Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

112 results about "Nanotube membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanotube membranes are either a single, open-ended nanotube(CNT) or a film composed of an array of nanotubes that are oriented perpendicularly to the surface of an impermeable film matrix like the cells of a honeycomb. 'Impermeable' is essential here to distinguish nanotube membrane with traditional, well known porous membranes. Fluids and gas molecules may pass through the membrane en masse but only through the nanotubes. For instance, water molecules form ordered hydrogen bonds that act like chains as they pass through the CNTs. This results in an almost frictionless or atomically smooth interface between the nanotubes and water which relate to a “slip length” of the hydrophobic interface. Properties like the slip length that describe the non-continuum behavior of the water within the pore walls are disregarded in simple hydrodynamic systems and absent from the Hagen–Poiseuille equation. Molecular dynamic simulations better characterize the flow of water molecules through the carbon nanotubes with a varied form of the Hagen–Poiseuille equation that takes into account slip length.

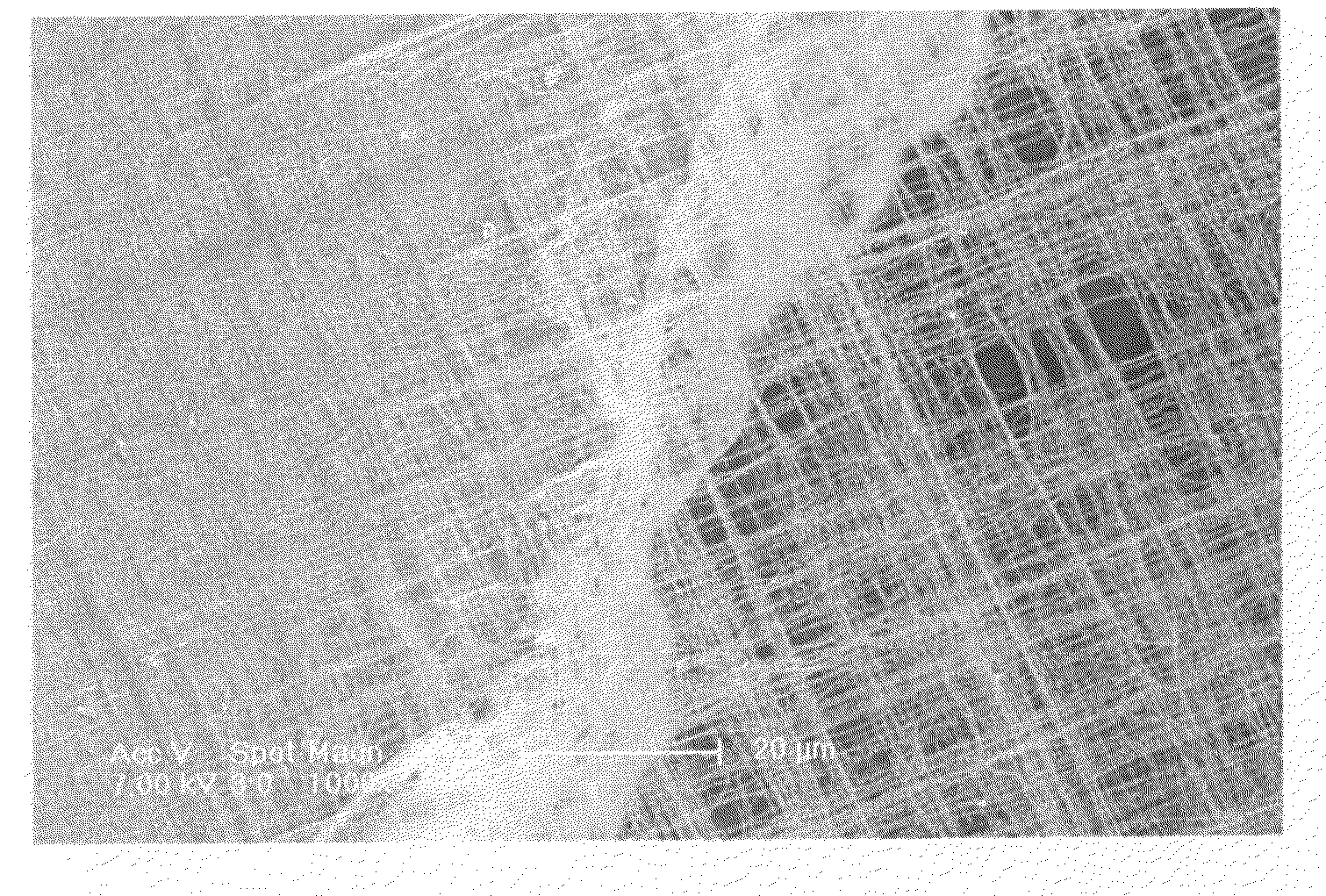

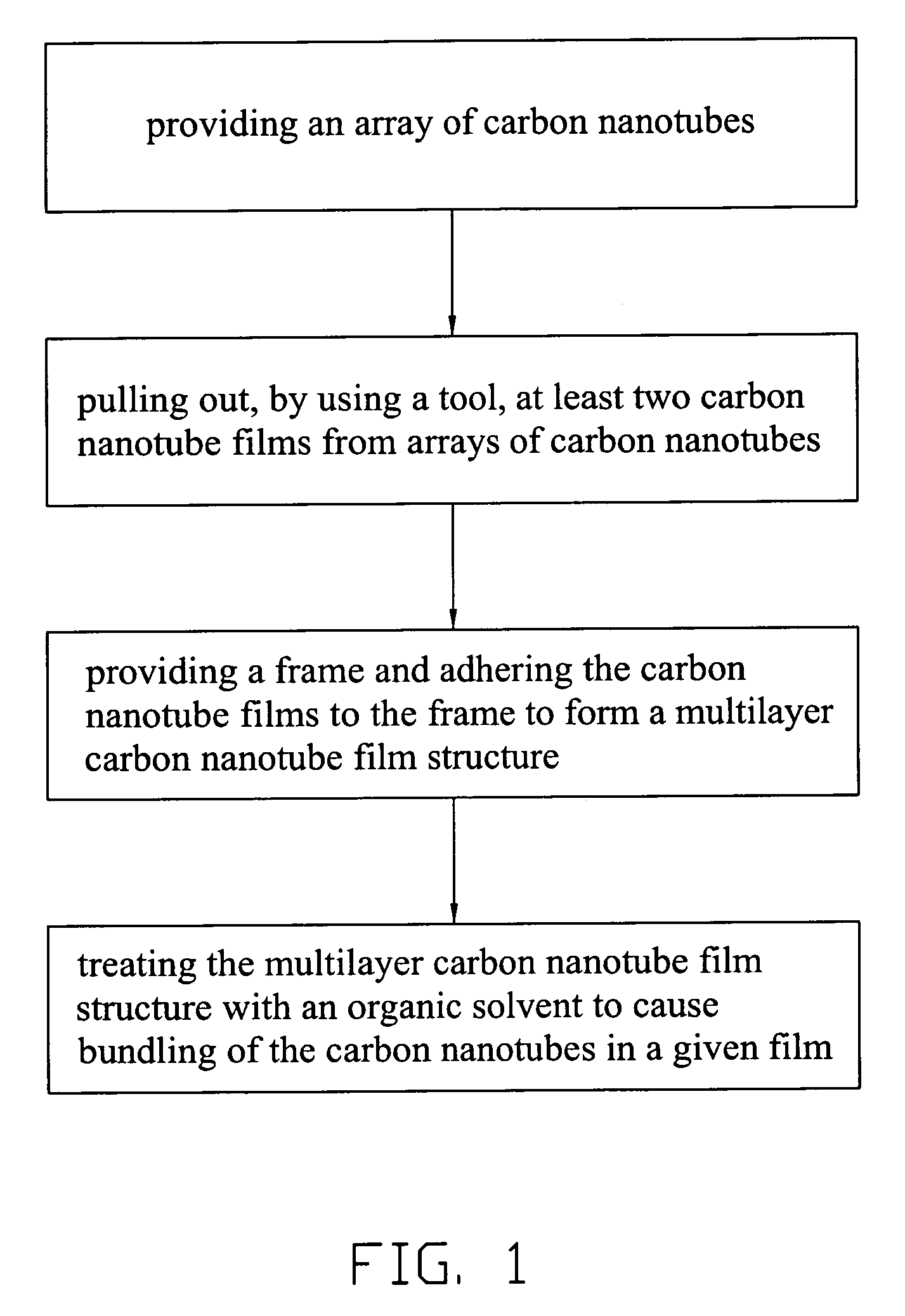

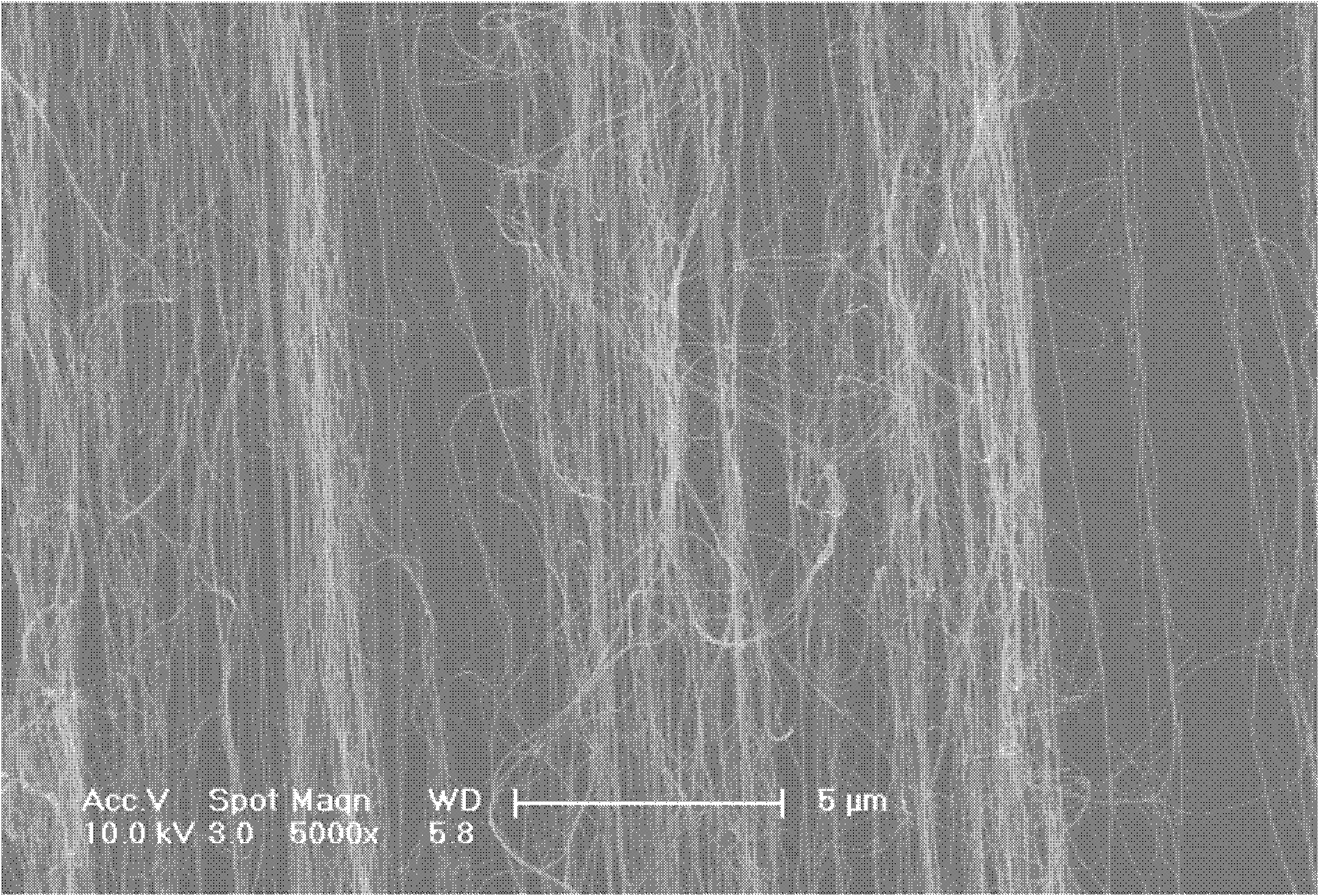

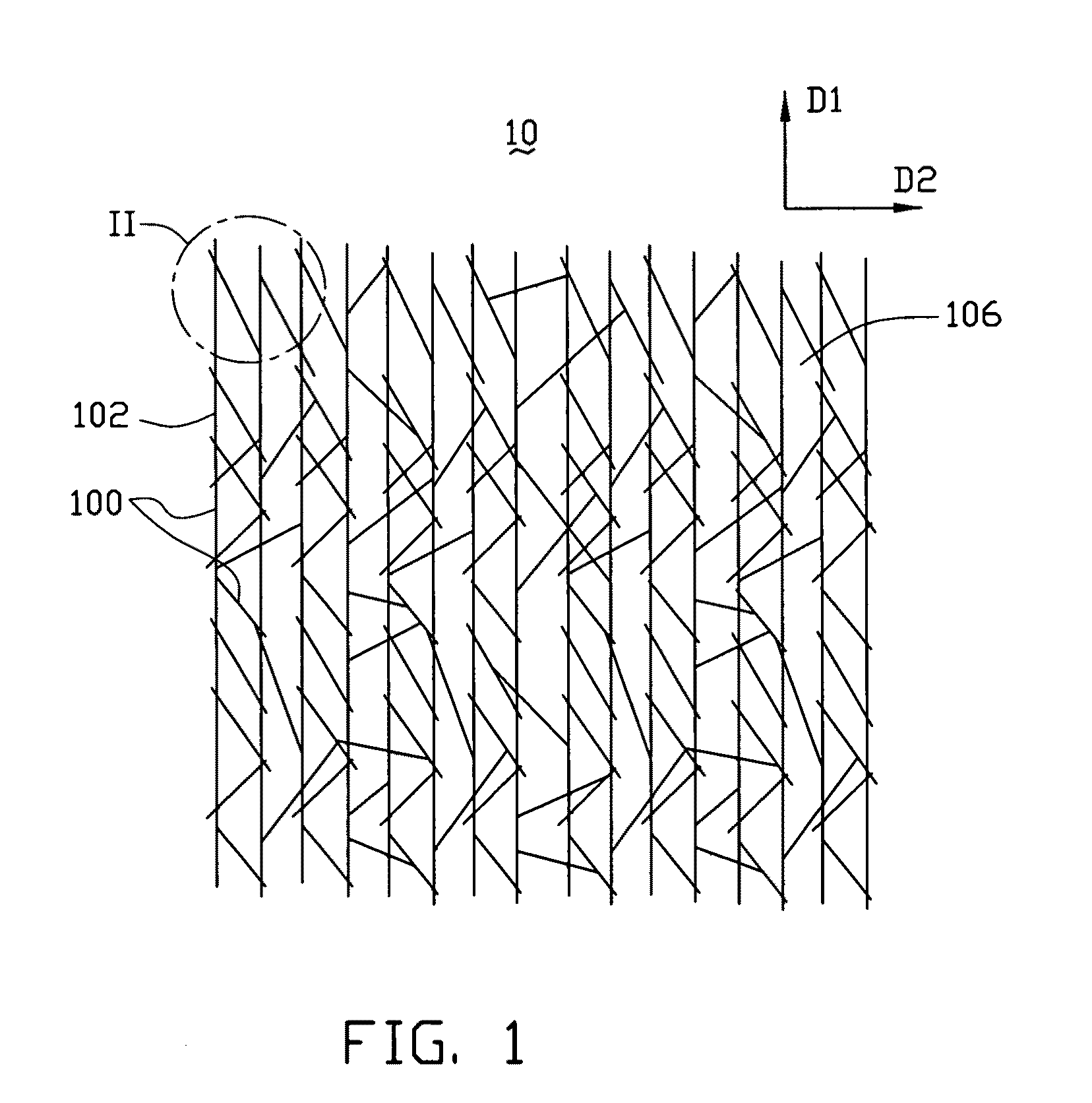

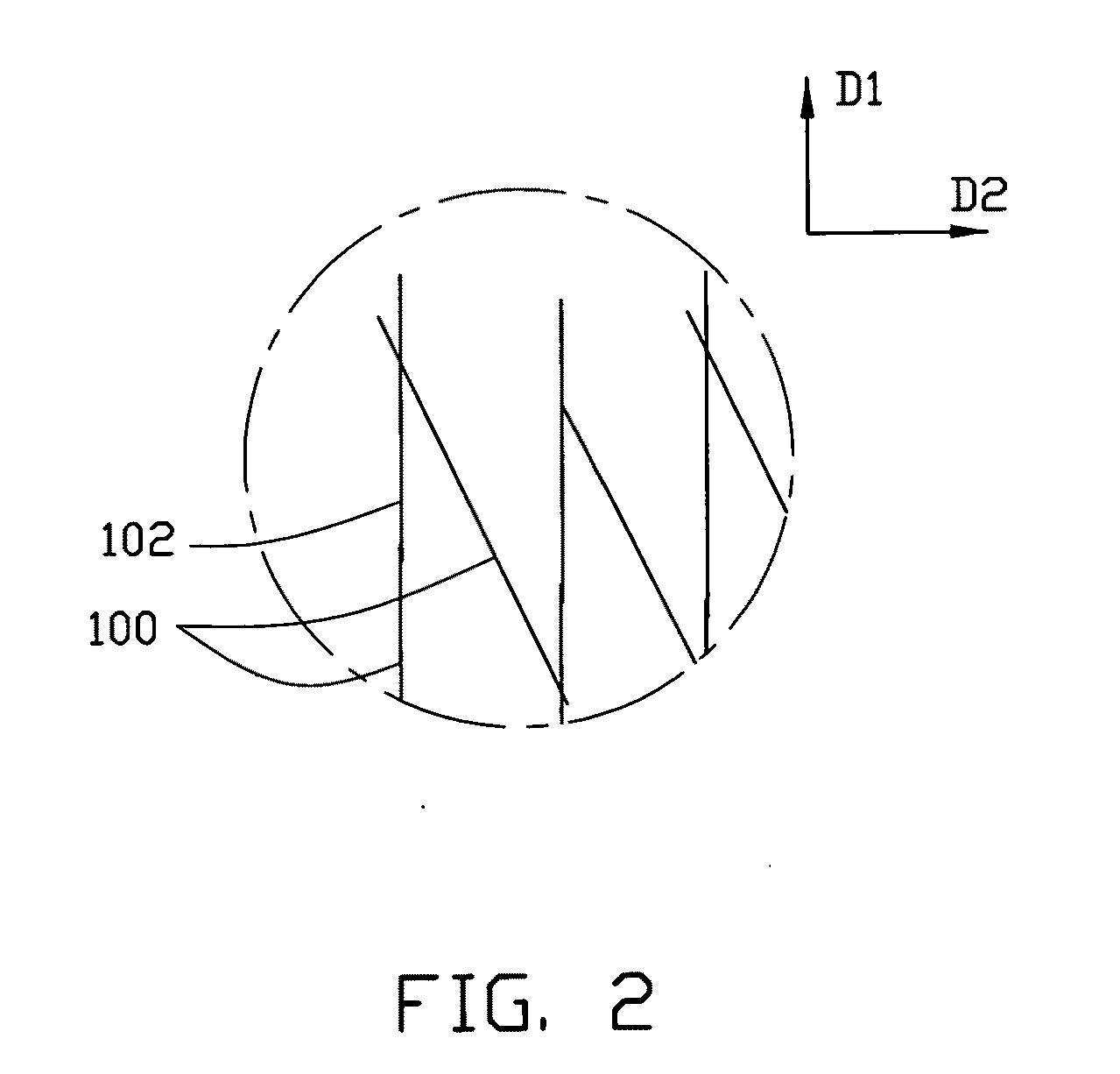

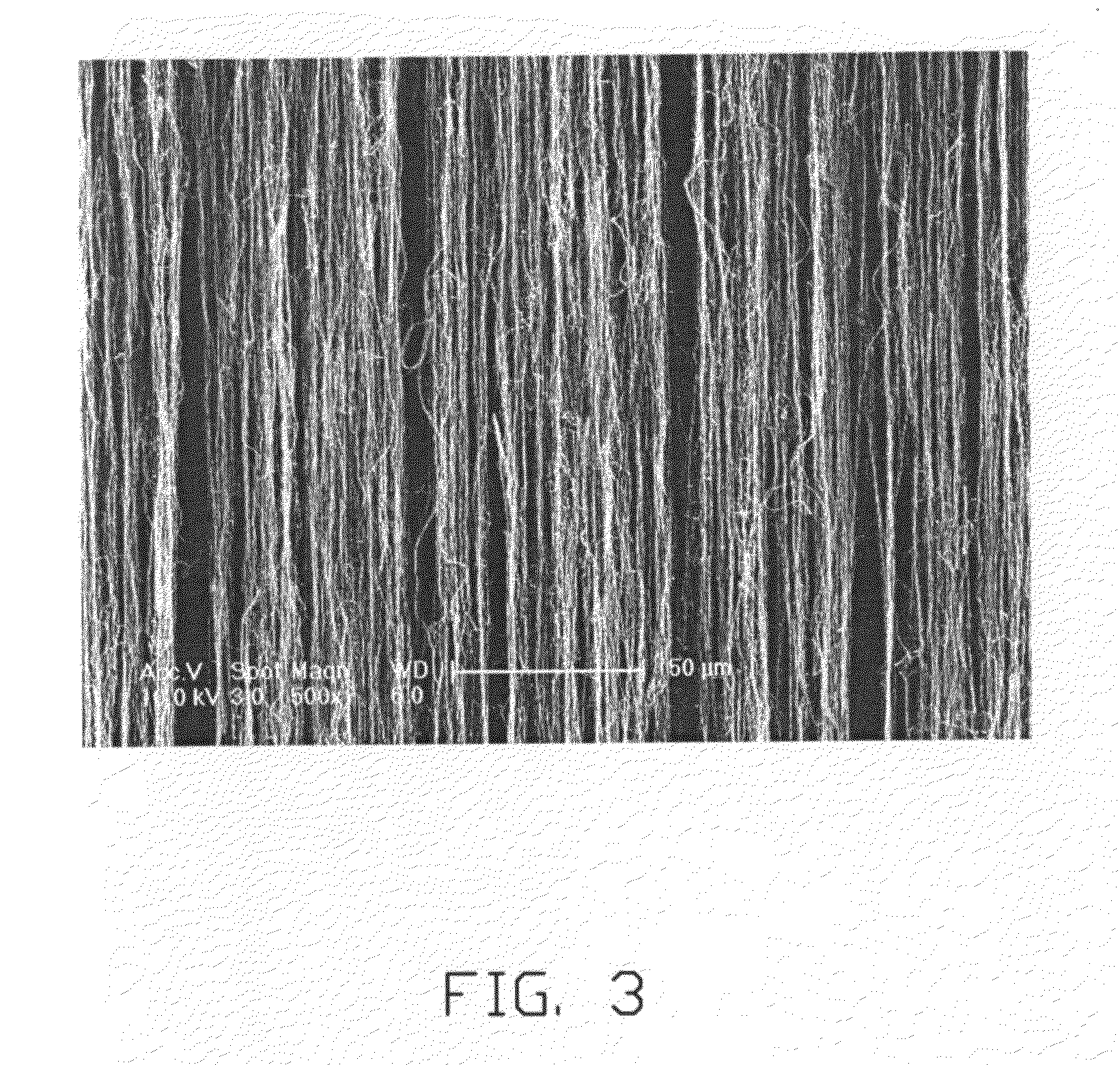

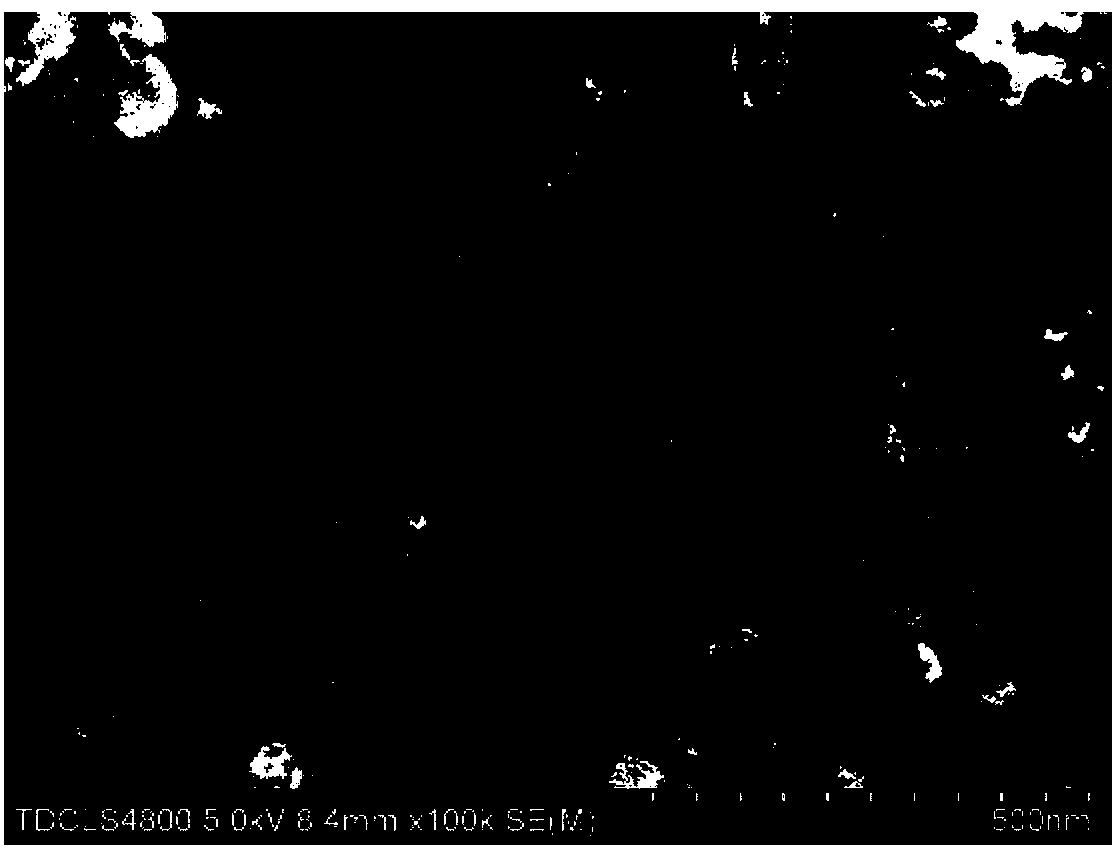

Carbon nanotube film structure and method for fabricating the same

A carbon nanotube film structure includes at least two overlapped carbon nanotube films, with adjoining films being aligned in different directions. Each carbon nanotube film includes a plurality of successive carbon nanotube bundles aligned in the same direction. The carbon nanotube structure further includes a plurality of micropores formed by / between the adjoining carbon nanotube bundles. A method for fabricating the carbon nanotube film structure includes the steps of: (a) providing an array of carbon nanotubes; (b) pulling out, using a tool, one carbon nanotube film from the array of carbon nanotubes; (c) providing a frame and adhering the carbon nanotube film to the frame; (d) repeating steps (b) and (c), depositing each successive film on a preceding film, thereby achieving at least a two-layer carbon nanotube film; and (e) peeling the carbon nanotube film off the frame to achieve the carbon nanotube structure.

