Covalent organic framework (COF) nanotube, and preparation method and application thereof

A technology of covalent organic frameworks and nanotubes, applied in the field of nanomaterials, can solve the problems of inability to obtain continuous and uniform COFs films, difficulty in polycrystalline powders, and insufficient stability of film formation, and achieve easy industrial scale-up production, good adsorption performance, Operational Security Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

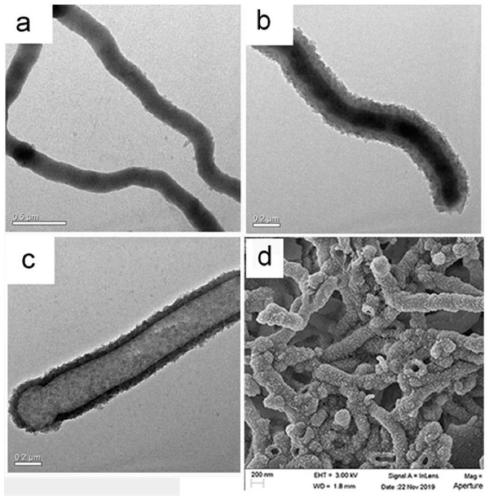

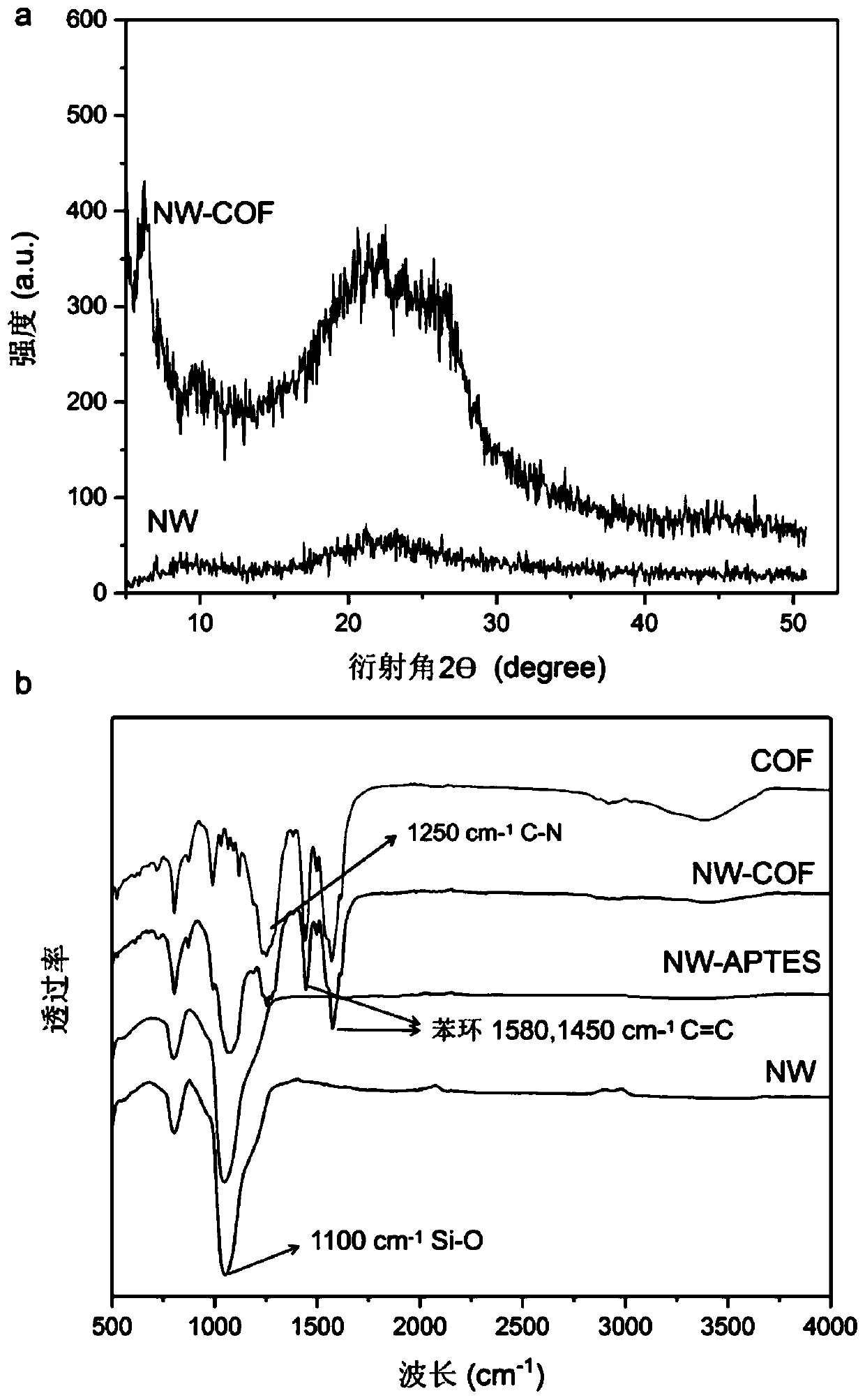

[0052] Example 1: Mix APTES-modified silica nanowires, trialdehyde phloroglucinol, glacial acetic acid, and dioxane at a ratio of 1:1:10:1000, and seal the tube at 130°C under an inert atmosphere 1 hour, and washed once each with tetrahydrofuran and dioxane. Then the material is dispersed in dioxane, trialdehyde group phloroglucinol modified silica nanowires and trialdehyde group phloroglucinol, 3,3'-dimethyl benzidine, glacial acetic acid, two Oxyhexane was mixed at a ratio of 1:1:1.5:5:1000, and the reaction was sealed under an inert atmosphere at 130°C for 72 hours, and washed once with acetone and methanol. The obtained COF tubes were dispersed in acetone, and a 0.001 g / mL solution was prepared, and a filter funnel with a sand core with a diameter of 0.5 cm was used for suction filtration to prepare a COF tube self-assembled membrane.

Embodiment 2

