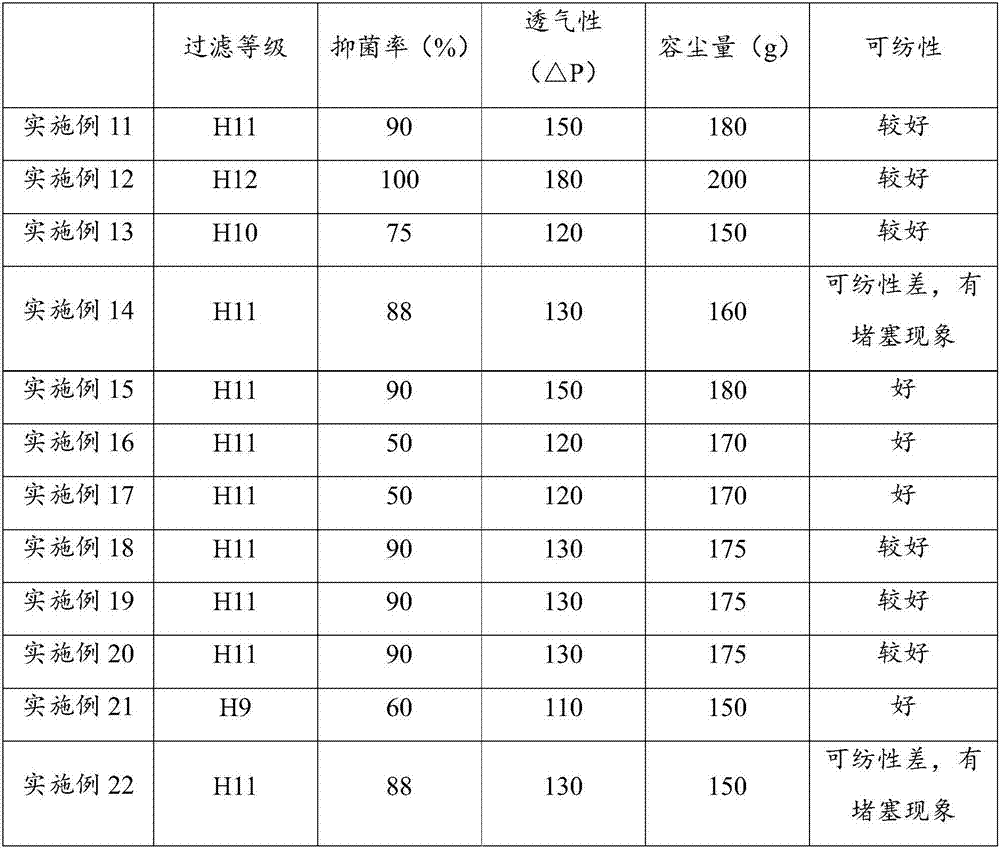

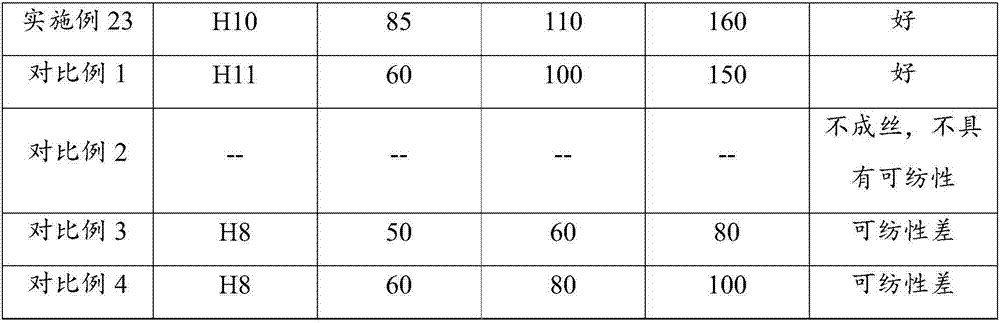

Modified polypropylene master batch, melt-blow cloth, preparation method and application thereof

InactiveCN107286473ALarge specific surface areaHigh conductivityFiltration separationNon-woven fabricsGraphene derivativesAntioxidant

The invention provides a modified polypropylene master batch, melt-blow cloth, a preparation method and an application thereof. The modified polypropylene master batch is mainly produced from, by weight, 77-90% of polypropylene, 5-20% of a graphene material and 1-5% of an additive. The graphene material includes any one or more of graphene, graphene oxide and graphene derivative. The additive includes any one or more of a coupling agent, a dispersant and an antioxidant and preferably includes the coupling agent, the dispersant and the antioxidant. The modified polypropylene master batch, when being used for manufacturing the melt-blow cloth, not only improves antibacterial and electrification property but also increases the filtering efficiency and dust capacity of the melt-blow cloth.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

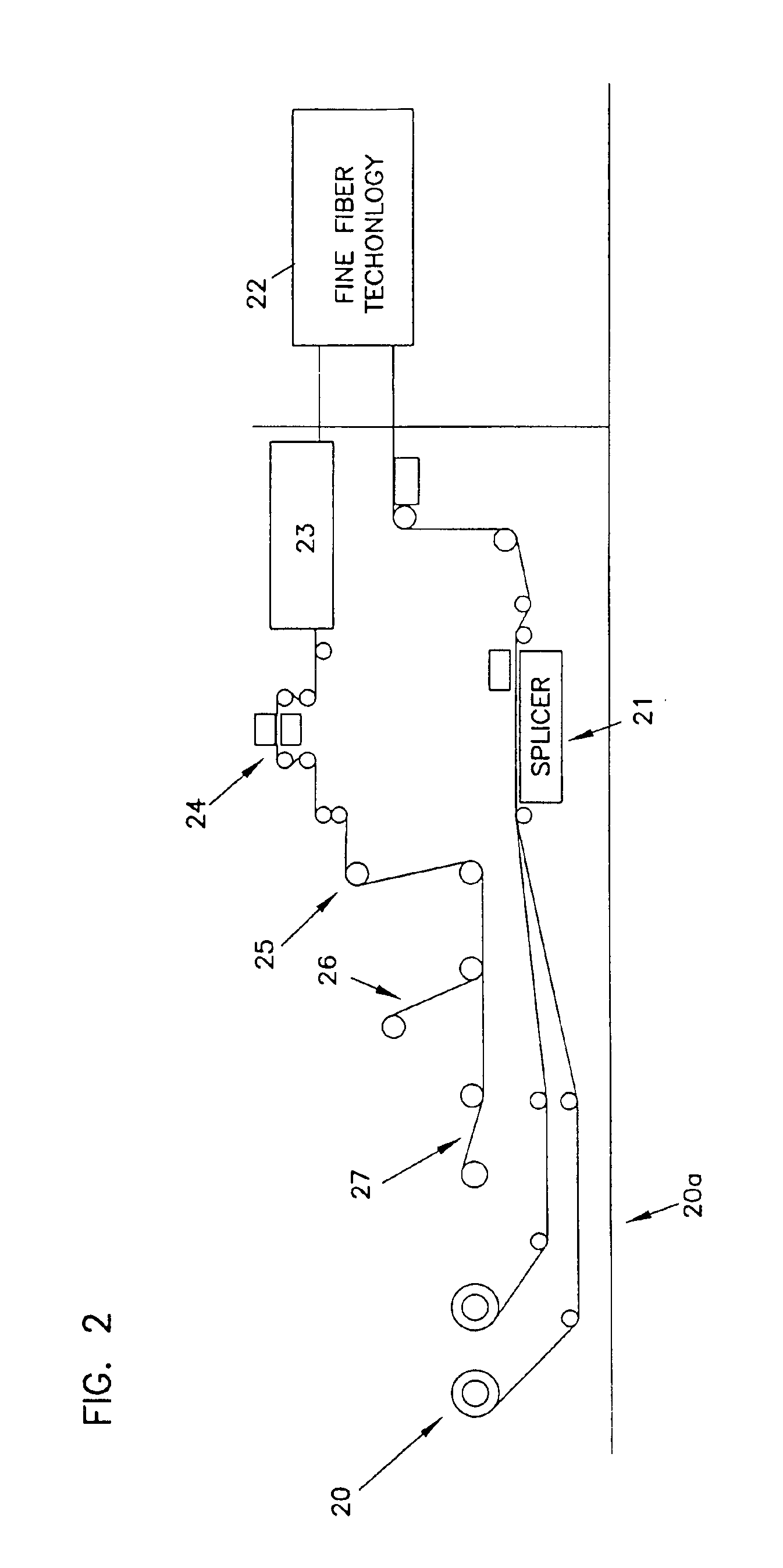

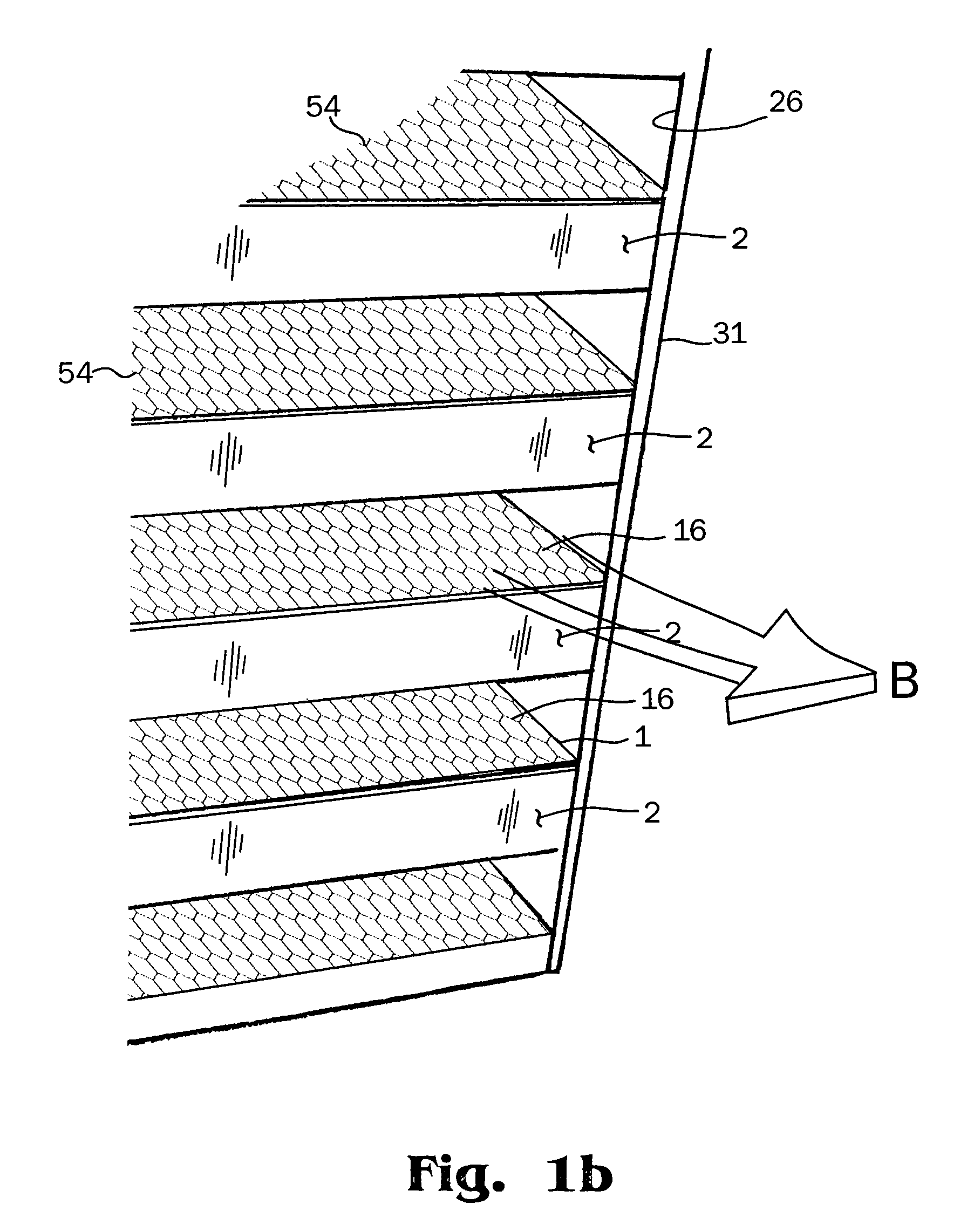

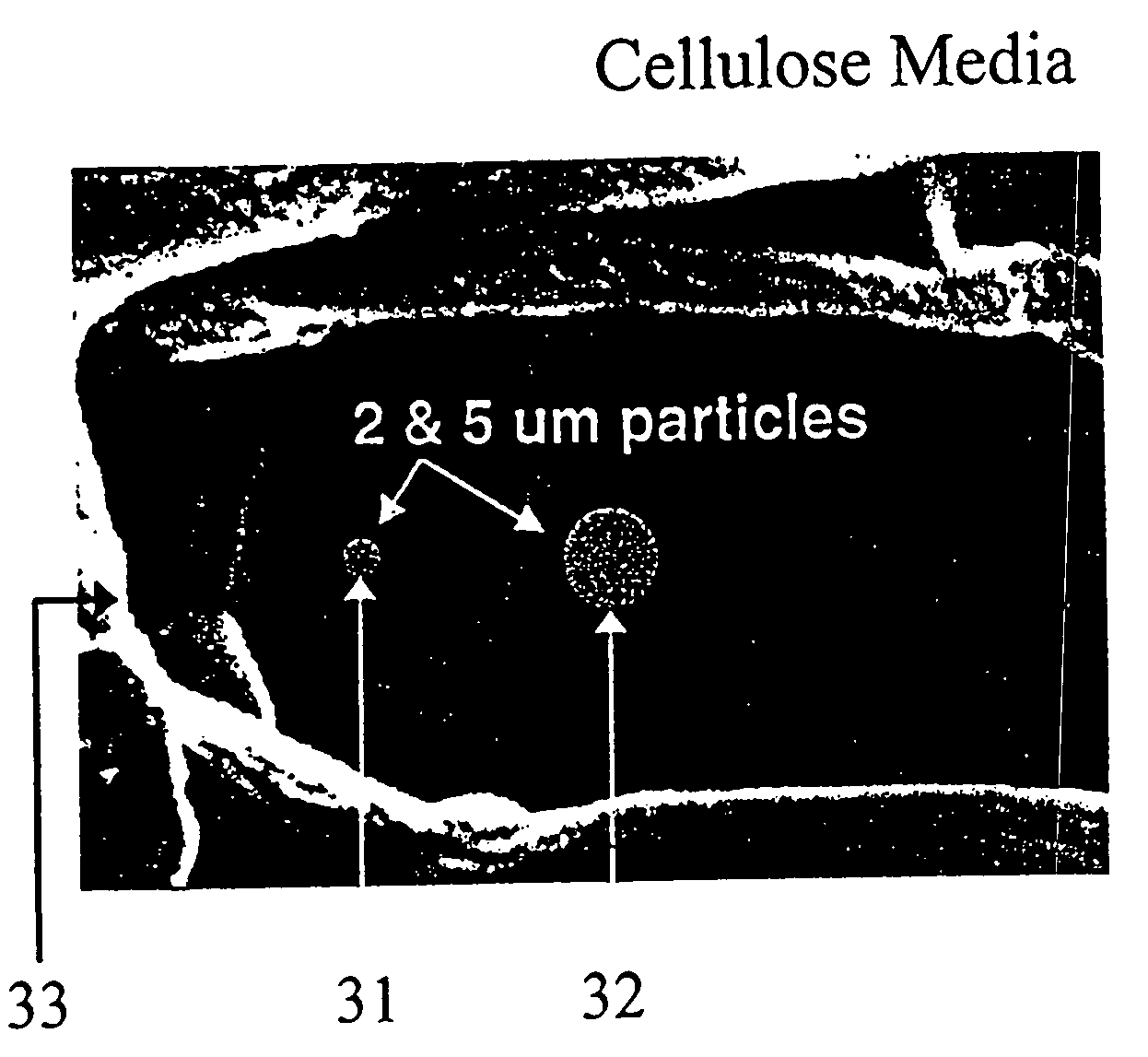

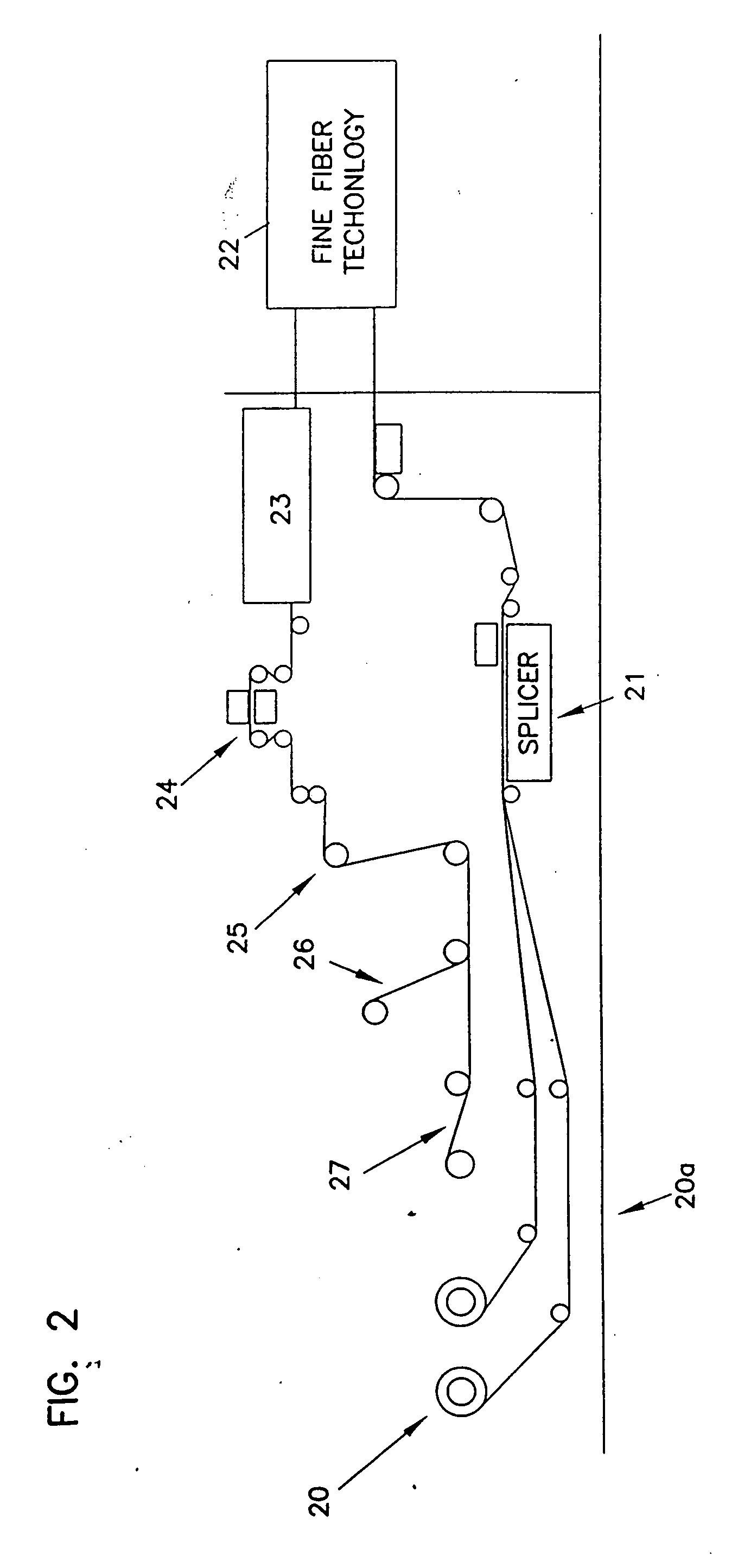

Air filter with fine fiber and spun bonded media

InactiveUS20070283808A1Simple materialSubstantial surface loadingCombination devicesDispersed particle filtrationAir filterNanofiber

Disclosed are improved polymer materials. Also disclosed are fine fiber materials that can be made from the improved polymeric materials in the form of microfiber and nanofiber structures. The microfiber and nanofiber structures can be used in a variety of useful applications including the formation of filter materials.