Owner:TSINGHUA UNIV +1

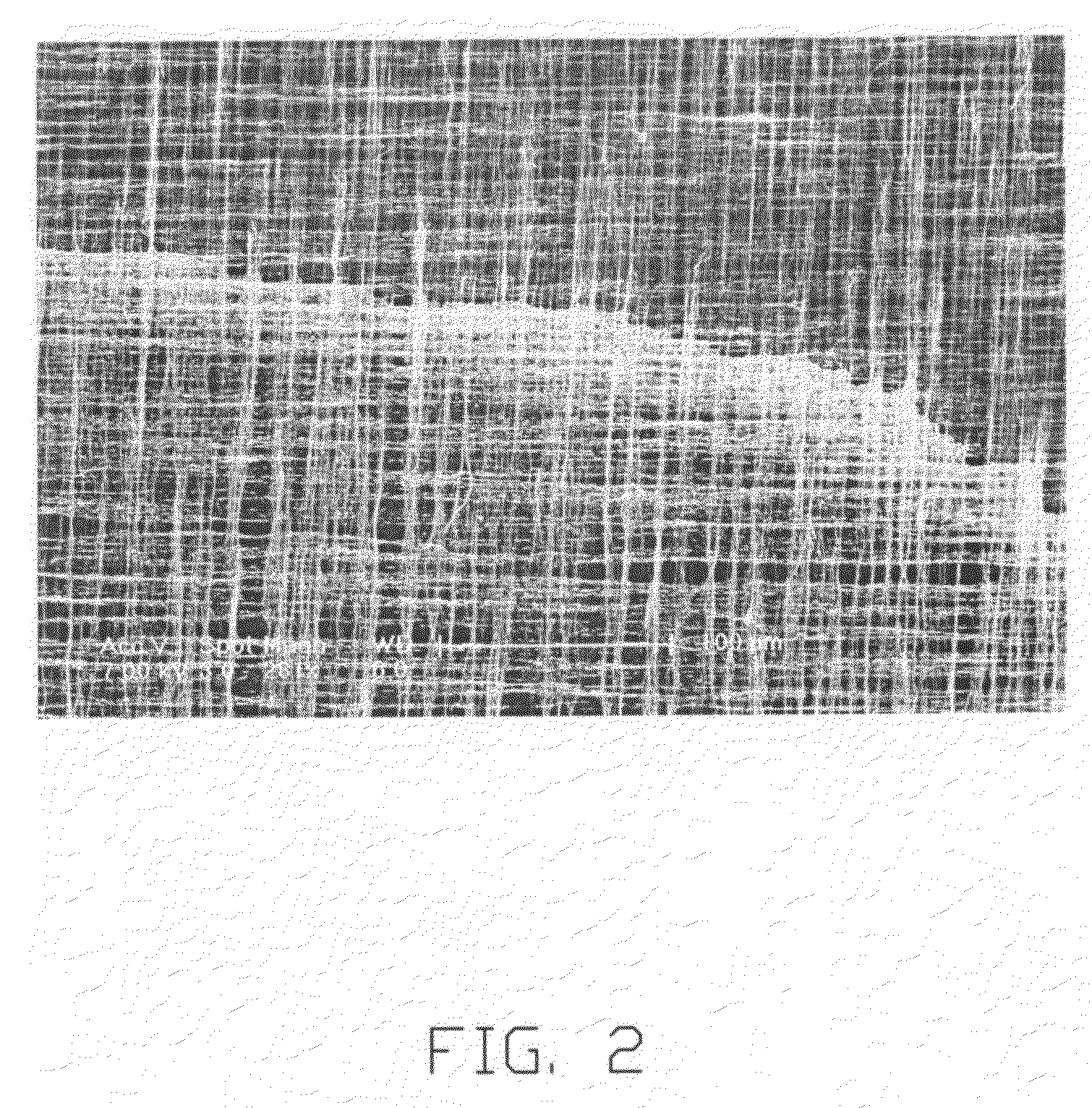

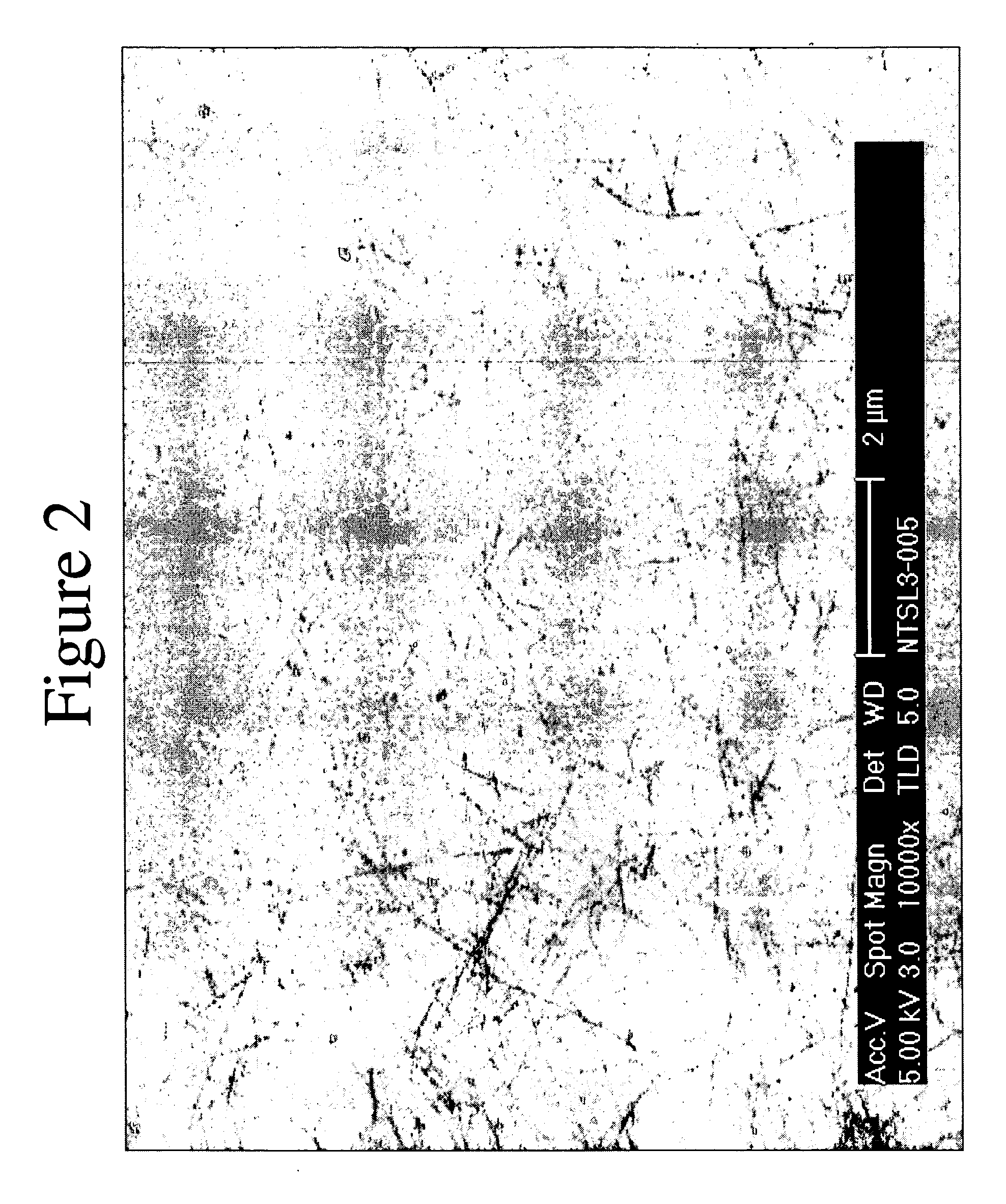

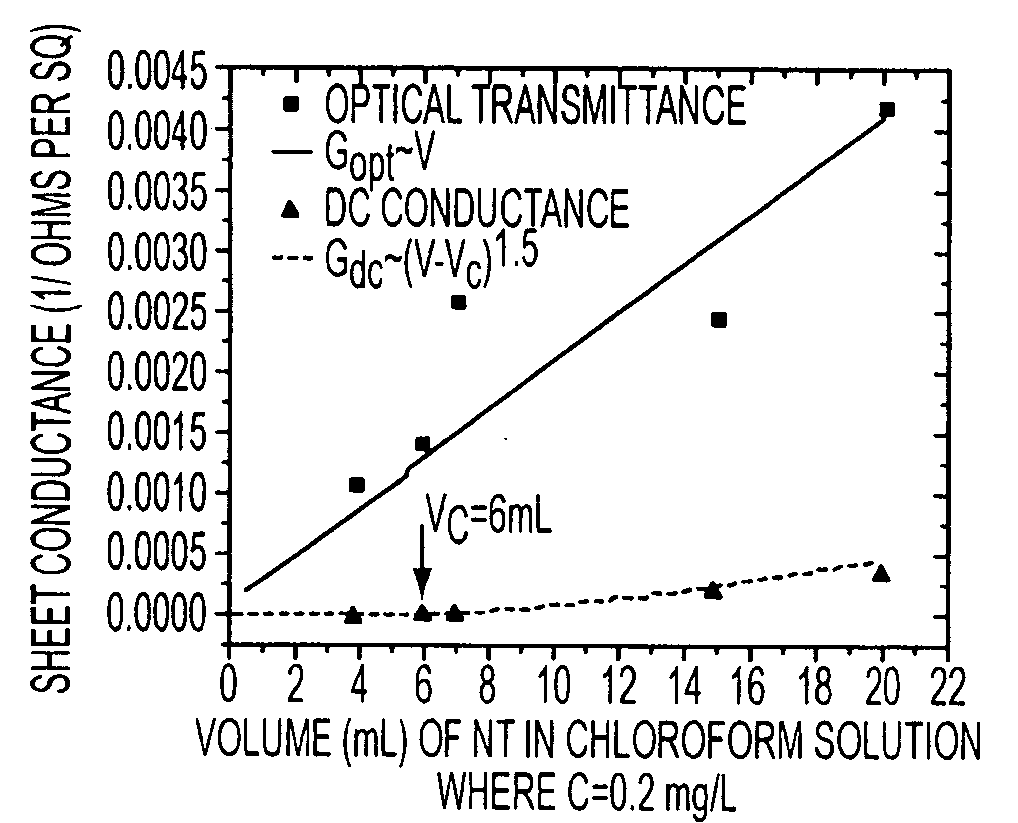

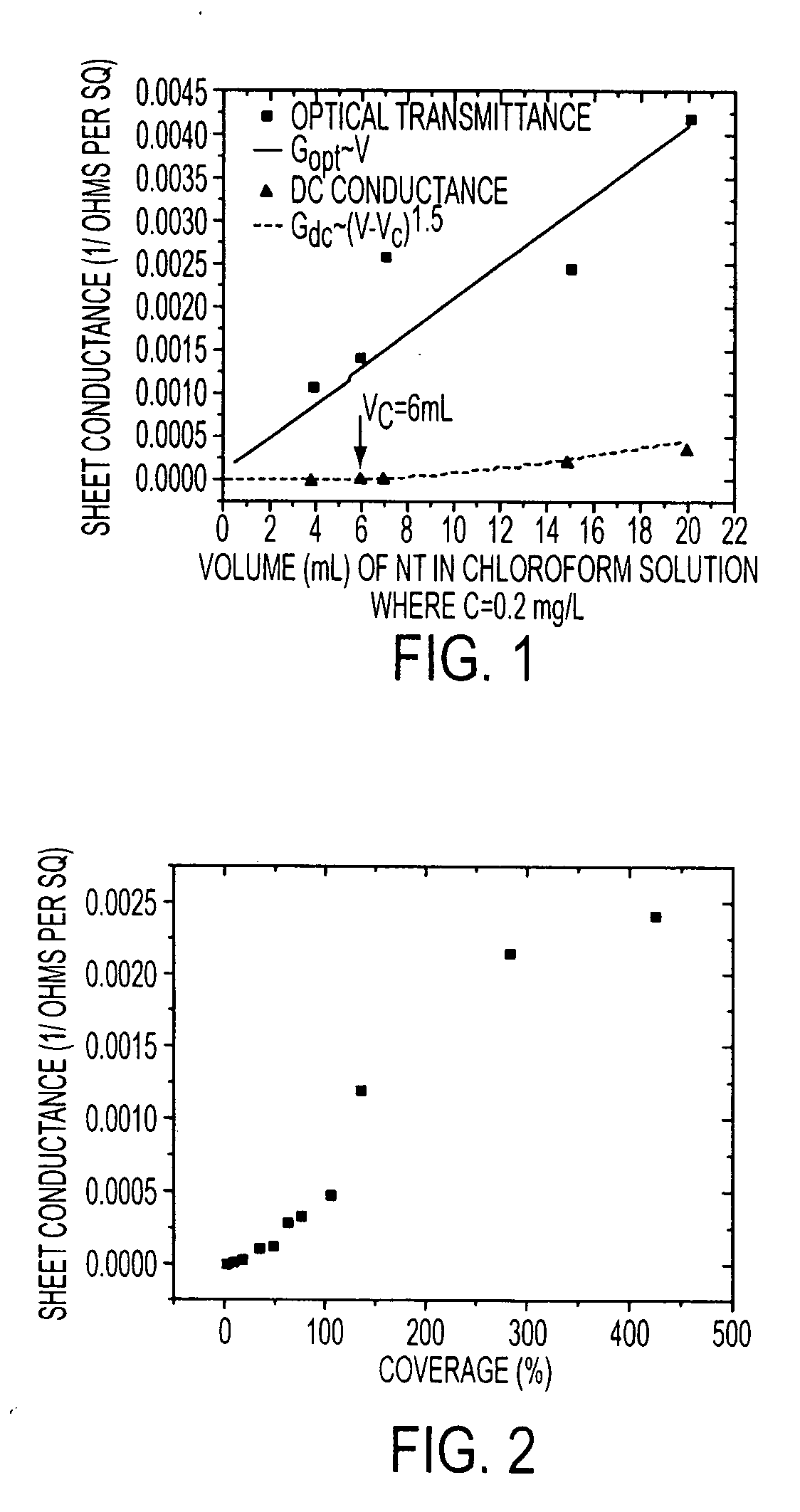

Method of producing devices having nanostructured thin-film networks

InactiveUS20070120095A1Improve conductivityCell electrodesFinal product manufactureFiltrationCarbon nanotube

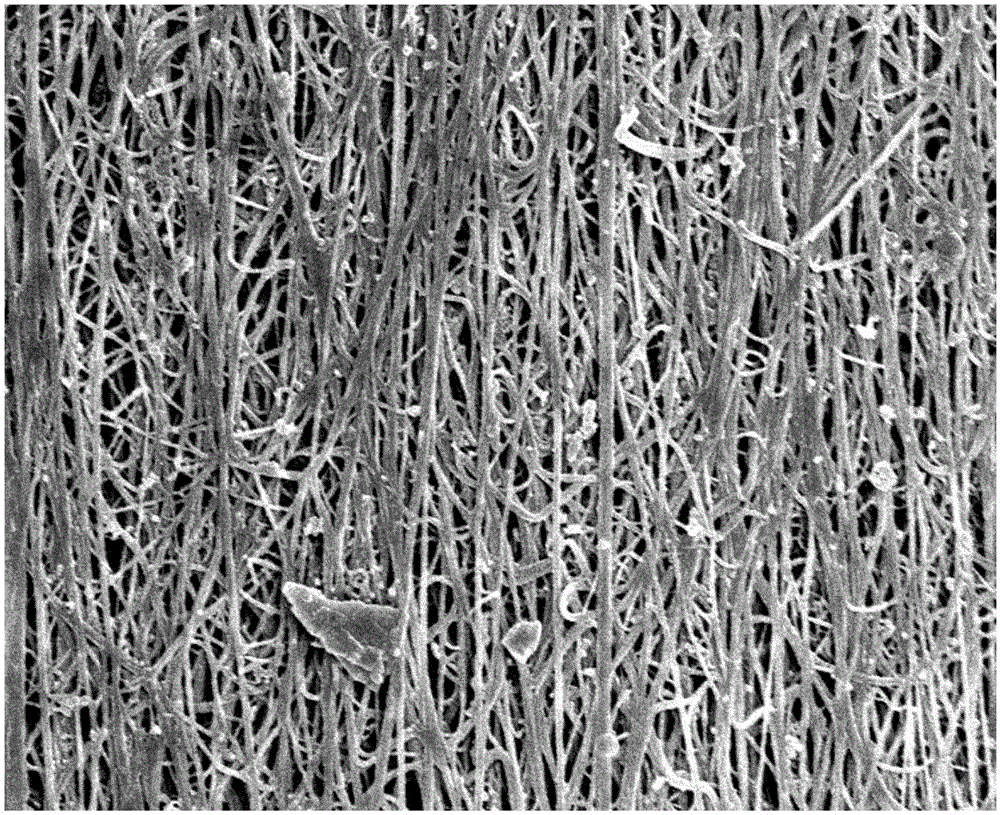

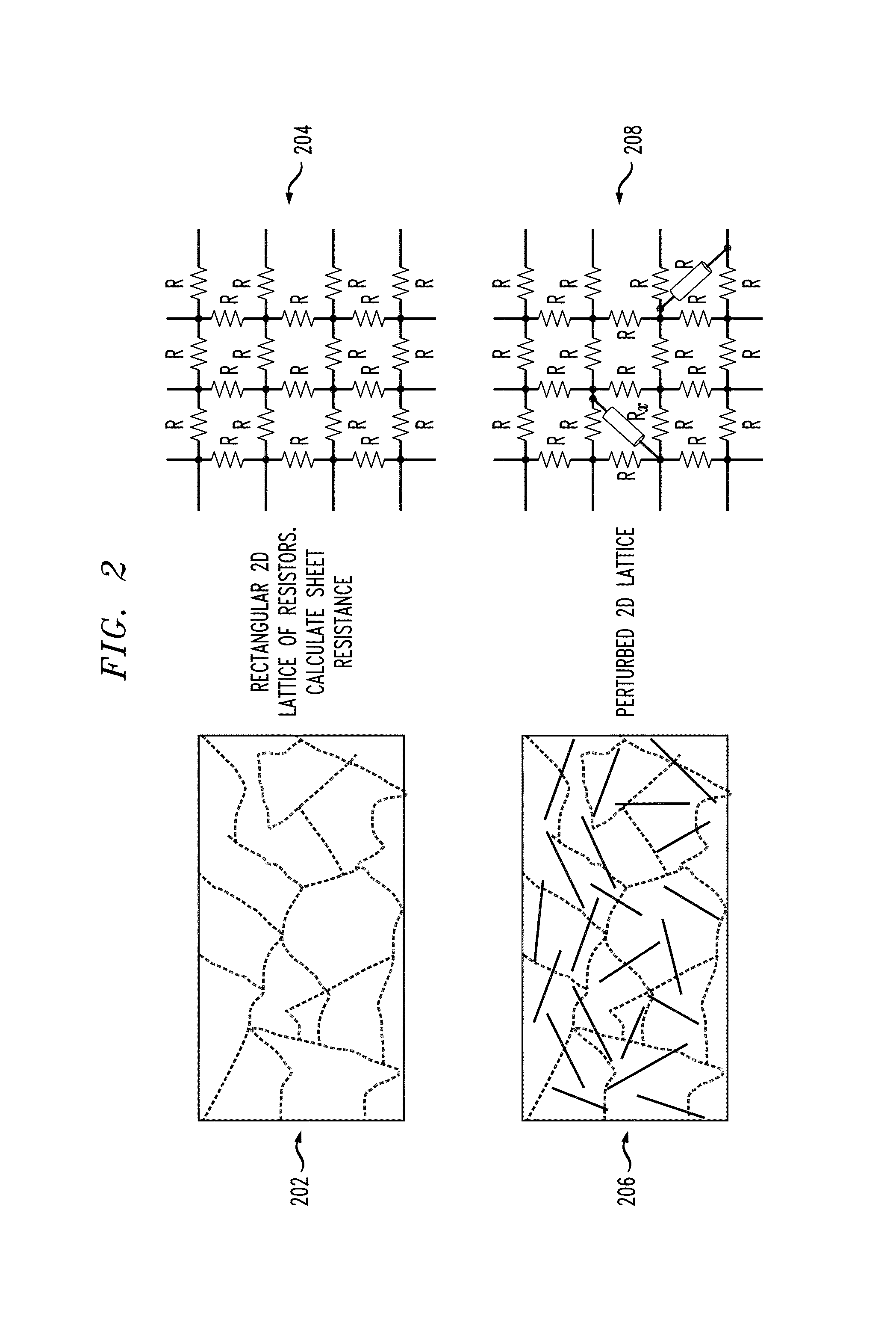

An electrode for an electro-optic device according to an embodiment of this invention has a network of carbon nanotubes. The electrode has an electrical conductivity of at least 600 S / cm and a transmittance for 550 nm light of at least 80%. An average thickness of the network of carbon nanotubes is at least 2 nm. A method of producing a device according to an embodiment of this invention includes forming a film of carbon nanotubes on a filter surface by vacuum filtration, pressing a stamp against at least a portion of the film of carbon nanotubes to cause a portion of the film of carbon nanotubes to adhere to the stamp, and pressing the stamp having the portion of carbon nanotubes adhered thereto against a substructure of the device to cause the network of carbon nanotubes to be transferred to a surface of the substructure upon removal of the stamp.

Owner:RGT UNIV OF CALIFORNIA

Applicator liquid containing ethyl lactate for preparation of nanotube films

ActiveUS20050269554A1High puritySuitable for useMaterial nanotechnologyNanoinformaticsEthyl esterNanotube membrane

Certain applicator liquids and application techniques are described, which can be used to form nanotube films or fabrics of controlled properties. An applicator liquid for preparation of a nanotube film or fabric includes a controlled concentration of nanotubes dispersed in ethyl lactate. The controlled concentration is sufficient to form a nanotube fabric or film of preselected density and uniformity.

Owner:ZEON CORP

Nanostructured thin-film networks

InactiveUS20070153353A1Improve conductivityFinal product manufactureLayered productsFiltrationCarbon nanotube

An electrode for an electro-optic device according to an embodiment of this invention has a network of carbon nanotubes. The electrode has an electrical conductivity of at least 600 S / cm and a transmittance for 550 nm light of at least 80%. An average thickness of the network of carbon nanotubes is at least 2 nm. A method of producing a device according to an embodiment of this invention includes forming a film of carbon nanotubes on a filter surface by vacuum filtration, pressing a stamp against at least a portion of the film of carbon nanotubes to cause a portion of the film of carbon nanotubes to adhere to the stamp, and pressing the stamp having the portion of carbon nanotubes adhered thereto against a substructure of the device to cause the network of carbon nanotubes to be transferred to a surface of the substructure upon removal of the stamp.

Owner:RGT UNIV OF CALIFORNIA

Multilayered device having nanostructured networks

InactiveUS20070153363A1Improve conductivityFinal product manufactureCell electrodesFiltrationTransmittance

An electrode for an electro-optic device according to an embodiment of this invention has a network of carbon nanotubes. The electrode has an electrical conductivity of at least 600 S / cm and a transmittance for 550 nm light of at least 80%. An average thickness of the network of carbon nanotubes is at least 2 nm. A method of producing a device according to an embodiment of this invention includes forming a film of carbon nanotubes on a filter surface by vacuum filtration, pressing a stamp against at least a portion of the film of carbon nanotubes to cause a portion of the film of carbon nanotubes to adhere to the stamp, and pressing the stamp having the portion of carbon nanotubes adhered thereto against a substructure of the device to cause the network of carbon nanotubes to be transferred to a surface of the substructure upon removal of the stamp.

Owner:RGT UNIV OF CALIFORNIA

Fabric having nanostructured thin-film networks

InactiveUS20070153362A1Improve conductivityCell electrodesFinal product manufactureFiltrationTransmittance

An electrode for an electro-optic device according to an embodiment of this invention has a network of carbon nanotubes. The electrode has an electrical conductivity of at least 600 S / cm and a transmittance for 550 nm light of at least 80%. An average thickness of the network of carbon nanotubes is at least 2 nm. A method of producing a device according to an embodiment of this invention includes forming a film of carbon nanotubes on a filter surface by vacuum filtration, pressing a stamp against at least a portion of the film of carbon nanotubes to cause a portion of the film of carbon nanotubes to adhere to the stamp, and pressing the stamp having the portion of carbon nanotubes adhered thereto against a substructure of the device to cause the network of carbon nanotubes to be transferred to a surface of the substructure upon removal of the stamp.

Owner:RGT UNIV OF CALIFORNIA

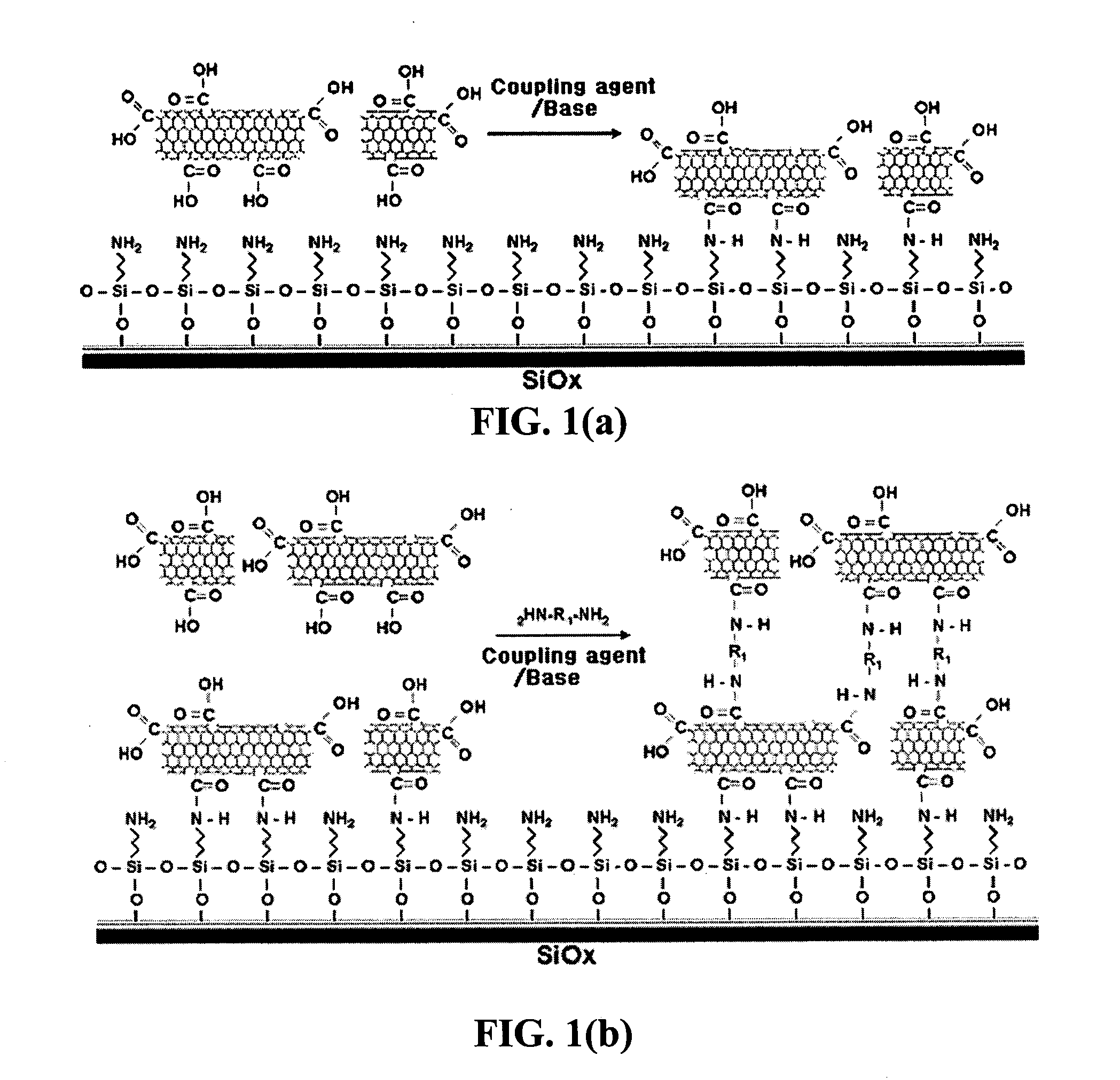

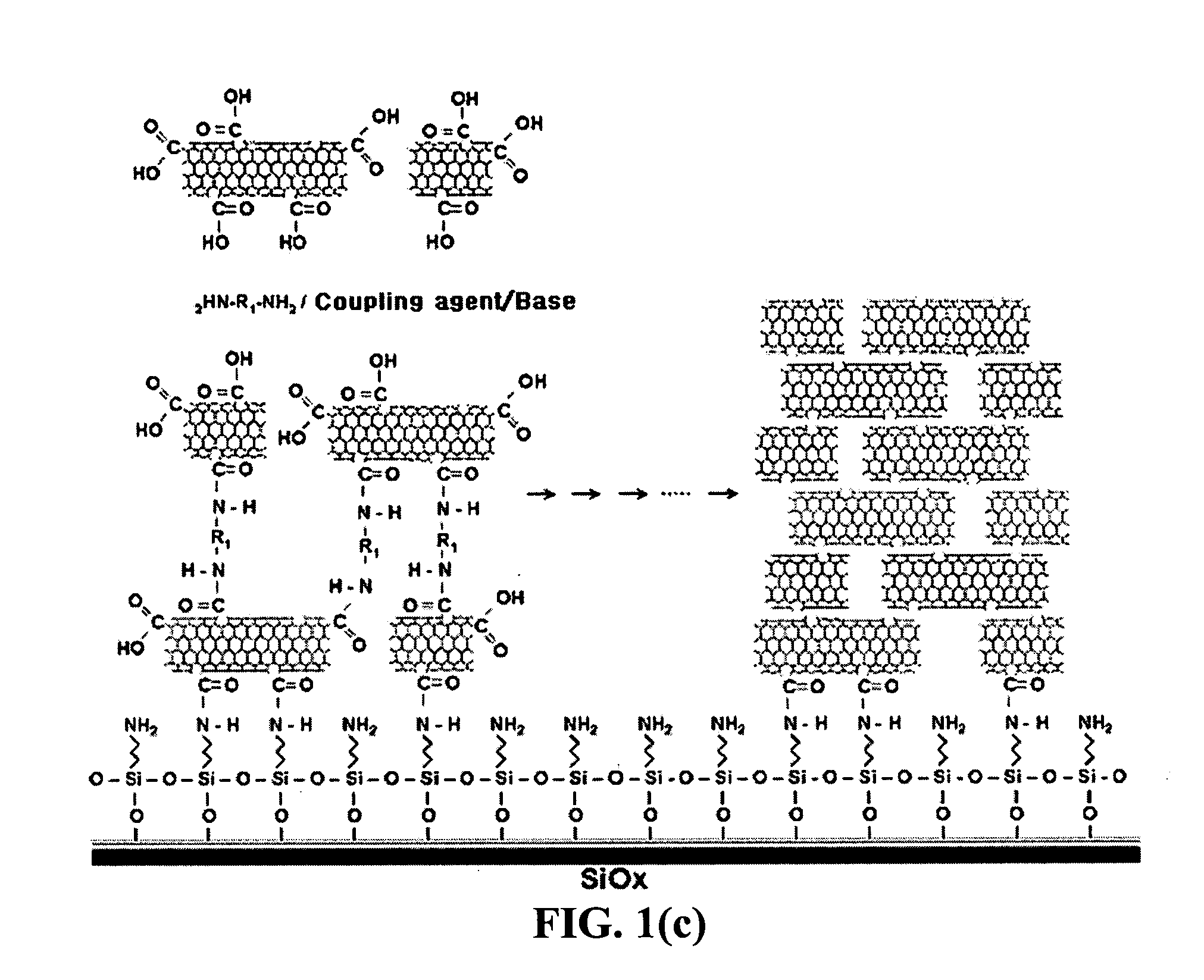

Method for fabricating a biochip using the high density carbon nanotube film or pattern

InactiveUS20050019791A1Improve defectsUtility and advantageBioreactor/fermenter combinationsMaterial nanotechnologyElectrical conductorFluorescence

The present invention relates to a CNT-biochip comprising a bio-receptor which is attached by means of an exposed chemical functional group on a surface of a high density CNT film or pattern which is produced by laminating repeatedly carbon nanotubes (CNT) by chemical bond on the substrate modified with amine groups, and a method for fabricating the same. According to the present invention, it is possible to fabricate various types of CNT-biochips by chemical or physicochemical bonding of various bio-receptors to a CNT pattern (or film) containing exposed carboxyl groups or a CNT pattern (or film) modified by various chemical functional groups. Also, it is possible to fabricate a CNT-biochip comprising bio-receptors attached evenly with high density on a surface of a CNT film where chemical functional groups are abundant and present evenly. Further, the CNT-biochip is applicable to next generation biochips which measure an electrical or electrochemical signal using both conductor and semiconductor properties of the CNT, thereby not needing labeling. Particularly, upon fluorescent measurement of DNA hybridization using the CNT-DNA chip according to the present invention, it is possible to show more distinct signals, thereby producing excellent results. The CNT-DNA chip is useful for genotyping, mutation detection, pathogen identification and the like.

