Carbon nanotube air filtering material with gradient structure and preparation method thereof

A technology of air filter materials and carbon nanotubes, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of unfavorable use of carbon nanotube membranes, low mechanical strength of carbon nanometer membranes, high filtration resistance, etc., and achieve Good industrial application prospects, long service life, and the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

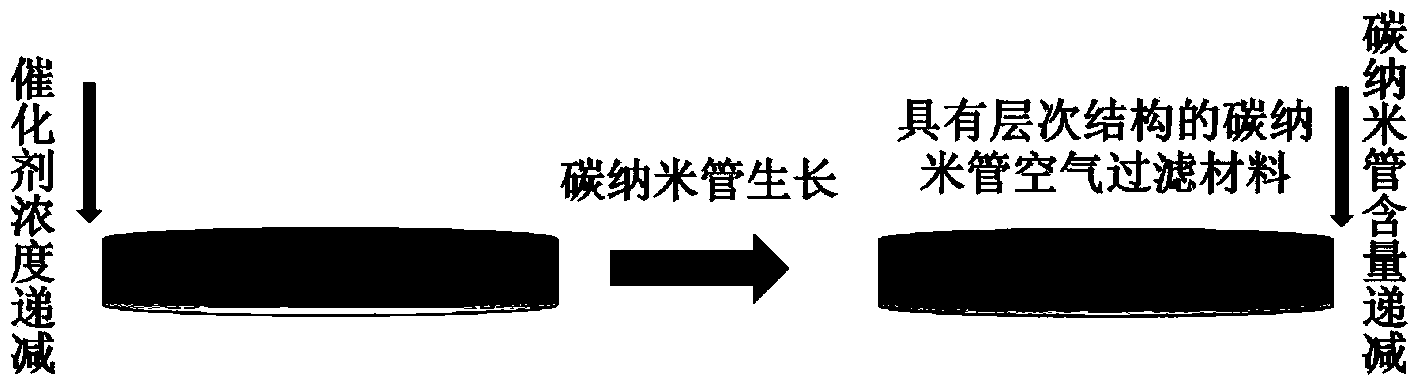

[0047] Embodiment 1, with the quartz fiber filter medium as the base, through the aerosol technology loading catalyst, prepare the carbon nanotube air filter material with gradient structure

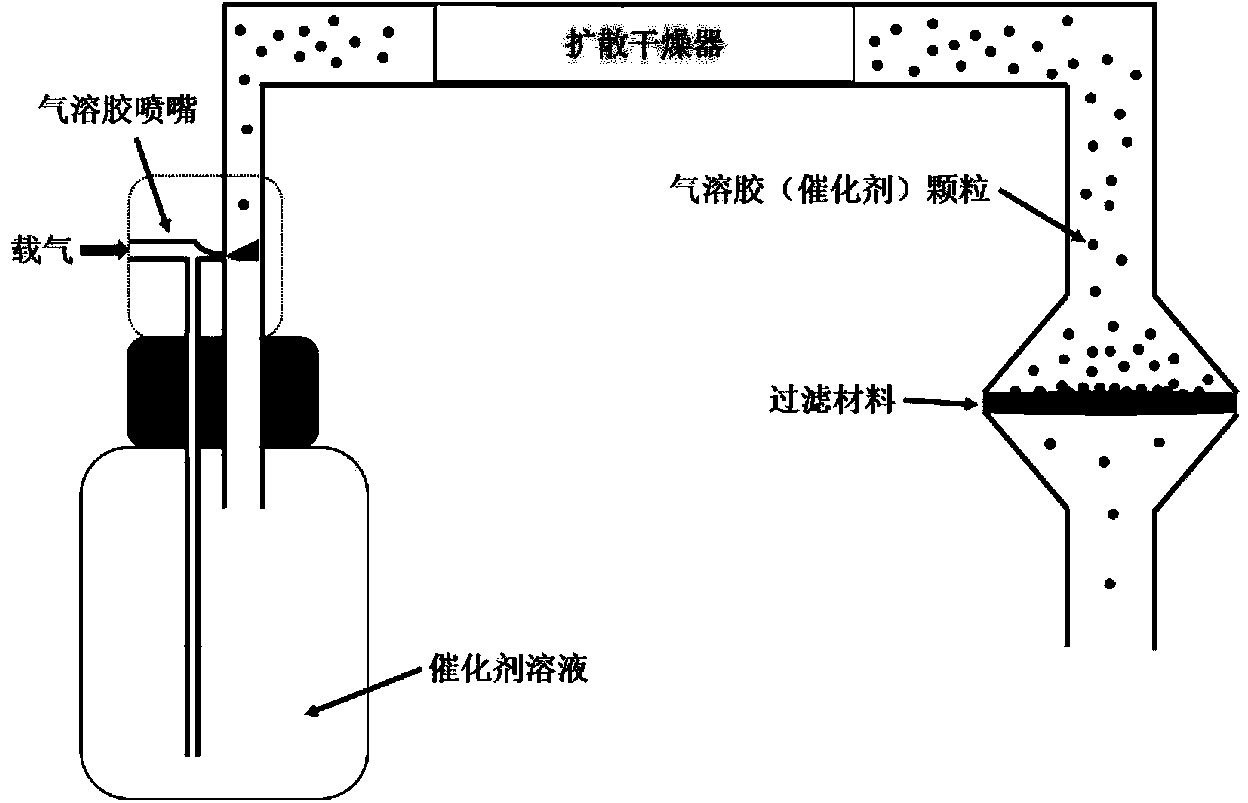

[0048] First, the quartz fiber filter medium (the average fiber diameter is 3 microns, the thickness is 0.43 mm, and the cross section is 100 m 2 ) for catalyst loading, the process is as figure 2 shown.