Owner:DONALDSON CO INC

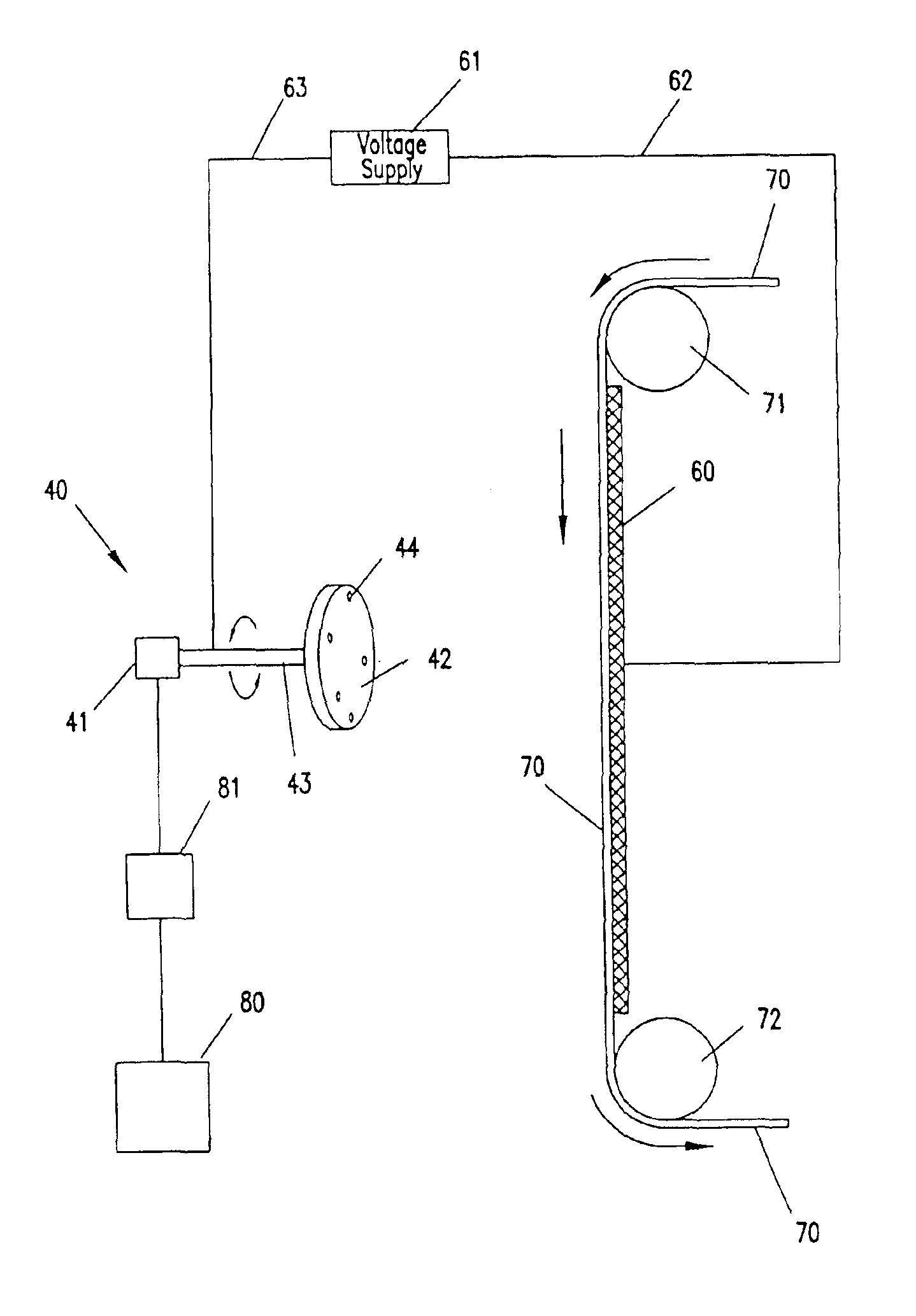

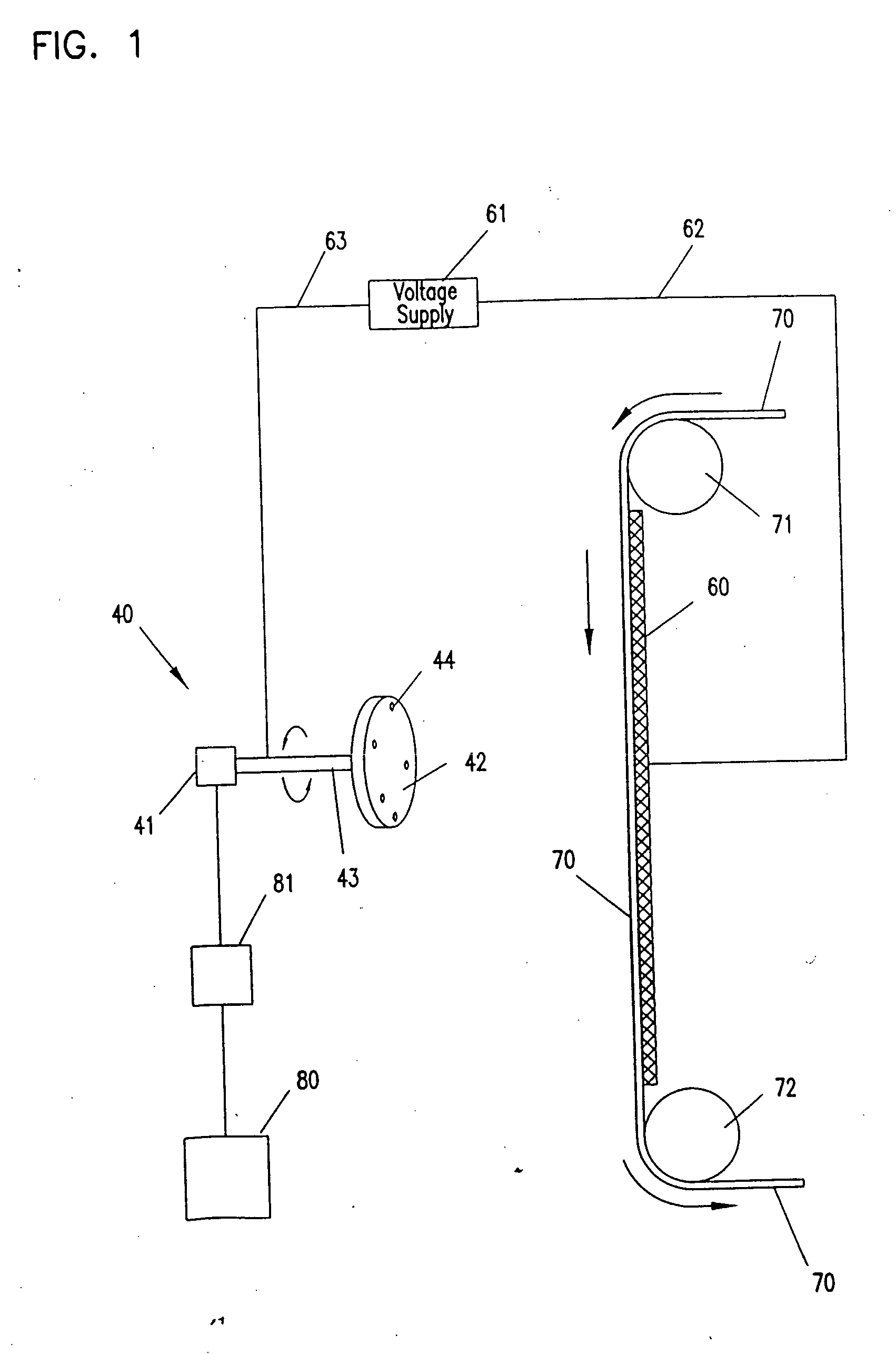

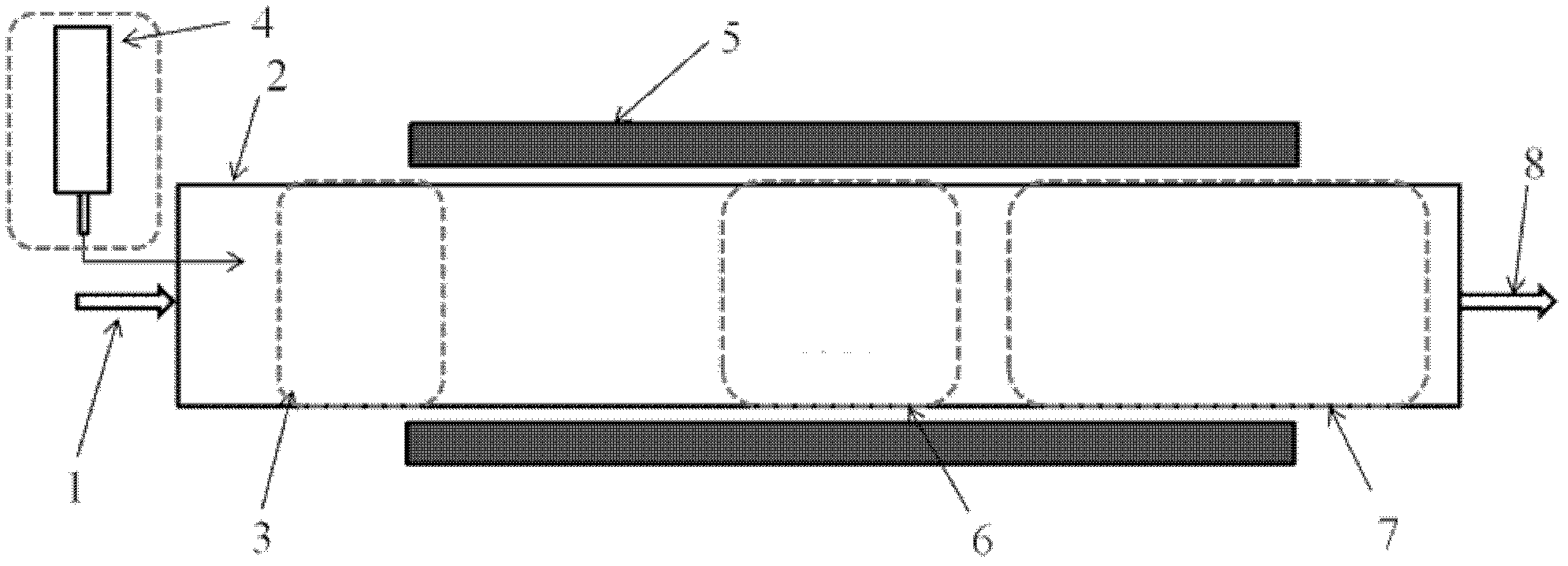

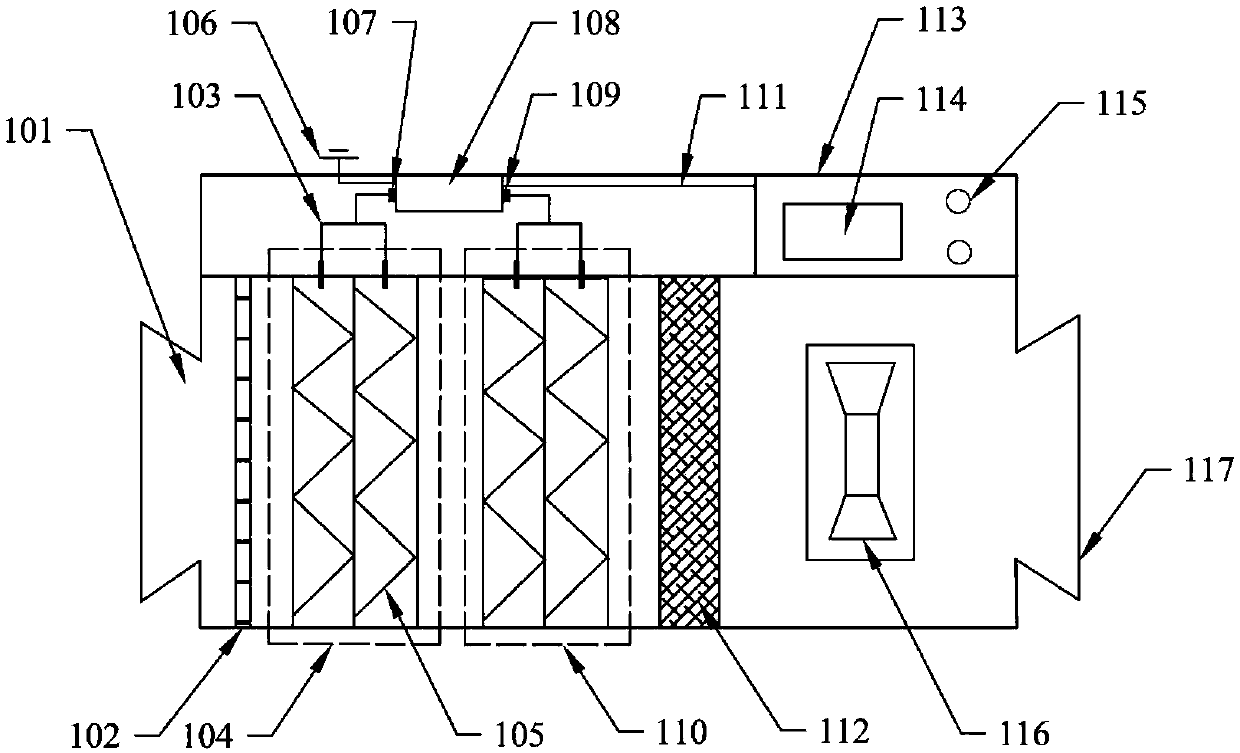

Low pressure drop deep electrically enhanced filter

InactiveUS7156898B2Large specific surface areaUniform and stable strengthOther chemical processesDispersed particle filtrationParticulatesEngineering

A method and apparatus using deep pleated filters to provide efficient and safe electrically enhanced filtering (EEF), with ultra low pressure drop, higher efficiency of particulate removal and higher dirt holding capacity over the life of the filter. An EEF may be constructed with a housing, with or without an internal air moving device such as a fan, a deeply pleated filter, preferably a V-pack filter with sets of downstream ground electrodes and charge transfer electrodes borne by the exterior surface of the filter packs that form the filtering element. An ionizer assembly that ionizes the gas and charges particles entering the deeply pleated filter and also transfers a charge to the charge transfer electrodes on the filter pack. A plate seals the gasket on the filtering element against the ionizing assembly. A high electrical potential is applied to charging elements in the ionizer and, in some embodiments, a fan or motor assembly. The charge transfer electrodes enable the device to function with a high particle collection field between the charge transfer electrodes and the downstream grounded electrodes to safely and efficiently attain higher entrapment of the particles on the filter medium.

Owner:JAISINGHANI RAJAN A

Polymer, polymer microfiber, polymer nanofiber and applications including filter structures

InactiveUS20060117730A1Simple materialSubstantial surface loadingCombination devicesDispersed particle filtrationPolymer scienceNanofiber

Disclosed are improved polymer materials. Also disclosed are fine fiber materials that can be made from the improved polymeric materials in the form of microfiber and nanofiber structures. The microfiber and nanofiber structures can be used in a variety of useful applications including the formation of filter materials.

Owner:DONALDSON CO INC

Filter element

InactiveUS6818037B2Easy to cleanSmall pressure lossCombination devicesDispersed particle filtrationVolumetric Mass DensityEngineering

A filter element is made of a first filtering member, and a second filtering member that is arranged on a downstream side of the first filtering member and is impregnated with an oil. The first filtering member consists of a downstream wet layer that is impregnated with the oil, which is transferred by contact to the second filtering member, and an upstream dry layer that is not impregnated with the oil. A density of the first filtering member may be set smaller than that of the second filtering member.

Owner:HONDA MOTOR CO LTD +1

Composite air filtering material for filtering bag and preparation method thereof

InactiveCN101491742AHigh strengthImprove breathabilityDispersed particle filtrationFiltration separationSodium bicarbonateAir filter

The invention relates to a compound air filter material and a method for preparing the same. The composite air filter material used for filter bags comprises a protective layer, a deodorizing layer and a filter layer, wherein the protective layer and the filter layer are compounded on two side faces of the deodorizing layer respectively; the protective layer is made of wood pulp fiber filter paper, spun-bond non-woven fabric or spun-lace non-woven fabric, and the gram weight of the material of the protective layer is 10 to 200g / m; the deodorizing layer is made of one of active carbon, zeolite , sodium bicarbonate, magnesium aluminum silicates and silica gel or a mixture of any two of the wood pulp fiber filter paper, the spun-bond non-woven fabric and the spun-lace non-woven fabric, and the gram weight of the material of the deodorizing layer is 10 to 300g / m; and the filter layer is made of melt-blown non-woven fabric, wood pulp fiber filter paper or SMS non-woven fabric, and the gram weight of the material of the filter layer is 10 to 100g / m. The compound air filter material has high filtration efficiency and deodorization efficiency, low filtration resistance and high dust capacity.

Owner:上海曾韩进出口有限公司

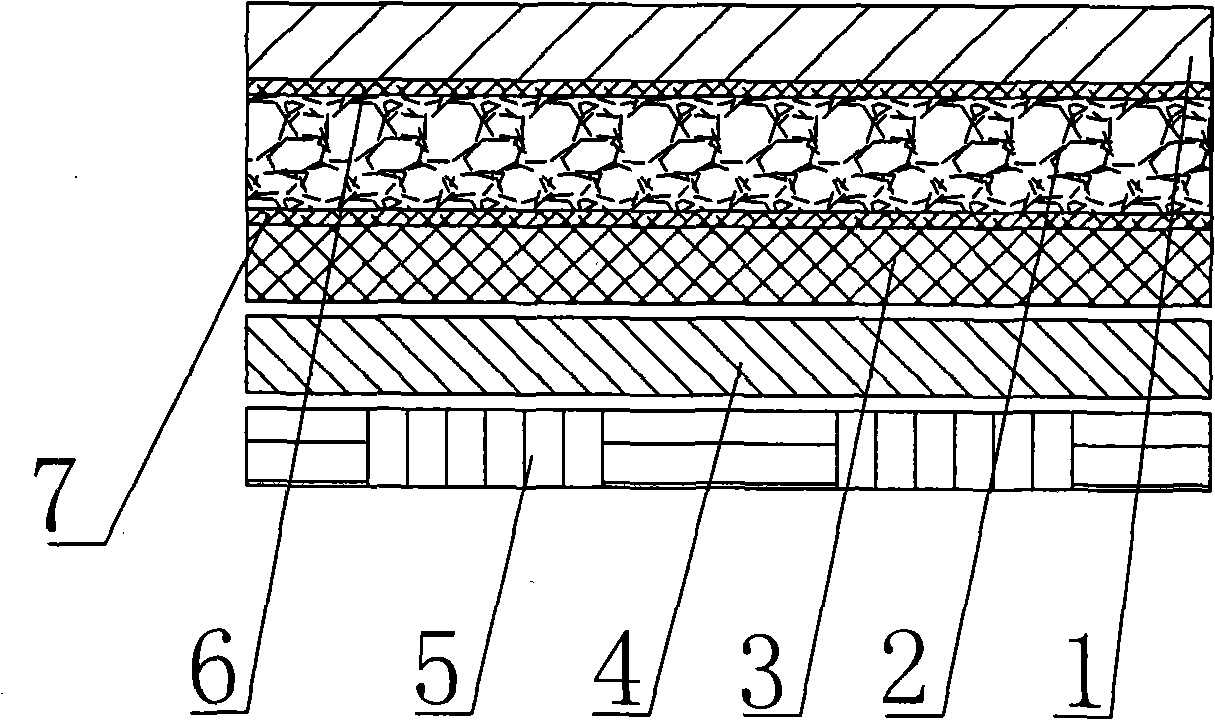

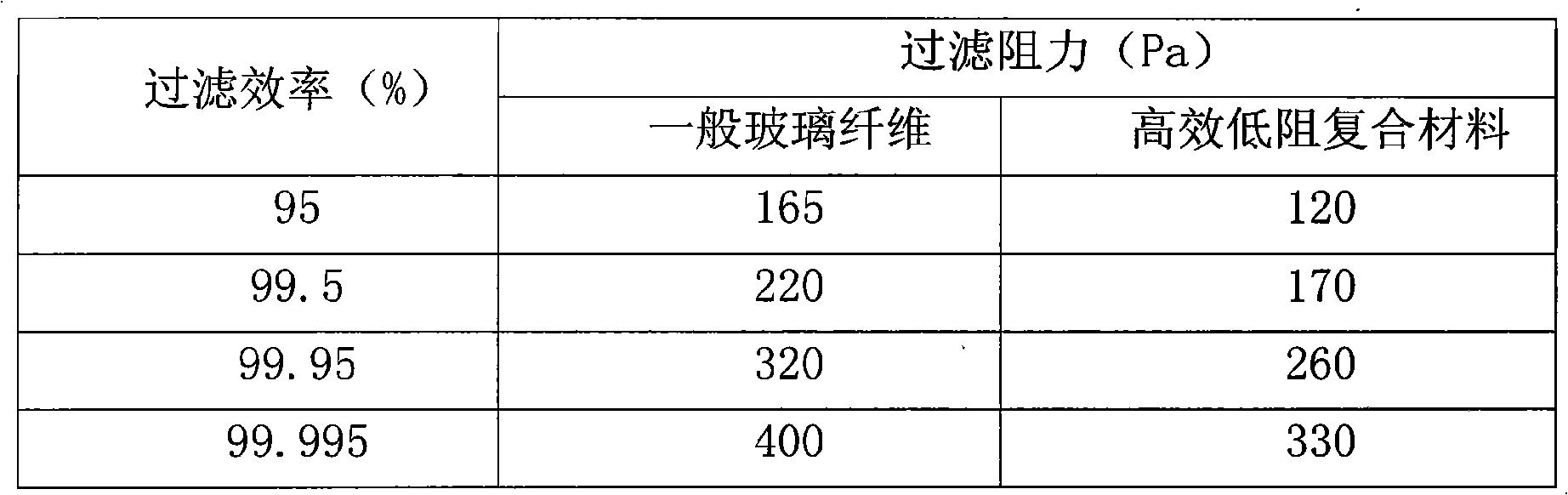

High-efficient low-resistance compound filter material and preparation method thereof

ActiveCN101352631AImprove filtration efficiencyFiltration efficiency reachesLaminationLamination apparatusFiberComposite filter

The invention provides a high-efficiency and low-resistance composite filter material and a preparation method thereof. The high-efficiency and low-resistance composite filter material is formed by the composing of at least a layer of fusing spray filter material and a layer of fibreglass filter material; the preparation method of the high-efficiency and low-resistance composite filter material comprises the following steps that: the fusing spray filter material and the fibreglass material are arranged on a material receiving frame and pass through a guiding roller; a hot fusing glue fibre gun is used for coating the fibre glue on the surface of the fibreglass; subsequently, the fusing spray filter material is attached to the fibreglass; finally, the finished product is gained by coiling. The high-efficiency and low-resistance composite filter material of the invention has high filter efficiency, extremely low filter resistance and high dust receiving capacity.

Owner:TONGXIANG JIANMIN FILTER MATERIALS

Needling static filter cotton and preparation method thereof

ActiveCN103537142ASmall filter resistanceLarge dust holding capacitySynthetic resin layered productsUltrasonic/sonic fibre treatmentBrute forcePressure resistance

The invention discloses needling static filter cotton. The needling static filter cotton comprises a needling non-woven layer, wherein any surface or two surfaces of the upper surface and the lower surface of the needling non-woven layer is or are provided with a spunbonded nonwoven fabric layer. A preparation method of the needling static filter cotton comprises the following steps of producing a needling cotton, drying, compositing the needling cotton, applying static electricity and packaging a finished product. The needling static filter cotton provided by the invention has the advantages that the needling cotton is composited, the wind pressure resistance of the needling cotton is enhanced, so that the needling cotton plays the supporting role, the high-density electrostatic charge is applied on the needling cotton, so that not only is the filter efficiency greatly improved to enable the filtration efficiency to be more than 98%, and also the filtration resistance is greatly reduced to be reduced to be below 7Pa. The needling static filter cotton after processing has the outstanding characteristics that the filtration efficiency is high, the filtration resistance is ultralow and the service life is long, the physical properties such as longitude and latitude brute force property and a wear-resisting property are excellent, and the needling static filter cotton is greatly superior to the common melt-blow static filter cotton at present.