Owner:KOREA ADVANCED INST OF SCI & TECH

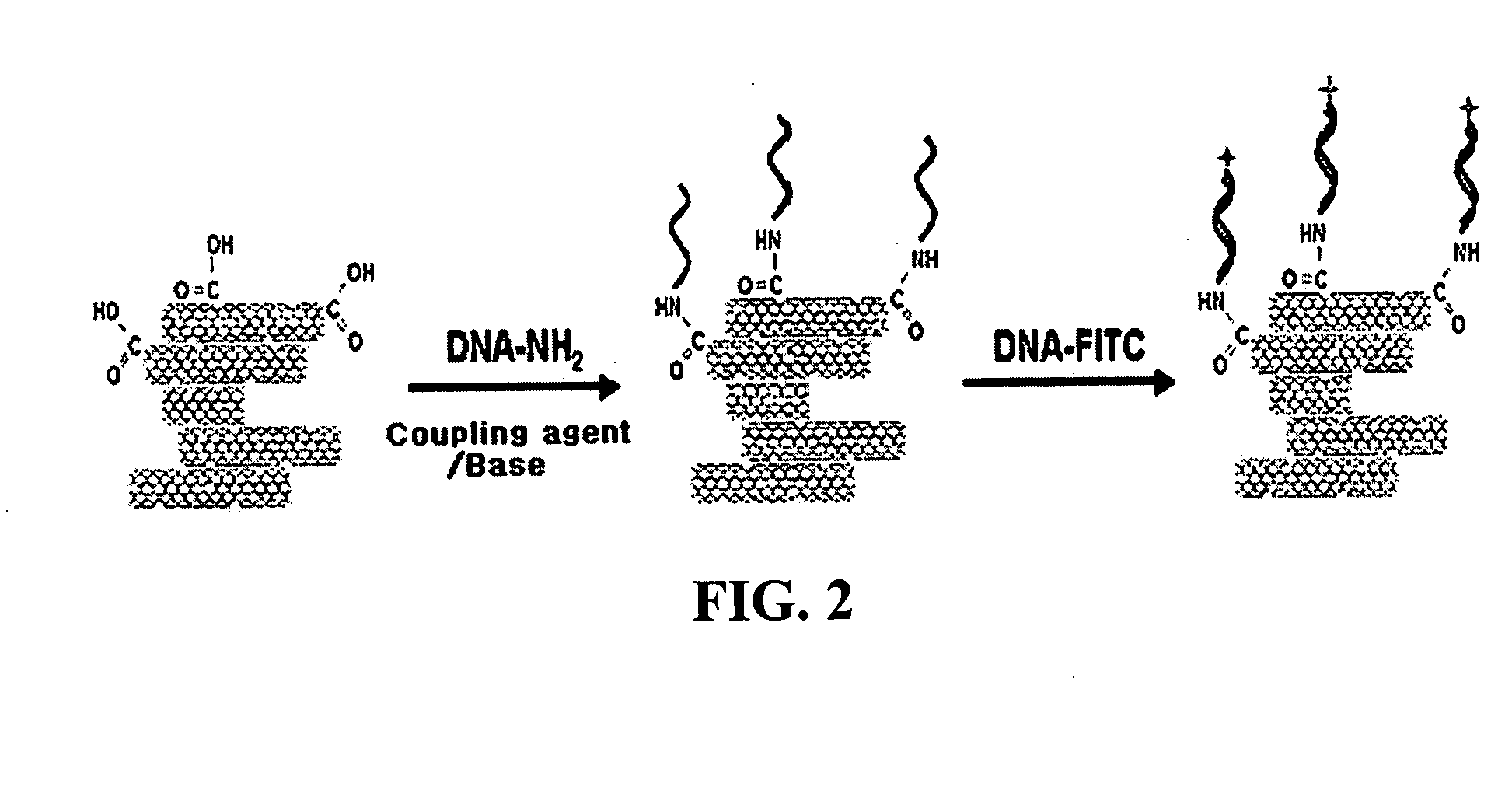

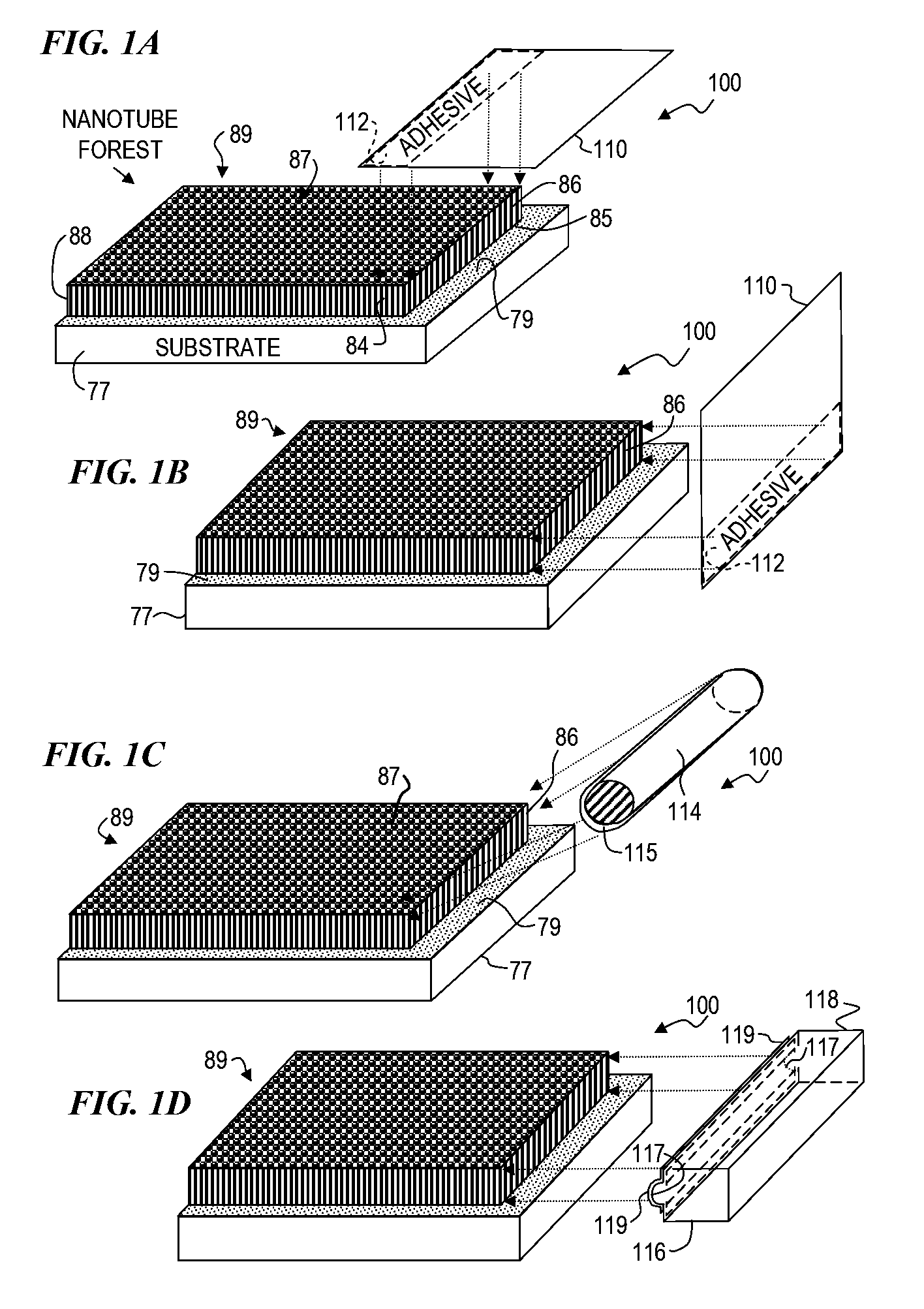

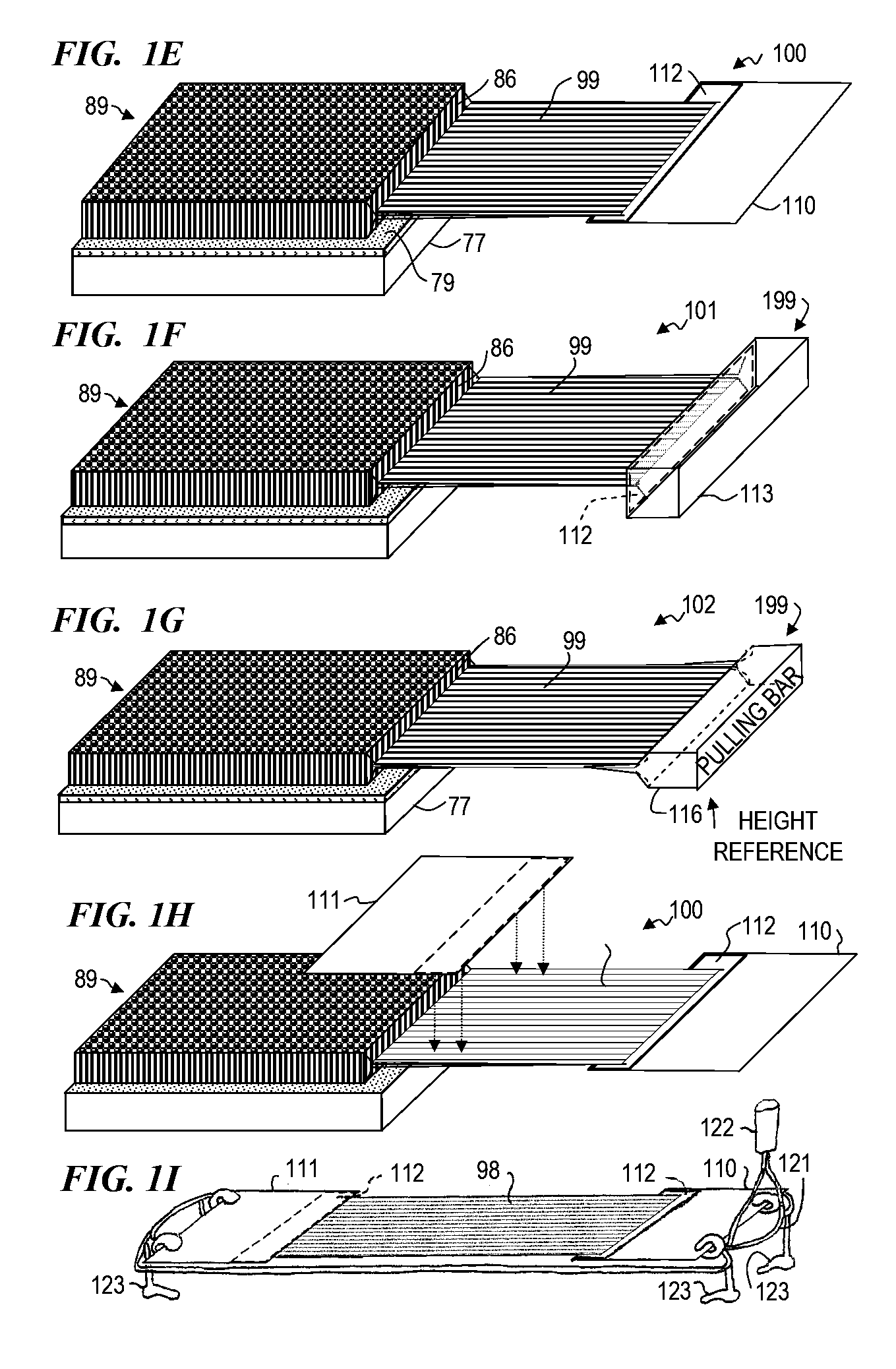

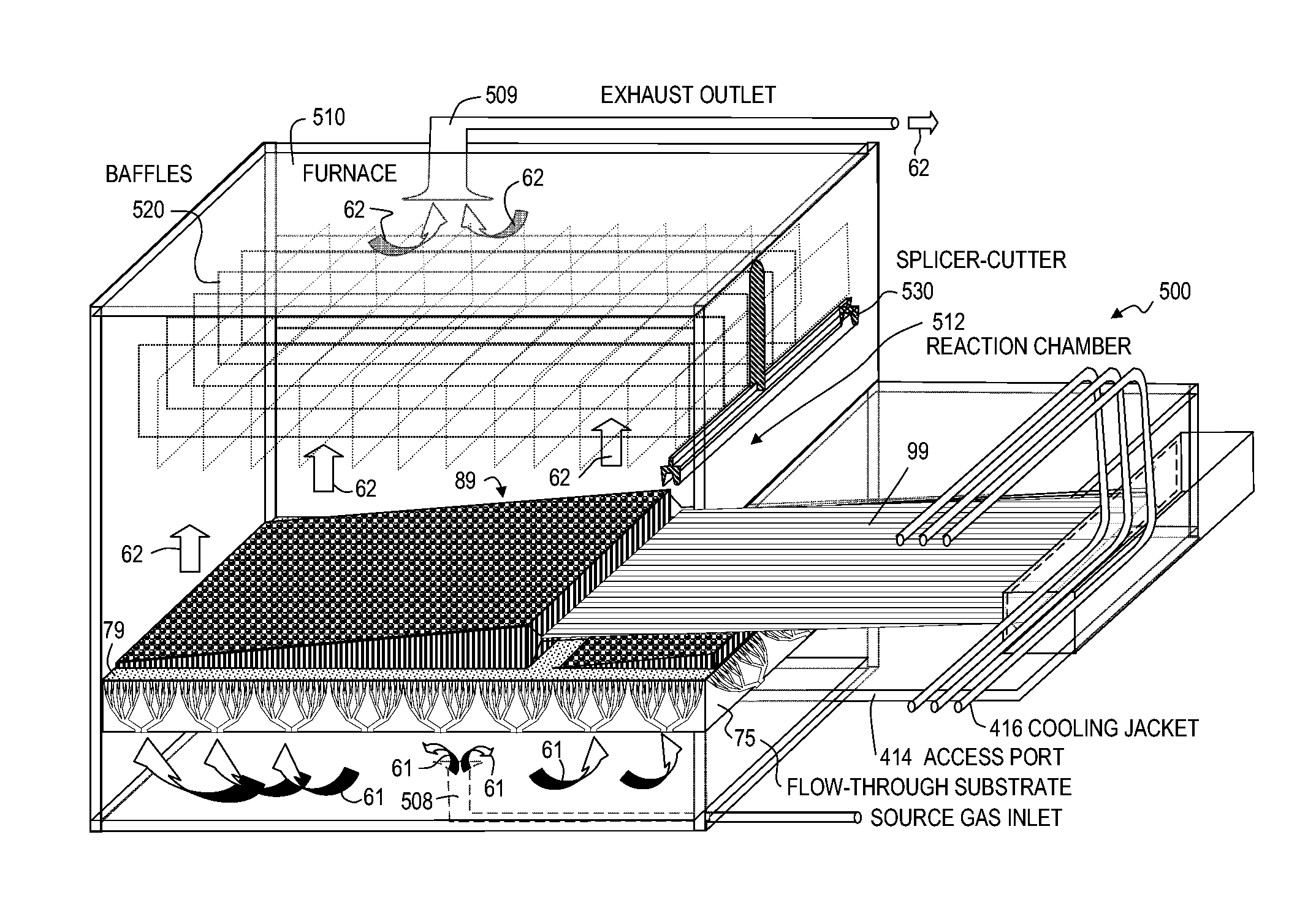

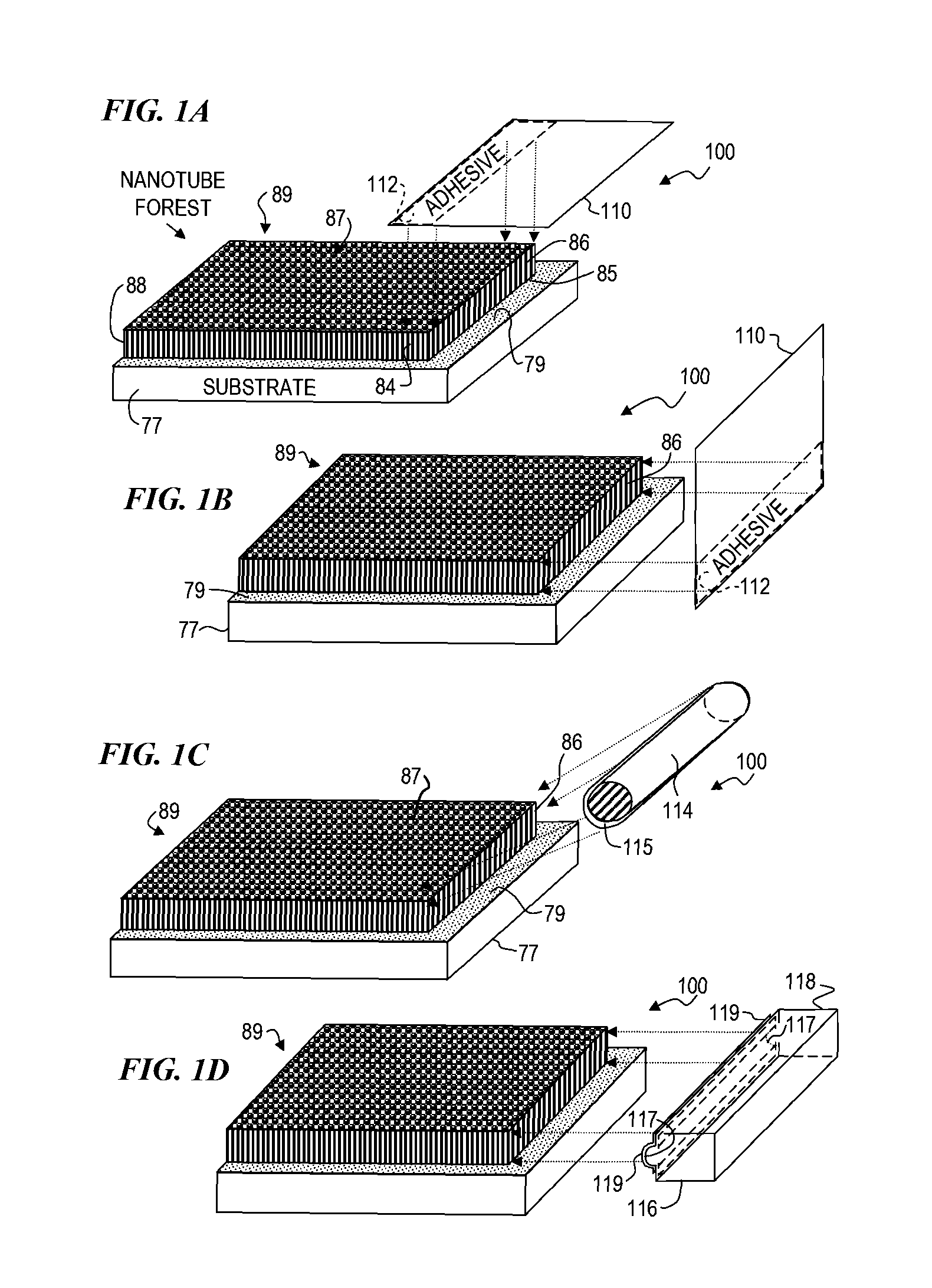

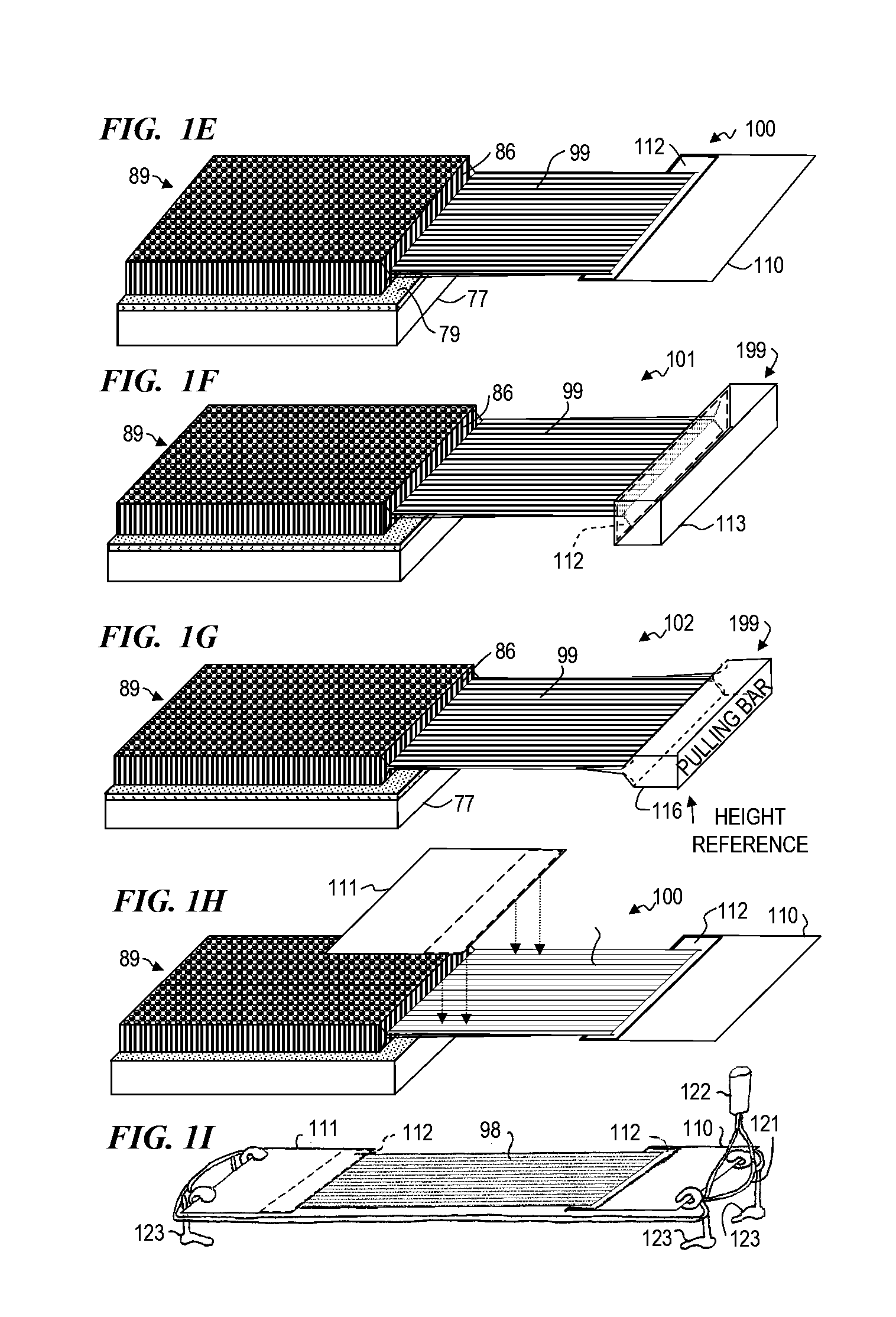

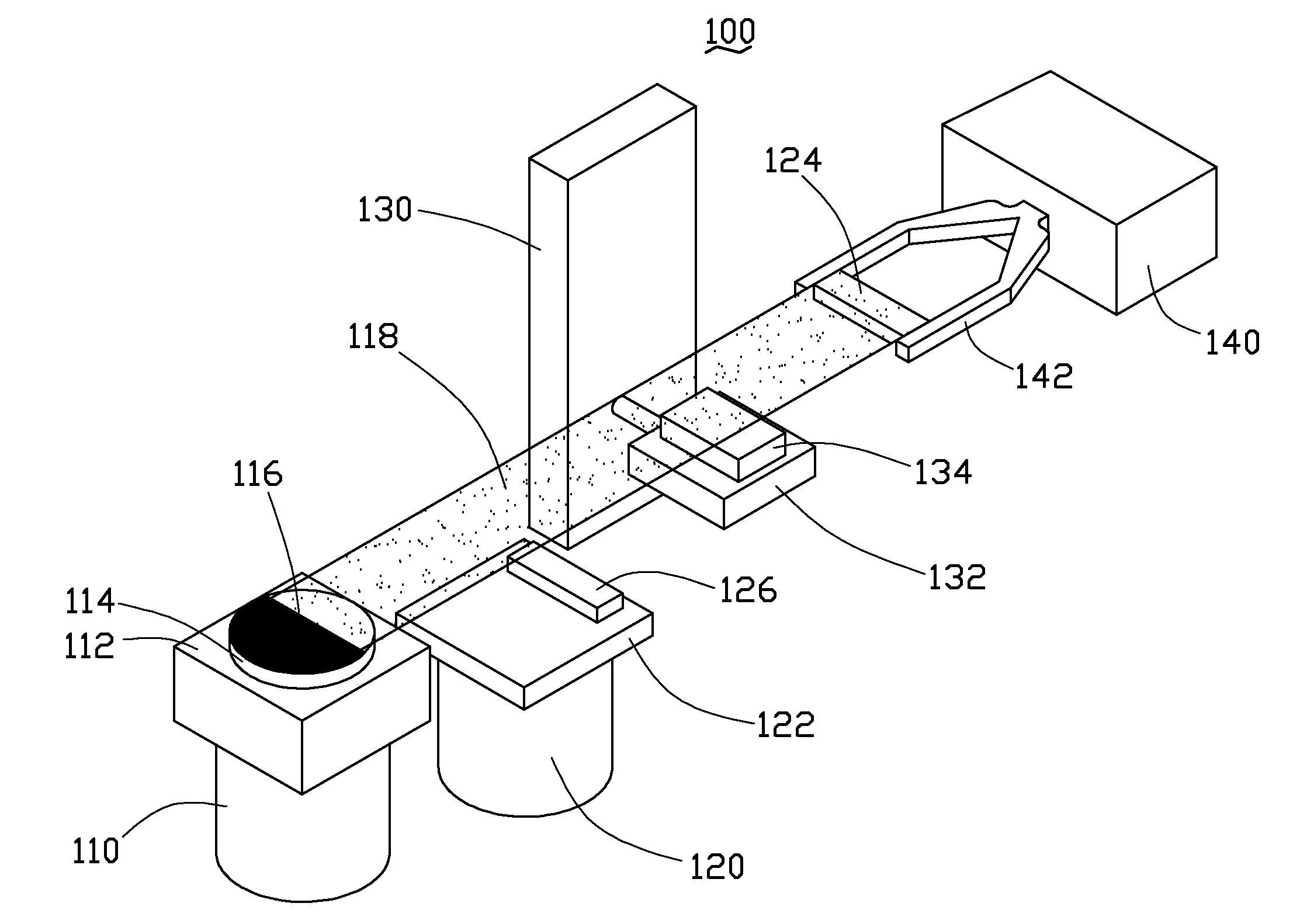

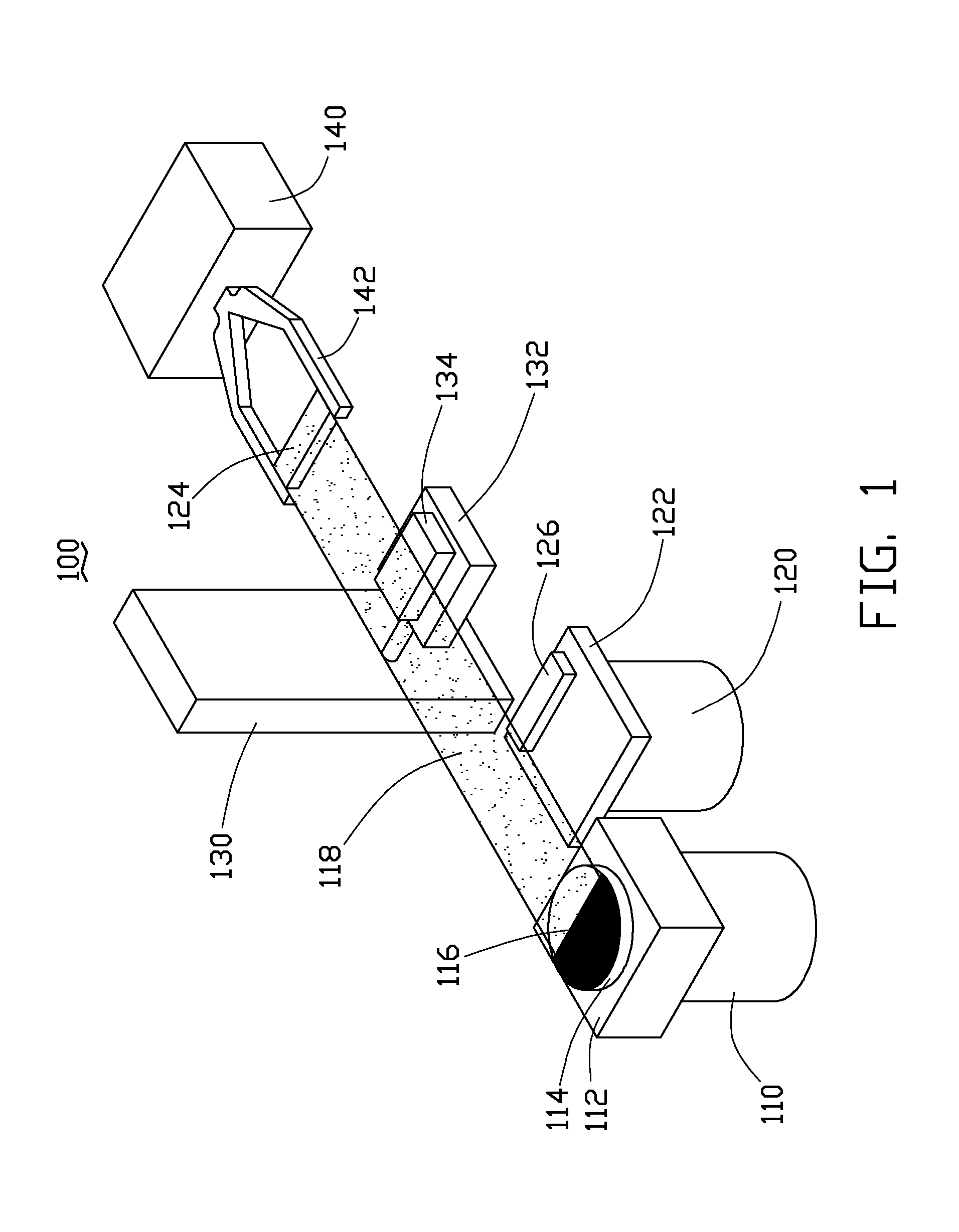

Apparatus and method for growing fullerene nanotube forests, and forming nanotube films, threads and composite structures therefrom

The present invention provides apparatus and methods for growing fullerene nanotube forests, and forming nanotube films, threads and composite structures therefrom. In some embodiments, an interior-flow substrate includes a porous surface and one or more interior passages that provide reactant gas to an interior portion of a densely packed nanotube forest as it is growing. In some embodiments, a continuous-growth furnace is provided that includes an access port for removing nanotube forests without cooling the furnace substantially. In other embodiments, a nanotube film can be pulled from the nanotube forest without removing the forest from the furnace. A nanotube film loom is described. An apparatus for building layers of nanotube films on a continuous web is described.

Owner:GRANDNANO

Apparatus and method for growing fullerene nanotube forests, and forming nanotube films, threads and composite structures therefrom

The present invention provides apparatus and methods for growing fullerene nanotube forests, and forming nanotube films, threads and composite structures therefrom. In some embodiments, an interior-flow substrate includes a porous surface and one or more interior passages that provide reactant gas to an interior portion of a densely packed nanotube forest as it is growing. In some embodiments, a continuous-growth furnace is provided that includes an access port for removing nanotube forests without cooling the furnace substantially. In other embodiments, a nanotube film can be pulled from the nanotube forest without removing the forest from the furnace. A nanotube film loom is described. An apparatus for building layers of nanotube films on a continuous web is described.

Owner:GRANDNANO

Asymmetric nanotube containing membranes

ActiveUS20110186506A1Increase the diameterImprove skinMaterial nanotechnologySemi-permeable membranesCrystallographyUltrafiltration

This invention relates to heterogenous pore polymer nanotube membranes useful in filtration, such as reverse osmosis desalination, nanofiltration, ultrafiltration and gas separation.

Owner:NAGARE MEMBRANES

Carbon nanotube film and composite film based on same

The invention relates to a carbon nanotube film. The carbon nanotube film comprises a plurality of carbon nanotubes which are basically parallel with one another and are arranged basically parallel to the surface of the carbon nanotube film, wherein the carbon nanotube film has resistance anisotropy, and the sheet resistance of the carbon nanotube film is of megohm level in the direction vertical to the carbon nanotube arrangement. The invention also provides a carbon nanotube composite film, which comprises a polymer substrate and the carbon nanotube film in the polymer substrate, wherein the carbon nanotube film comprises a plurality of carbon nanotubes which are basically parallel with one another and are arranged basically parallel to the surface of the carbon nanotube film; the carbon nanotube film has resistance anisotropy, and the sheet resistance of the carbon nanotube film is of megohm level in the direction vertical to the carbon nanotube arrangement. The megohm level carbon nanotube film or the carbon nanotube composite film can be applied in the fields of transparent electrodes, thin film transistors, touch screens and the like.

Owner:BEIJING FUNATE INNOVATION TECH

Variable-density carbon nanotube film and method for manufacturing the same

A method for making a variable-density carbon nanotube film is provided. A drawn carbon nanotube film, including a number of carbon nanotubes aligned along an aligned direction, is prepared. A number of thin regions are formed in the drawn carbon nanotube film along the aligned direction by reducing density of carbon nanotubes in each of the plurality of thin regions. A variable-density carbon nanotube film is provided and includes a number of thin regions and at least one normal region having a density of carbon nanotubes greater than that of the thin regions. The at least one normal region includes a number of carbon nanotubes substantially aligned along an aligned direction. The thin regions are arranged in the form of at least one row extending along the aligned direction.

