Production method of hot-rolled non-woven base material and product of production method

A technology of non-woven fabrics and manufacturing methods, applied in the direction of non-woven fabrics, separation methods, layered products, etc., can solve the problems of poor physical properties of strength and burst resistance, and cannot be used in a single layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

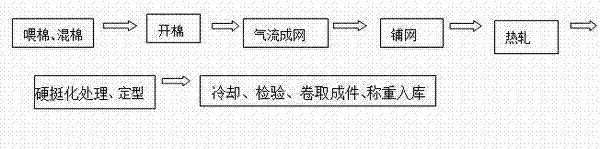

[0032] Such as figure 1 As shown in , a method for manufacturing a hot-rolled nonwoven fabric substrate includes the following steps in turn:

[0033] A. Cotton feeding and cotton blending: Put the low-melting point polyester fiber and ordinary polyester fiber in the mass ratio of 1:1.05 on the conveyor belt of the cotton feeding machine;

[0034] B. Cotton opening: the fiber raw material is conveyed by the cotton feeder to the cotton opener, and the fiber raw material is broken up;

[0035] C. Air-laid: form the fiber raw material dispersed in step B into a net;

[0036] D. Laying: The fiber raw materials straightened out in step C are superimposed vertically and horizontally into multiple layers;

[0037] E. Hot rolling: The fiber raw materials superimposed into multiple layers in step D are sent to a hot rolling mill, and the multi-layer fiber raw materials are hot rolled into nonwoven fabrics through the rolls of the hot rolling mill;

[0038] F. Stiffening treatment a...

Embodiment 2

[0042] Such as figure 1 Shown, a kind of manufacturing method of hot-rolled nonwoven fabric base material, comprises the following steps successively:

[0043] A. Cotton feeding and cotton blending: Put the low-melting point polyester fiber and ordinary polyester fiber in the mass ratio of 1:1.35 on the conveyor belt of the cotton feeding machine;

[0044] B. Cotton opening: the fiber raw material is conveyed by the cotton feeder to the cotton opener, and the fiber raw material is broken up;

[0045] C. Air-laid: form the fiber raw material dispersed in step B into a net;

[0046] D. Laying: The fiber raw materials straightened out in step C are superimposed vertically and horizontally into multiple layers;

[0047] E. Hot rolling: The fiber raw materials superimposed into multiple layers in step D are sent to a hot rolling mill, and the multi-layer fiber raw materials are hot rolled into nonwoven fabrics through the rolls of the hot rolling mill;

[0048] F. Stiffening tr...

Embodiment 3

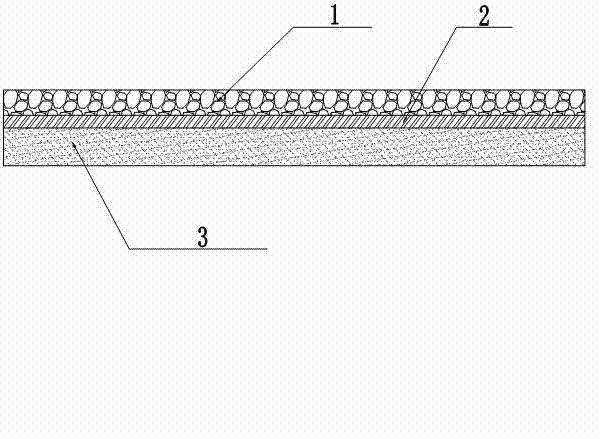

[0052] Such as figure 2 As shown, set the grammage to 80 g / m 2 Unwind the hot-rolled non-woven fabric base material, apply glue on the surface of the hot-rolled non-woven fabric base material layer 3 to form an adhesive layer 2, bond it with polytetrafluoroethylene film (PTFE), pass through a pressing roller, dry, and collect roll to form a film-coated filter material layer 1. The filtration efficiency of the filter material is 99.95% (0.3 μm, 5.3 cm / s), the filtration resistance is 265 pa (5.3 cm / s, 0.3 μm), the material thickness is 0.25 mm, and the stiffness is 700 mg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com