Owner:常州百朋纺织有限公司

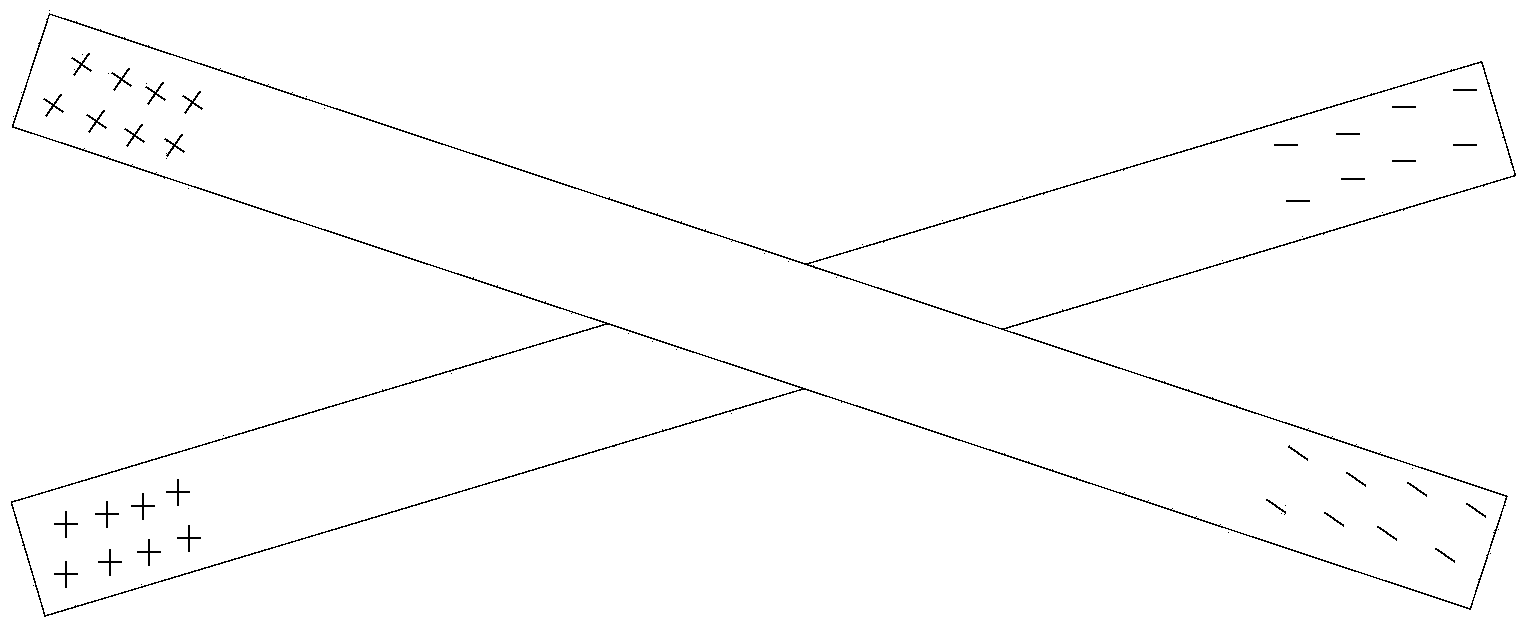

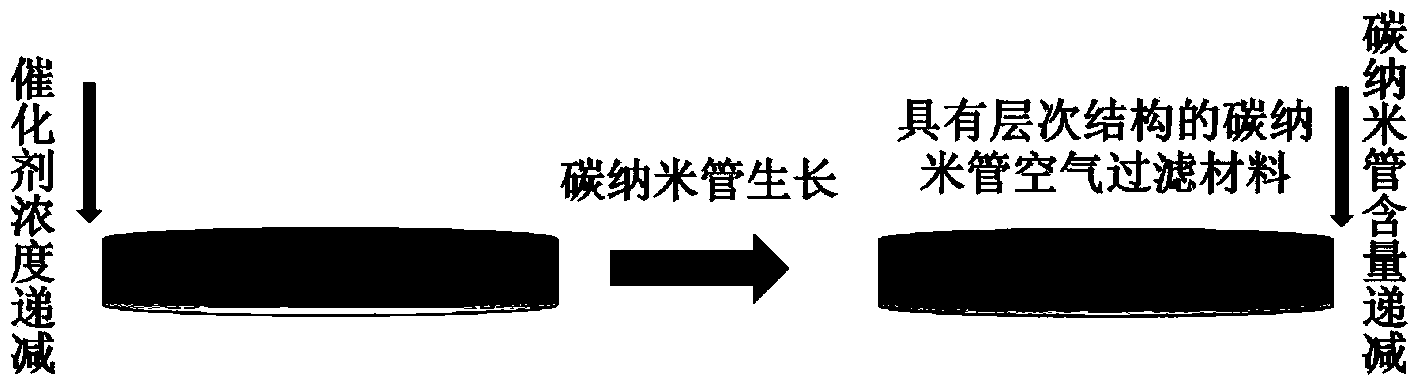

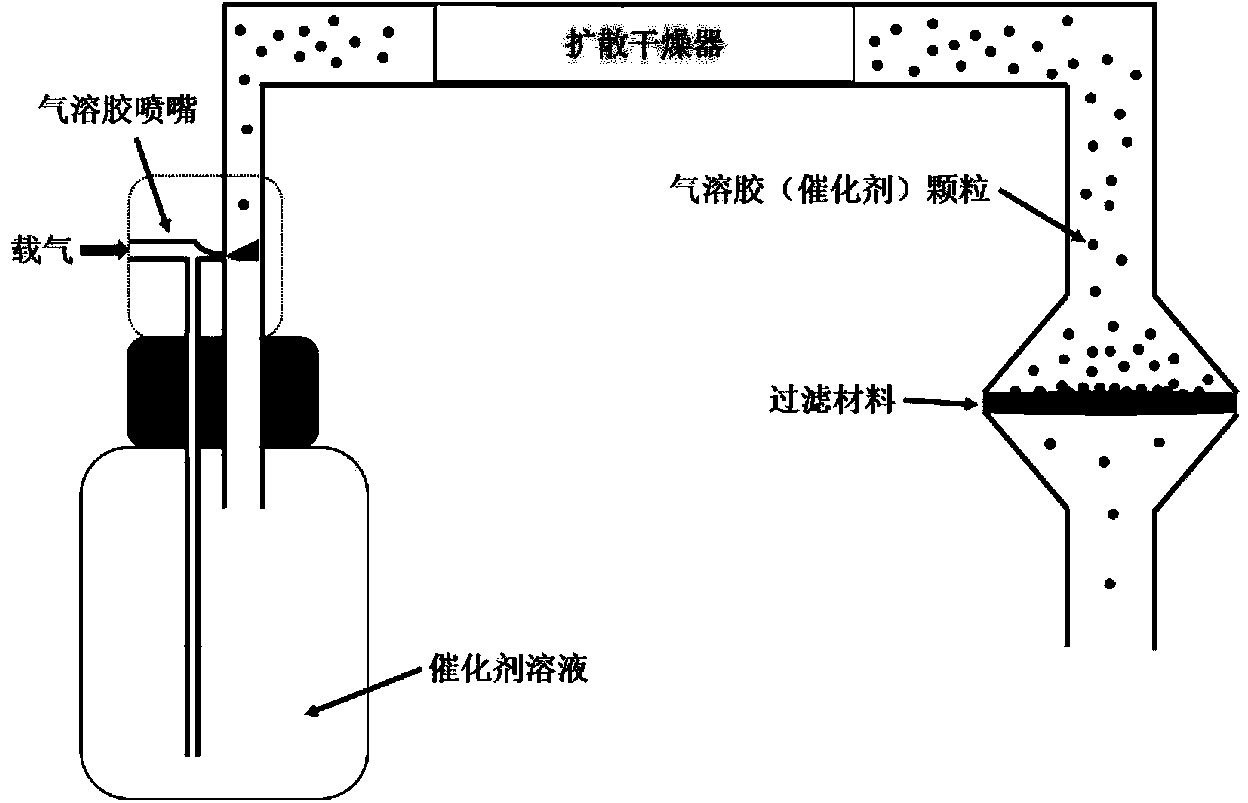

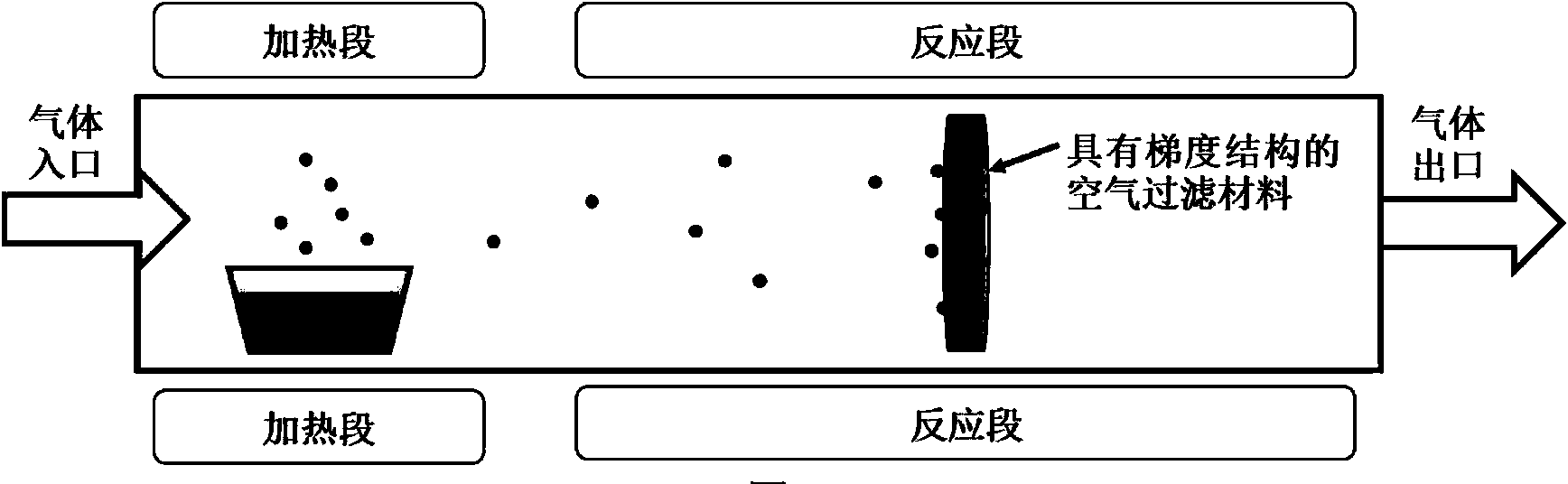

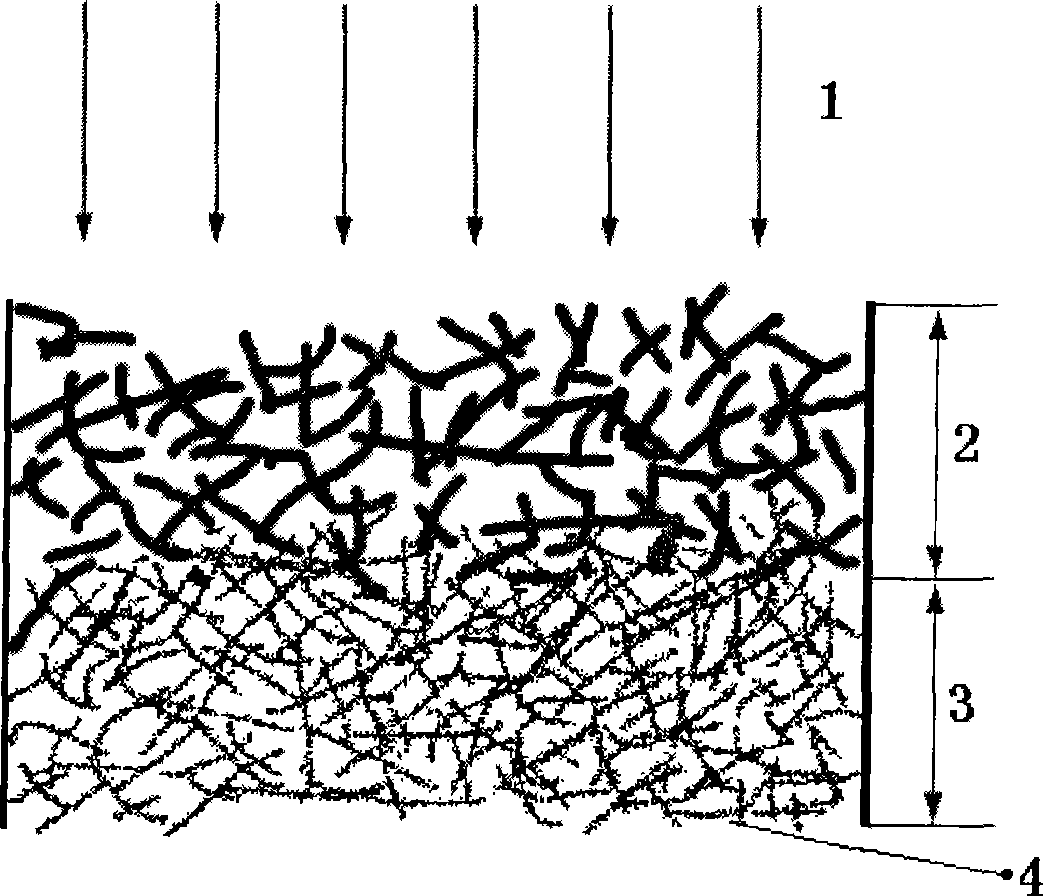

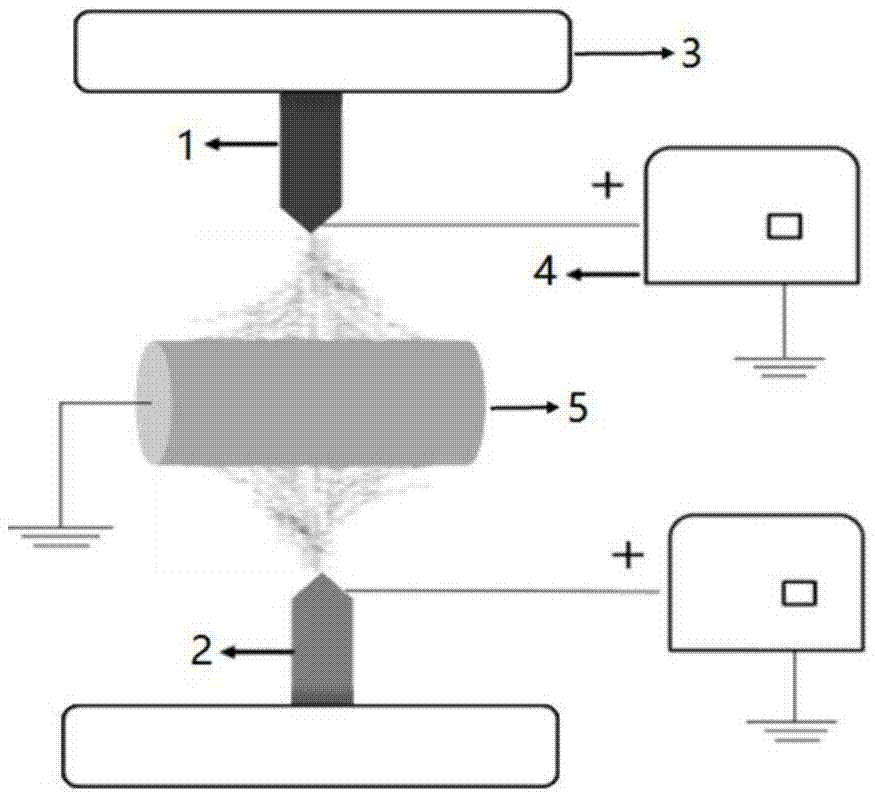

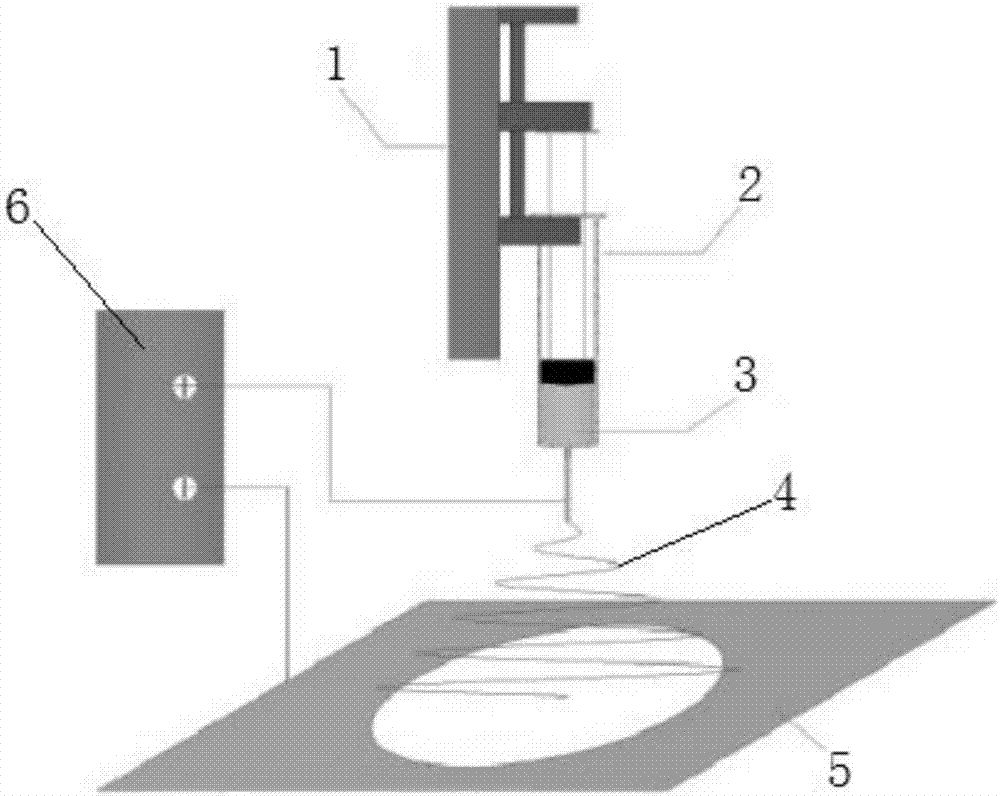

Carbon nanotube air filtering material with gradient structure and preparation method thereof

ActiveCN103446804AIncrease dust holding capacitySolve the strength problemFiltration separationChemical vapor deposition coatingAir filtrationFiber

The invention discloses a carbon nanotube air filtering material with a gradient structure and a preparation method thereof. The method comprises the following steps: with a fiber filtering medium as a substrate, preparing a metal catalyst; distributing the metal catalyst along the thickness direction of the substrate in a gradient manner; and growing a carbon nanotube on the surface of the fiber filtering medium through a chemical vapor deposition method to obtain the carbon nanotube air filtering material with a gradient structure. The carbon nanotube air filtering material with a gradient structure, provided by the invention, has a multilevel structure, and the carbon nanotube grows on the fiber surface to both solve the strength problem of the nano material in macro scale and fully utilize the excellent performance of the nano material in nano scale; meanwhile, the gradient structure exists in the thickness direction of the filtering material, the design can greatly improve the dust holding capacity of the filtering material, and the prepared filtering material has long service life.

Owner:TSINGHUA UNIV

Ultrafine glass fiber composite filter paper and making method thereof

InactiveCN105396372ASmall diameterImprove flexibilityMembrane filtersFiltration separationEpoxyAdhesive cement

The invention discloses an ultrafine glass fiber composite filter paper. The filter paper is composed of 70-80% of ultrafine glass fibers with the fiber diameter of 2-4[mu]m and the fiber length of 3-10mm, 10-20% of meta-aramid with the diameter of 5-10[mu]m and the fiber length of 3-15mm, and 10-20% of polypropylene fibers with the diameter of 5-10[mu]m and the fiber length of 3-15mm and an adhesive, and the adhesive is one of phenolic resin, epoxy resin, acrylic resin and melamine resin. The invention also discloses a making method of the hydrophobic glass fiber filter paper. The method comprises the following steps: beating and mixing the ultrafine glass fibers, meta-aramid and the polypropylene fibers in proportion, removing residues, conveying the obtained mixed slip to a paper molding machine, molding to obtain wet paper, carrying out vacuum pumping filtration to remove water, sprinkling the adhesive, and drying the wet paper to obtain the above product. The ultrafine glass fiber composite filter paper made in the invention has the advantages of high filterability, high strength, good temperature resistance and wide application.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

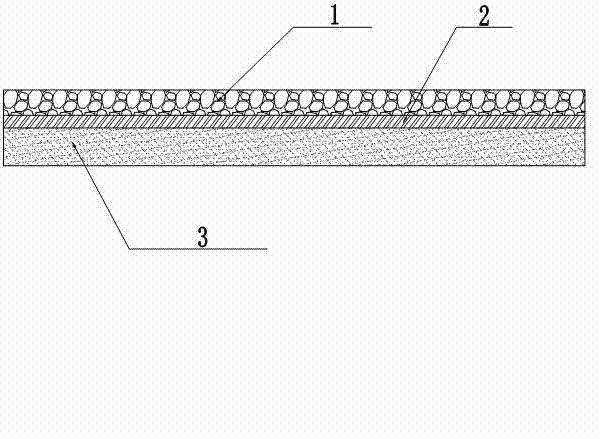

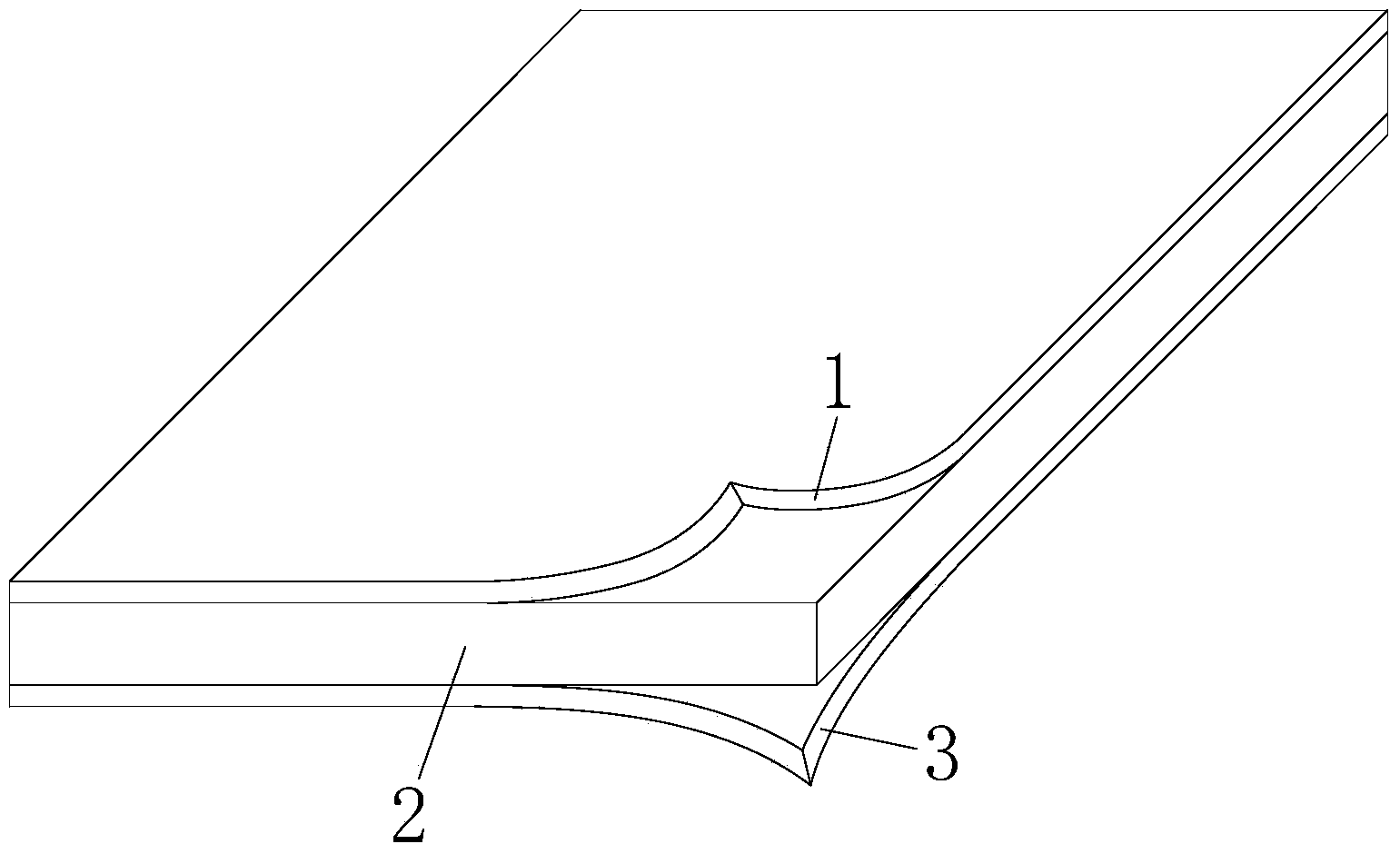

Double-layer filter material for internal combustion engine

InactiveCN101367020ASmall filter resistanceIncrease dust holding capacityLayered productsCombustion-air/fuel-air treatmentMetallurgyFiltration

The invention provides a double-layer filtering material for an internal combustion engine. The double-layer filtering material is provided with a coarse filtering layer and a fine filtering layer according to the direction of flow; the fine filtering layer consists of fibrillating fiber with the quality fraction between 2 to 100 percent and natural fiber with the quality fraction between 0 to 98 percent, wherein the diameter of the trunk of the fibrillating fiber is 1 to 20 microns, the length of the fibrillating fiber is 0.1 to 10 millimeters, the beating degree of the fibrillating fiber is 12 to 65 degrees SR, the diameter of the natural fine filtering layer fiber is 5 to 30 microns, and the length of the natural fine filtering layer fiber is 0.5 to 3.5 millimeters. The double-layer filtering material realizes to improve the filtering efficiency of the filtering material while keeping low filtration resistance and high capacity of holding dust.