Owner:BEIJING FUNATE INNOVATION TECH

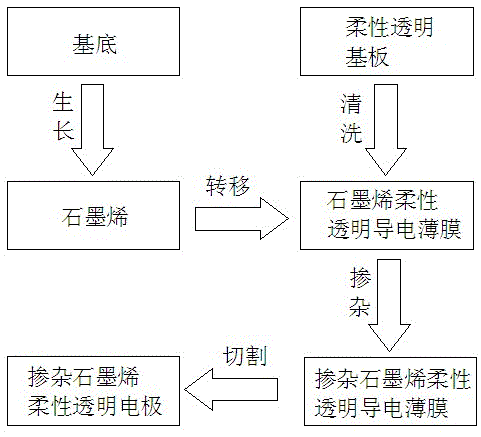

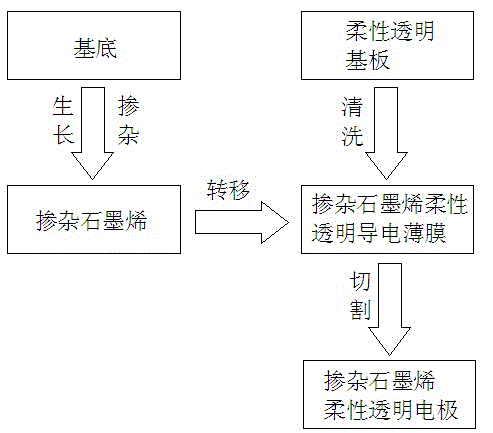

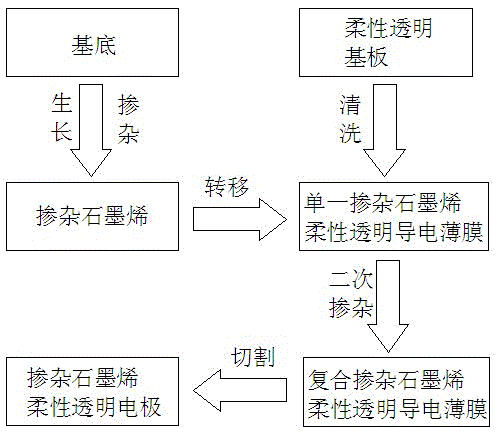

Doped graphene flexible transparent electrode and preparation method thereof

ActiveCN103151101AHigh light transmittanceLower resistanceConductive layers on insulating-supportsMetal/alloy conductorsDoped grapheneCarbon nanotube

The invention discloses a doped graphene flexible transparent electrode and a preparation method thereof. The doped graphene flexible transparent electrode consists of a flexible transparent substrate and doped graphene which is arranged on the flexible transparent substrate and is doped with heterogeneous atoms and molecules. The doping methods of graphene comprise non-substitutional doping, substitutional doping and composite doping. By using the graphene which grows through chemical vapor deposition (CVD) as raw materials, realizing the doping of the heterogeneous atoms and molecules of the graphene by chemical means and using the doped graphene to construct the flexible transparent electrode, the prepared doped graphene flexible transparent electrode has excellent properties of low resistance, high light transmittance and high bendability. The square resistance of the electrode reaches 3-500ohm / sq, the light transmittance reaches 87.4-97.6 percent, and the doped graphene flexible transparent electrode is superior to the existing transparent electrodes which are prepared by using indium tin oxide (ITO), carbon nanotube films and the like.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

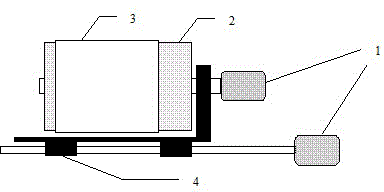

Method for monitoring stress of composite material in all directions based on carbon nanotube film

ActiveCN106643464AQuick responseIncreased sensitivityElectrical/magnetic solid deformation measurementTime changesCarbon nanotube

The invention discloses an integrated stress monitoring method for a carbon nanotube film / composite material, and the method comprises the steps: preparing a carbon nanotube alignment film; cutting the carbon nanotube alignment film into U-shaped toothed sensors according to the demands; carrying out the recombination of the prepared carbon nanotube film stress sensors and resin, and forming a carbon nanotube alignment film prefabricated body through precuring; carrying out the laying of the composite material, enabling the carbon nanotube alignment film prefabricated body to be laid on the upper and lower surfaces of a composite material prepreg, and forming a carbon nanotube film composite material which can be used for stress monitoring; connecting an electrode material, carrying out the online monitoring of stress, applying the stress to the composite material in various types of loading modes, recording the change of a resistance instrument, and calculating the real-time change of the stress. According to the invention, the prepared carbon nanotube film composite material stress sensors can effectively monitor various types of stress on the composite material, are quick in response, are high in sensitivity, and avoid the impact from multidirectional stress caused by the Poisson effect of the sensors. Meanwhile, the piezoresistance characteristics of carbon nanotubes can be played in a better way through traction alignment.

Owner:BEIHANG UNIV

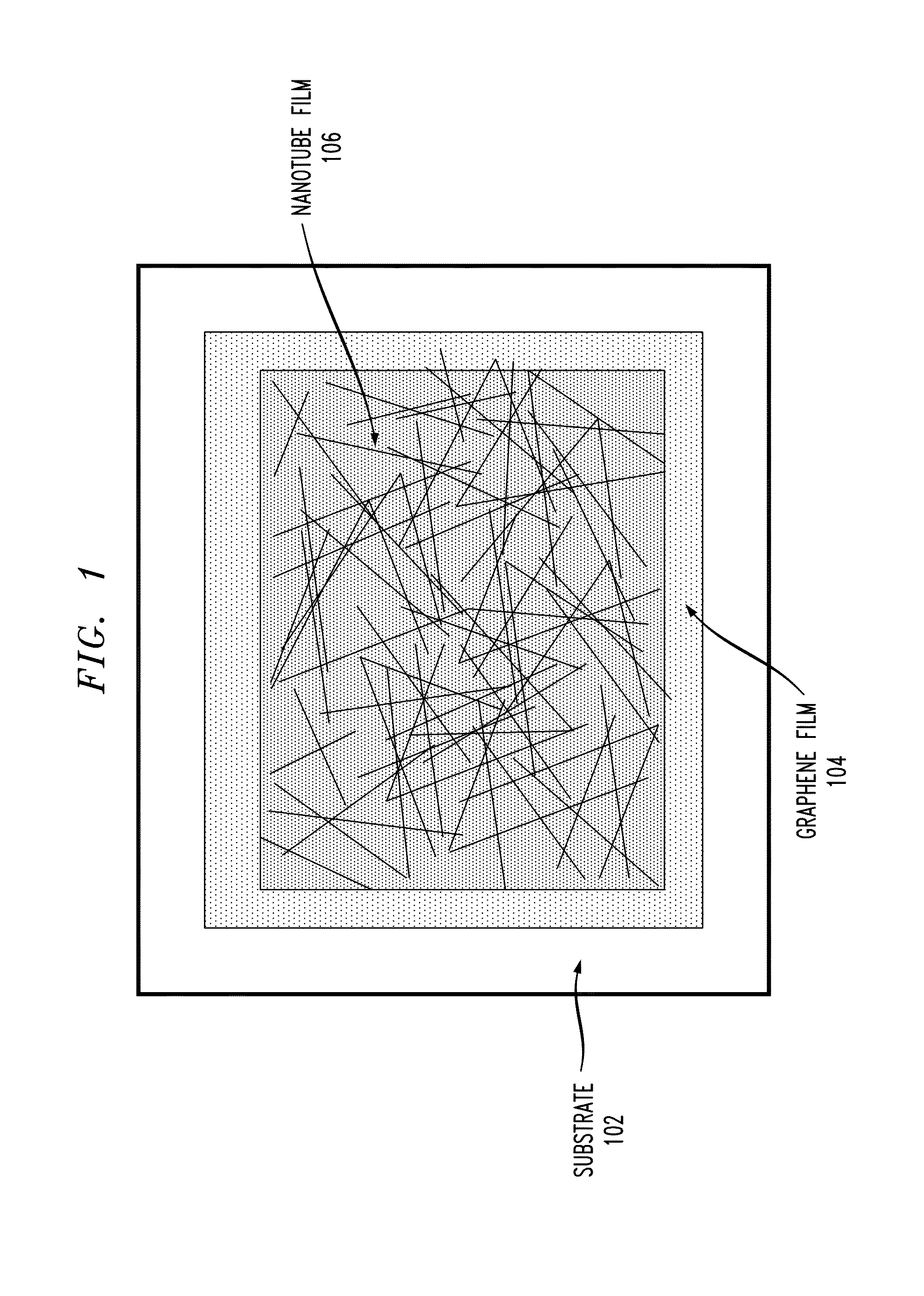

Carbon nanotube-graphene hybrid transparent conductor and field effect transistor

ActiveUS9177688B2Improve electrical performanceDecreasing nanotubeTransistorMaterial nanotechnologyElectrical conductorMetal foil

A nanotube-graphene hybrid film and method for forming a cleaned nanotube-graphene hybrid film. The method includes depositing nanotube film over a substrate to produce a layer of nanotube film, removing impurities from a surface of the layer of nanotube film not contacting the substrate to produce a cleaned layer of nanotube film, depositing a layer of graphene over the cleaned layer of nanotube film to produce a nanotube-graphene hybrid film, and removing impurities from a surface of the nanotube-graphene hybrid film to produce a cleaned nanotube-graphene hybrid film, wherein the hybrid film has improved electrical performance. Another method includes depositing nanotube film over a metal foil to produce a layer of nanotube film, placing the metal foil with as-deposited nanotube film in a chemical vapor deposition furnace to grow graphene on the nanotube film to form a nanotube-graphene hybrid film, and transferring the nanotube-graphene hybrid film over a substrate.

Owner:IBM CORP +1

Method for stretching carbon nanotube film

A method for stretching a carbon nanotube film includes providing one or more carbon nanotube films and one or more elastic supporters, attaching at least one portion of the one or more carbon nanotube films to the one or more elastic supporters, and stretching the elastic supporters.

Owner:TSINGHUA UNIV +1

Self-supporting CNT (Carbon Nano-Tube) film-faradaic pseudocapacitance composite material

InactiveCN103400703ASimple methodEasy to operate and controlHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceComposite film

The invention discloses self-supporting CNT (Carbon Nano-Tube) film-faradaic pseudocapacitance composite material and a preparation method thereof. A CNT film participates in reaction by being used as a self-supporting continuous base body, the wall of a single CNT or the surface of a CNT bundle in a network structure of the CNT film is compounded with material with good faradaic pseudocapacitance performance, and the faradaic pseudocapacitance material comprises MnO2, Ni(OH)2 and PANI. According to the preparation method disclosed by the invention, the process is simple, and the defects of tedious technology and the like of a traditional electrode coating preparation method are overcome; and a prepared composite thin film has the advantages of large mechanical strength and good electrical conductivity, has excellent ductility and flexibility, is flexible electrode material and has a great application prospect in fields of a super capacitor and the like.

Owner:TIANJIN UNIV

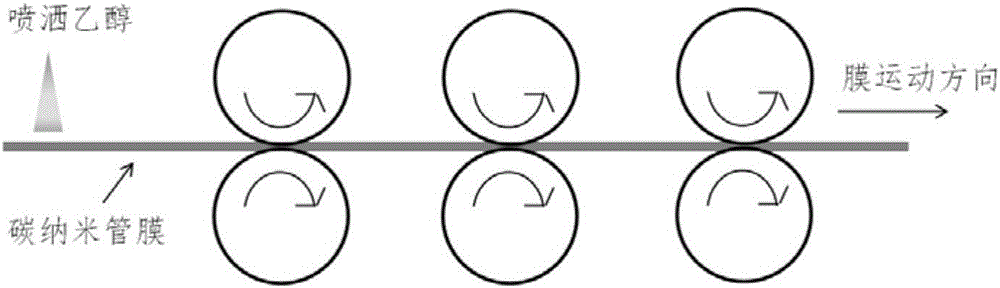

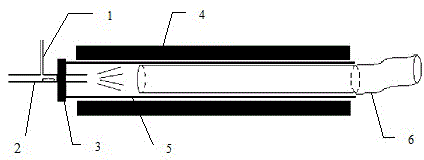

Continuous preparation of carbon nanotube macroscopic body, and film forming method and apparatus

The invention discloses a continuous preparation method for a cylindrical carbon nanotube macroscopic body, and a method and apparatus for preparing a pure carbon nanotube film in an opened atmosphere system based on the macroscopic body, and belongs to the technical field of nanometer materials. The method comprises the following technological steps: dissolving ferrocene and thiophene in a hdydrocarbon composed of carbon and hydrogen elements, or an alcohol, ketone or carboxylic acid compound composed of carbon, hydrogen and oxygen elements, or a mixed solution of the hydrocarbon and the alcohol, ketone or carboxylic acid compound, bringing the above mixed solution into a high-temperature tubular furnace by an inert gas, performing catalytic cracking in the furnace tube, synthesizing the carbon tube and forming the cylindrical carbon nanotube macroscopic body through combination, and continuously blowing out by the furnace tube. A roller for spinning a film is put at the furnace tail, the roller is paved with a substrate film wetted by a solidification liquid, and thus the cylindrical carbon nanotube macroscopic body is orderly wound around the substrate film, and the film is formed through shrinkage. The substrate film is reserved or removed according to needs. The multifunctional carbon nanotube film is prepared in the opened system. Equipment is simple, and industrialized large-scale production can be realized.

Owner:EAST CHINA UNIV OF SCI & TECH

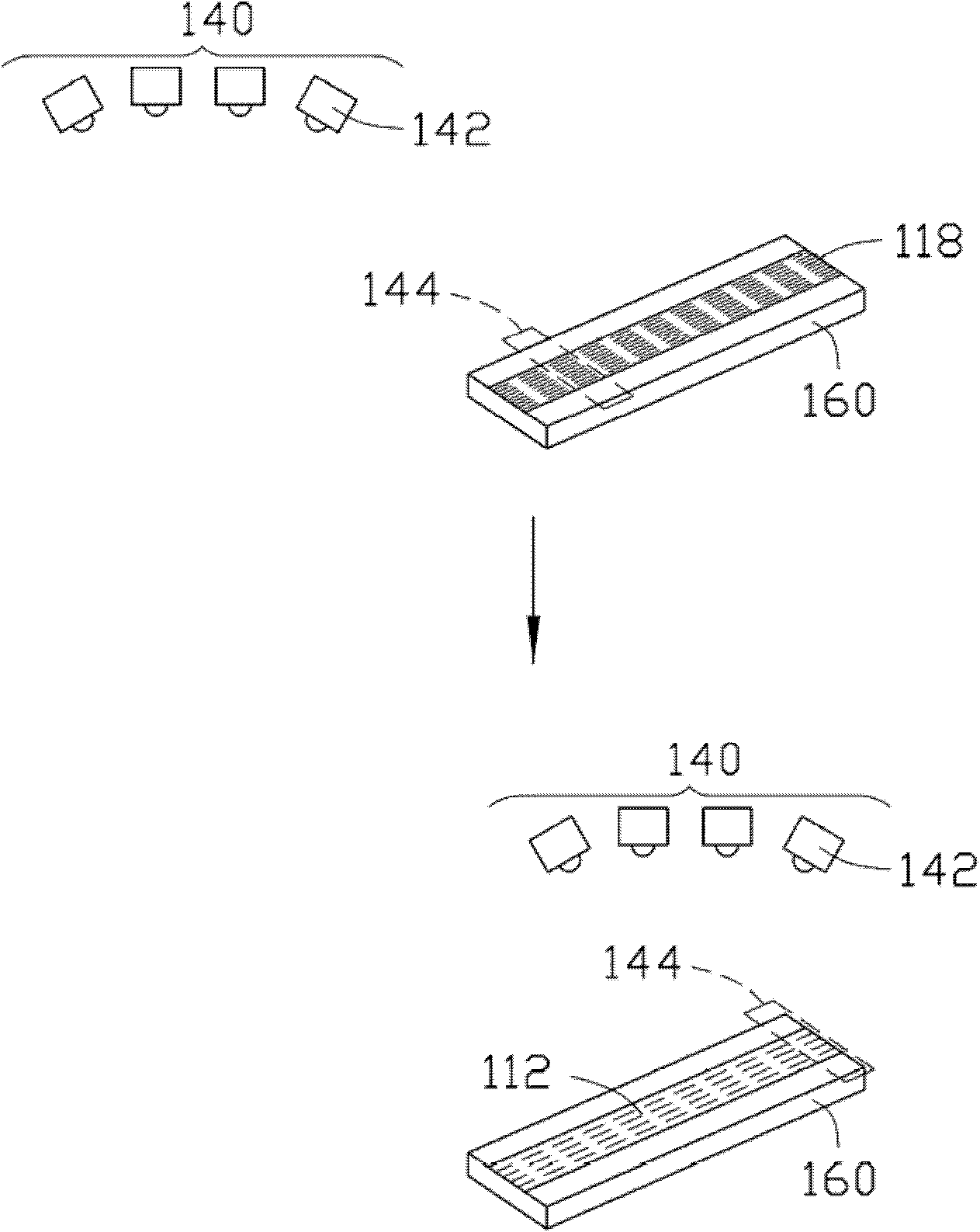

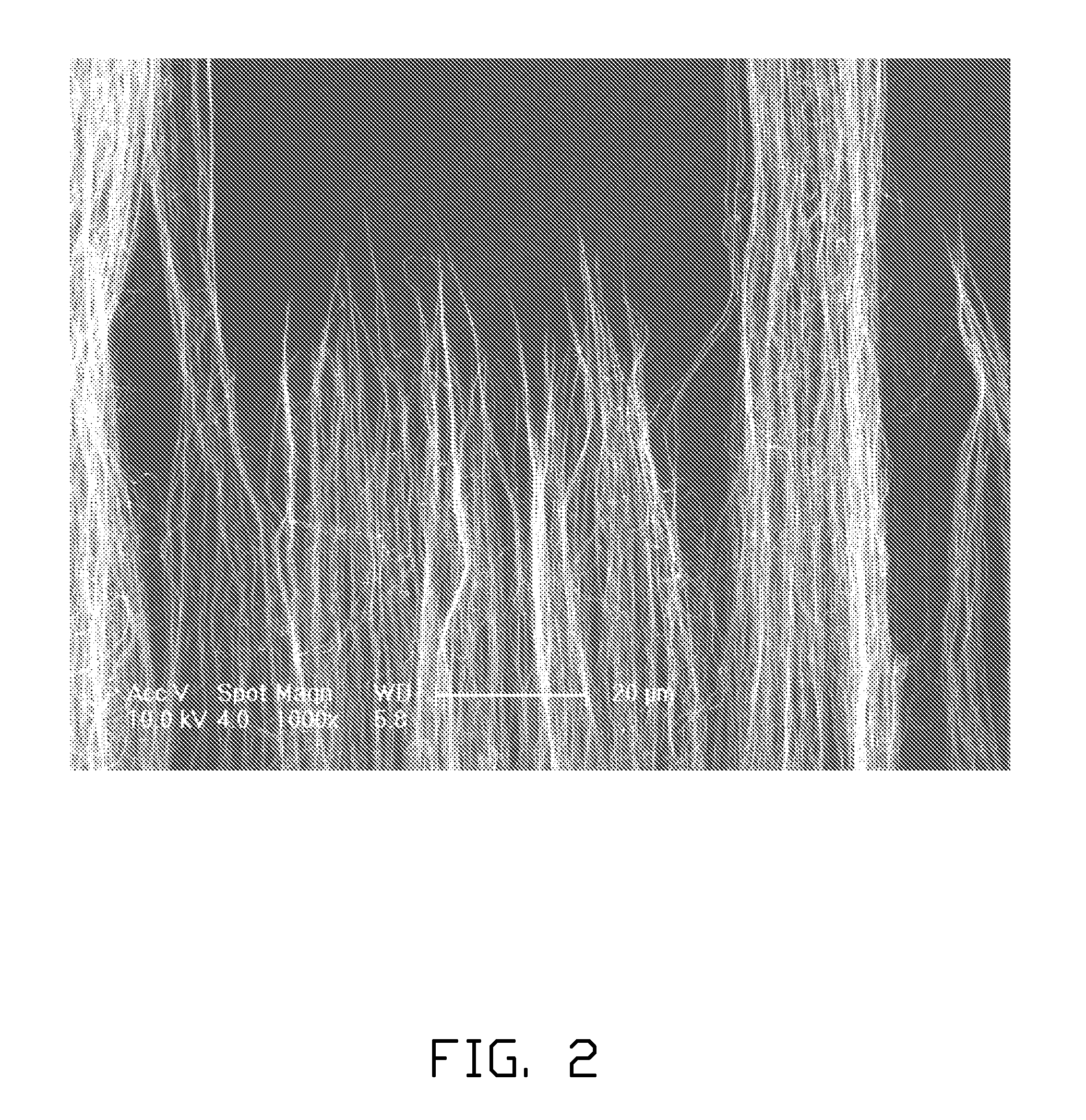

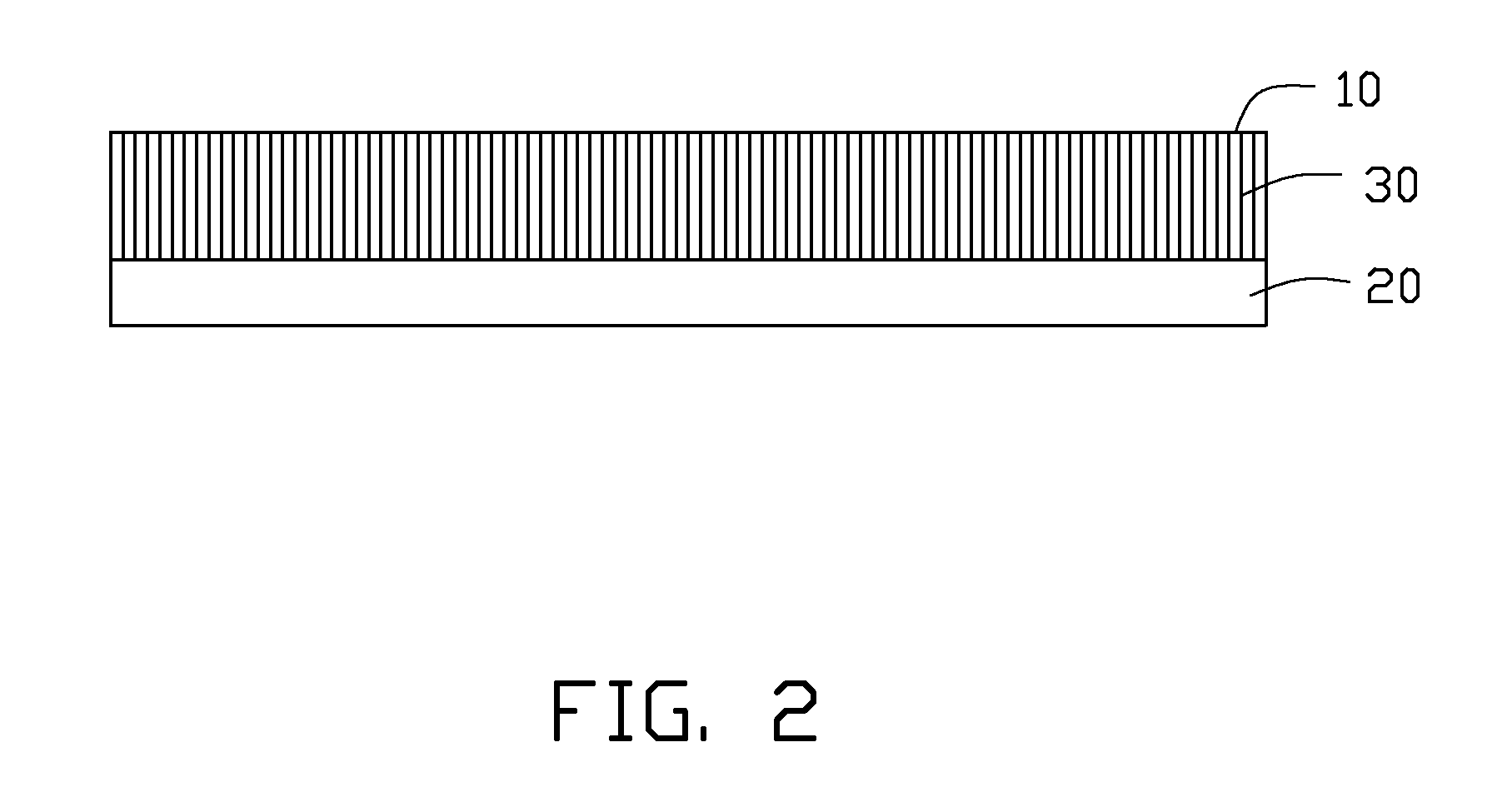

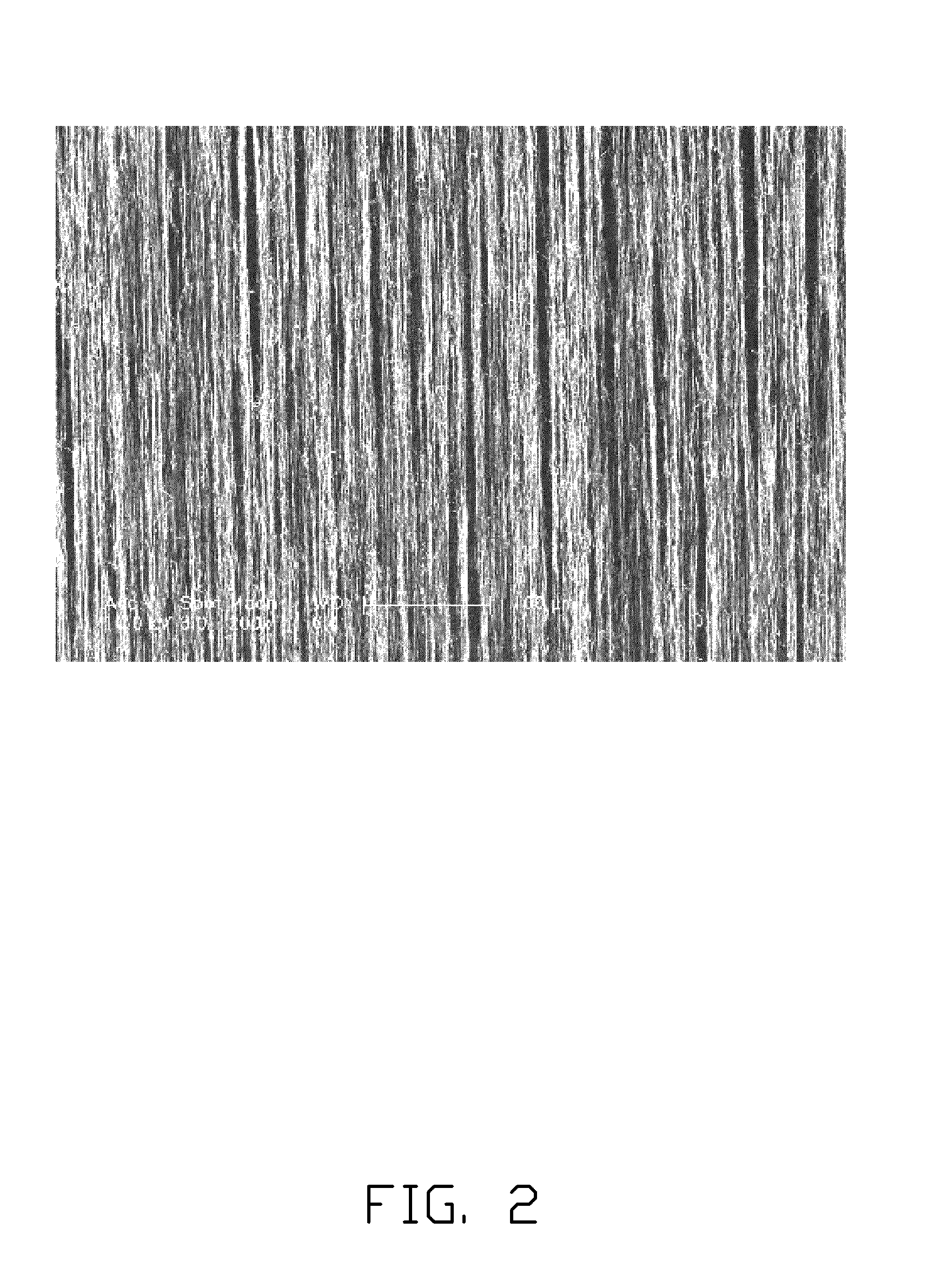

Carbon nanotube precursor, carbon nanotube film and method for making the same

A carbon nanotube film includes a plurality of carbon nanotubes. The plurality of carbon nanotubes is arranged approximately along a same first direction. The plurality of carbon nanotubes are joined end to end by van der Waals attractive force therebetween. The carbon nanotube film has a uniform width. The carbon nanotube film has substantially the same density of the carbon nanotubes along a second direction perpendicular to the first direction. The change in density across the width is within 10 percent. The present application also relates to a carbon nanotube film precursor and a method for making the carbon nanotube film.

Owner:TSINGHUA UNIV +1

A kind of positive electrode of lithium ion battery and preparation method thereof

ActiveCN103715394BImprove bindingLight in massCell electrodesCell component detailsCarbon nanotubePole piece

The invention discloses a lithium ion battery anode and a preparation method thereof. The anode utilizes a carbon nano pipe film formed by a carbon nano pipe macroscopic pipe as a current collector, and an anode material layer is formed on the carbon nano pipe film. Compared with the traditional aluminum foil current collector anode, the lithium ion battery anode has the advantages that the weight of the lithium ion battery anode prepared by the method is light, and the anode material layer and the current collector are firmly combined. The preparation method comprises the following steps of preparing a high strength carbon nano pipe on a glass substrate by utilizing a carbon nano pipe macroscopic pipe continuum generated by a reactor port, generating the anode material layer on the carbon nano pipe film layer, separating the carbon nano pipe film layer with the anode material layer from and the glass substrate, and mounting a pole ear on a pole piece. Under the same size, the carbon nano pipe film is far lighter than the aluminum foil, the weight of the saved part can be replaced by the anode material, and the capacity of the battery is 15%-50% higher than that of a battery which takes the aluminum foil as an anode current collector. The lithium ion battery anode is low in cost, high in generation efficiency, simple in equipment, capable of realizing semicontinuous operation and suitable for mass production.