[0049] The catalyst solution is Fe(NO 3 ) 3 : Al(NO 3 ) 3 0.1 g / ml aqueous solution with a molar ratio of 0.8:1. Fe(NO 3 ) 3 with Al(NO 3 ) 3 After the aerosol particles are diffused and dried, they pass through the quartz fiber filter material. The concentration of aerosol particles can be controlled by adjusting the carrier gas flow of the aerosol nebulizer. In this embodiment, the size of the aerosol particles is 100 nm and the concentration is 3×10 5 per cubic centimeter, the carrier gas is high-purity nitrogen, and the gas velocity is 30mm / s. According to the principl...

Embodiment 2

[0052] Example 2, with the quartz fiber filter medium as the base, the catalyst is loaded by solution impregnation technology, and the carbon nanotube air filter material with gradient structure is prepared

[0053] First, the quartz fiber filter medium (the average fiber diameter is 3 microns, the thickness is 0.43 mm, and the cross section is 100 m 2 ) for catalyst loading. The catalyst solution is Fe(NO 3 ) 3 : Al(NO 3 ) 3 0.1 g / ml aqueous solution with a molar ratio of 0.8:1. Soak the quartz fiber filter medium in the catalyst solution for 6 hours. The filter medium was taken out and placed on a heating plate at 60° C. for 12 hours, during which the thickness direction was kept perpendicular to the heating plate. During the slow heating and drying process, the catalyst will achieve a ladder-like distribution in the thickness direction of the filter material. Carbon nanotube growth was then performed on the catalyst-loaded quartz fiber filter media. In this example,...

Embodiment 3

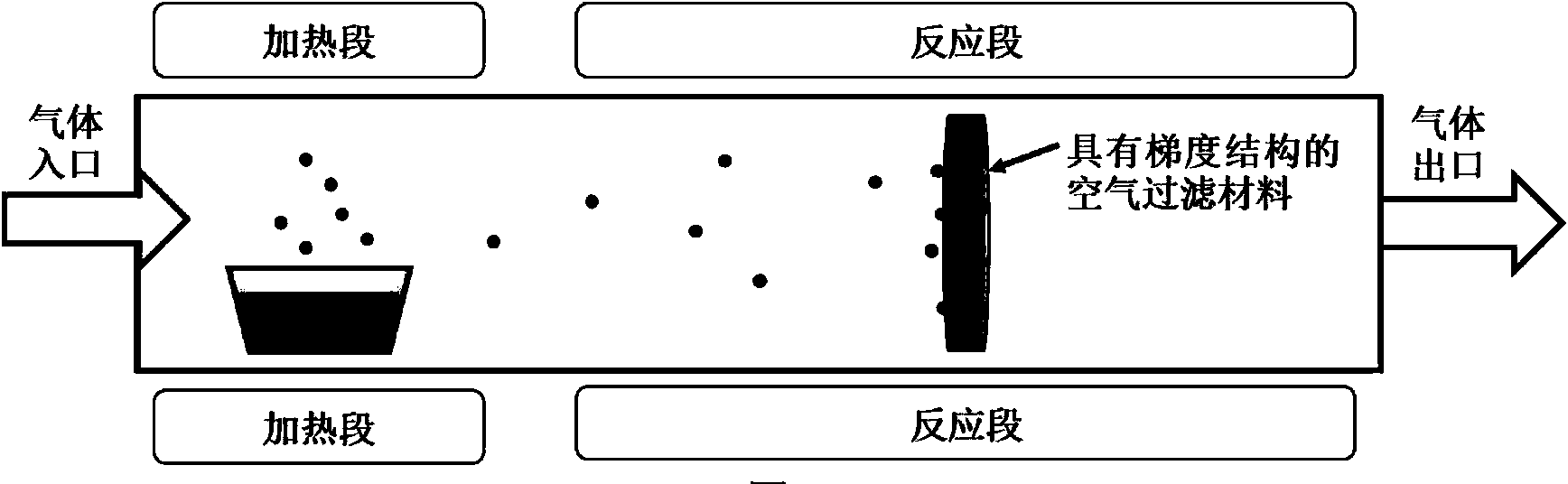

[0055] Example 3. In-situ preparation of carbon nanotube air filter material with ladder-like structure by planktonic catalytic method

[0056] The schematic diagram of the process of this embodiment is as follows image 3 shown.

[0057] Quartz fiber filter media (the average fiber diameter is 3 microns, the thickness is 0.43 mm, and the cross-section is 100 m 2 ) is placed in the reaction section of the quartz furnace, and the catalyst is ferrocene, which is placed in the heating section. At the beginning of the reaction, a mixed gas is introduced, the ratio is argon: hydrogen: ethylene = 3: 1: 1, and the gas flow rate is 30mm / s. Keep the temperature in the heating section at 120°C and the temperature in the reaction section at 800°C. During this process, the ferrocene is heated and sublimated, and when it passes through the reaction section area, it is heated to form catalyst nanoparticles, which are deposited in the quartz fiber filter medium, and its concentration decre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com