Owner:SOUTH CHINA UNIV OF TECH

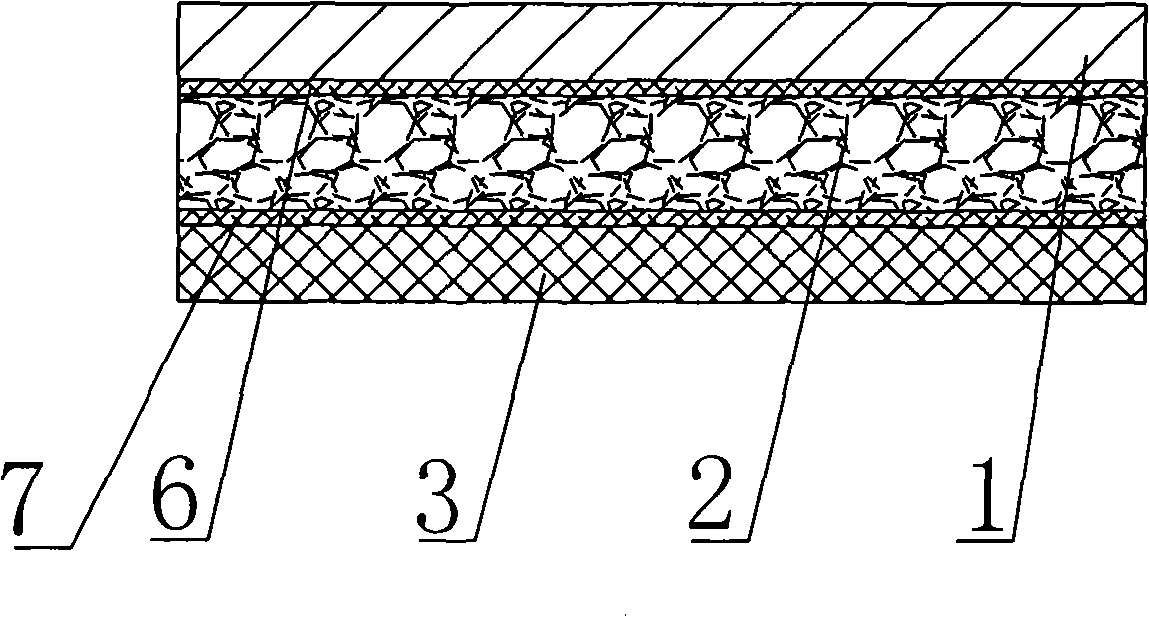

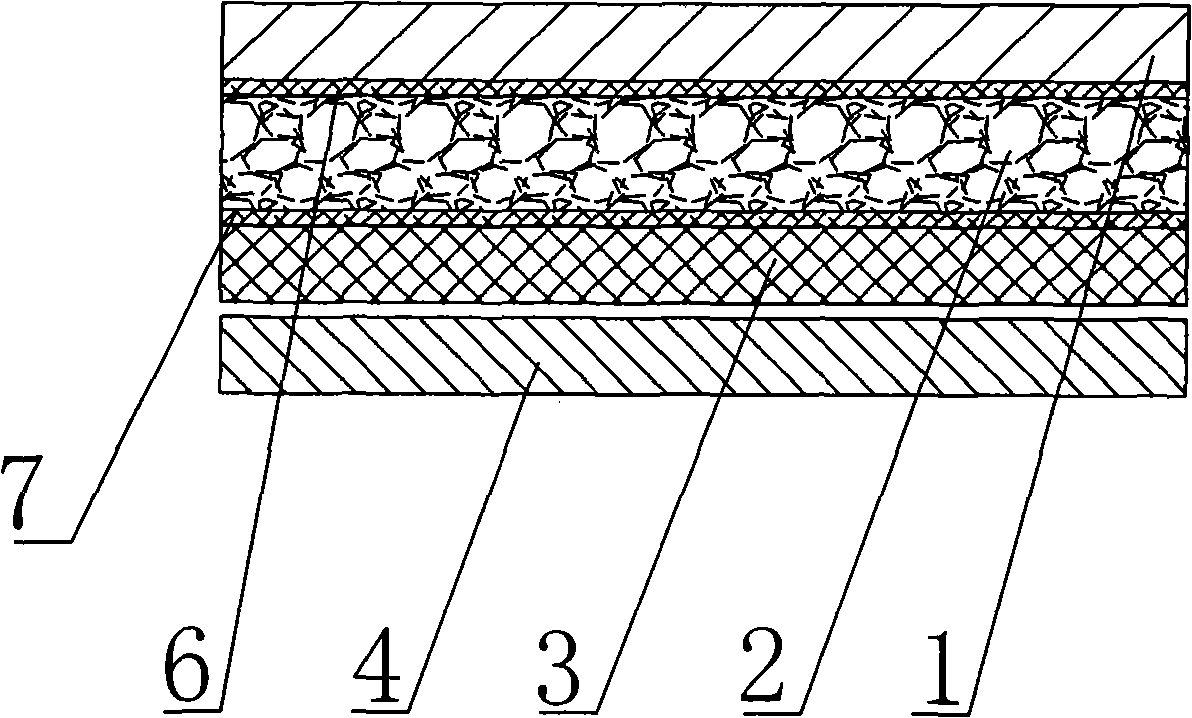

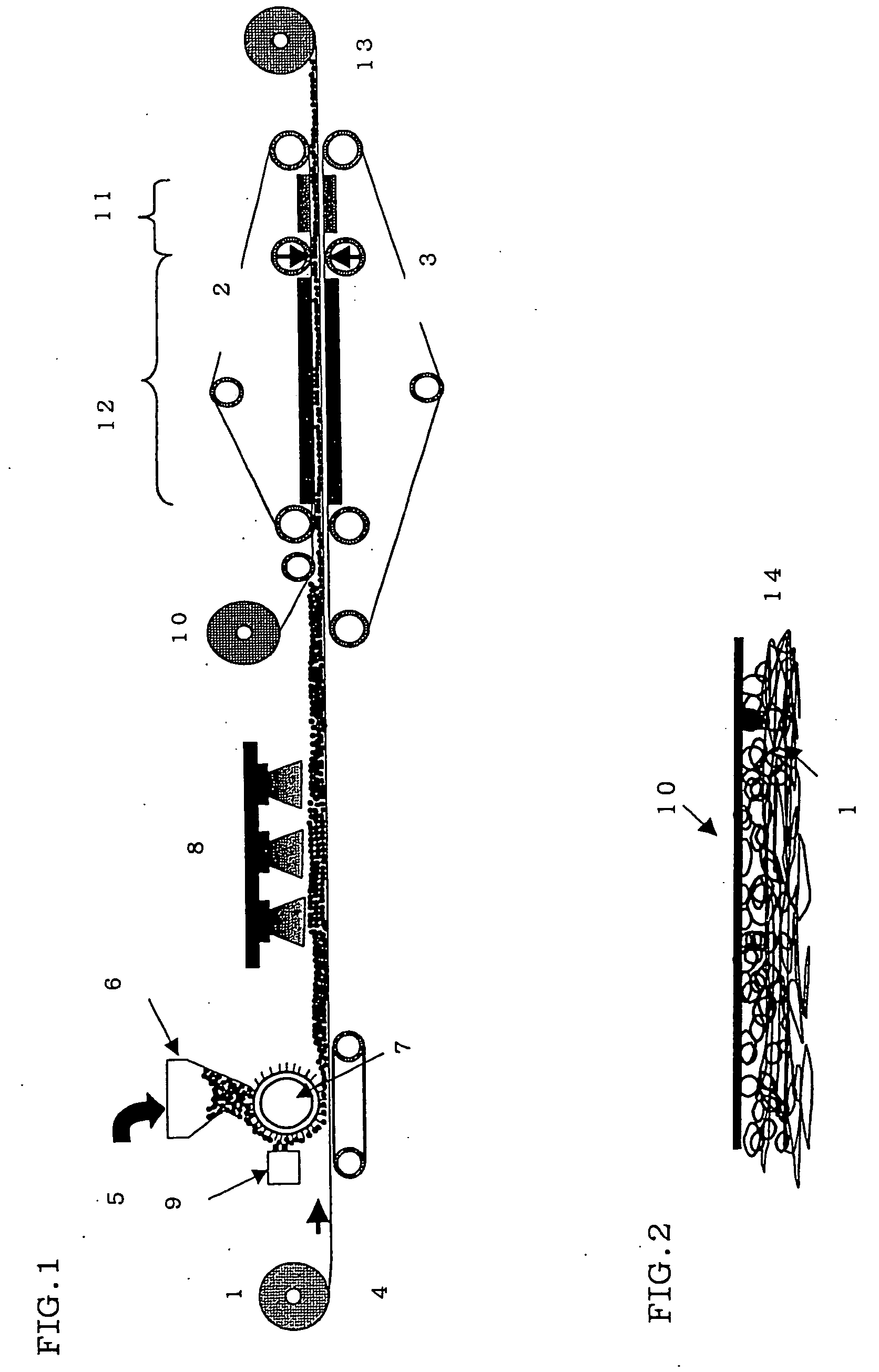

Adsorptive sheet and filter for clarifying air

InactiveUS6936094B2Improve adhesionGood dispersionDispersed particle filtrationIsotope separationThermoplasticActivated carbon

Provided are an adsorption sheet and an air-purifying filter, which can have low air-flow resistance and high deodorizing performance and be resistant to clogging by dust, from which a powdered adsorbent can hardly drop off, and in which any attached agent can hardly lose its effect. Such a product can be obtained by a process including the steps of: sufficiently premixing an agent-bearing activated carbon powder and a powdered thermoplastic resin to form a mixed powder; then spreading the mixed powder on a base sheet having a certain bulkiness and bearing an agent; stacking an air-permeable sheet thereon; and hot-pressing them.

Owner:TOYOBO CO LTD

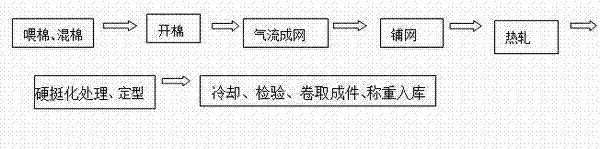

Production method of hot-rolled non-woven base material and product of production method

InactiveCN102899805AIncrease flexibilityImprove breathabilitySynthetic resin layered productsFiltration separationGramAirflow

The invention discloses a production method of a hot-rolled non-woven base material and a product of the production method of the hot-rolled non-woven base material. The production method of the hot-rolled non-woven base material comprises the following steps of: A, feeding and mixing cotton; B, breaking and opening; C, air laying; D, lapping; E, hot rolling; F, stiffening process and shaping; and G, cooling, inspecting and coiling to obtain the base material, and weighing and entering warehouse. The stiffening process is one or combination of gumming and surface gluing. The gram weight range of the product obtained by the production method of the hot-rolled non-woven base material is 50 to 250g / m<2>, the thickness range is 0.1 to 0.8mm, the air permeability is 500 to 6,000L / m<2>.s, and the longitudinal and transverse stiffness can reach 500mg or more. The hot-rolled non-woven base material has very strong flexibility and excellent air permeability; furthermore, the hot-rolled non-woven base material is low in thickness, therefore, the area of a filter material can be increased, the resistance of a filter unit is reduced, and the clogging capacity of the filter unit is improved; meanwhile, the hot-rolled non-woven base material is excellent in stiffness, therefore, the different folding and forming requirements are met; and the cost of the hot-rolled non-woven base material has a more obvious advantage than that of materials with the same application aim.

Owner:ZHEJIANG ZHAOHUI FILTRATION TECH

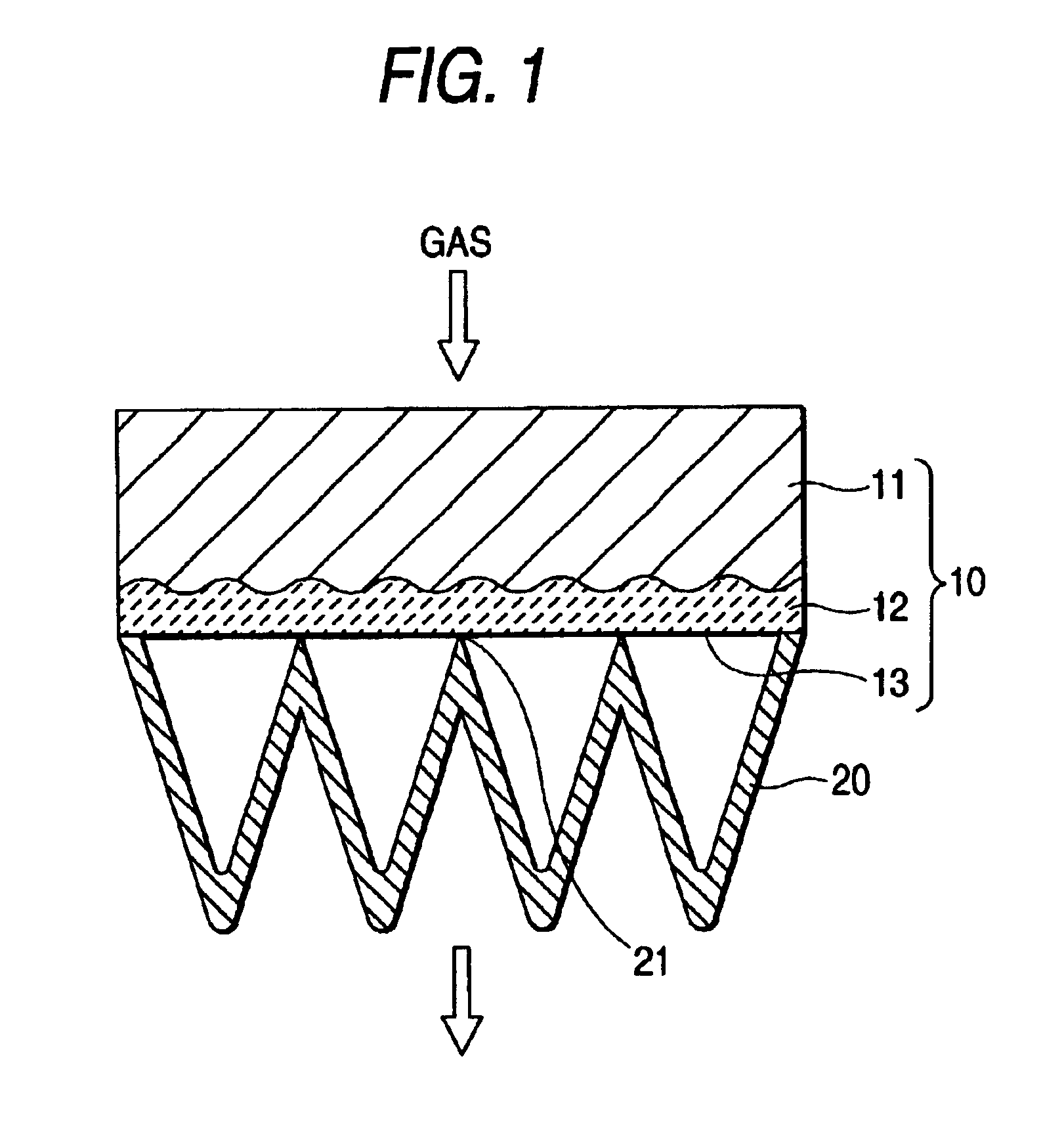

Filter element

InactiveUS20030106293A1Easy to cleanSmall pressure lossCombination devicesDispersed particle filtrationVolumetric Mass DensityEngineering

A filter element is made of a first filtering member, and a second filtering member that is arranged on a downstream side of the first filtering member and is impregnated with an oil. The first filtering member consists of a downstream wet layer that is impregnated with the oil, which is transferred by contact to the second filtering member, and an upstream dry layer that is not impregnated with the oil. A density of the first filtering member may be set smaller than that of the second filtering member.

Owner:HONDA MOTOR CO LTD +1

Air filter material based on carbon nano tube and preparation method thereof

ActiveCN102600667ASolve the problem of too low intensityReduce intensityFiltration separationFiberLevel structure

The invention discloses an air filter materials based on a carbon nano tube and a preparation method thereof. The method comprises the following steps: taking a fibre filter medium as a substrate, and preparing the carbon nano tube on the substrate according to chemical vapor deposition method to obtain the product. The fibre filter medium is made of at least one of the group consisting of quartz fibre, carbon fiber, glass fibre, metal fibre and polymer fiber; according to the invention, the air filter materail based on the carbon nano tube comprises two-level structure so as to solve the problem that the intensity of the carbon nano tube membre is too low as air filter materails, the bulk density is too high, the resistance is too much and the clogging capacity is low, and to implement preparation for high-intensity, high-clogging-capacity, high-efficiency and low-resistance air filter material.

Owner:TSINGHUA UNIV

Low voltage electrostatic dust collection module and air purification device

ActiveCN107837964AIncreased Coulomb forceSmall filter resistanceDispersed particle separationElectrostatic separation detailsWoven fabricElectrostatic precipitator

The invention discloses a low voltage electrostatic dust collection module and an air purification device. The low voltage electrostatic dust collection module comprises a positive electrode low voltage electrostatic dust collection unit, a negative electrode low voltage electrostatic dust collection, an electrostatic generator and a degeneration control adjuster, wherein the positive electrode low voltage electrostatic dust collection unit and the negative electrode low voltage electrostatic dust collection at least comprises a layer of electrostatic dust collection filter screen; each electrostatic dust collection filter screen comprises a conductive non-woven fabric filter screen with a microcellular structure; the electrostatic generator continuously conveys a positive charge to the conductive non-woven fabric filter screen in the positive electrode low voltage electrostatic dust collection unit, and continuously conveys a negative charge to the conductive non-woven fabric filter screen in the negative electrode low voltage electrostatic dust collection unit; the degeneration control adjuster is used for monitoring an electric charge quantity change on each conductive non-wovenfabric filter screen, and feeding back changed signals to a control system; and the control system controls a periodic intermitting supply manner of the electrostatic generator and the magnitude of output voltage according the feedback signals. The conductive non-woven fabric filter screens are utilized for loading a static charge so as to form a contact electrification mechanism, so that the generation of ozone can be completely avoided.

Owner:贾玉玺

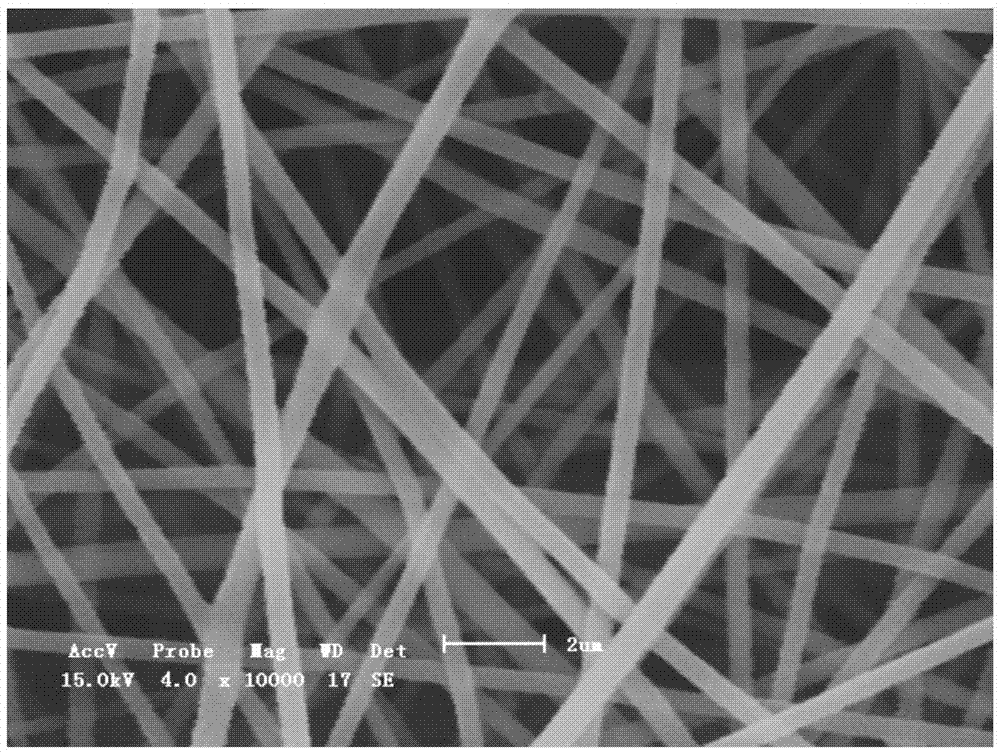

Preparation method of epoxidized lignin modified polyacrylonitrile filter material

InactiveCN106012089AImprove filtration efficiencyIncrease dust holding capacityDispersed particle filtrationConjugated cellulose/protein artificial filamentsAcetic acidMaterials preparation

The invention relates to a preparation method of an epoxidized lignin modified polyacrylonitrile filter material and belongs to the technical field of material preparation. According to the preparation method, firstly, corn stalk lignin is extracted from corn stalks and is mixed with hydrochloric acid, glacial acetic acid, epoxy chloropropane and other substances for a reaction, epoxidized lignin is obtained, the epoxidized lignin is dissolved in dimethylformamide and mixed with a polyacrylonitrile solution, the mixture is heated and subjected to a cross-linking reaction, a reaction liquid is concentrated, a spinning solution is obtained, finally, the spinning solution is subjected to electrostatic spinning, and the epoxidized lignin modified polyacrylonitrile filter material can be prepared. The prepared epoxidized lignin modified polyacrylonitrile filter material has high filtering efficiency, the filtering efficiency of PM 2.5 in air reaches 99.7% or above, the dust holding capacity is high and reaches 485.8-635.6 g.m<-2>, the strength is higher, and the stiffness is 550-620 mg.

Owner:佛山市顺德品维源无纺布有限公司

Perforated plate fresh air introducing and purifying device

ActiveCN104697102AImprove efficiencySave electricityEnergy recovery in ventilation and heatingMechanical apparatusFresh airEngineering

The invention discloses a perforated plate fresh air introducing and purifying device and belongs to the technical field of air energy recycling and high efficiency energy saving in ventilation equipment. The device comprises a perforated plate purifying, energy recycling and heating core, a fresh air machine, an exhaust fan and an electric cabinet, wherein the size of the perforated plate purifying, energy recycling and heating core is 160mm*160mm to 350mm*350mm; the perforated plate purifying, energy recycling and heating core comprises 45 to 2400 pieces of perforated plate semi-closed conductive combinations and corrugated pieces; each perforated plate semi-closed conductive combination comprises a perforated plate, conductive bands, purifying copper sheets A and B, and heating copper sheets A and B; a square hole shaped fresh air channel with the side length being 1 to 20mm is formed in the perforated plate; the conductive bands are printed or sprayed on the two outer surfaces of the perforated plate; the purifying copper sheets A and B and the heating copper sheets A and B are respectively adhered to the two ends of the conductive bands on the two outer surfaces of the perforated plate; the perforated plate semi-closed conductive combinations and the corrugated pieces form 90 degrees and are assembled alternately and crosswise. The perforated plate fresh air introducing and purifying device has the benefits that new pollutant, such as ozone and the like, is not produced, energy can be efficiently recycled, condensation cannot be produced when the device is used in cold regions, and meanwhile the purification efficiency is high.

Owner:NINGBO DONGDA AIR CONDITIONING EQUIP

Adsorptive sheet and filter for clarifying air

InactiveUS20050000363A1Improve adhesionGood dispersionDispersed particle filtrationIsotope separationThermoplasticActivated carbon

Provided are an adsorption sheet and an air-purifying filter, which can have low air-flow resistance and high deodorizing performance and be resistant to clogging by dust, from which a powdered adsorbent can hardly drop off, and in which any attached agent can hardly lose its effect. Such a product can be obtained by a process including the steps of: sufficiently premixing an agent-bearing activated carbon powder and a powdered thermoplastic resin to form a mixed powder; then spreading the mixed powder on a base sheet having a certain bulkiness and bearing an agent; stacking an air-permeable sheet thereon; and hot-pressing them.