Owner:北京旭江科技有限公司

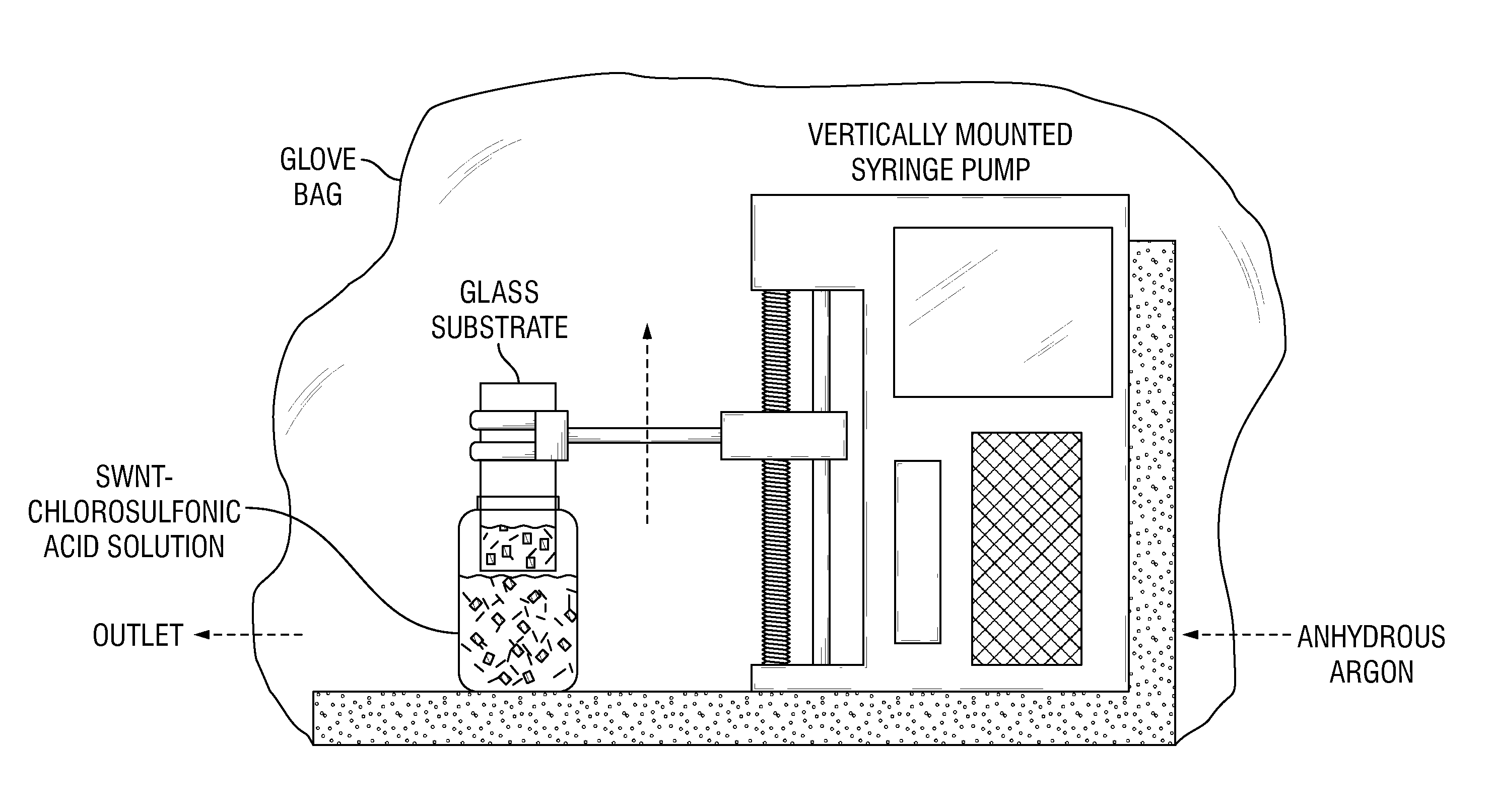

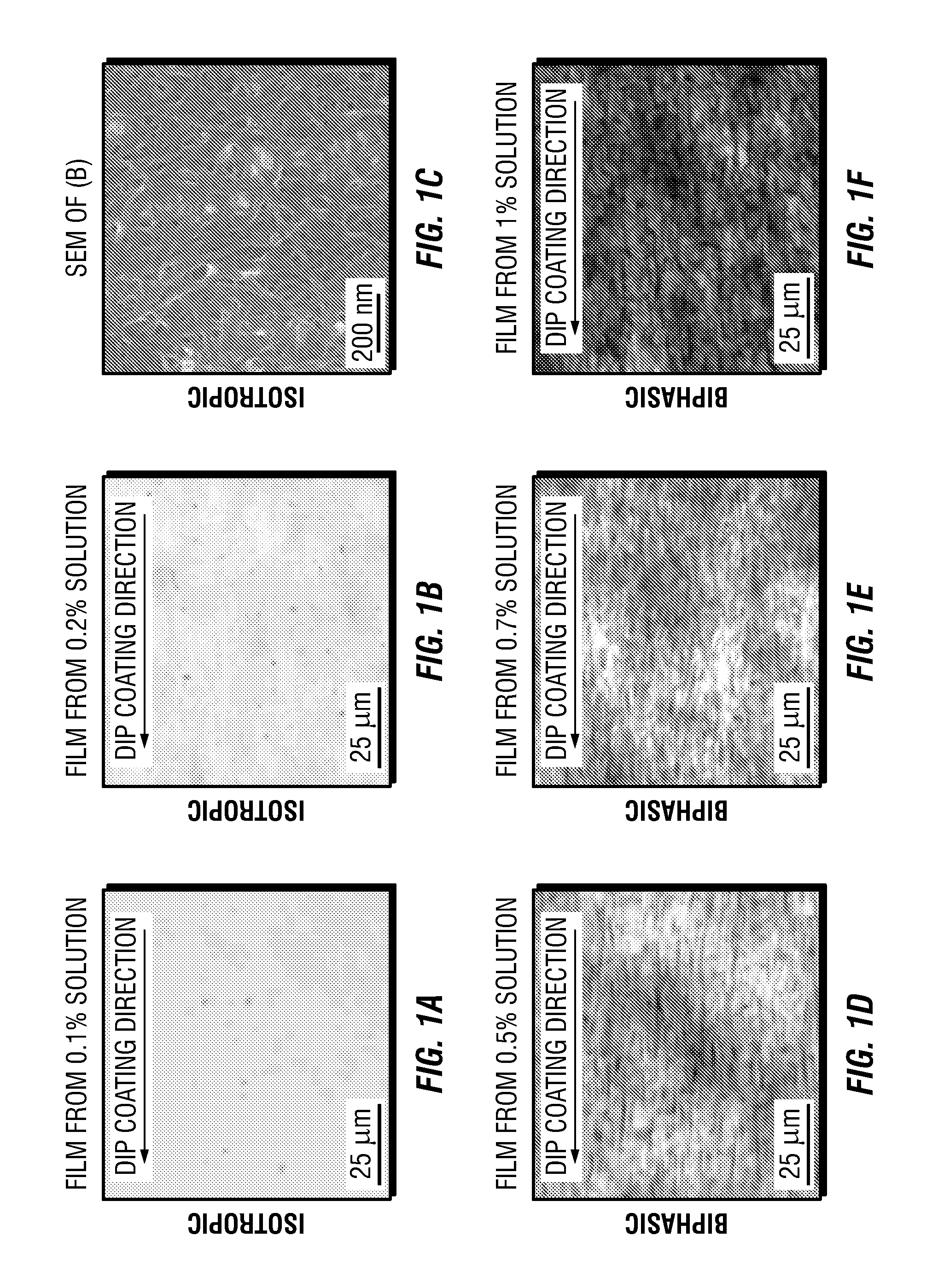

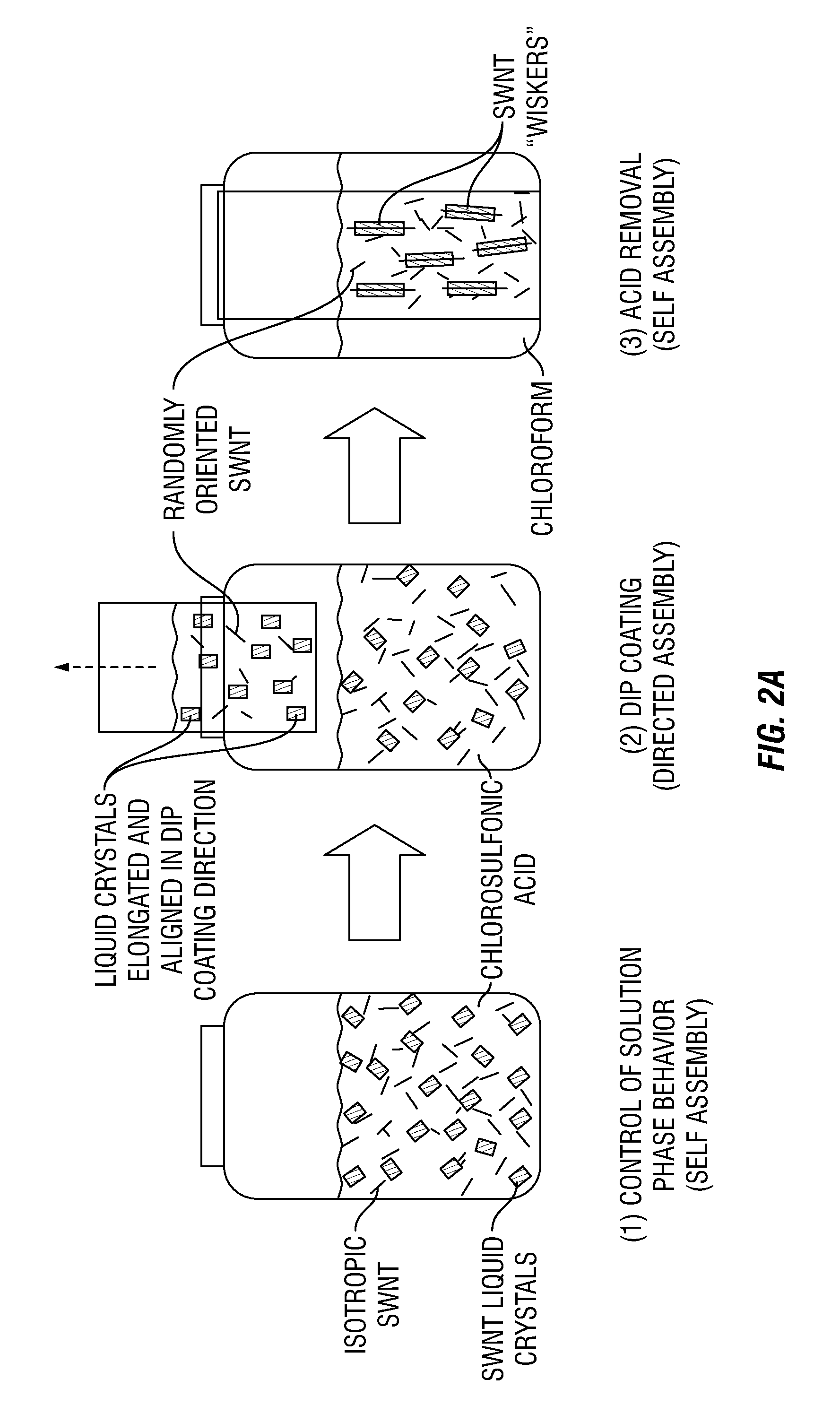

Carbon nanotube films processed from strong acid solutions and methods for production thereof

InactiveUS20150298164A1Material nanotechnologySynthetic resin layered productsStrong acidsCarbon nanotube

In some embodiments, the present disclosure provides methods for fabricating carbon nanotube films. Such methods generally comprise: (i) suspending carbon nanotubes in a superacid (e.g. chloro sulfonic acid) to form a dispersed carbon nanotube-superacid solution, wherein the carbon nanotubes have substantially exposed sidewalls in the carbon nanotube-superacid solution; (ii) applying the dispersed carbon nanotube-superacid solution onto a surface to form a carbon nanotube film; and (iii) removing the superacid. Desirably, such methods occur without the utilization of carbon nanotube wrapping molecules or sonication. Further embodiments of the present disclosure pertain to carbon nanotube films that are fabricated in accordance with the methods of the present disclosure. Such carbon nanotube films comprise a plurality of carbon nanotubes that are dispersed and individualized. Additional embodiments of the present disclosure pertain to macroscopic objects comprising the carbon nanotube films made in accordance with the methods of the present disclosure described supra.

Owner:RICE UNIV

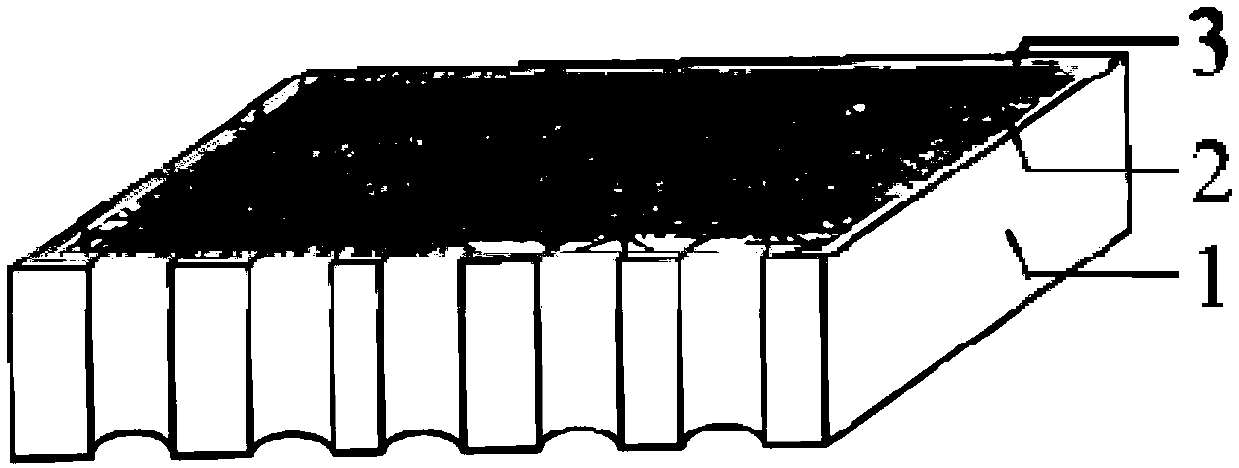

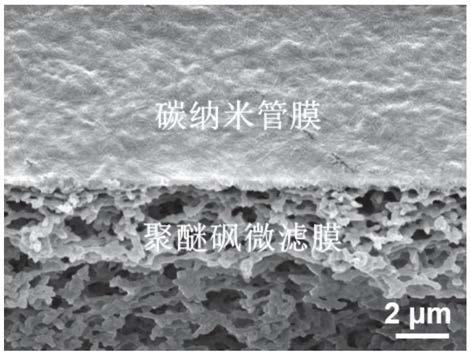

Reverse osmosis membrane, preparation method and application thereof

InactiveCN111214965AHigh porosityAchieve ultra-thinGeneral water supply conservationSeawater treatmentPolymer scienceCarbon nanotube

The invention discloses a reverse osmosis membrane, a preparation method and application thereof. The reverse osmosis membrane comprises a porous filter membrane supporting layer, a carbon nanotube membrane middle layer and a polyamide membrane selection layer which are arranged in sequence. According to the invention, the reverse osmosis membrane is a stable composite membrane integrating a porous filter membrane, a carbon nano tube membrane and a polyamide membrane, wherein the porous filter membrane serves as the substrate loaded by the carbon nano tube membrane and provides good mechanicalstrength, the carbon nano tube membrane has uniformly distributed nano-sized apertures and high porosity, and is used as a support for an interfacial polymerization reaction so as to achieve uniformdistribution of a monomer solution and controllable release of a monomer to prepare an ultrathin and high-quality polyamide membrane, and the polyamide membrane as a performance determination layer has the characteristic of ultra-thinness, and makes the novel reverse osmosis membrane have the flux far higher than that of the traditional reverse osmosis membrane while retaining the high rejection rate. According to the reverse osmosis membrane disclosed by the invention, the carbon nano tube membrane middle layer with uniformly distributed nano-sized apertures and high porosity is introduced for the first time, so that the performance is substantially improved.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

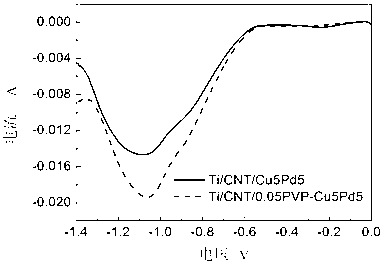

Carbon nano tube film load cuprum and palladium bimetallic catalyst, preparation method and application

InactiveCN103252243ALarge specific surface areaImprove conductivityWater/sewage treatmentMetal/metal-oxides/metal-hydroxide catalystsOrganic dyeCarbon nanotube

The invention discloses a carbon nano tube film load cuprum and palladium bimetallic catalyst, a preparation method and an application. The catalyst takes cuprum and palladium as catalytic activity ingredients, and carbon nano tube film modified titanium plate as a substrate. The preparation method comprises the steps of pretreating the titanium plate and a carbon nano tube respectively, taking the treated titanium plate as an anode, taking a dispersed carbon nano tube suspension as deposition liquid, depositing the carbon nano tube on the titanium plate uniformly by the electrophoresis action to form a dense carbon nano tube film, taking the dried carbon nano tube film modified titanium plate as the substrate, placing the substrate in a sodium chloride electroplating solution containing cupric ions, palladium ions and polyvinylpyrrolidone, synchronously depositing the cuprum and the palladium by an electrochemical reduction method, and obtaining the titanium-based carbon nano tube film load cuprum and palladium bimetallic catalyst. The catalyst has high and stable electrochemical activity and electro-catalytic properties, and can serve as a working electrode to degrade organic dye in a water body and reduce inorganic negative ions such as nitrate, bromate and chromate.