Owner:TOYOBO CO LTD

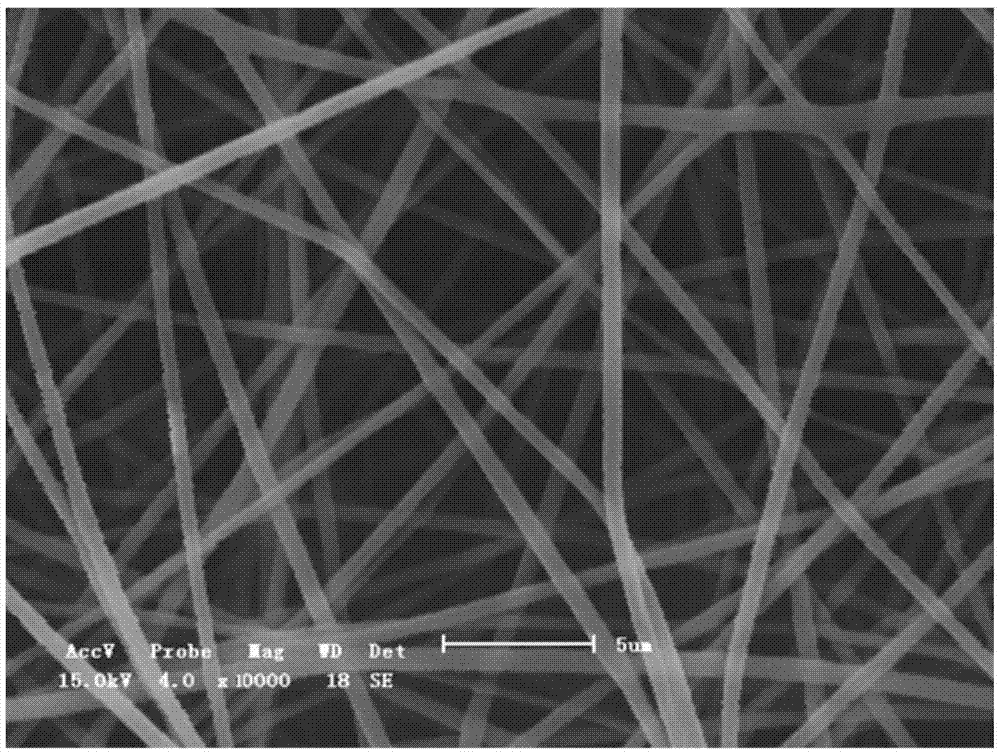

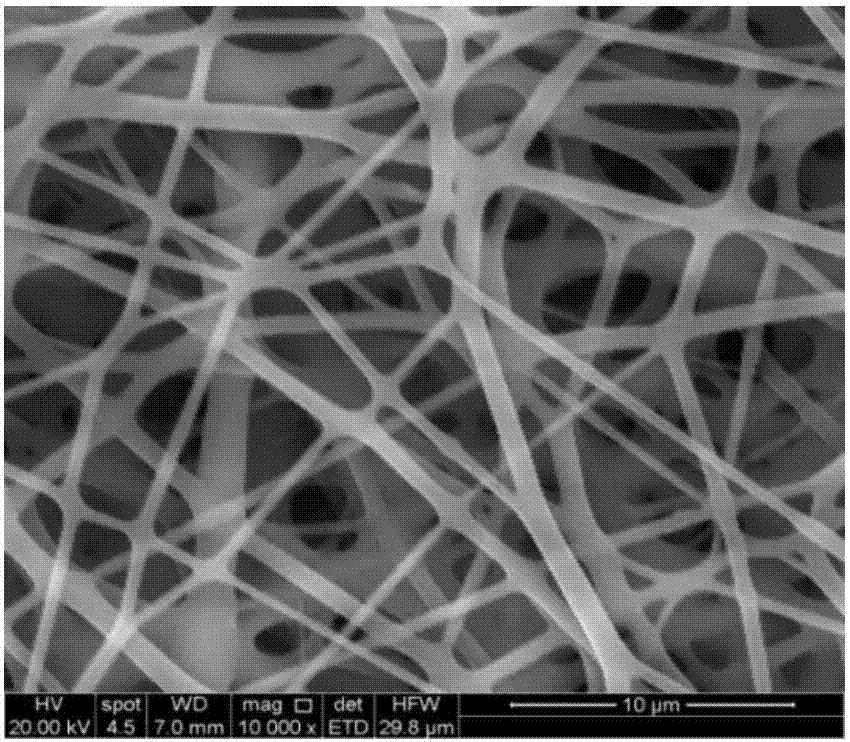

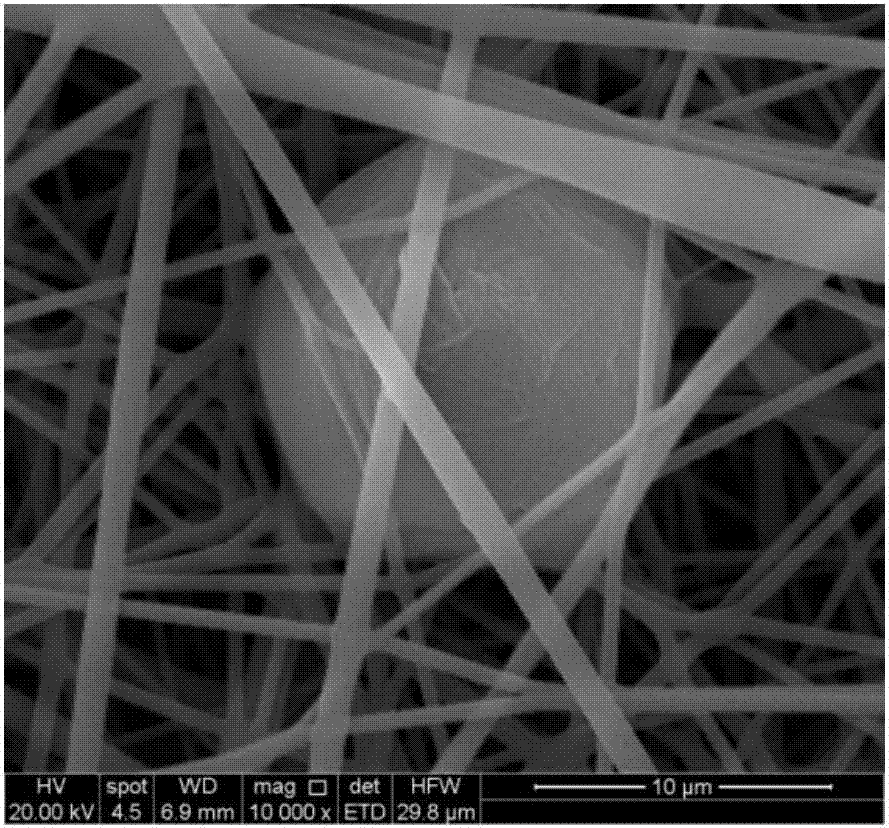

Composite nanofiber air filtration material and preparation method thereof

InactiveCN105435538ALarger than the areaIncrease dust holding capacityFibre typesMembrane filtersTesting equipmentPolyvinyl alcohol

The invention relates to a composite nanofiber air filtration material and a preparation method thereof. The material comprises a nanometer polyvinyl alcohol fiber layer and an interweaving layer of nanometer polyvinyl alcohol fibers and polyacrylonitrile fibers, the air filtration material in the four layer structure of the nanometer polyvinyl alcohol fiber layer and the interweaving layer of the nanometer polyvinyl alcohol fibers and the polyacrylonitrile fibers in cross distribution is obtained through one-time electrostatic spinning, the diameter of the polyvinyl alcohol fiber layer ranges from 400 nm to 1,000 nm, the diameter of the electrostatic spinning polyacrylonitrile fibers ranges from 150 nm to 500 nm, the porosity ranges from 75% to 90%, the average pore size ranges from 0.4 mu m to 6 mu m, and crosslinking treatment is performed. The performance that the composite nanofiber air filtration material is not prone to layering and better mechanical properties can be obtained, the filtration efficiency to NaCl aerosol with number median diameter of 75 nm ranges from 99.94% to 99.99%, and the pressure is reduced to be 180-600 Pa. The material is particularly suitable for fields such as personal protective products, air quality testing equipment and air purification devices.

Owner:JILIN UNIV

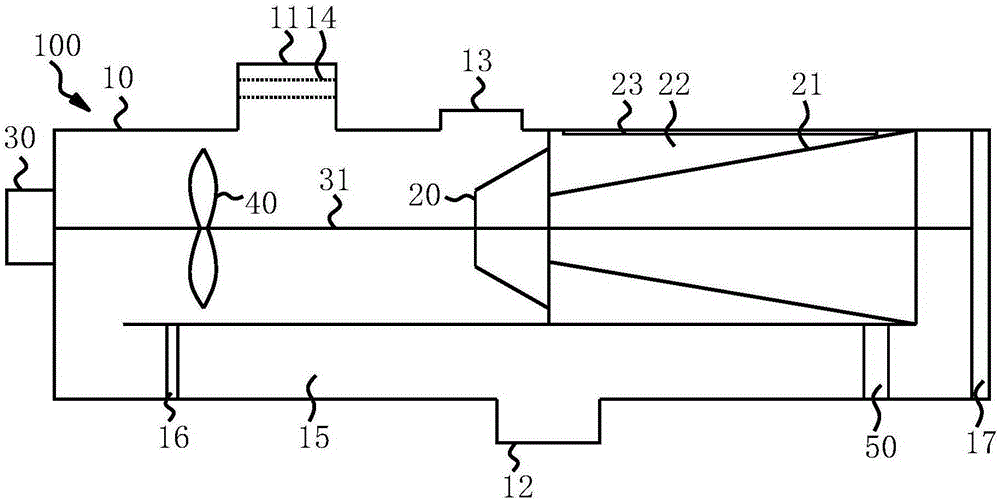

Personal respirable dust sampling device

ActiveCN105181396AIncrease dust holding capacityGuaranteed reliabilityWithdrawing sample devicesDrive shaftRespirable dust

The invention provides a personal respirable dust sampling device. The personal respirable dust sampling device comprises a sampling box, a filter screen, a sampling filter membrane and a driving device, wherein the sampling box is used for providing an installation space for a sampling component; the filter screen is installed inside the sampling box, comprises a rough filter screen used for filtering out particles exceeding the dust sampling standard, and a fine filter screen used for filtering dust conforming to the sampling standard in a grading manner; the sampling filter membrane is installed at one end of a gas outlet of the fine filter screen and is used for adsorbing filtered dust and is taken as an analysis sample of dust content; the driving device comprises a driving motor and a driving shaft which simultaneously penetrates through axle lines of the rough filter screen and the fine filter screen to drive the rough filter screen and the fine filter screen to simultaneously rotate. According to the device, the technology of combination of impact type separation and a double-layer conical surface filter screen is adopted, the dusty environment is sampled, large granular dust can be separated firstly by utilizing the rough filter screen, and then respirable dust conforming to the regulations of a BMRC sampling efficacy curve is separated by utilizing the fine filter screen, so that the sampling precision is improved.

Owner:THE BEIJING PREVENTION & TREATMENT HOSPITAL OF OCCUPATIONAL DISEASE FOR CHEM IND +1

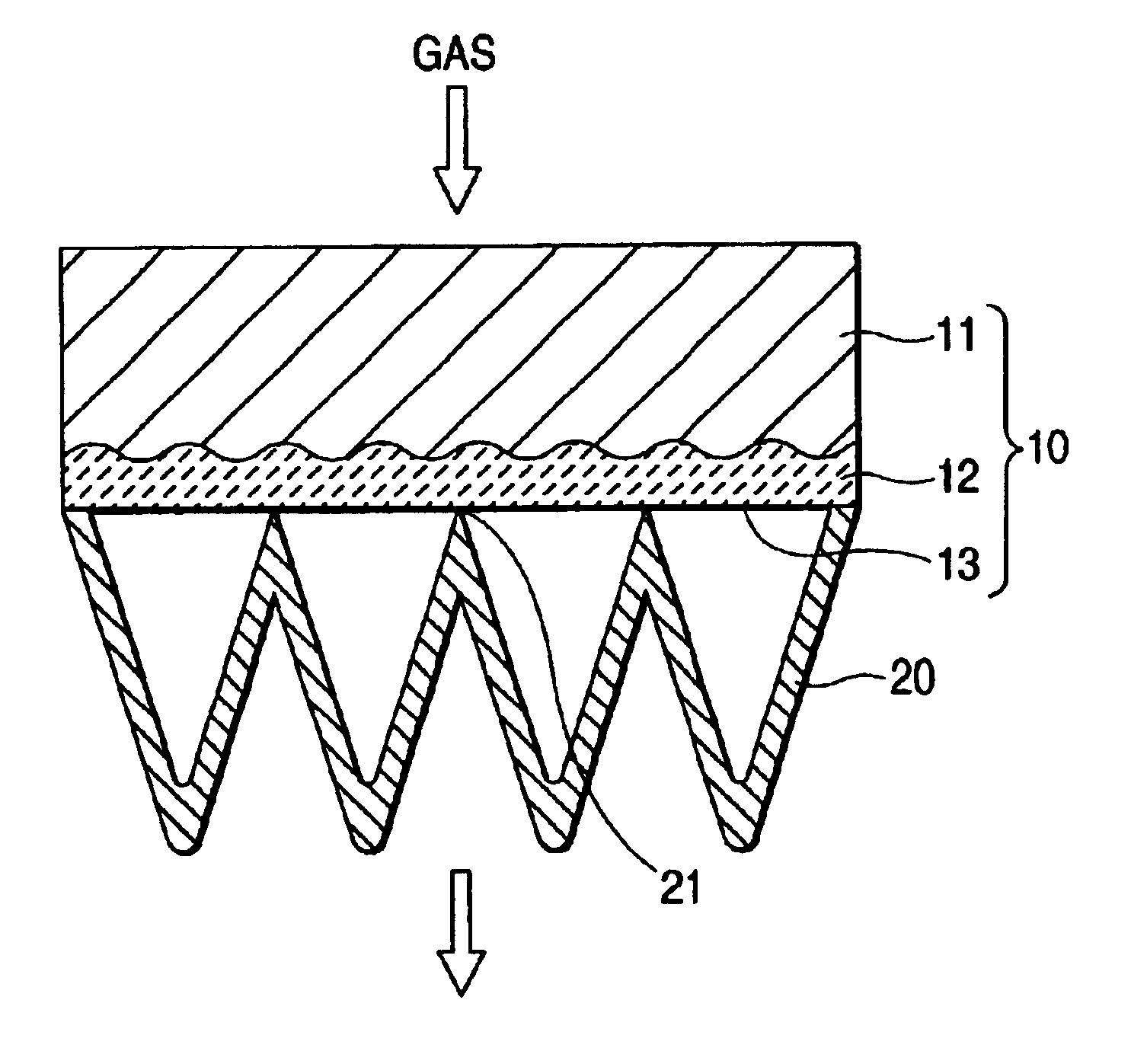

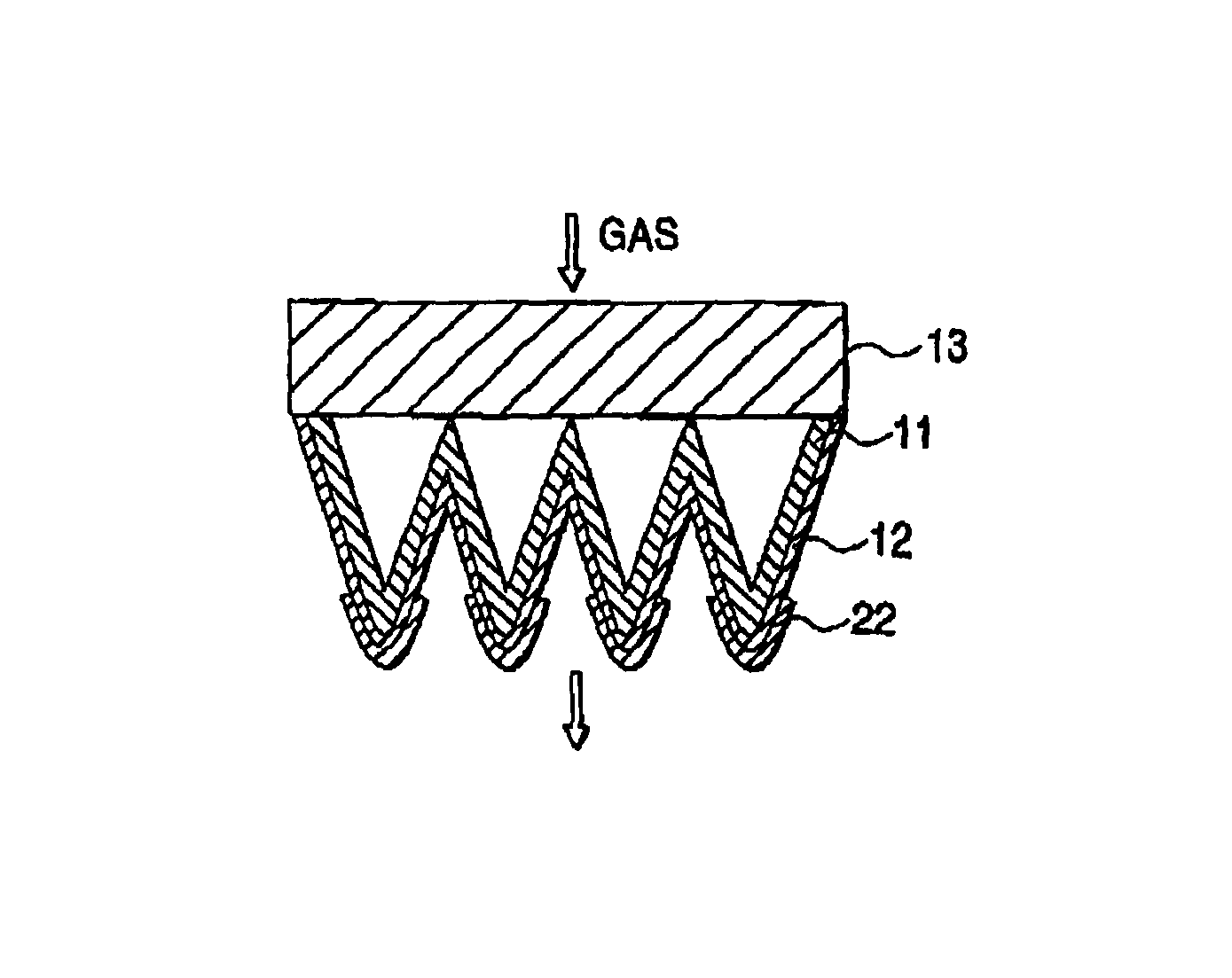

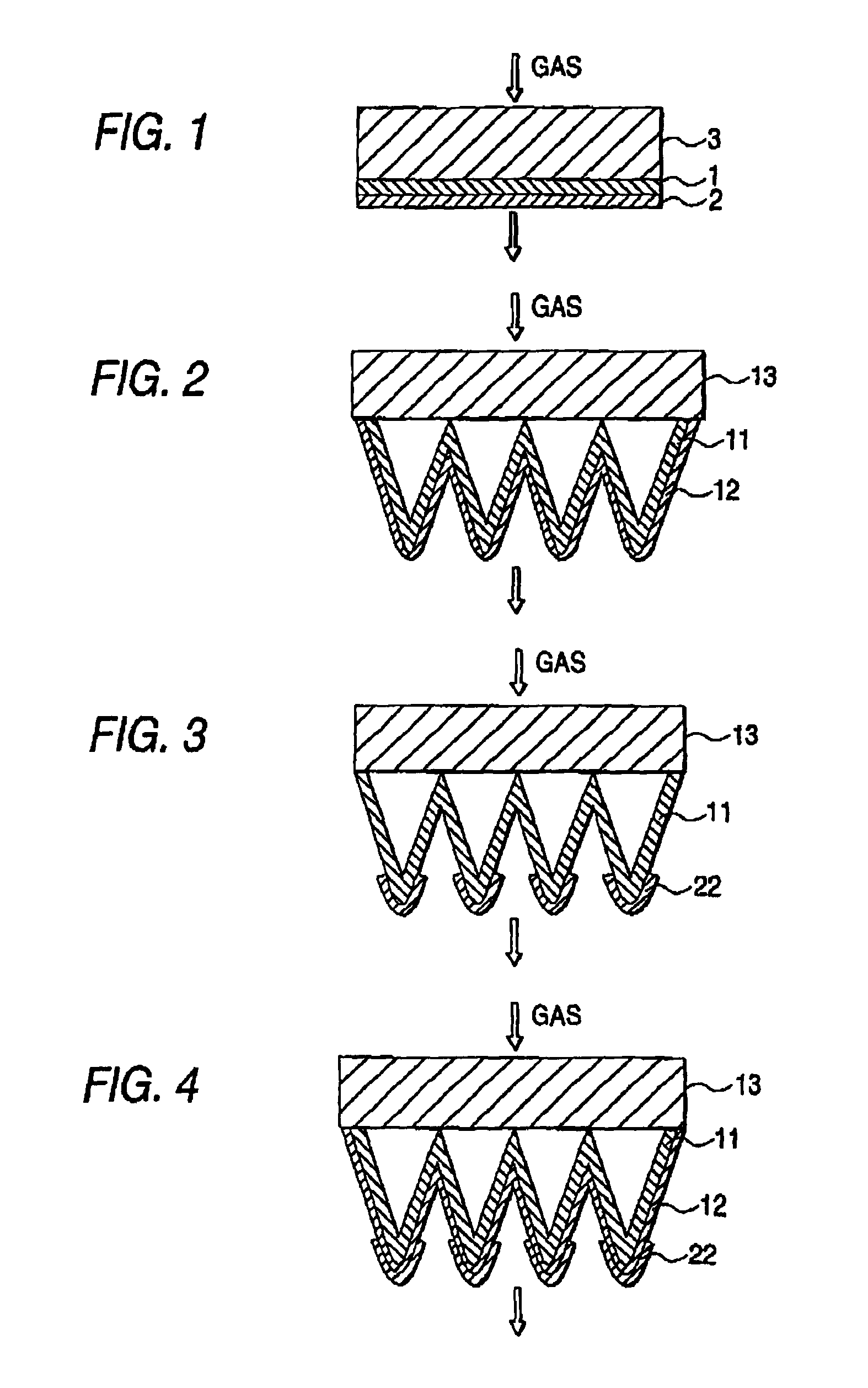

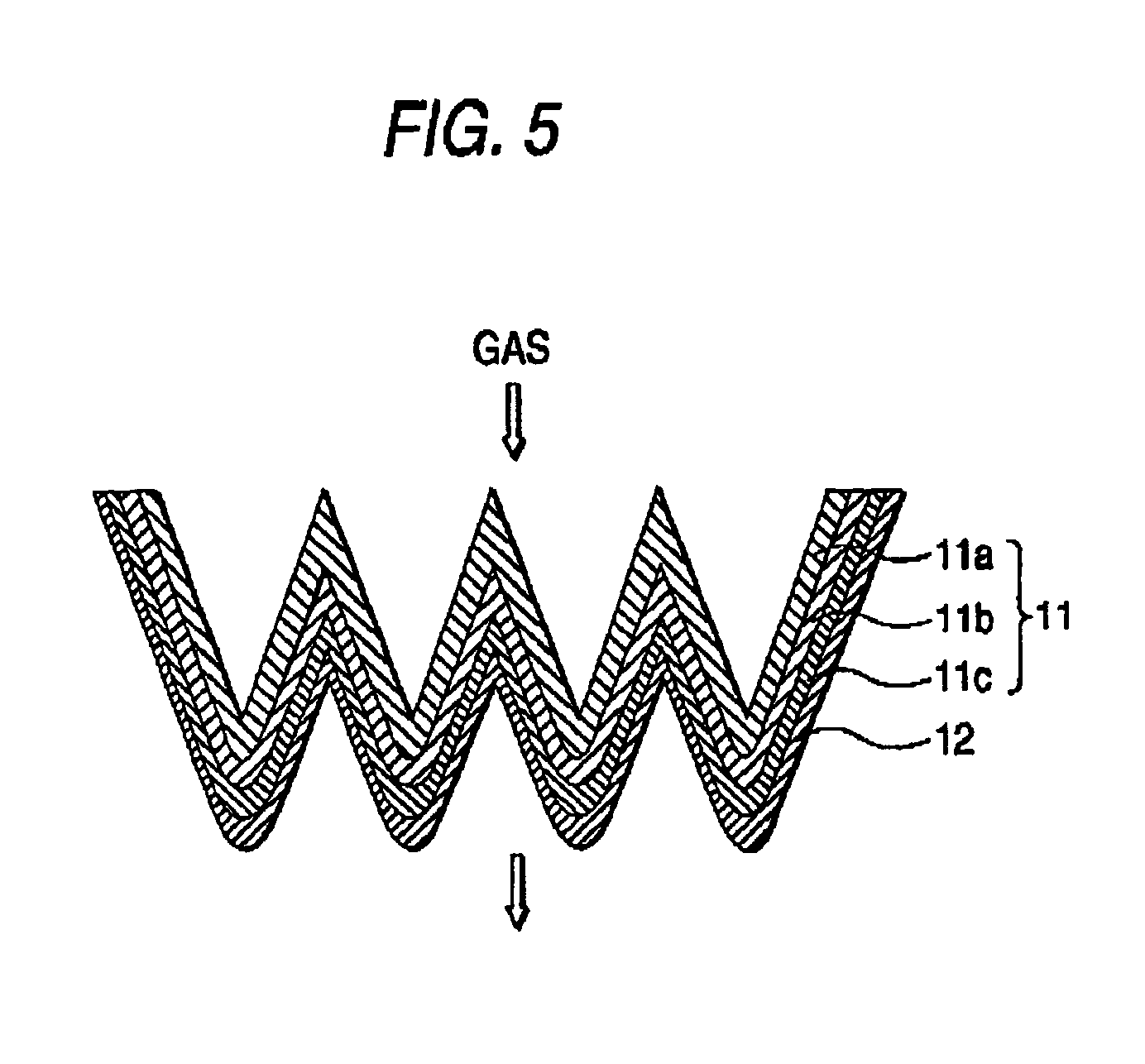

Filter element

InactiveUS6926750B2Improve cleaning efficiencyExtended service lifeCombination devicesDispersed particle filtrationFolded structureRidge

A filter element comprises an oil-impregnated filtering member, and a transmission preventing layer formed on a downstream side of the filtering member, for restricting transmission of at least the carbon dusts from the oil-impregnated filtering member. The filtering member may be formed like a ridge-like-folded structure. The transmission preventing layer may be formed of a coating layer having a resistance against a viscous oil that is impregnated in the filtering member. This coating layer may be formed uniformly as a whole or the thickness or the content of the coating layer may be increased partially. A ventilation shutting-off member (filling layer) may be formed as the transmission preventing layer in the root portion areas of the ridge portions. The transmission preventing layer may comprise a resistant component that is insoluble in the oil that is impregnated in the filtering member.

Owner:HONDA MOTOR CO LTD +1

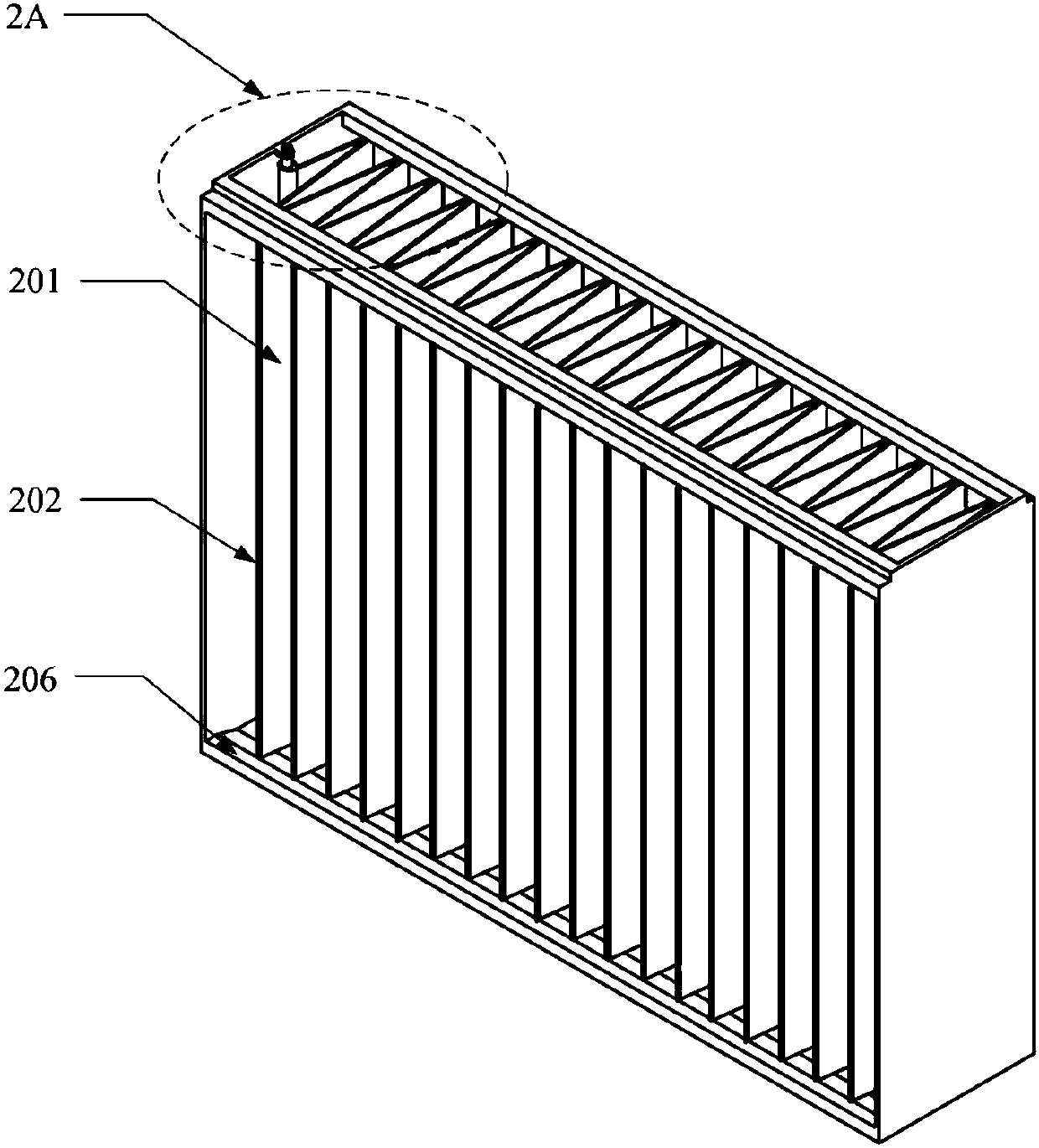

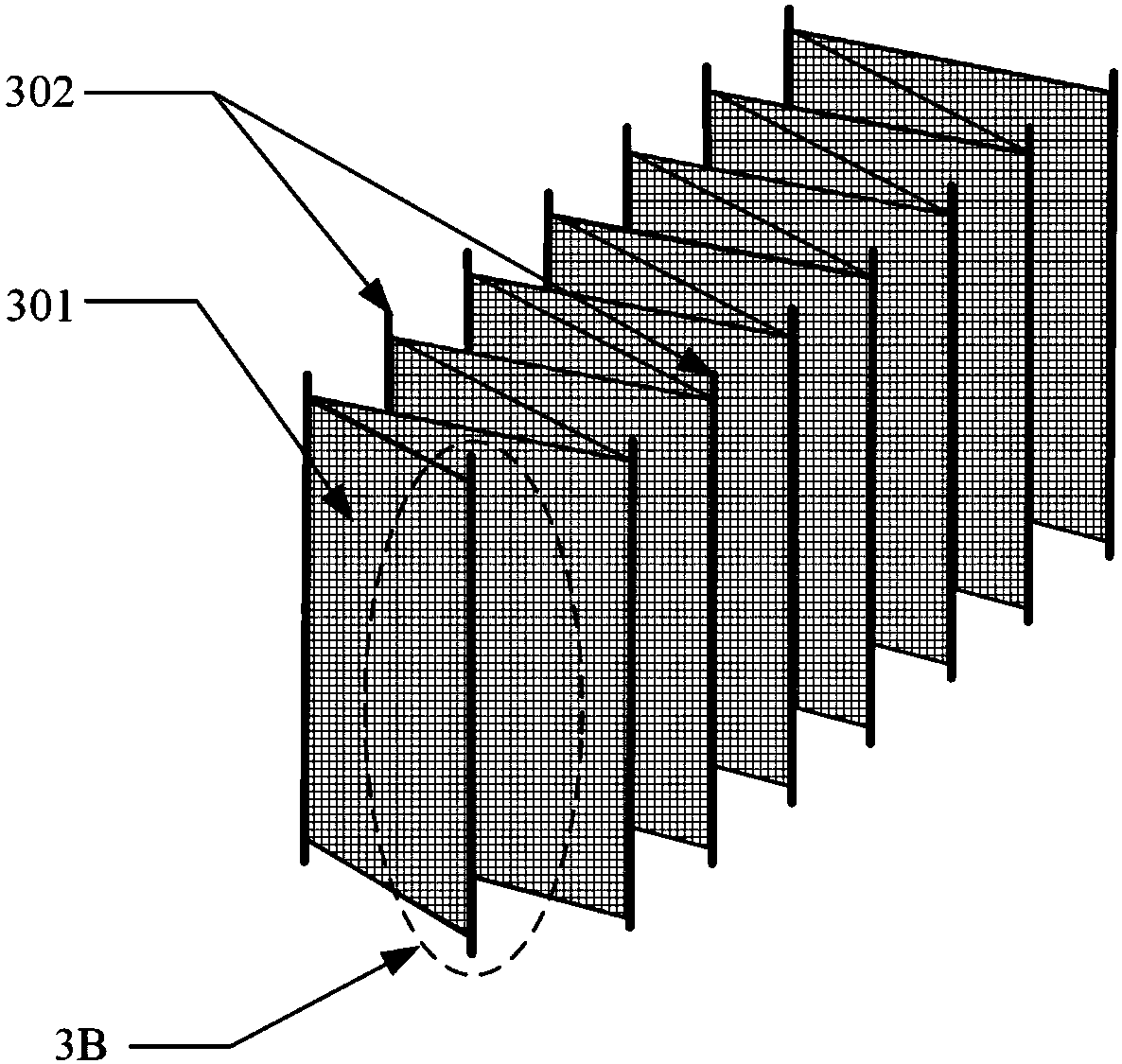

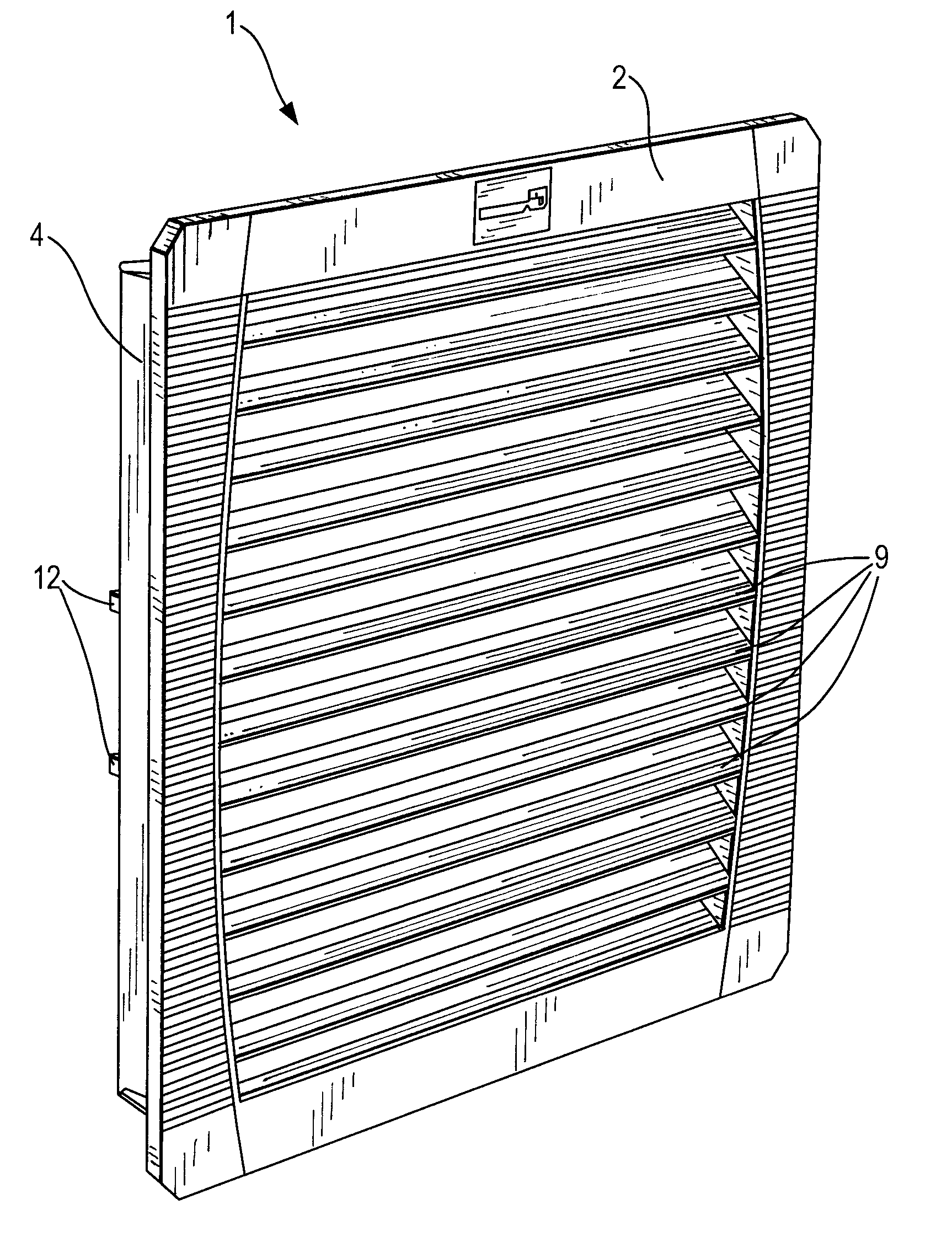

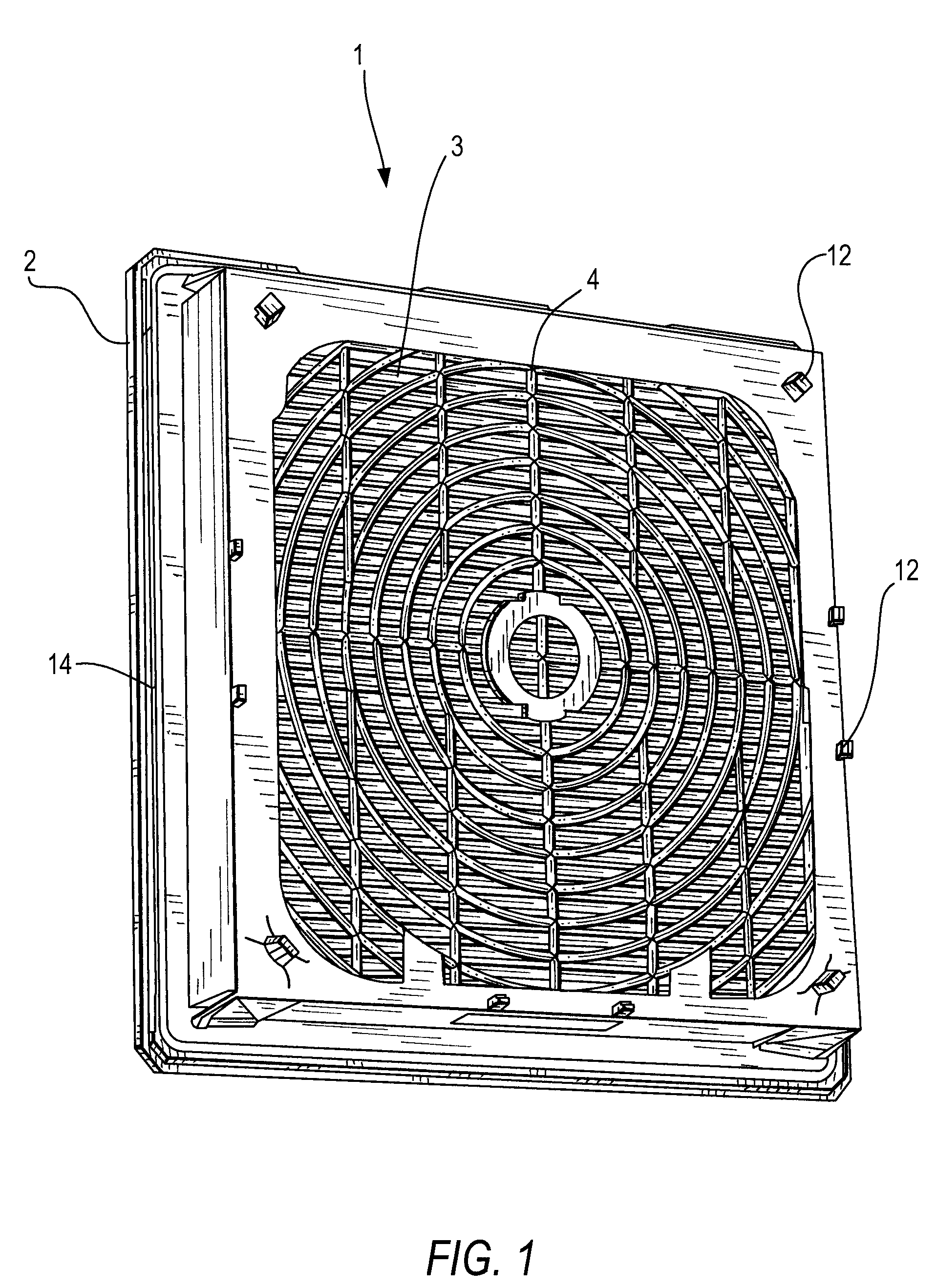

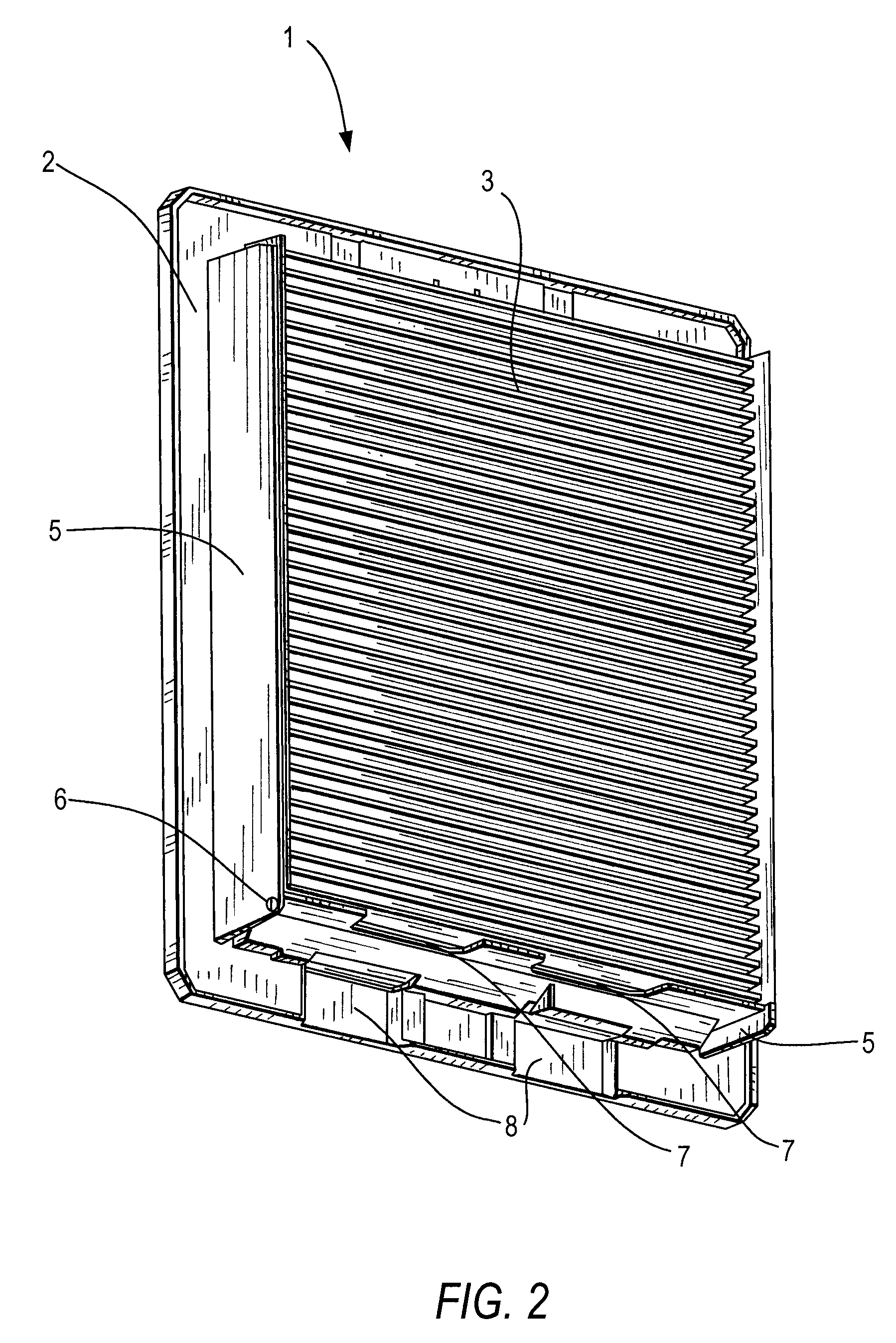

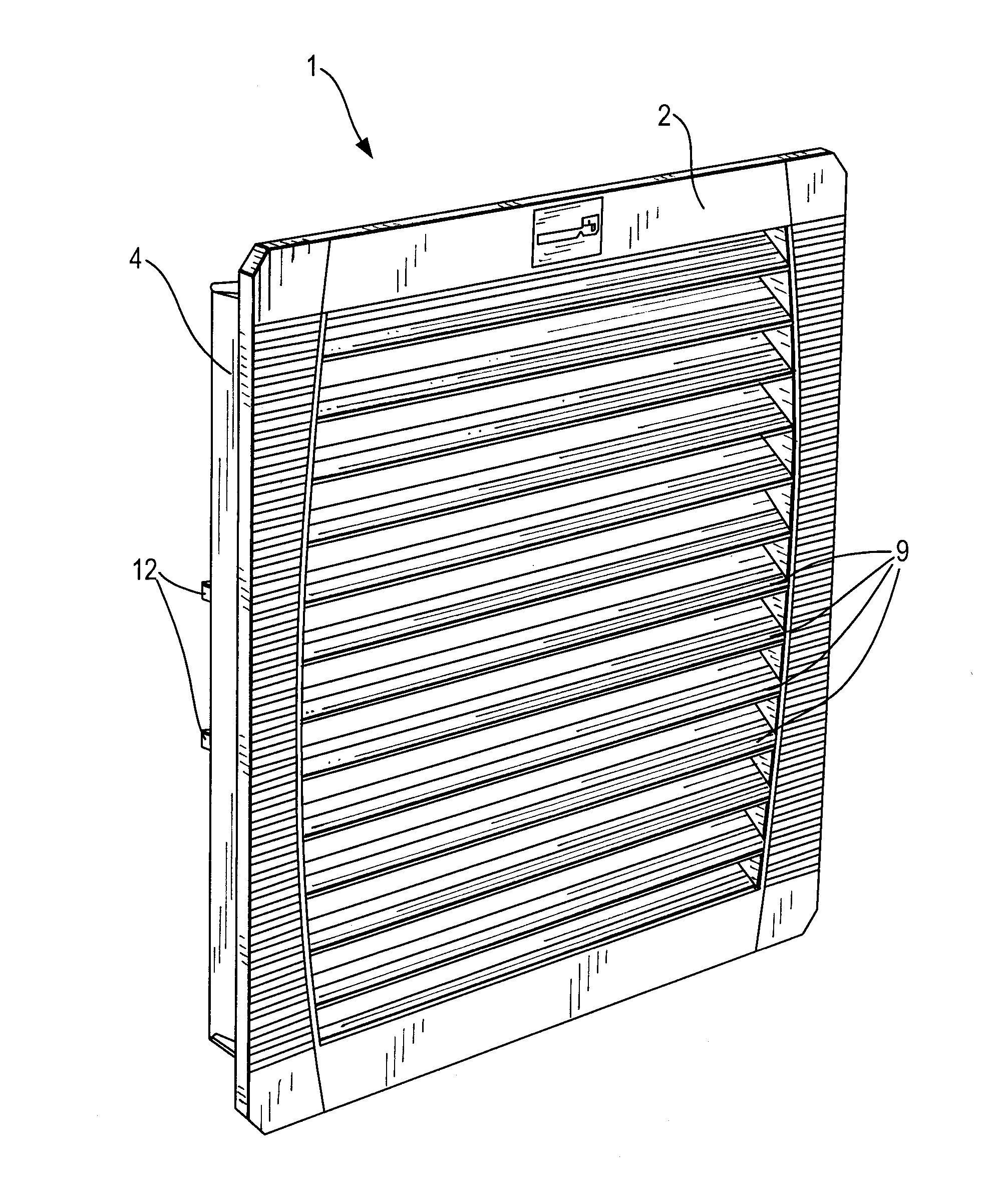

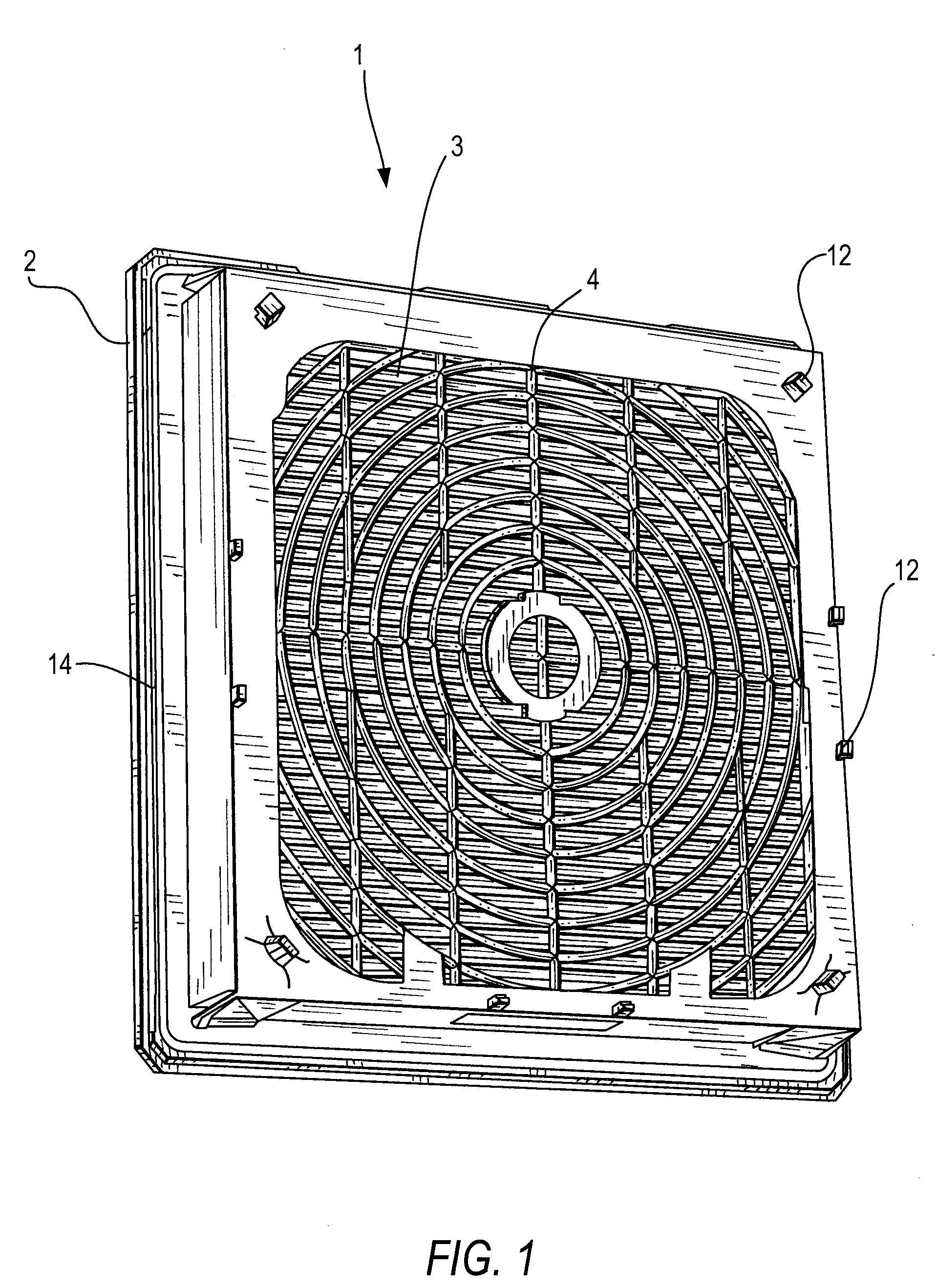

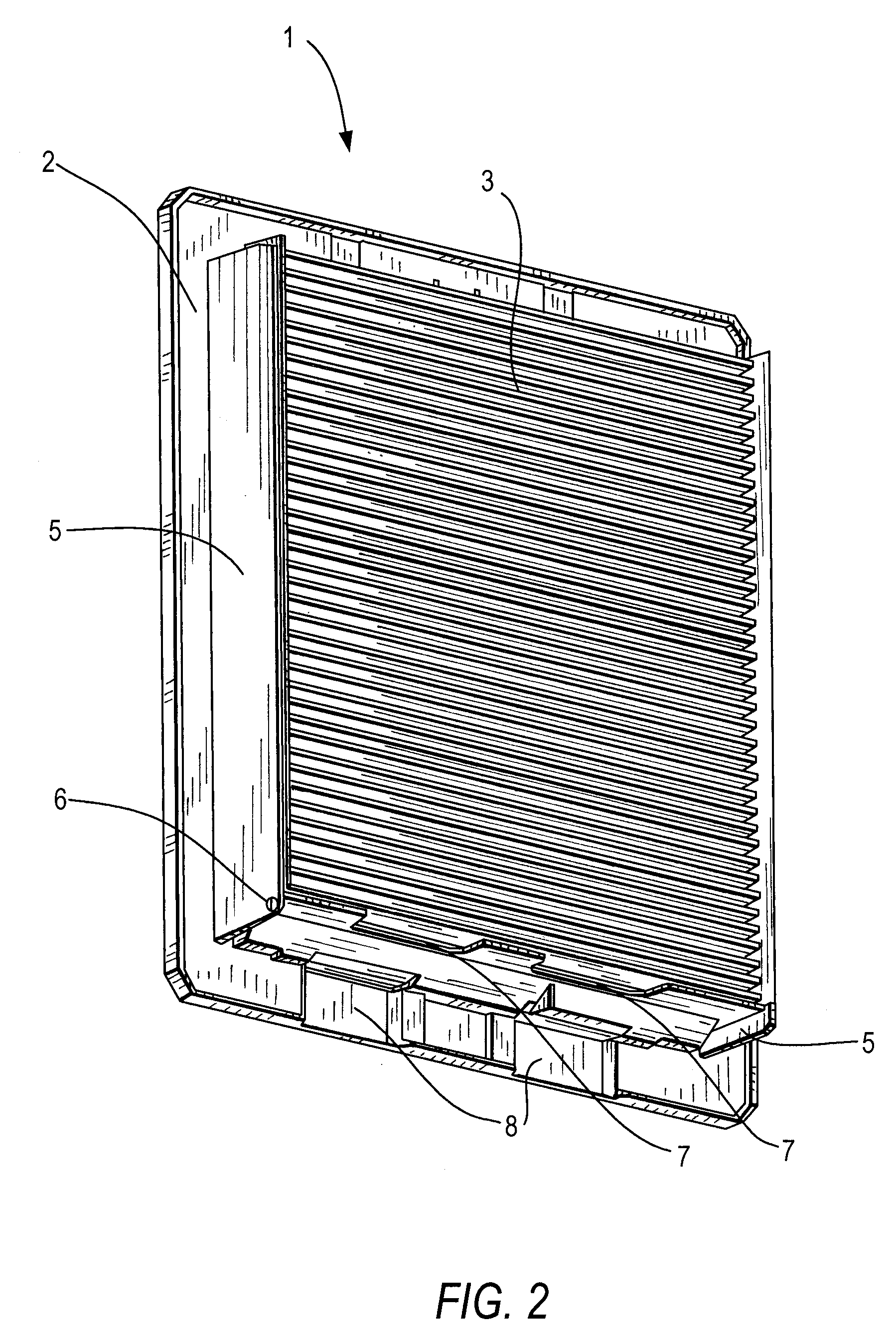

Filter fan

ActiveUS8951322B2Produced economicallyLow necessary blast powerCombination devicesLiquid degasificationFree distanceEngineering

A filter fan of a switch cupboard or of an electrical and / or electronic device placed in a casing with a blast producing an air flow and with a filter element (3) which is placed in the air flow and separates a clean side, on which the blast is placed, from an unclean side, wherein the filter element is held in a frame which can be fixed on the casing by covering the air passage opening penetrating through the casing wall and wherein a protective grid (4) is placed between the filter element (3) and the blast, the invention proposes that a bridging-free distance is provided between the filter surface of the filter element (3) and the protective grid (4), wherein this distance is dimensioned so as to make possible the discharge of water drops on the clean side surface of the filter element and to avoid a contact of the water drops with the protective grid.