Owner:NANJING UNIV

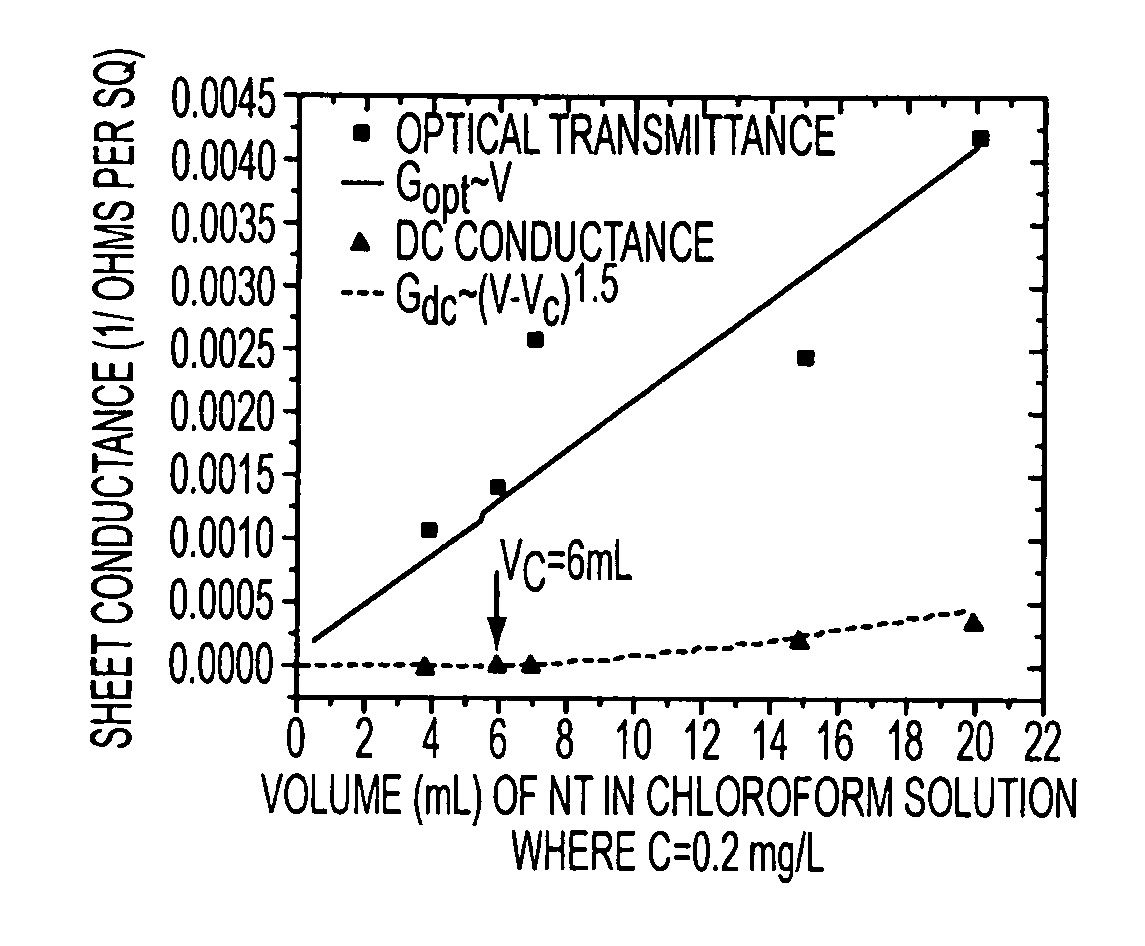

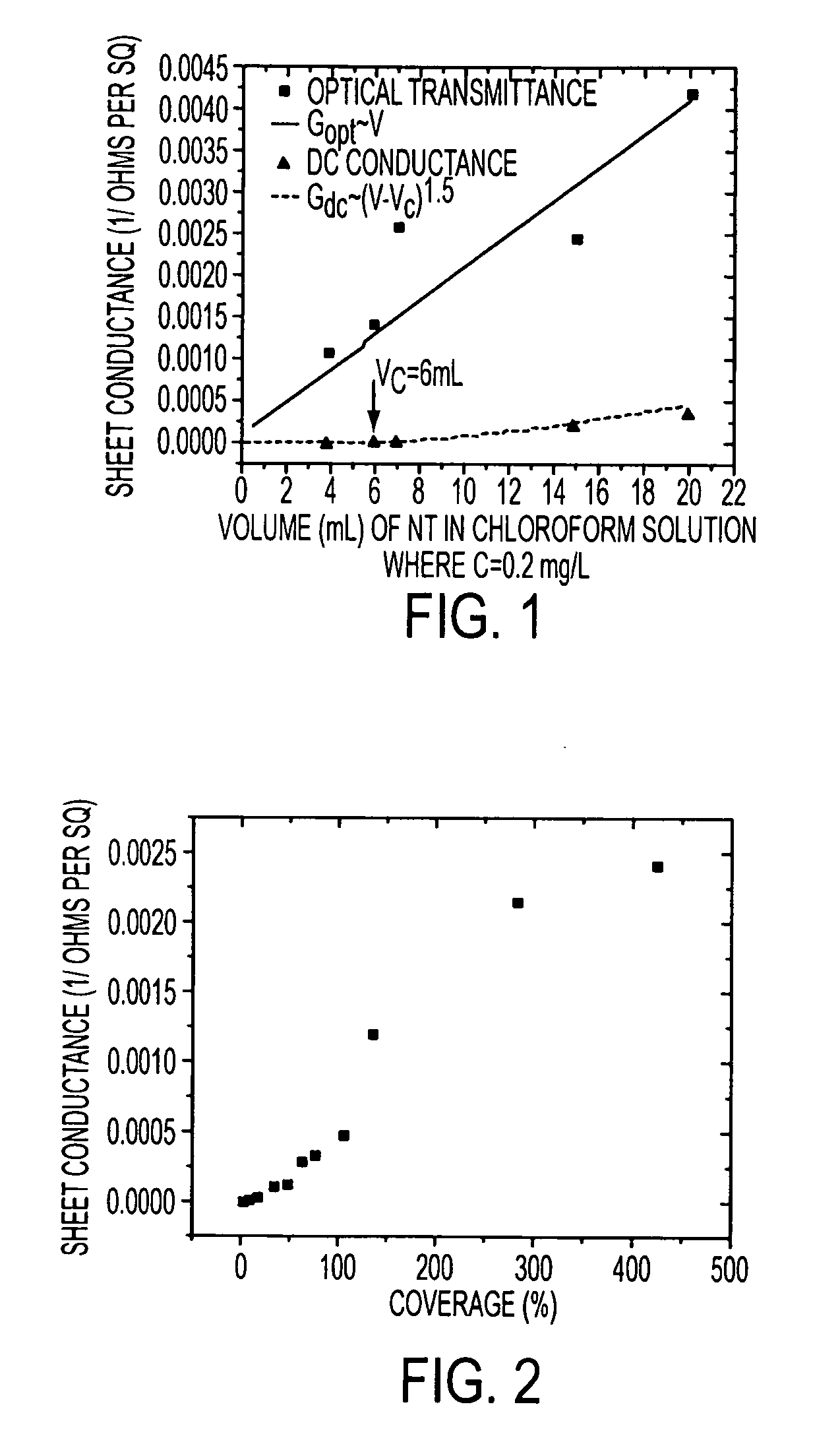

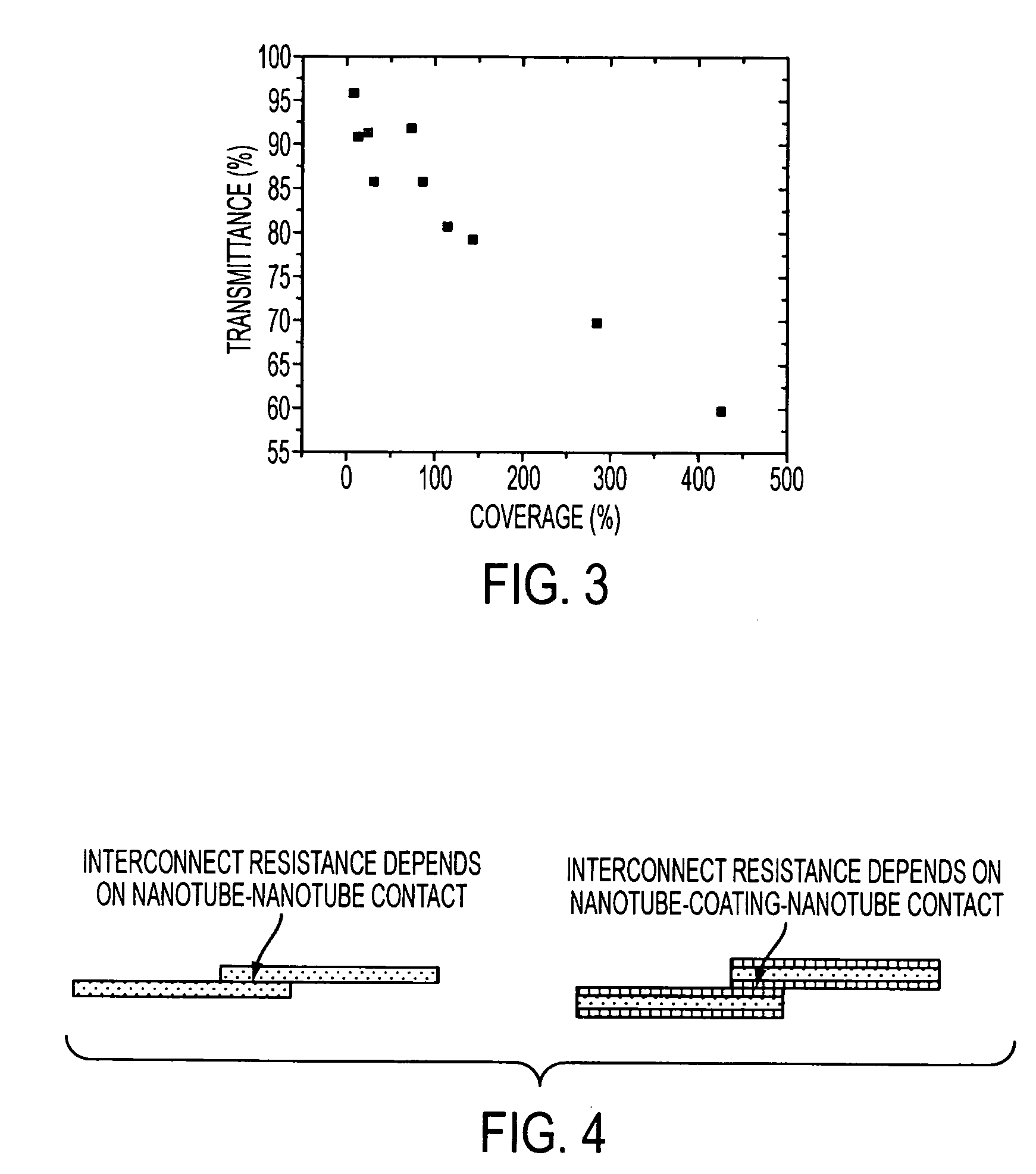

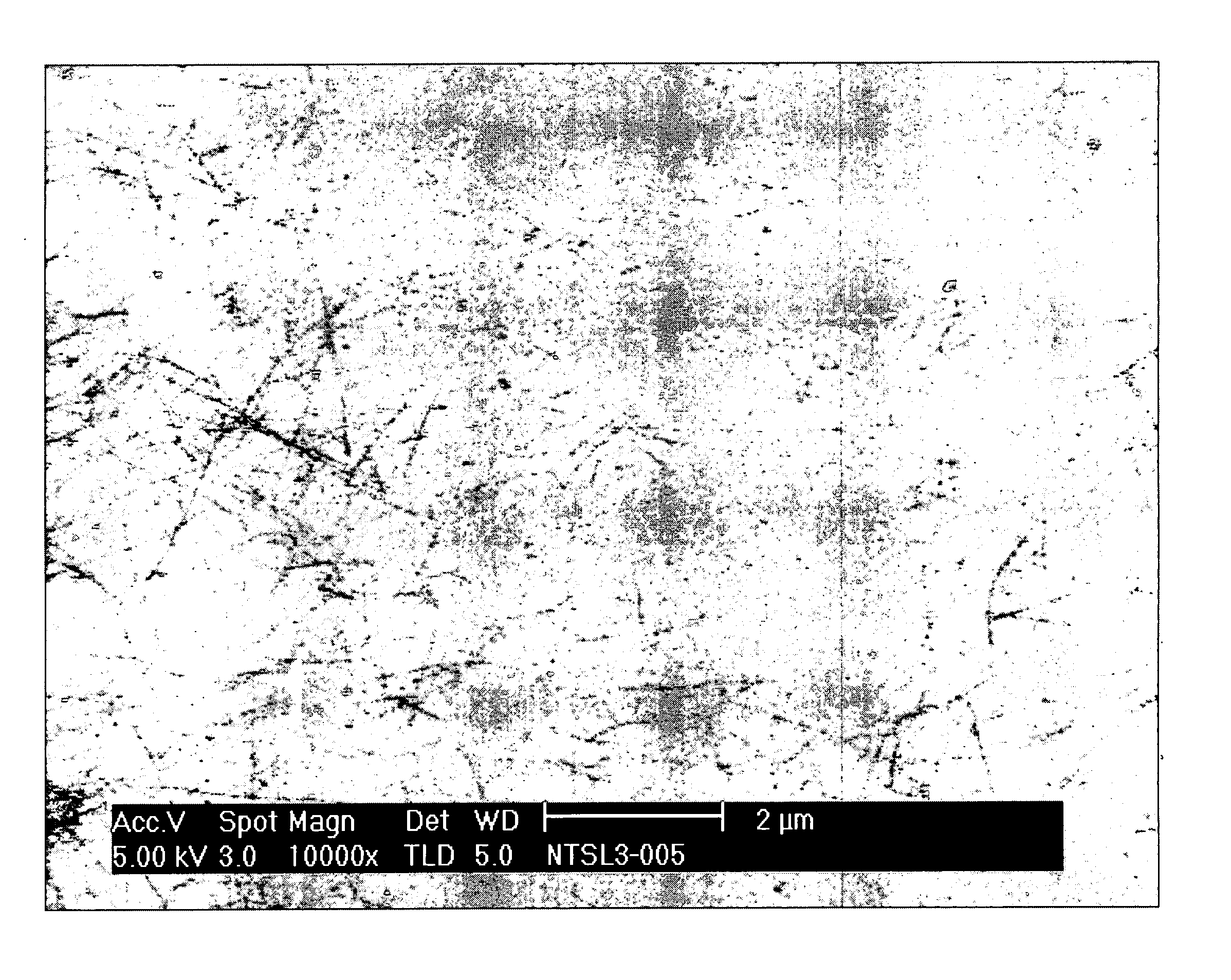

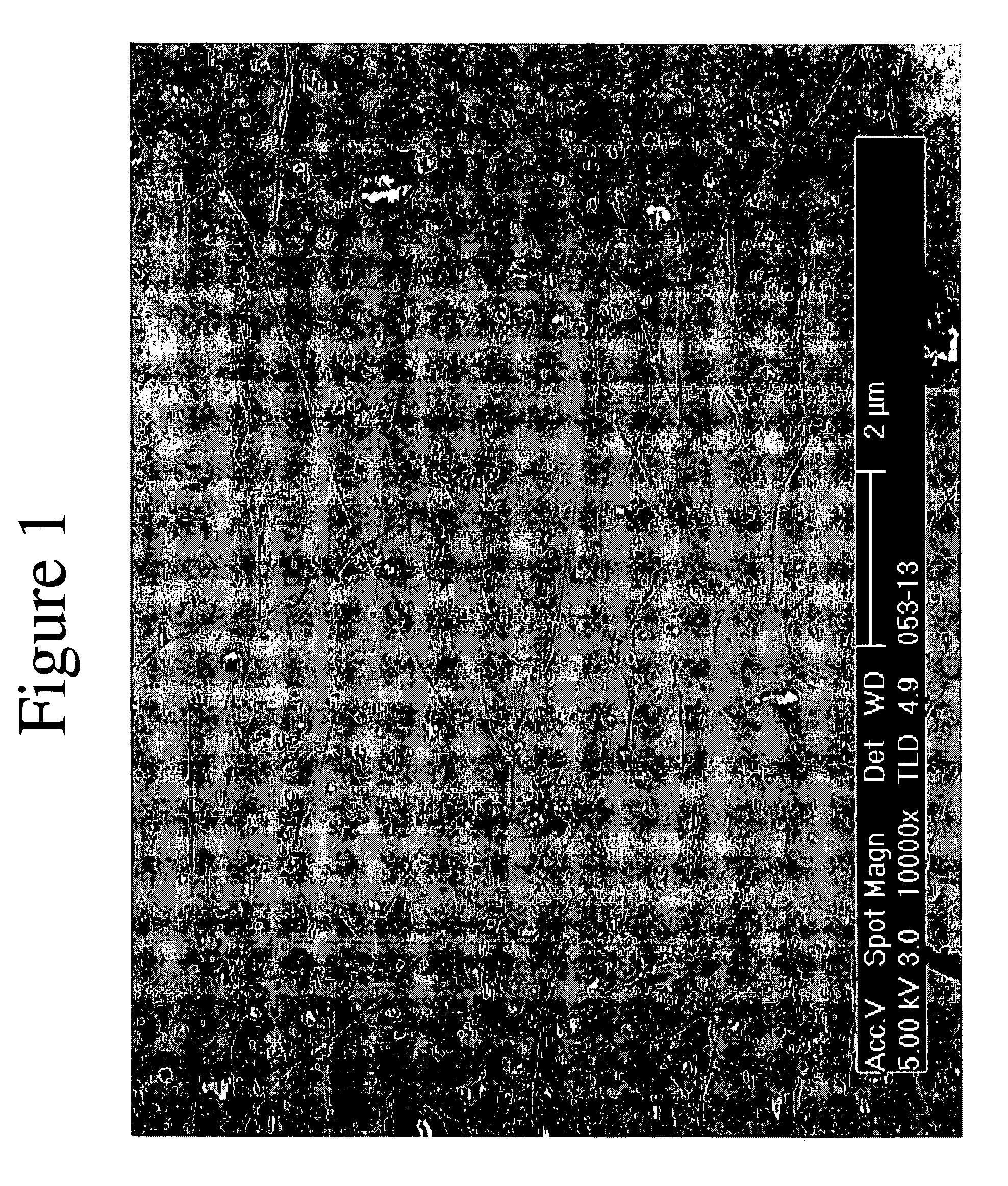

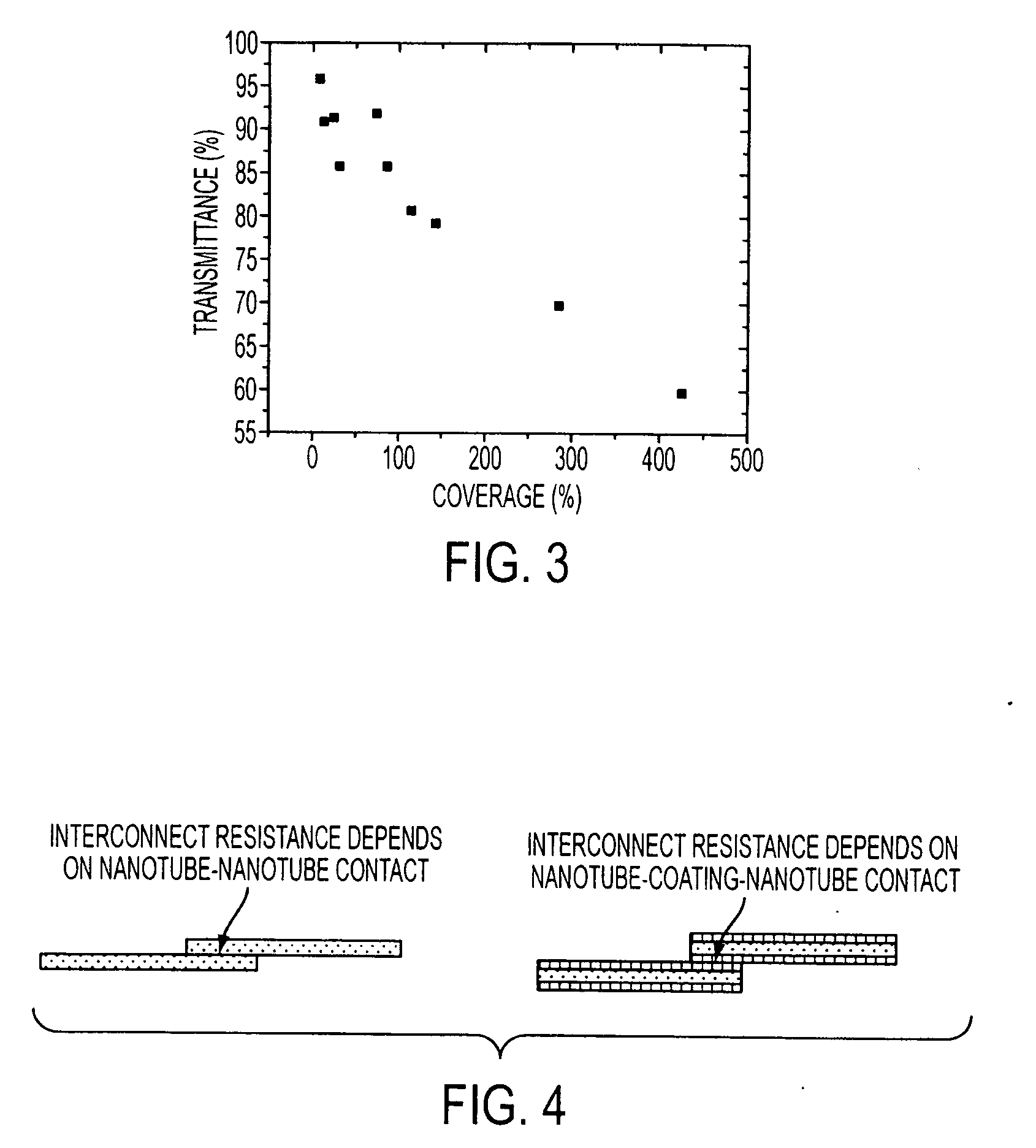

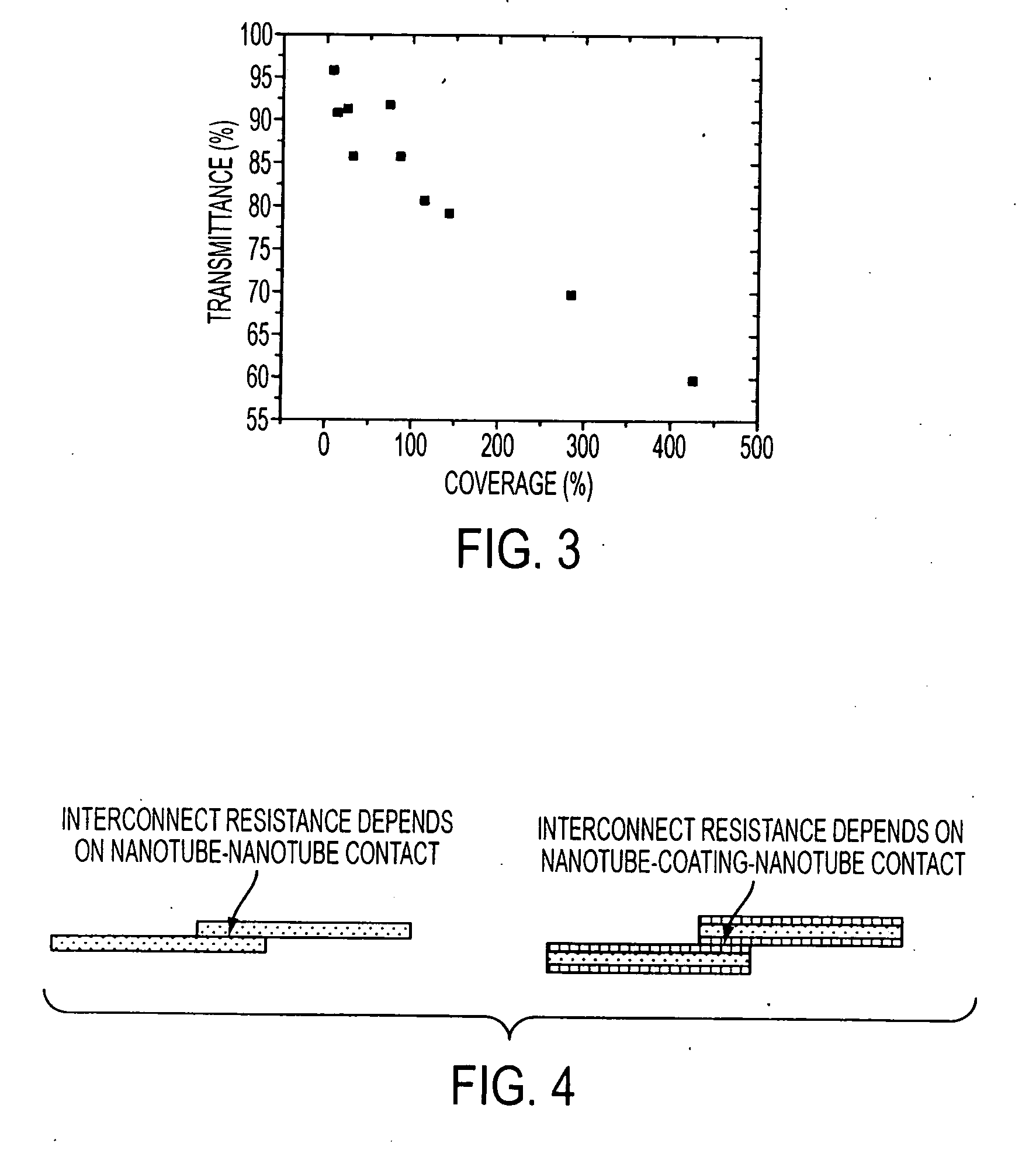

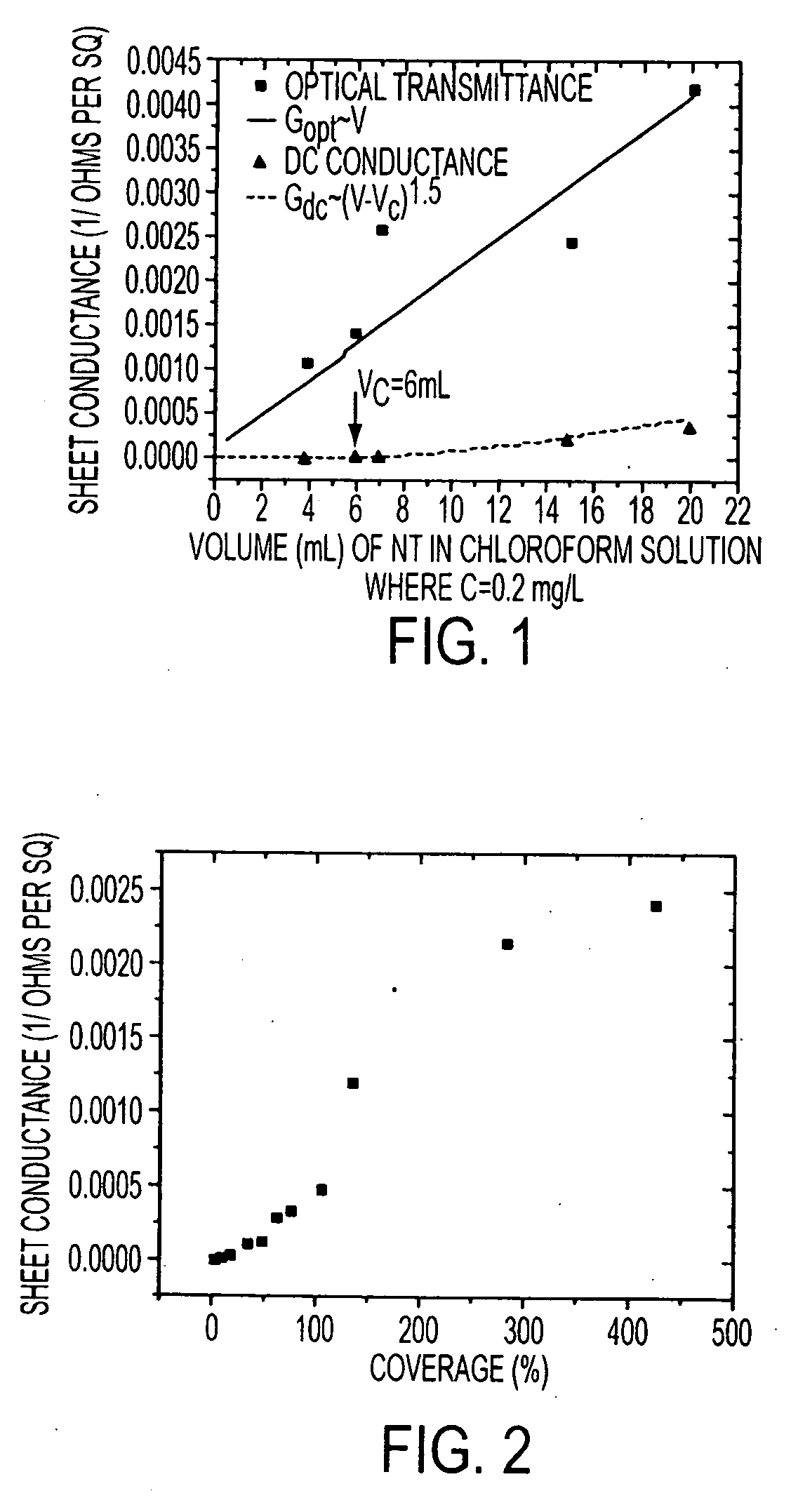

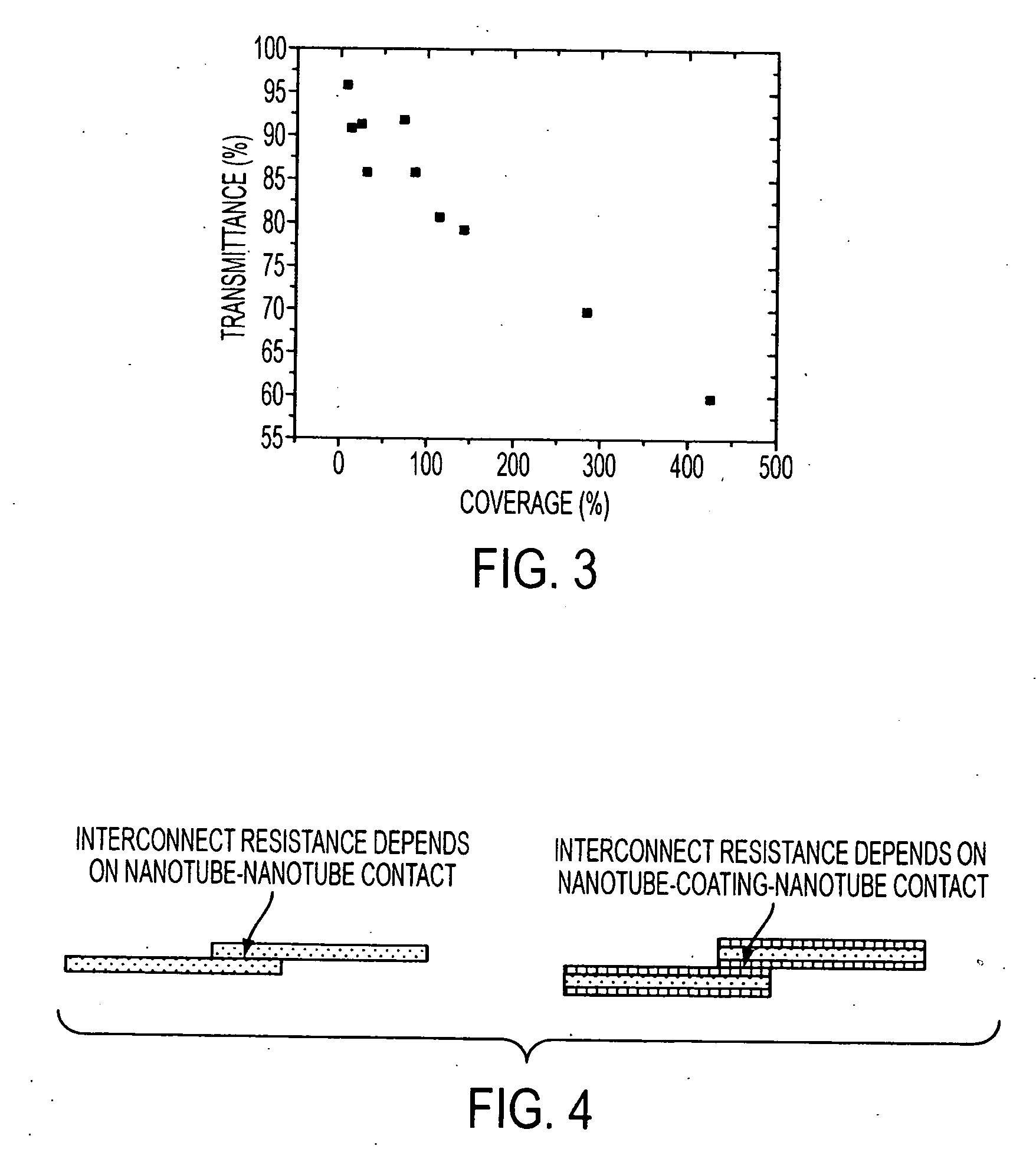

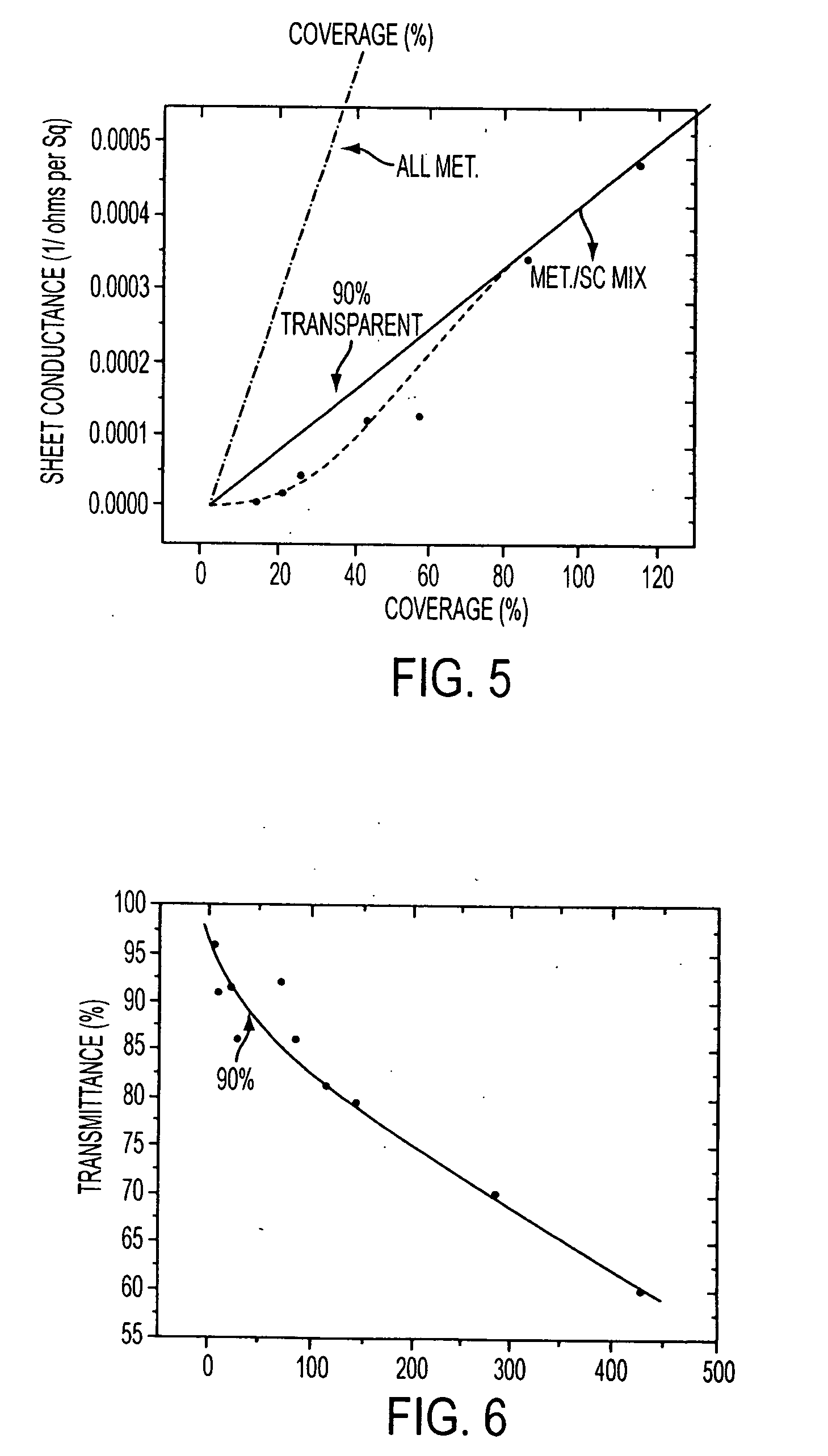

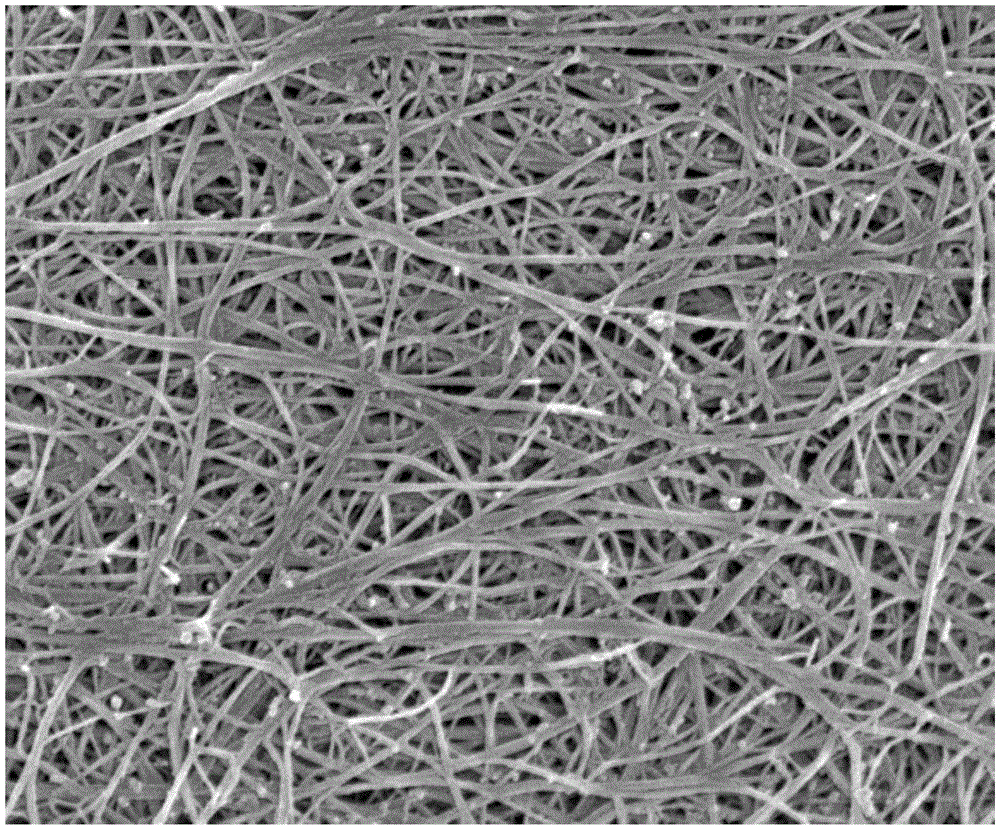

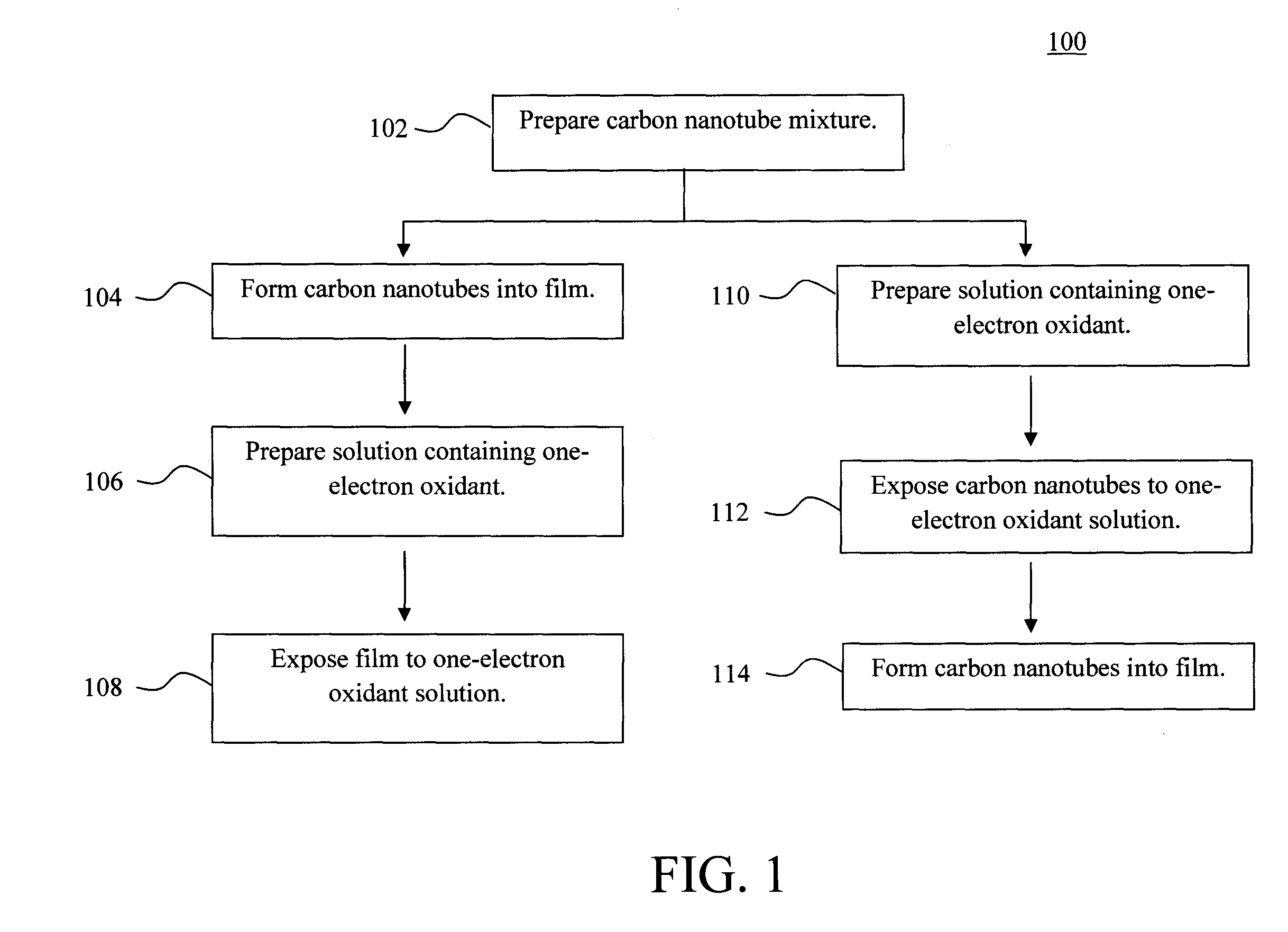

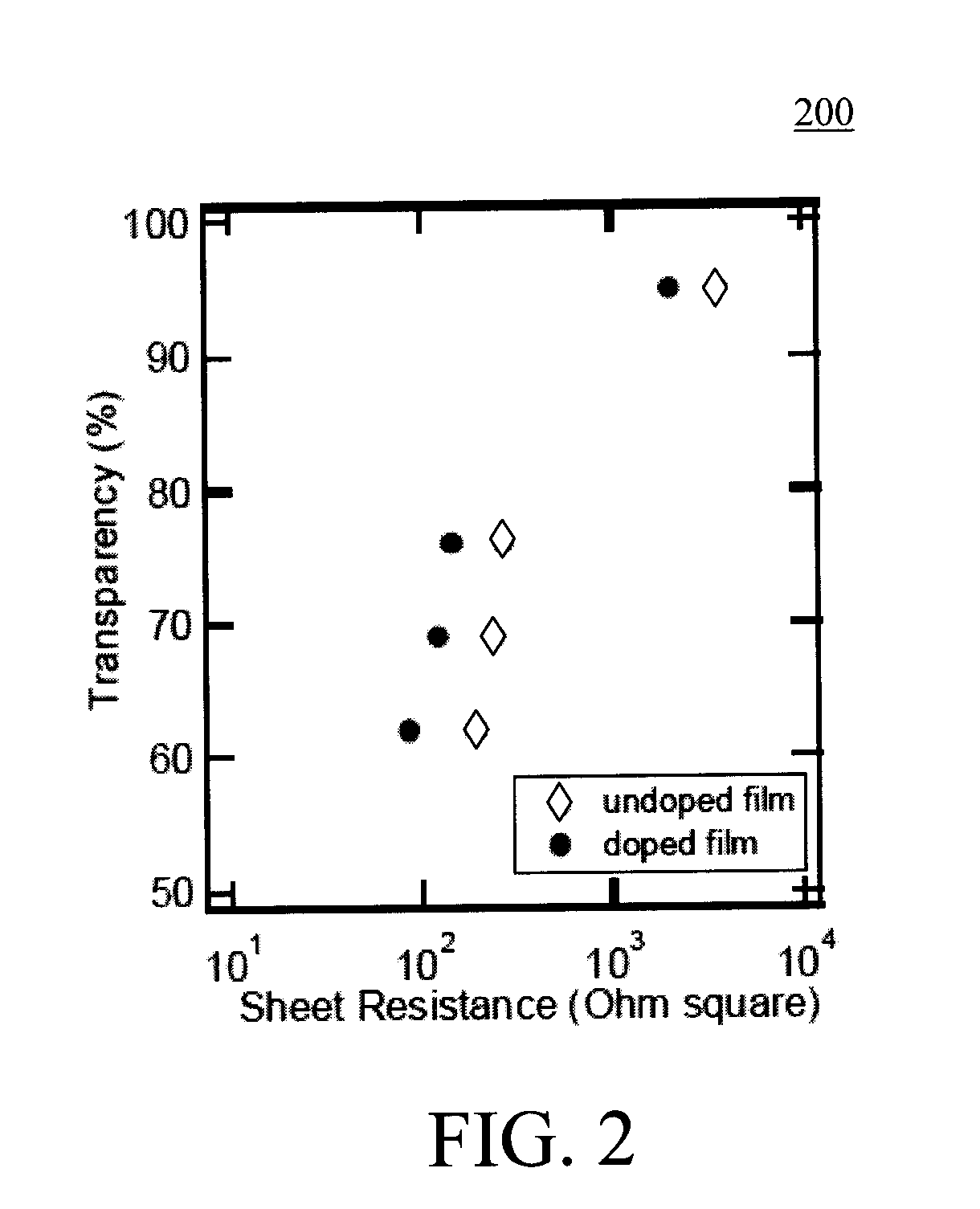

Doping of Carbon Nanotube Films for the Fabrication of Transparent Electrodes

InactiveUS20110048508A1Improve conductivityFinal product manufactureSolid-state devicesCarbon nanotubeNanotube membrane

Techniques for increasing conductivity of carbon nanotube films are provided. In one aspect, a method for increasing conductivity of a carbon nanotube film includes the following steps. The carbon nanotube film is formed from a mixture of metallic and semiconducting carbon nanotubes. The carbon nanotubes are exposed to a solution comprising a one-electron oxidant configured to dope the semiconducting carbon nanotubes to increase a conductivity thereof, thereby increasing the overall conductivity of the film. The step of forming the carbon nanotube film can be performed prior to the step of exposing the carbon nanotubes to the one-electron oxidant solution. Alternatively, the step of exposing the carbon nanotubes to the one-electron oxidant solution can be performed prior to the step of forming the carbon nanotube film. A method of fabricating a transparent electrode on a photovoltaic device from a carbon nanotube film is also provided.