Owner:PFANNENBERG GMBH

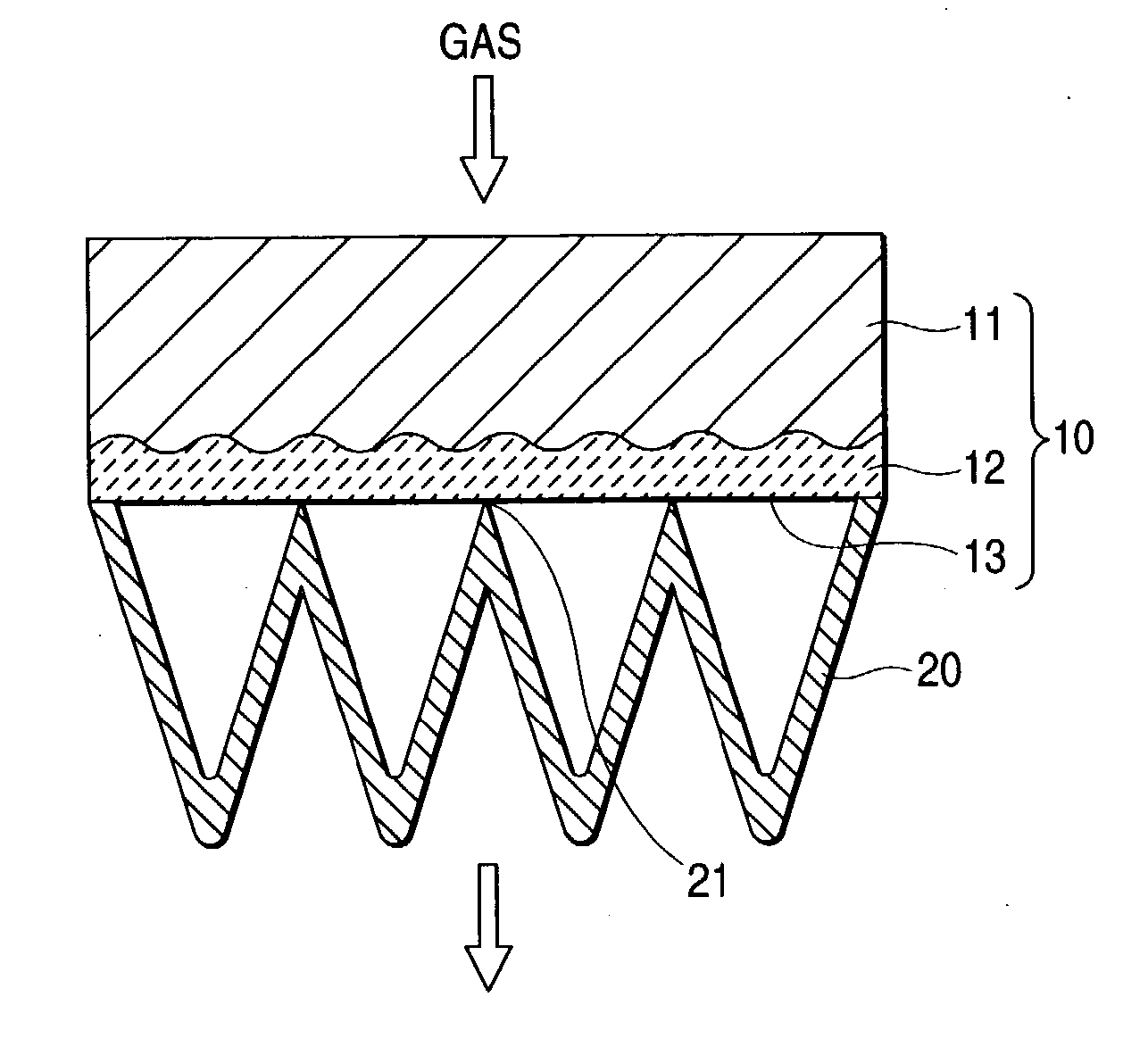

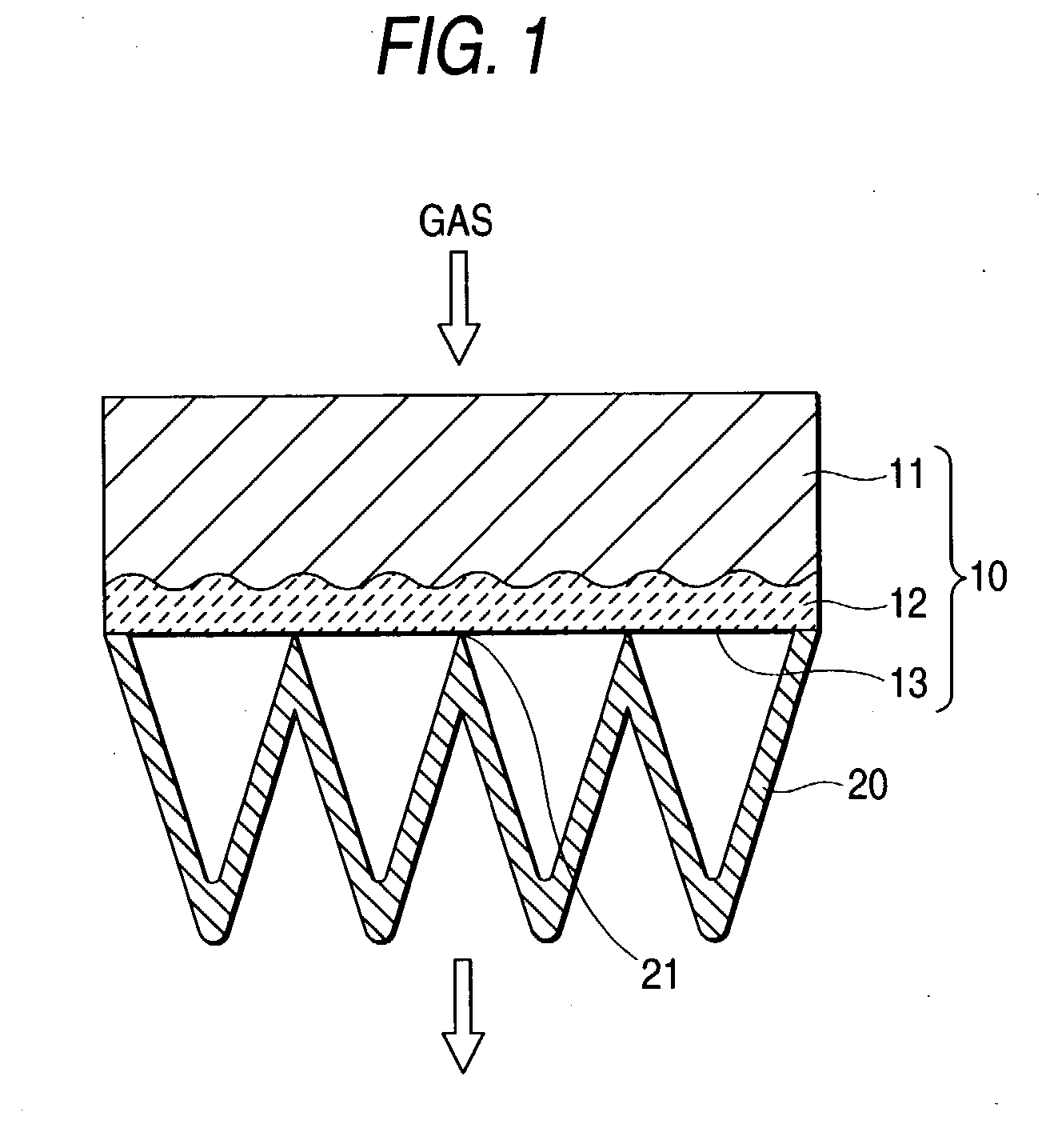

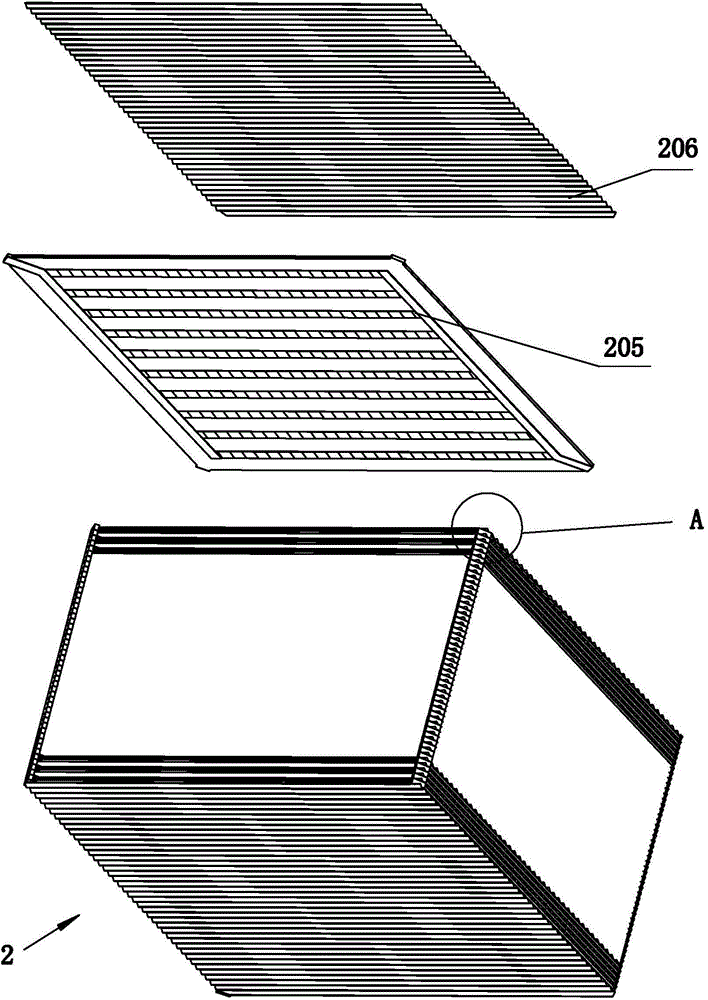

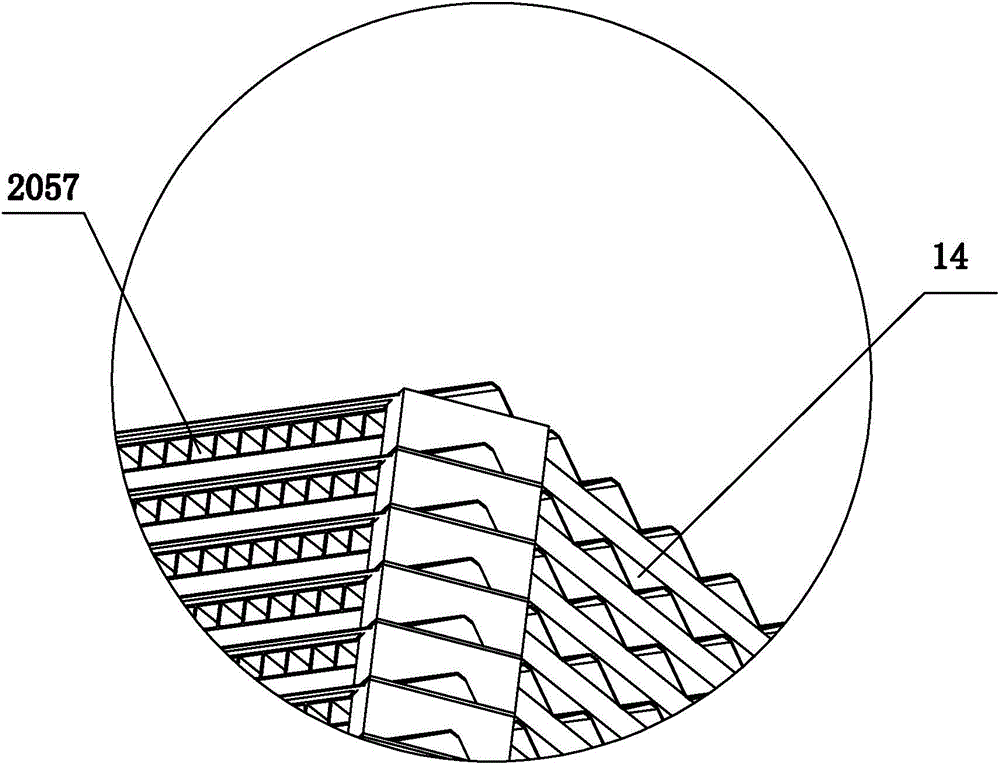

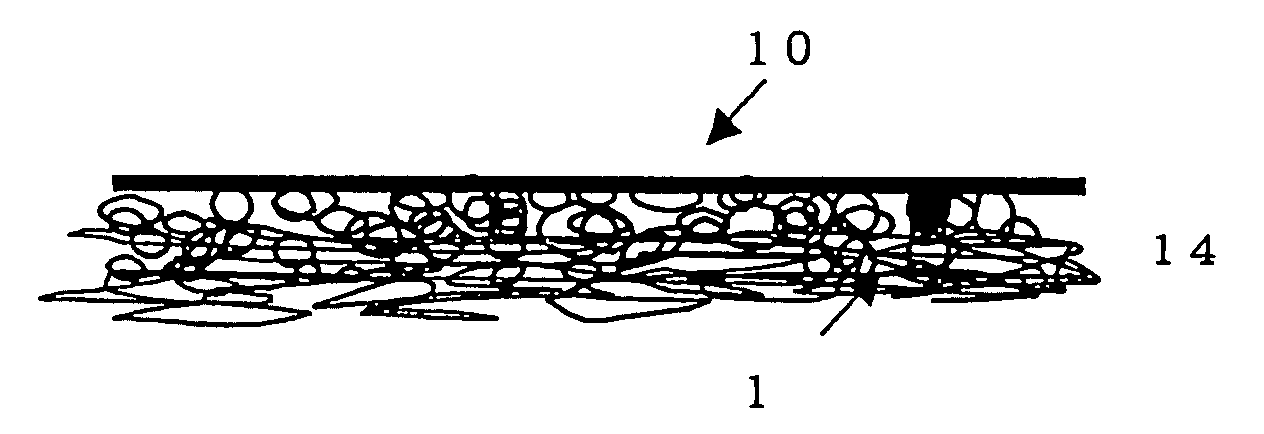

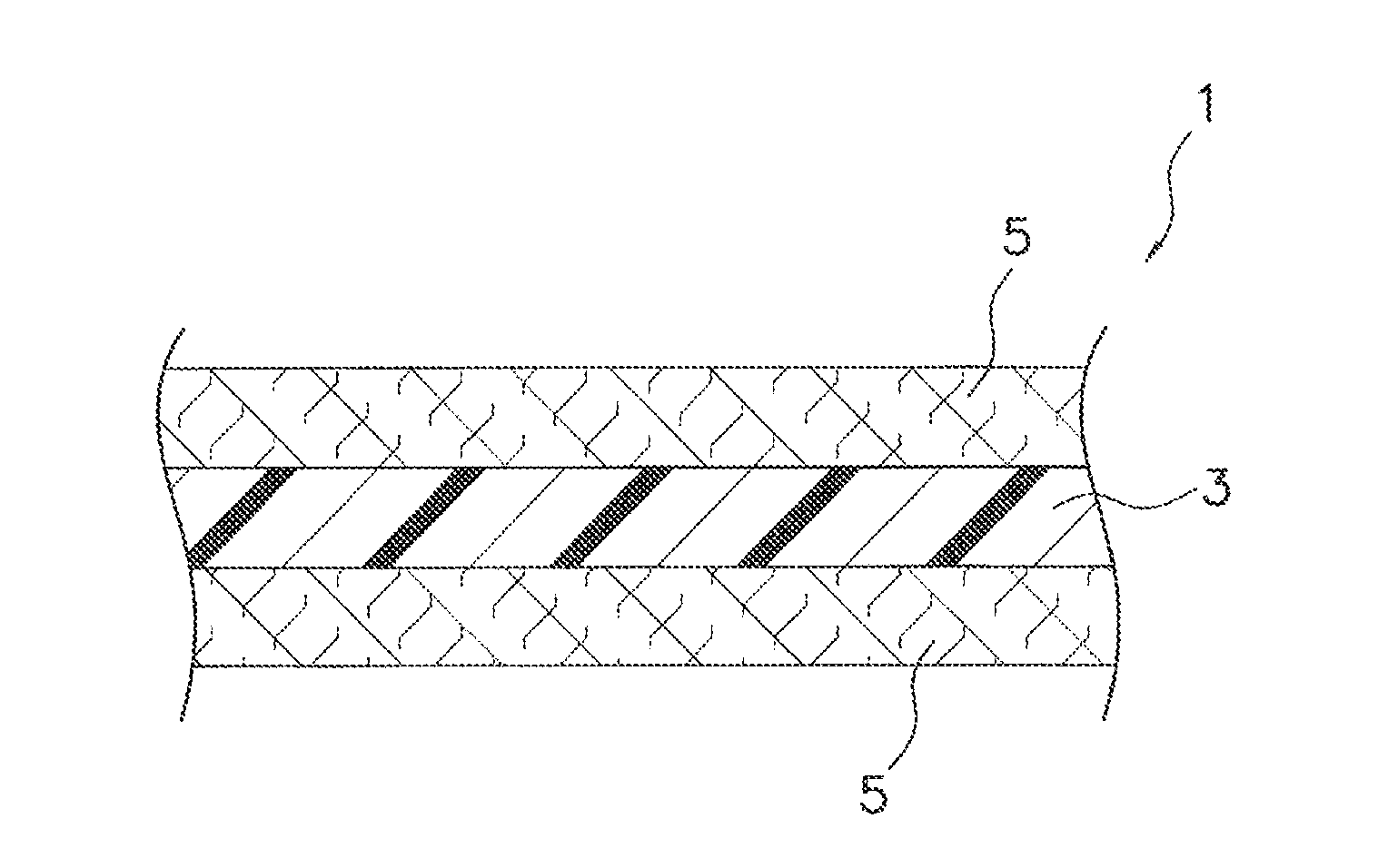

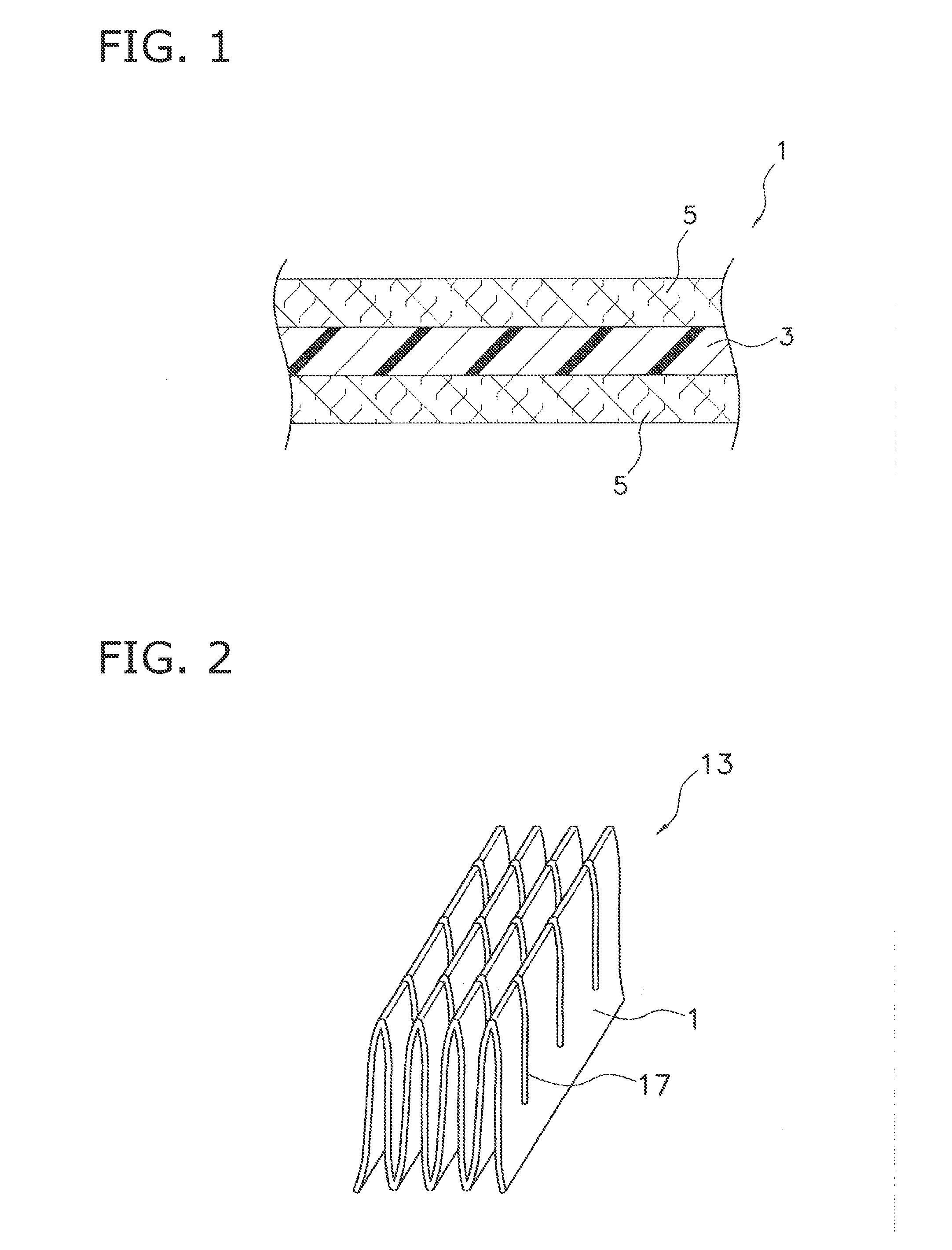

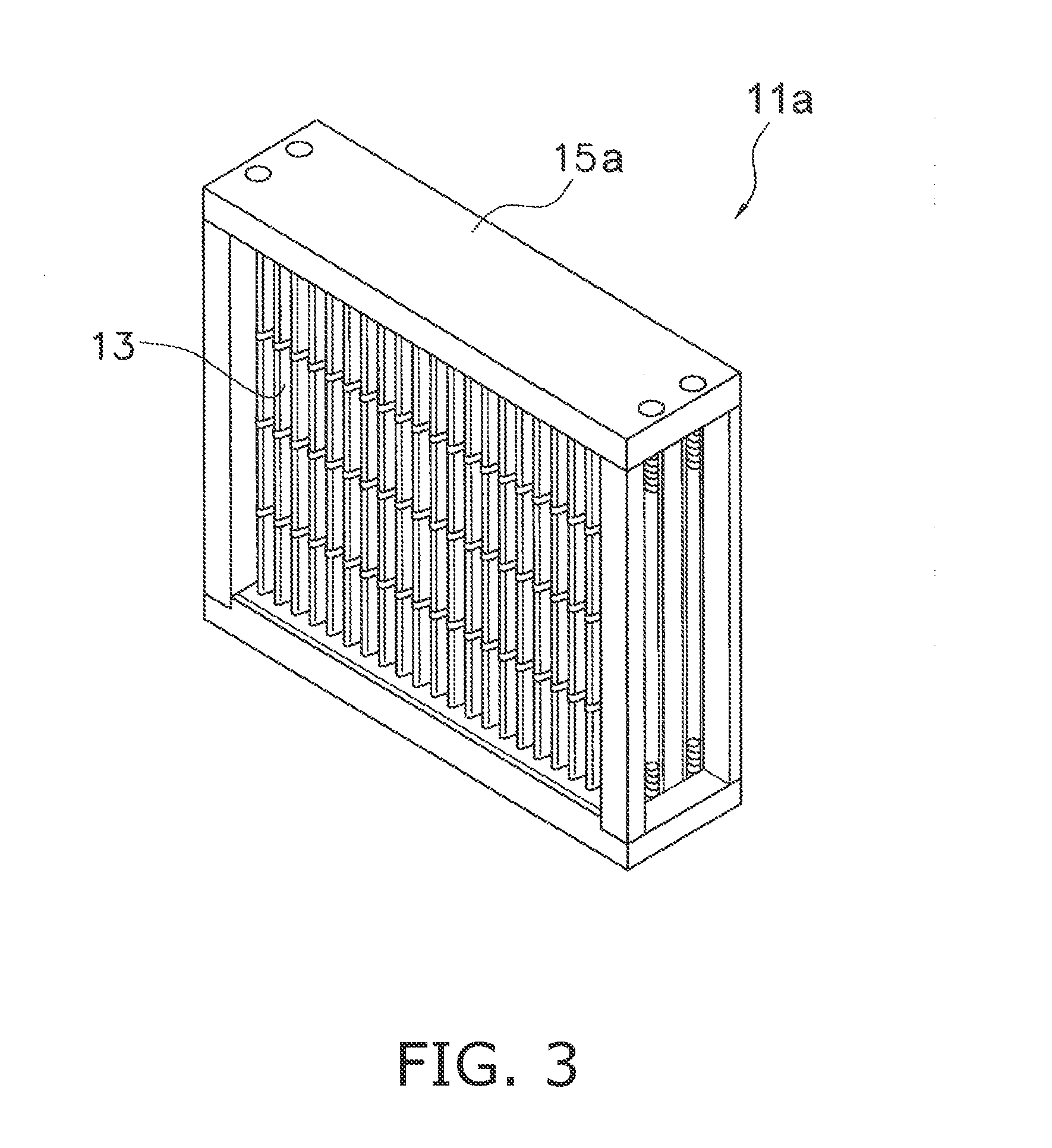

Filter medium equipped with porous film, method of manufacturing same, filter pack, and filter unit

ActiveUS20130097982A1Increase dust holding capacityLow pressure lossDispersed particle filtrationLaminationFilter mediaPore diameter

A filter medium includes a porous film and a support material supporting the porous film. The porous film includes polytetrafluoroethylene, has an average pore diameter of at least 2.5 μm, and has a porosity of at least 95%. A pressure loss is less than 100 Pa when air is passed through the filter medium at a velocity of 5.3 cm / sec. A collection efficiency of NaCl particles is at least 95% when air including NaCl particles with a particle diameter of 0.3 μm is passed through the filter medium at a velocity of 5.3 cm / sec. A PF value is at least 30, where PF={−log [(100−collection efficiency (%)) / 100] / pressure loss (Pa)}×1000. A dust holding capacity of polyalphaolefin particles held in the filter medium is at least 15 g / m2 when air including polyalphaolefin particles with a count median diameter of 0.25 μm is continuously passed through the filter medium at a velocity of 5.3 cm / sec and pressure loss reaches 300 Pa.

Owner:DAIKIN IND LTD

Composite nano-fiber PM2.5 filtering material and preparation method thereof

ActiveCN106925033AEvenly distributedHigh porosityDispersed particle filtrationMembrane filtersCross-linkFiber

The invention discloses a composite nano-fiber PM2.5 filtering material and a preparation method thereof. The material comprises a polyacrylonitrile and gelatin cross-linked composite nano-fiber film. An air filtering material provided by the invention with a polyacrylonitrile and gelatin composite nano-fiber netted cross-linked structure is acquired through the disposable electrostatic spinning and heating after-treatment. The diameter of the polyacrylonitrile and gelatin composite nano-fiber is 150-300nm, the porosity is 80%-90% and the average pore size is 0.5um-6um. The composite nano-fiber with compact structure, uniform netted cross-linking and better mechanical property and hydrophilic air permeability can be acquired; the filtering efficiency thereof for the NaCI aerosol with the median diameter of 200-300nm is 99.82%-99.91%; the pressure drop is 120-150Pa; the breaking strength is 10.92mPa; the elongation at break is 89.85%; the air permeability is 16820mL / (cm<2>.h). The material is especially suitable for the fields of personal protection products, air quality detecting equipment, air purifying equipment, and the like.

Owner:SHAANXI UNIV OF SCI & TECH

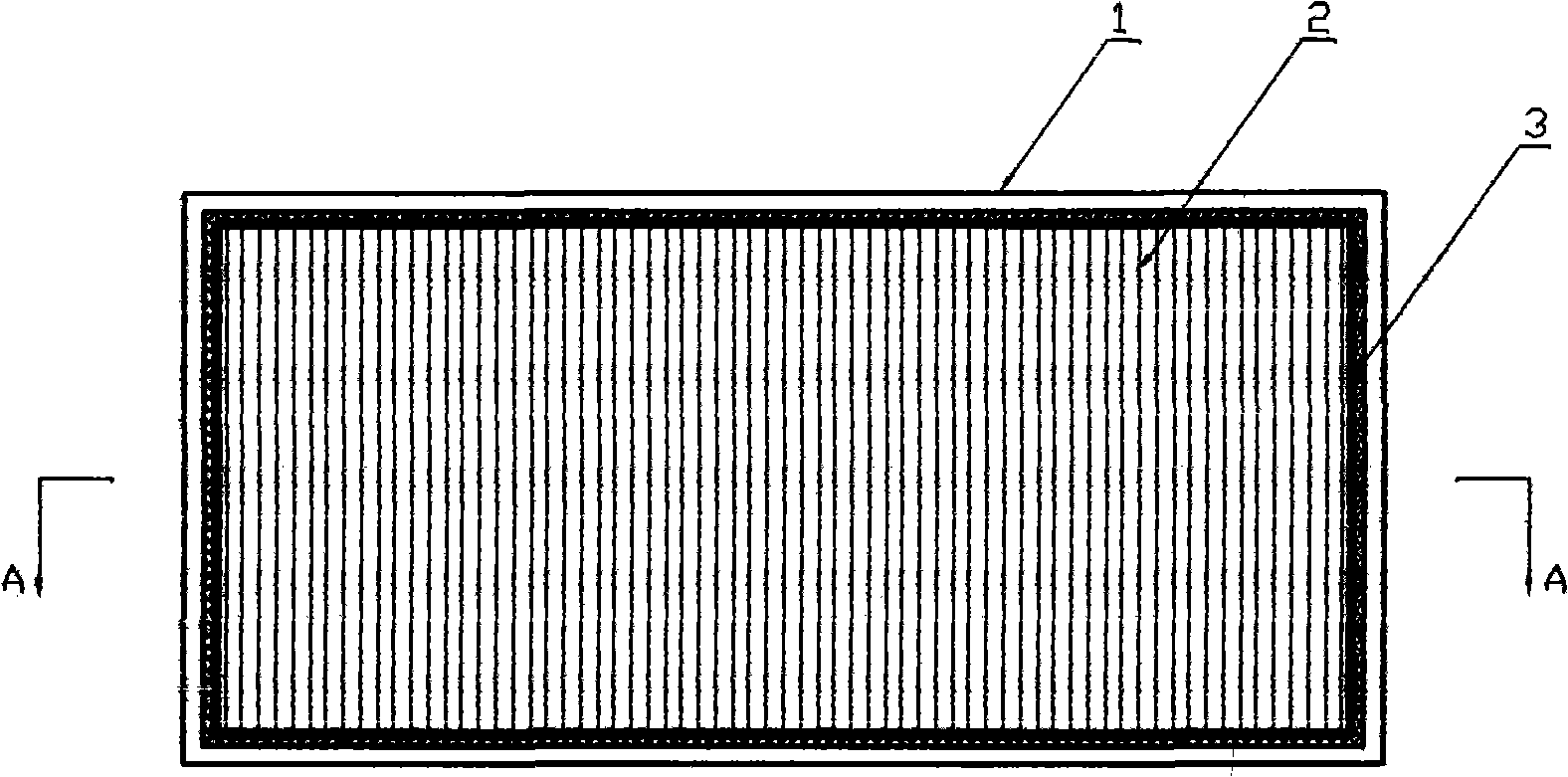

High dust holding filter material for filter bag

ActiveCN103638747AImprove breathabilityEasy to processDispersed particle filtrationSynthetic resin layered productsPorosityCarding

The invention discloses a high dust holding filter material for a filter bag. The high dust holding filter material is in a three-layer overlap structure formed by clamping a middle dust holding layer clamped by an upper protective layer and a lower protective layer, wherein the three layers are compounded into a whole by adopting a punching or ultrasonic welding process; the total gram weight of the high dust holding filter material is 50-200g / m<2>; the upper protective layer and the lower protective layer are made of polypropylene spunbond nonwoven fabrics with the gram weight of 10-30g / m<2>. The invention aims to give a certain strength to the high dust holding filter material, the dust holding layer is clamped, and the effects of fixing fibers and preventing the fibers from dropping are achieved. Moreover, the dust holding layer is a key layer of the high dust holding filter material, has the gram weight of 30-140 g / m<2> and is made of a polypropylene short fiber raw material, and a high-bulk high-porosity three-dimensional stereoscopic structure is manufactured by utilizing the mechanical carding and mechanical wet forming technology. The high dust holding filter material has the characteristics of high dust holding capacity, high processing performance and the like.