Owner:IBM CORP

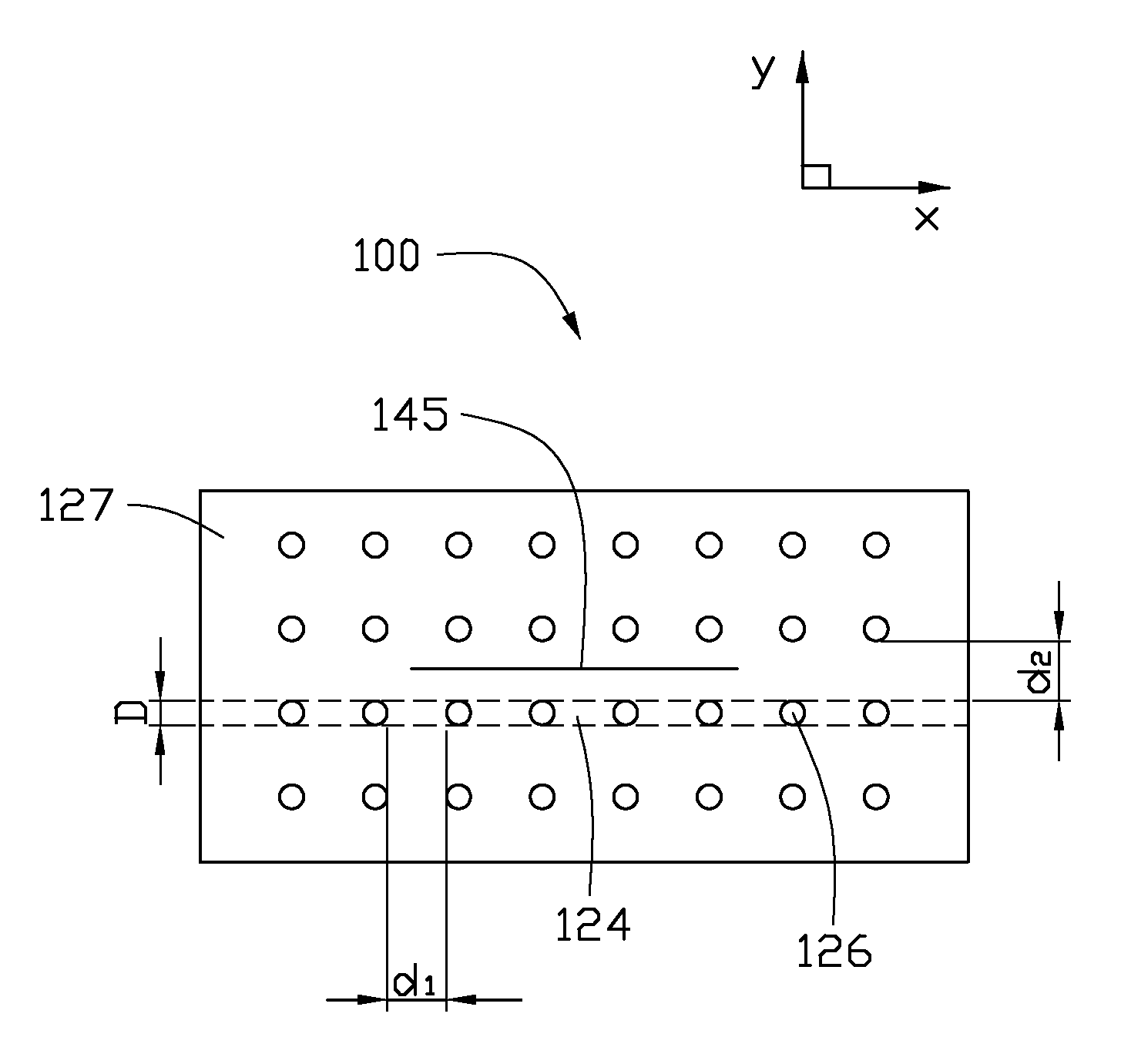

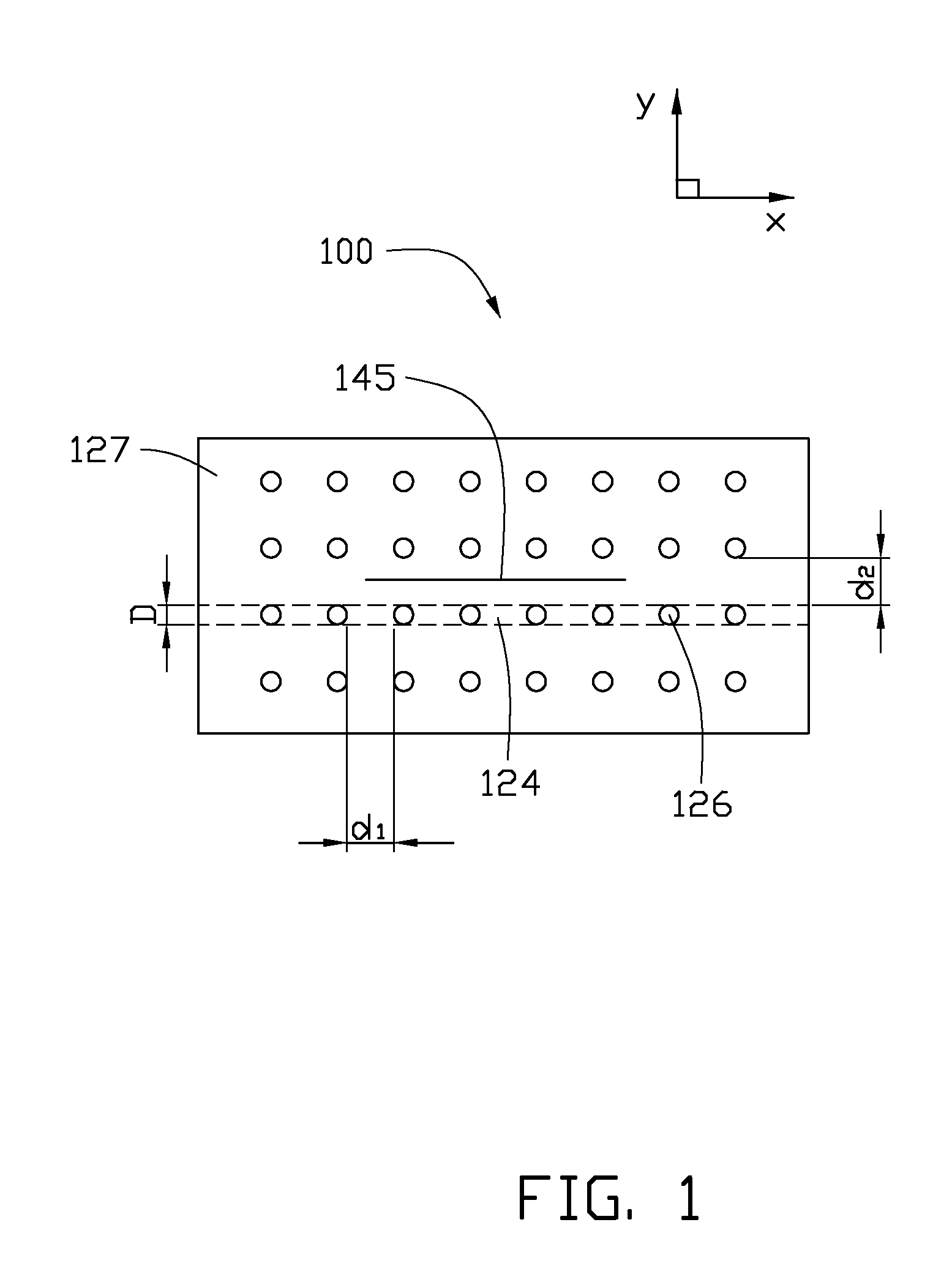

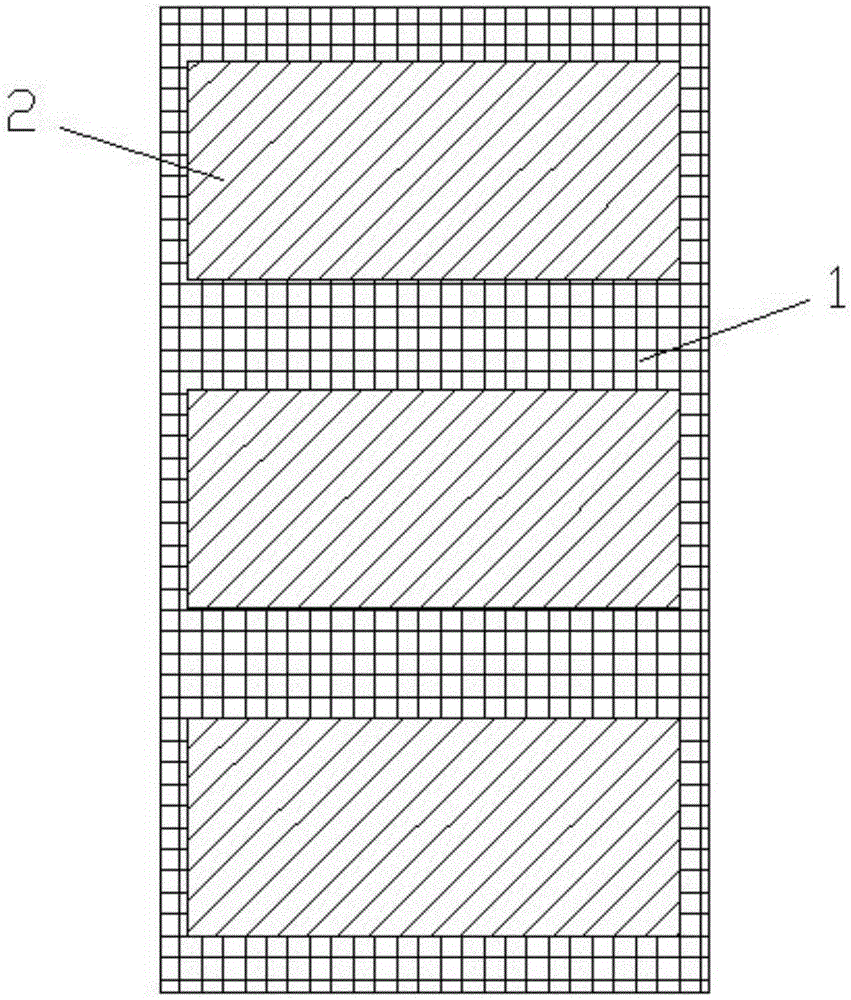

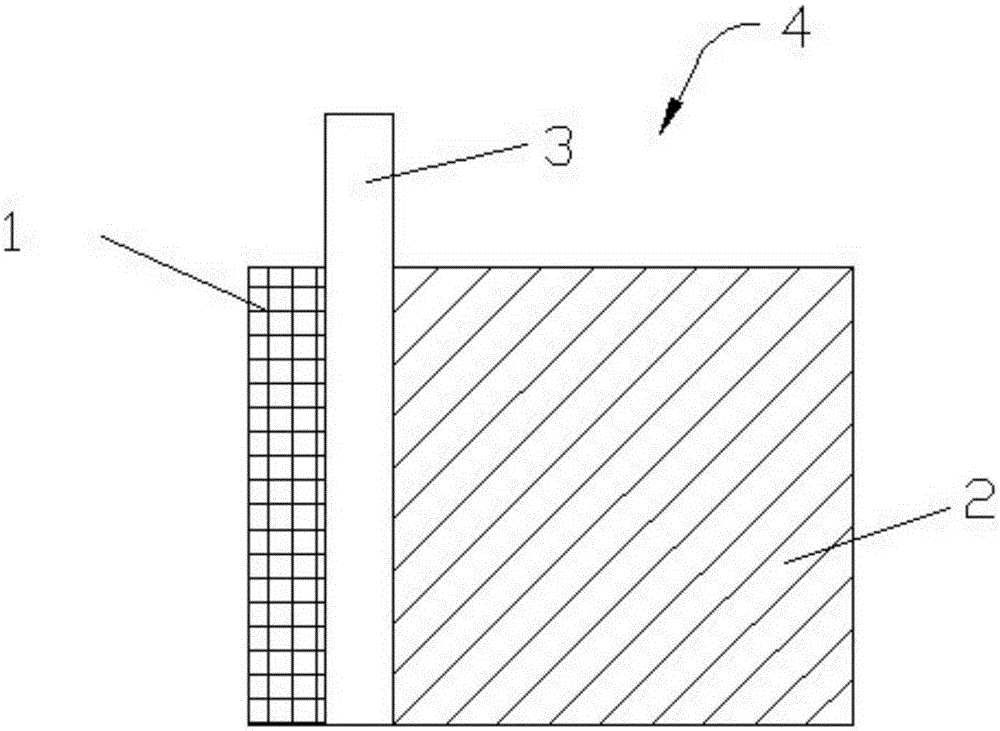

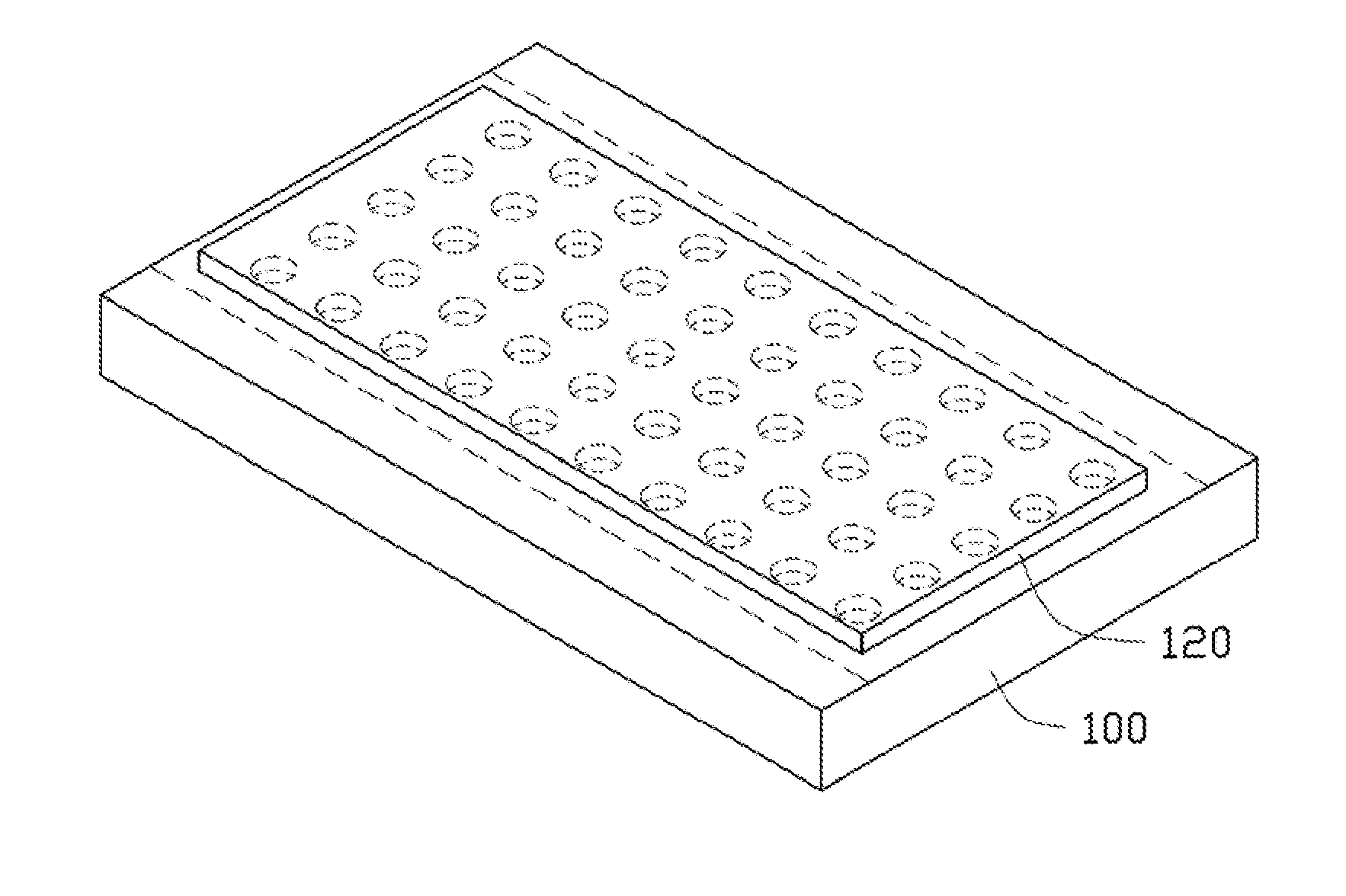

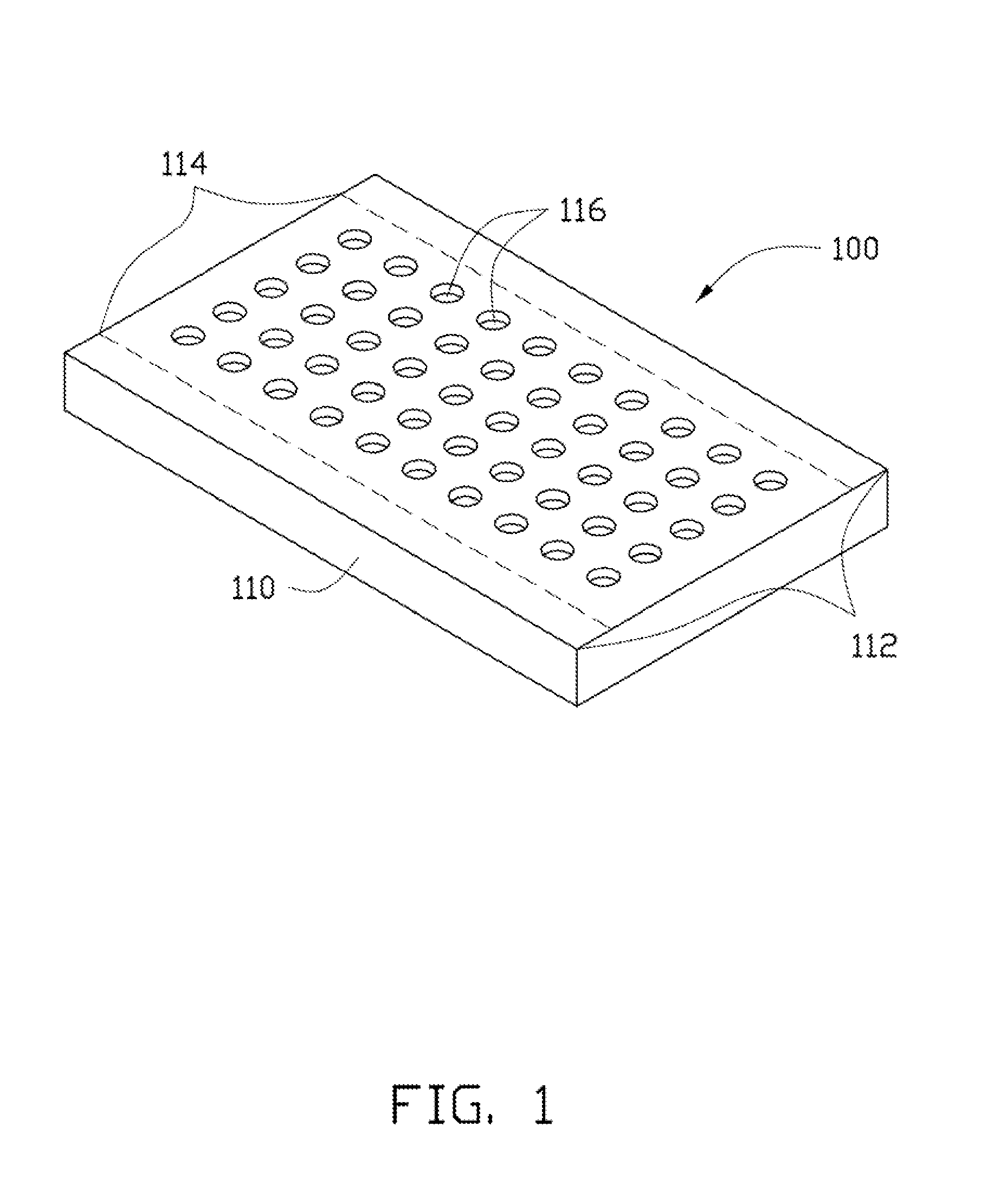

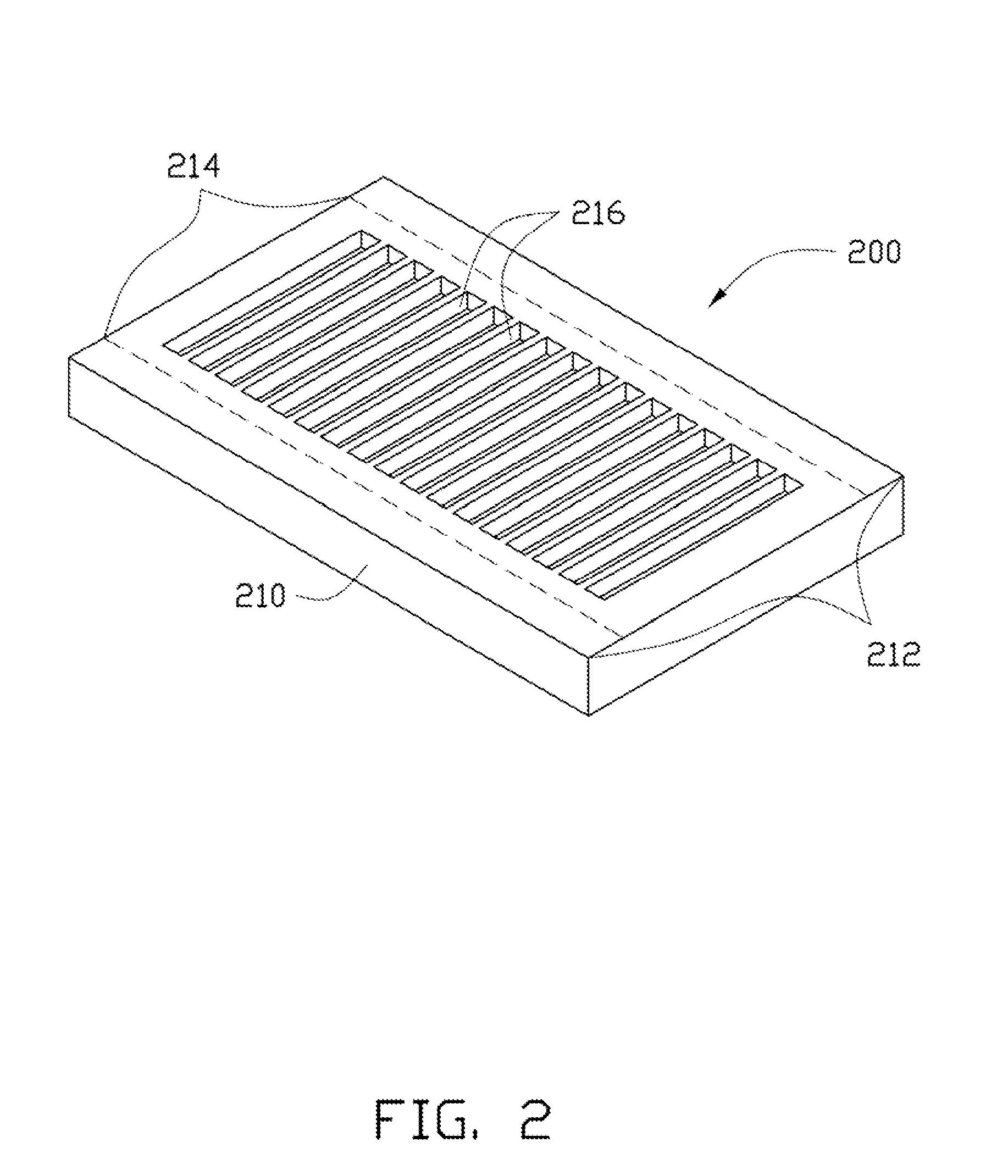

Carbon nanotube film supporting structure and method for using same

A carbon nanotube film supporting structure is provided. The carbon nanotube film supporting structure is used for supporting a carbon nanotube film structure. The carbon nanotube film supporting structure includes a body and a number of voids. The body has a surface defining a support region. The voids are defined in the support region. A void ratio of the support region is greater than or equal to 80%. The present disclosure also provides a method for using the carbon nanotube film supporting structure.

Owner:BEIJING FUNATE INNOVATION TECH

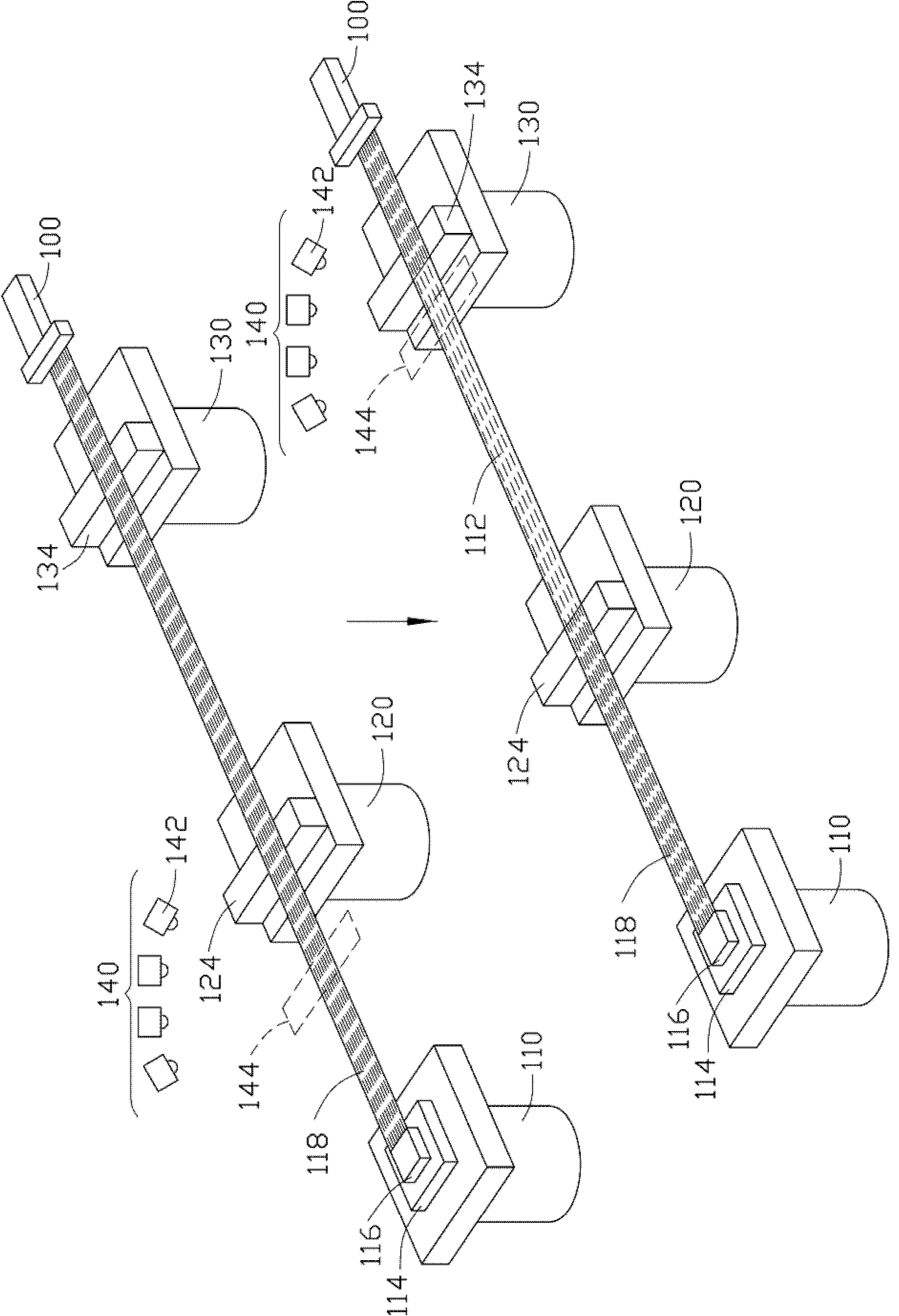

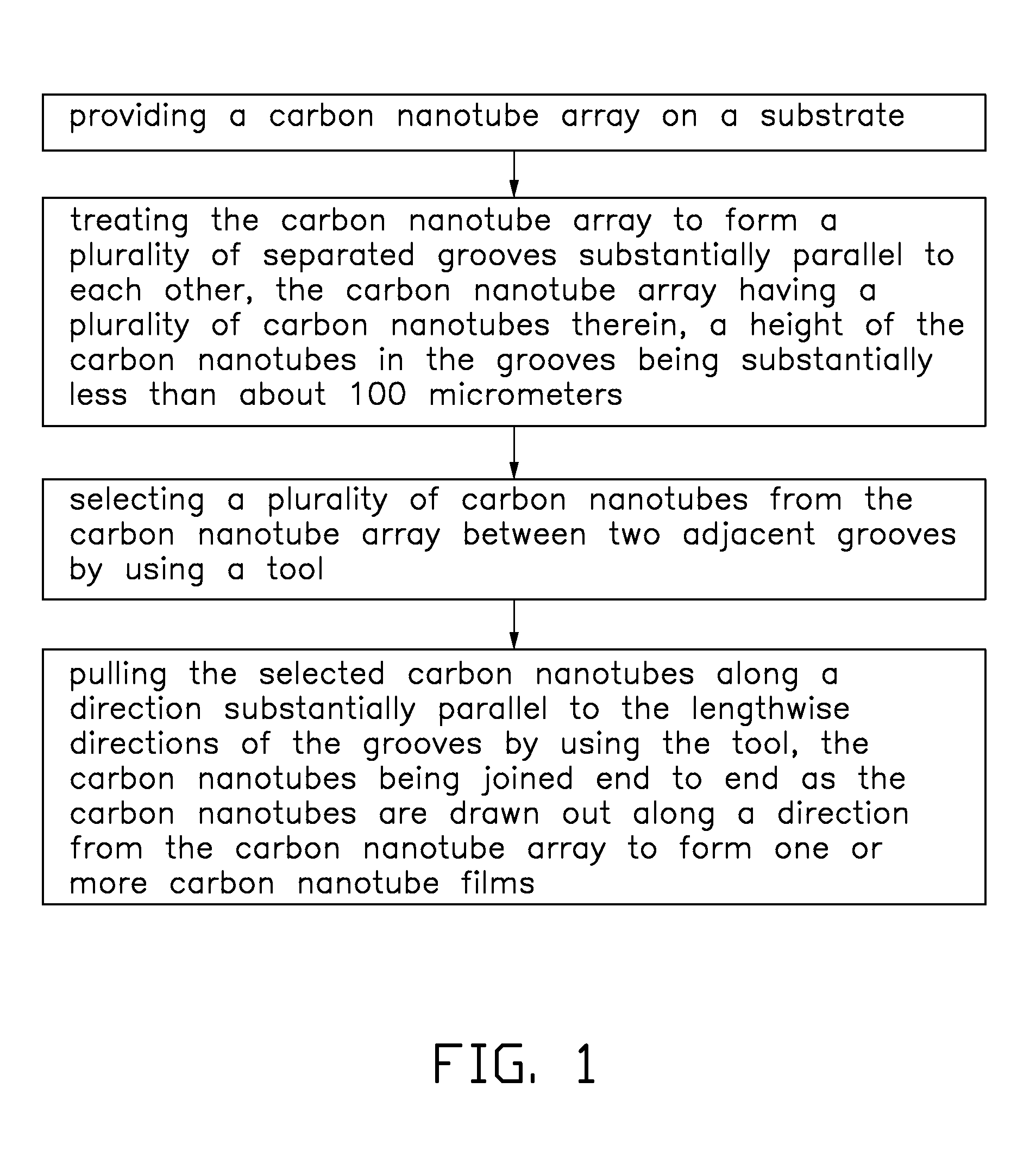

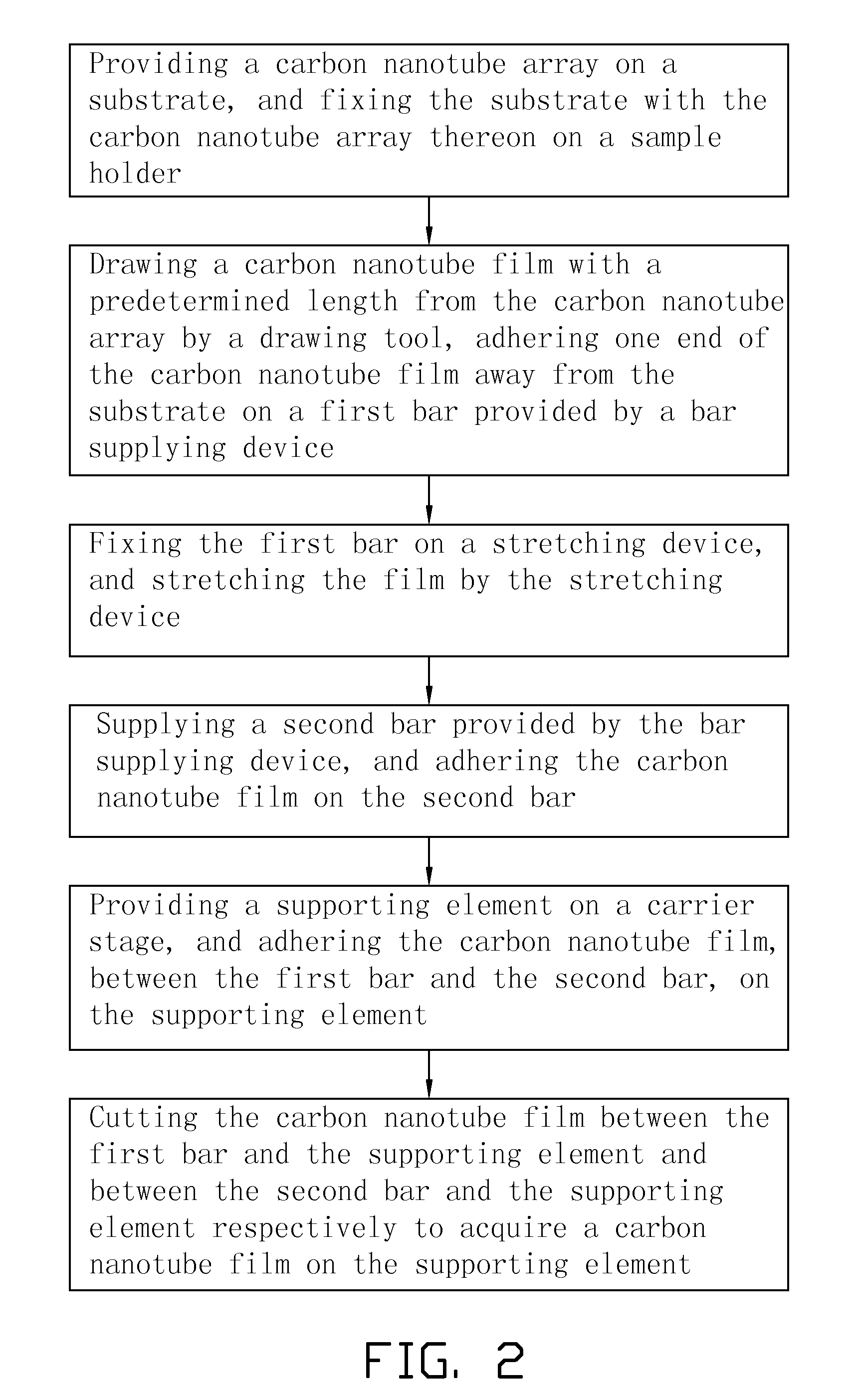

Method for making carbon nanotube film

ActiveUS20110120633A1Material nanotechnologyLamination ancillary operationsCarbon nanotubeMaterials science