Owner:桐乡市朗裕净化科技股份有限公司

Multifunctional high-efficiency filter screen capable of cleaning and method for producing the same

ActiveCN101274175AIncrease dust holding capacityExtended service lifeDispersed particle filtrationFiltration separationGlass fiberEngineering

The invention provides a multifunctional high-efficient cleanable filter screen, comprising a frame. Cleanable filter materials, a multifunctional filter screen and glass fiber are fixed in the frame by adhesive matters. The invention also provides a preparation method of the multifunctional high-efficient cleanable filter screen. In the preparation method, one layer of filter materials and one layer of glass fiber are sandwiched by two layers of reinforced nets which are then folded and formed by a folding machine, processed as suitable size by a cutting machine, compounded by the multifunctional filter screen and the glass fiber, and finally fixed in the frame by the adhesive matters. The multifunctional high-efficient cleanable filter screen has the advantages of high filtering efficiency, easy cleaning and long service life. Furthermore, various additional functions are added of which materials with durable effects are gradually released by a special inducer.

Owner:SHUNDE APOLLO AIR CLEANER

Filter fan

ActiveUS20110005177A1Produced economicallyReduce differential pressureCombination devicesGas treatmentEngineeringElectron

A filter fan of a switch cupboard or of an electrical and / or electronic device placed in a casing with a blast producing an air flow and with a filter element (3) which is placed in the air flow and separates a clean side, on which the blast is placed, from an unclean side, wherein the filter element is held in a frame which can be fixed on the casing by covering the air passage opening penetrating through the casing wall and wherein a protective grid (4) is placed between the filter element (3) and the blast, the invention proposes that a bridging-free distance is provided between the filter surface of the filter element (3) and the protective grid (4), wherein this distance is dimensioned so as to make possible the discharge of water drops on the clean side surface of the filter element and to avoid a contact of the water drops with the protective grid.

Owner:PFANNENBERG GMBH

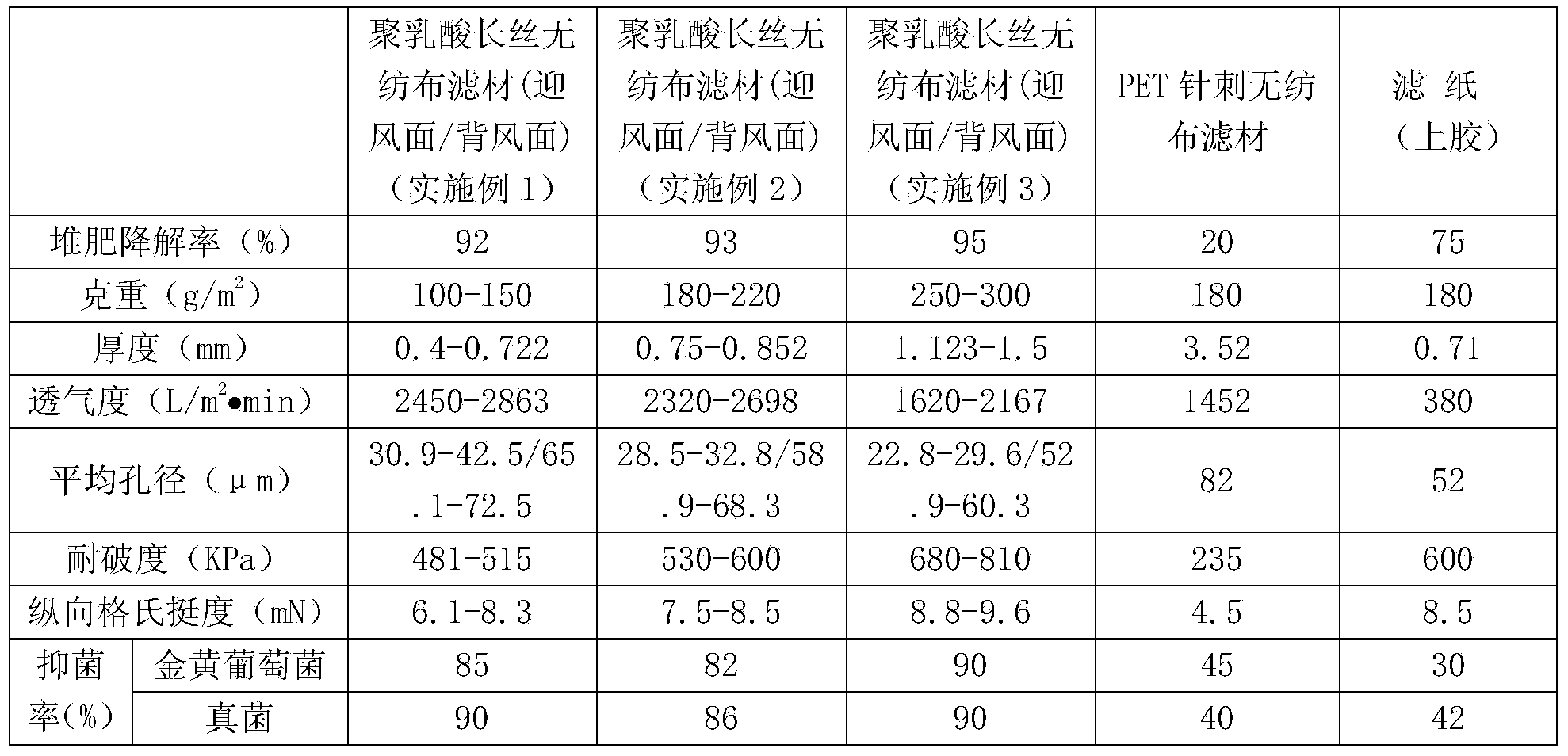

Polylactic acid filament yarn non-woven filter material and application thereof

ActiveCN103520998AImprove adsorption capacityGood Density Gradient StructureDispersed particle filtrationFiltration separationAir filtrationRenewable materials

The invention discloses a polylactic acid filament yarn non-woven filter material and application thereof. Most of the existing air filtration materials adopt non-renewable materials, thus bringing difficulty in follow-up waste treatment. The filter material comprises 100% polylactic acid filament yarn fiber net, and is prepared by the following steps of firstly thoroughly drying pre-crystallized polylactic acid slices; then melting and squeezing by more than two groups of spinning machines, cooling, drafting and separating yarns so as to form nets respectively, and overlaying to form a composite fiber net; finally, rolling the composite fiber net into a whole by a hot mill. The filter material has a surface filtration effect, has the characteristics of high filtration efficiency, large clogging capacity, low resistance, good air permeability, low ash removal frequency, antibacterial performance and deodorization, and can be completely degraded after being discarded.

Owner:山东星地新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com