A method for making a carbon nanotube film includes the following steps. A carbon nanotube array fixed on a substrate holder is provided. A carbon nanotube film is drawn from the carbon nanotube array. A first part of the carbon nanotube film is adhered to a first bar placed on a bar supply device. The carbon nanotube film is stretched by the first bar. A second part of the carbon nanotube film is adhered to a second bar positioned on the bar supply device. A third part of the carbon nanotube film is adhered to a supporting element placed on a carrier device. The third part of the carbon nanotube film is separated from the first part and the second part of carbon nanotube film. The third part of the carbon nanotube film adhered to the supporting element is obtained.

Owner:TSINGHUA UNIV +1

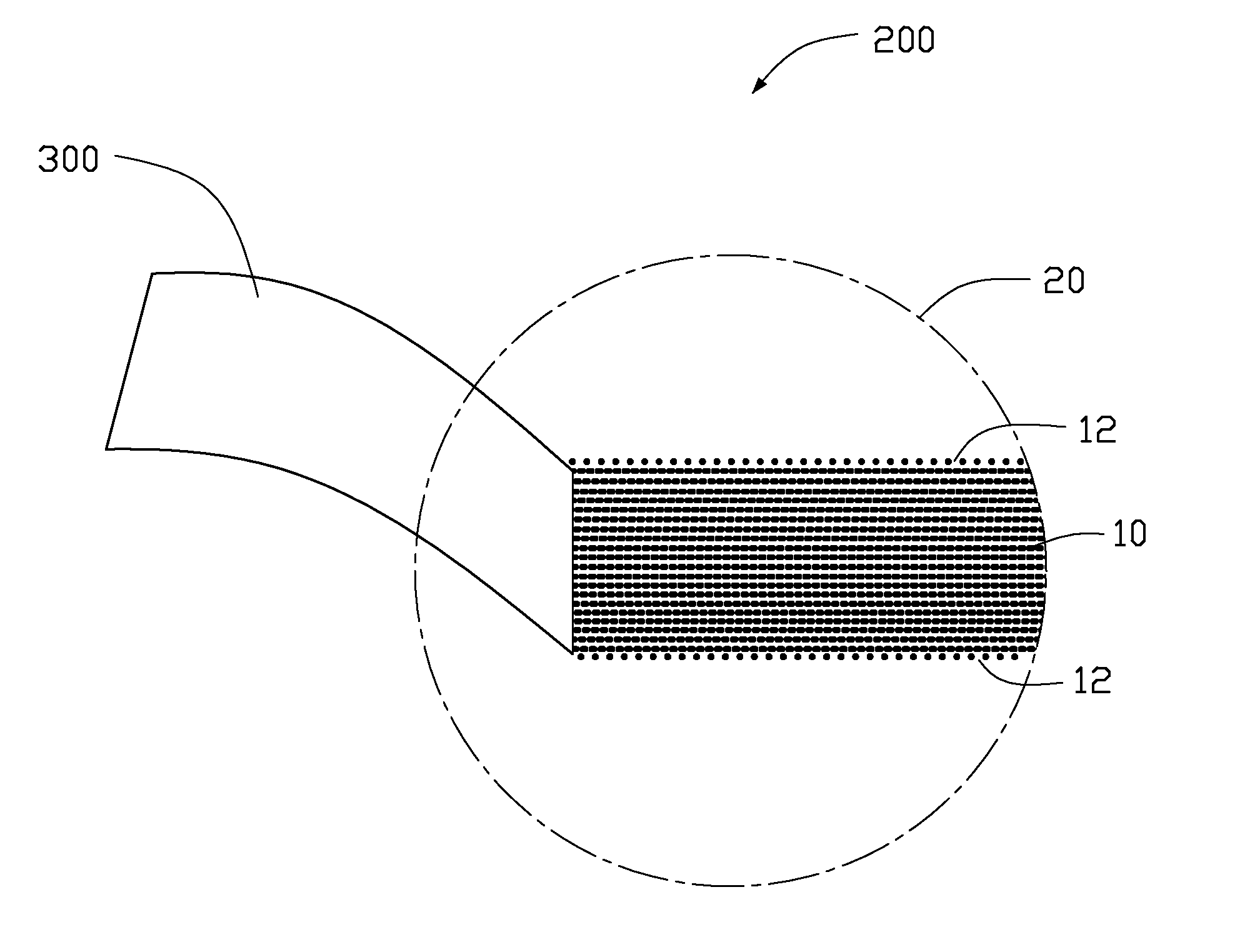

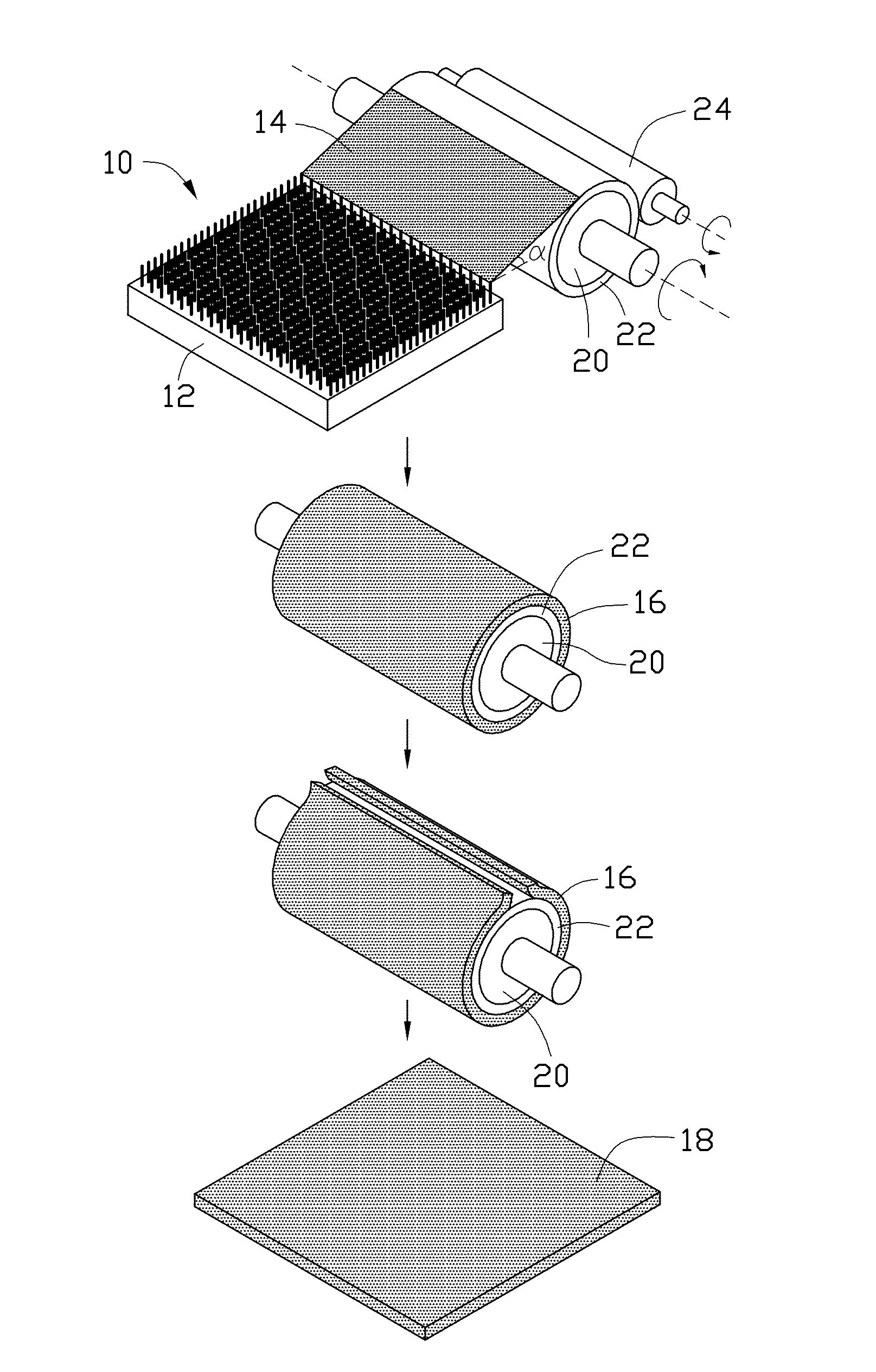

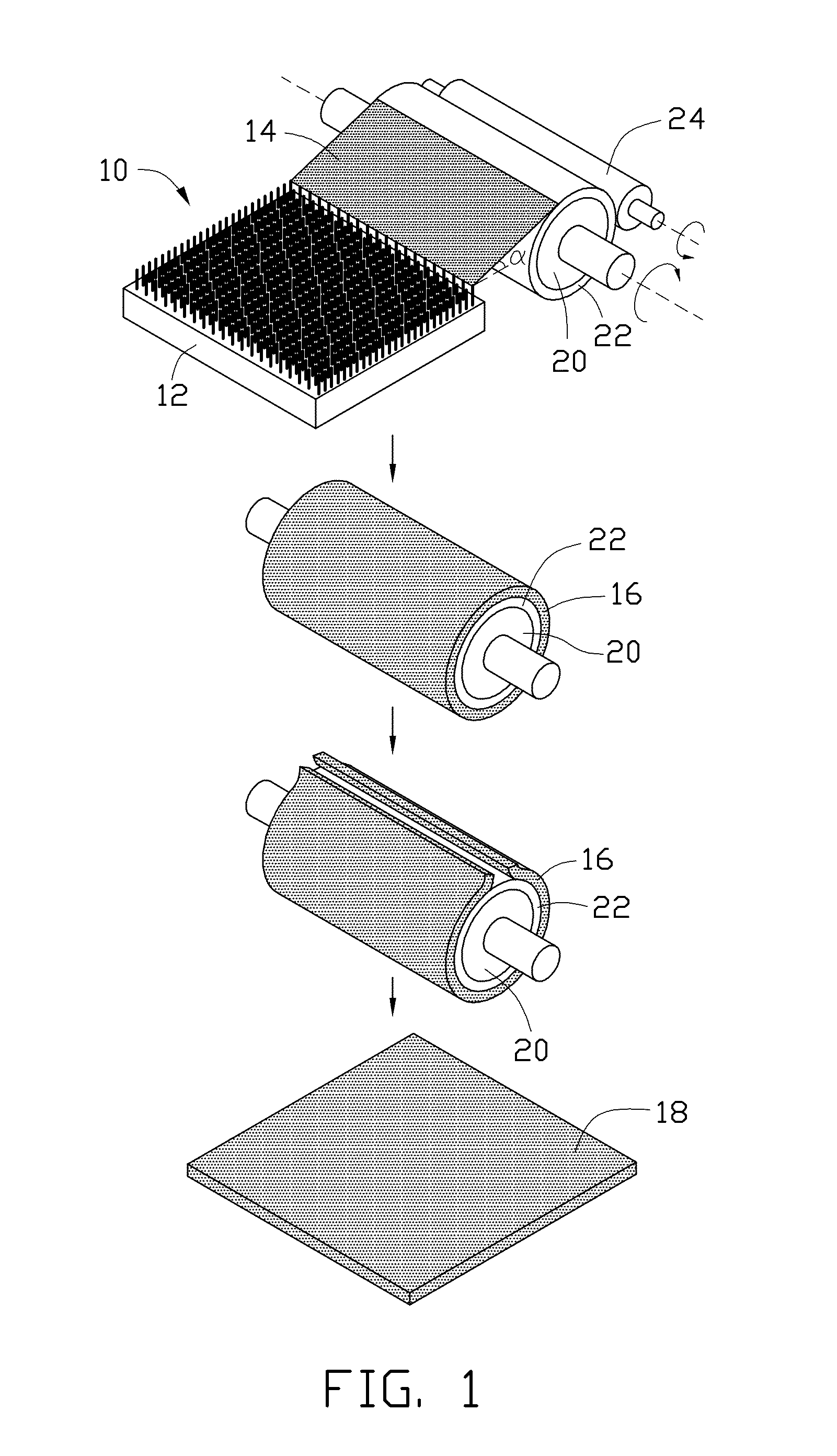

Method for making carbon nanotube film structures

ActiveUS20130146215A1Lamination ancillary operationsCarbon compoundsCarbon nanotubeNanotube membrane

A method for making a carbon nanotube film structure is related. A rotator having an axis and a rotating surface is provided. A carbon nanotube film drawn from a carbon nanotube array is adhered on the rotating surface of the rotator. The rotator is rotated about the axis to wrap the carbon nanotube film on the rotating surface of the rotator to form a carbon nanotube layer. The carbon nanotube layer is cut along a direction to form the carbon nanotube film structure.

Owner:BEIJING FUNATE INNOVATION TECH

One-dimensional organic semiconductor nanotube with fluorescent response to organic amine gas and preparation method and application of one-dimensional organic semiconductor nanotube

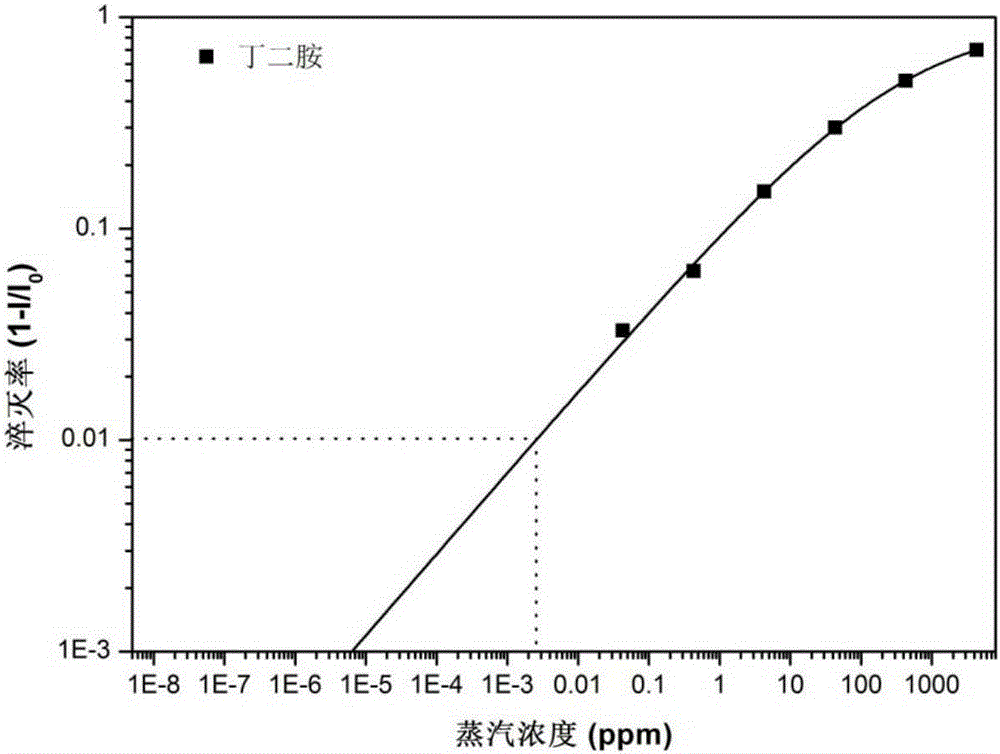

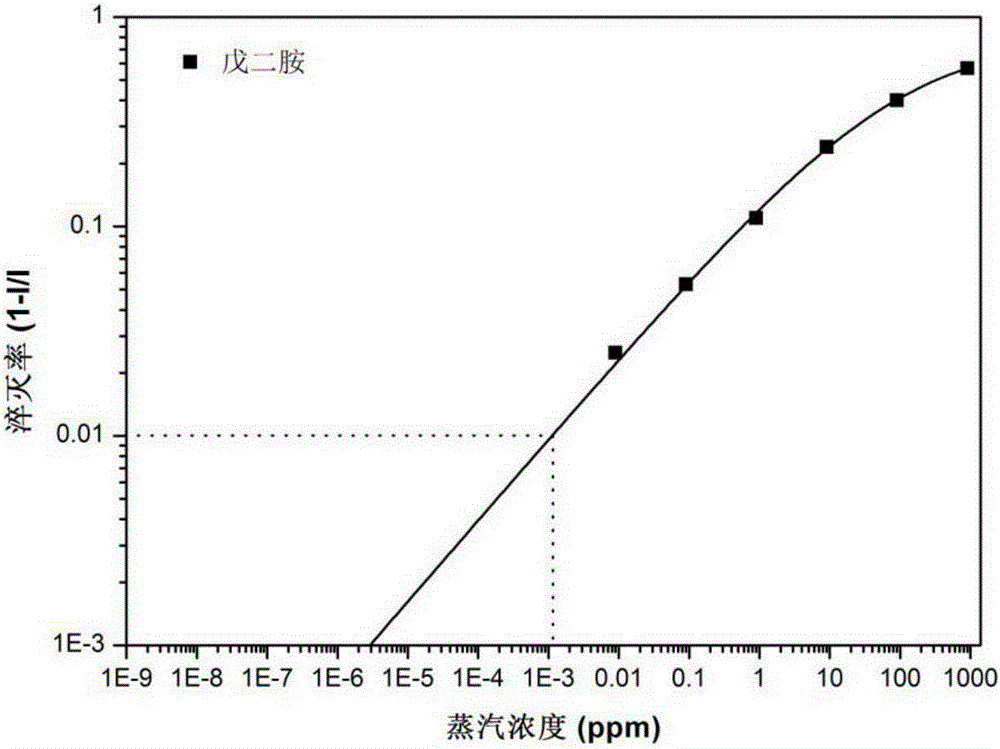

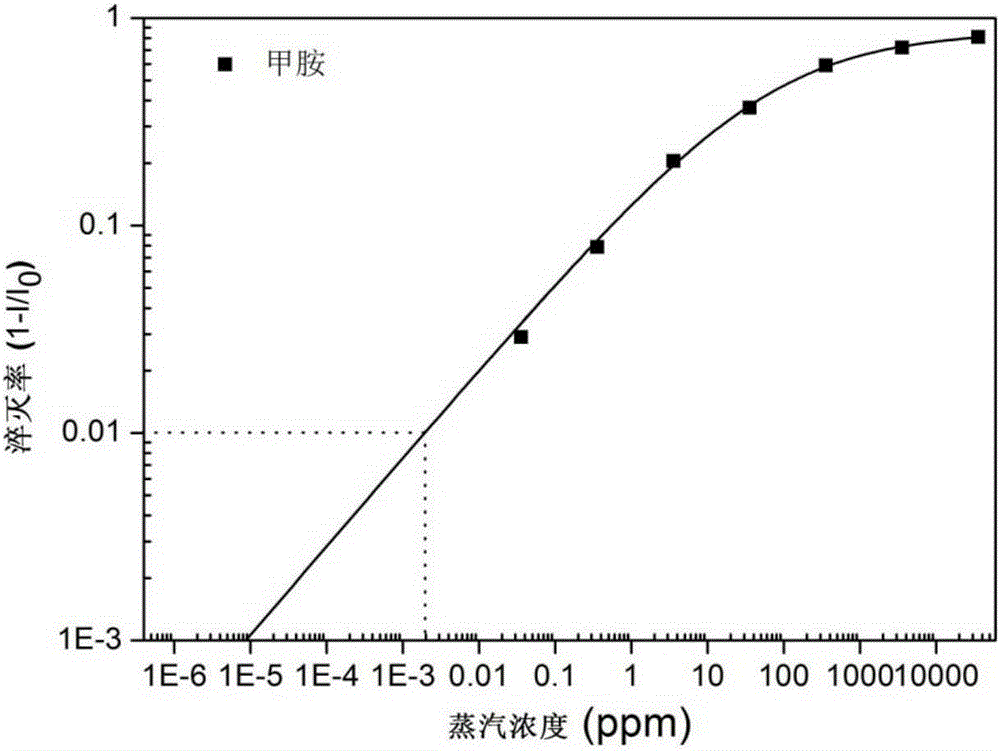

ActiveCN105175417AHigh fluorescence quantum yieldFacilitate adsorption and diffusionOrganic chemistryFluorescence/phosphorescenceQuantum yieldGlass sheet

The invention relates to a one-dimensional organic semiconductor nanotube and a preparation method thereof. The one-dimensional organic semiconductor nanotube is formed by self-assembling a plurality of perylene bisimide derivatives with asymmetric amphipathic substituent groups at the two ends through the pai-pai interaction between perylene bisimide. The obtained one-dimensional organic semiconductor nanotube has a high fluorescence quantum yield (up to 50%). The organic nanotube suspending in a solution can be smeared to different substrates, such as glass sheets, silicon wafers and tetrafluoroethylene films, through a direct dripping film forming or rotary film forming method. The prepared organic nanotube films are provided with porous net structures, and organic amine molecules can be dispersed in the films. When the naotube is in contact with gas (with the concentration lower than the ppb grade) generated by bad meat and seafood products, the fluorescence intensity can be quenched. The safety condition of meat food can be detected with high sensitivity through the provided fluorescence method.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for preparing titanium dioxide nanotube membrane

InactiveCN101717984APromote exchangeImprove photocatalytic performanceNanostructure manufactureSurface reaction electrolytic coatingElectrolysisHigh voltage pulse

The invention discloses a method for preparing a titanium dioxide (TiO2) nanotube membrane with two permeable ends of a nanotube thereof. The method for preparing the titanium dioxide nanotube membrane comprises the following steps of: firstly, generating a titanium dioxide membrane with a required thickness on the surface of a titanium substrate material in a mode of electrolytic oxidation; secondly, thinning a barrier layer at the bottom of the titanium dioxide nanotube membrane by adopting gradual voltage-lowering oxidation; and finally, applying a high-voltage pulse higher than an anode oxidation voltage to continue oxidizing after finishing the last process until the titanium dioxide nanotube membrane with two permeable ends is shed from the substrate.

Owner:LANZHOU UNIVERSITY

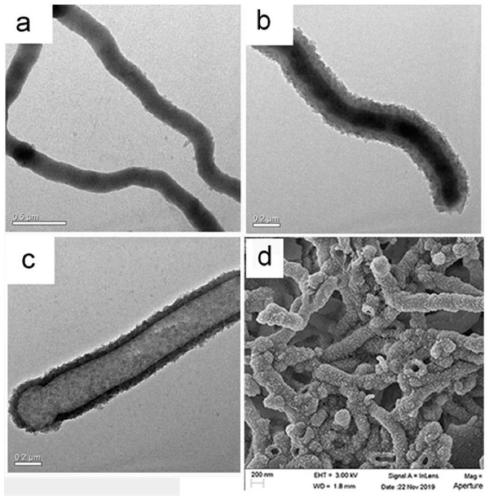

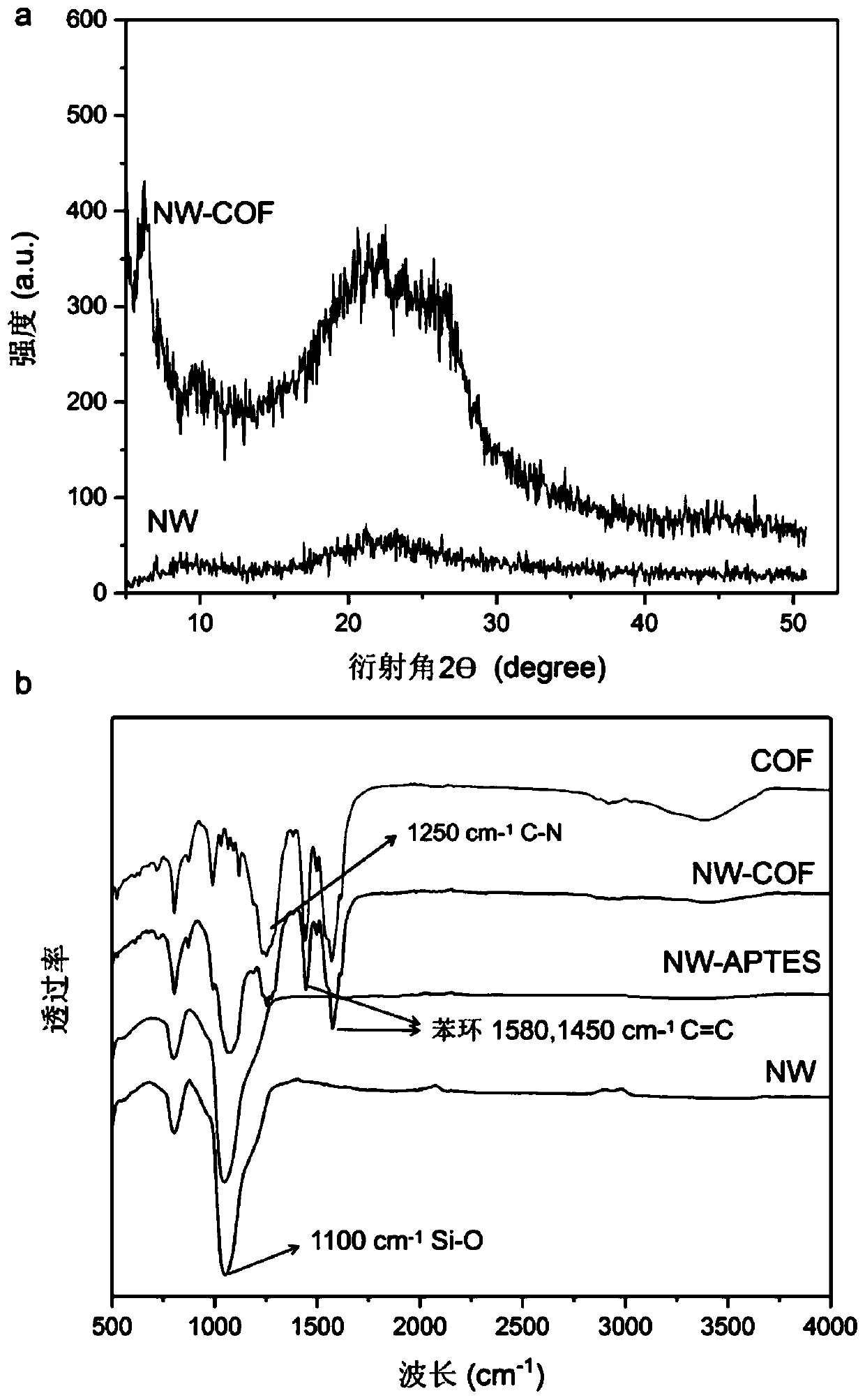

Covalent organic framework (COF) nanotube, and preparation method and application thereof

The invention belongs to the technical field of nanometer materials, and particularly relates to a COF nanotube, and a preparation method and application thereof. According to the method, silicon dioxide nanowires are used as a hard template, and the silicon dioxide nanowires can be deposited on the surfaces of stainless steel wires and other materials through soaking and extraction methods to form a silicon dioxide nanowire film; and with the dispersed silicon oxide nanowires or the film with the deposited silicon dioxide nanowires as a substrate, a layer of COF film grows in situ, and the silicon oxide nanowire template is etched to respectively obtain the dispersed COF nanotube and a stainless steel wire modified by a COF nanotube film. Due to rich micropores of the COF, the COF nanotube has a very high specific surface area, and a hollow pipeline structure provides a rapid substance transmission channel for molecules, so the COF nanotube is an ideal separation and enrichment material and can be used for effectively enriching trace organic pollutants in a solution. The stainless steel wire modified by the COF nanotube film can be used as a stainless steel wire solid-phase micro-extraction head and is used as a pretreatment material for quantitative enrichment and purification of harmful substances.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com