[0053] Example 2: Mix APTES-modified silica nanowires, trialdehyde phloroglucinol, glacial acetic acid, and dioxane at a ratio of 1:1:10:1000, and seal the tube at 130°C under an inert atmosphere 1 hour, and washed once each with tetrahydrofuran and dioxane. Then the material is dispersed in dioxane, trialdehyde group phloroglucinol modified silica nanowires and trialdehyde group phloroglucinol, 3,3'-dimethyl benzidine, glacial acetic acid, two Oxyhexane was mixed at a ratio of 1:1:1.5:5:1000, and the reaction was sealed under an inert atmosphere at 130°C for 72 hours, and washed once with acetone and methanol. After soaking in 5M HF for 5 min, the silica substrate was removed to form a hollow COF tube. The obtained COF tubes were dispersed in acetone, and a 0.001 g / mL solution was prepared, and the COF nanotube self-assembled membrane was prepared by suction filtration using a sand core suction filter funnel with a diameter of 0.5 cm.

Embodiment 3

[0054] Example 3: Mix APTES-modified silica nanowires, trimesaldehyde, glacial acetic acid, and dioxane at a ratio of 1:1:10:1000, and seal the tube at 130°C for 1 hour under an inert atmosphere. Wash once more with tetrahydrofuran and once with dioxane. Then the material is dispersed in dioxane, trimylene triglyceraldehyde modified silica nanowires and trimylene triglyceraldehyde, 3,3'-dimethylbenzidine, glacial acetic acid, dioxane with 1: Mix at a ratio of 1:1.5:5:1000, seal the tube at 130°C for 72 hours under an inert atmosphere, and wash once with acetone and methanol. After soaking in 5M HF for 5 minutes, the silica substrate can be removed to form a hollow COF tube. The obtained COF tubes were dispersed in acetone, and a 0.001 g / mL solution was prepared, and the COF nanotube self-assembled membrane was prepared by suction filtration using a sand core suction filter funnel with a diameter of 0.5 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

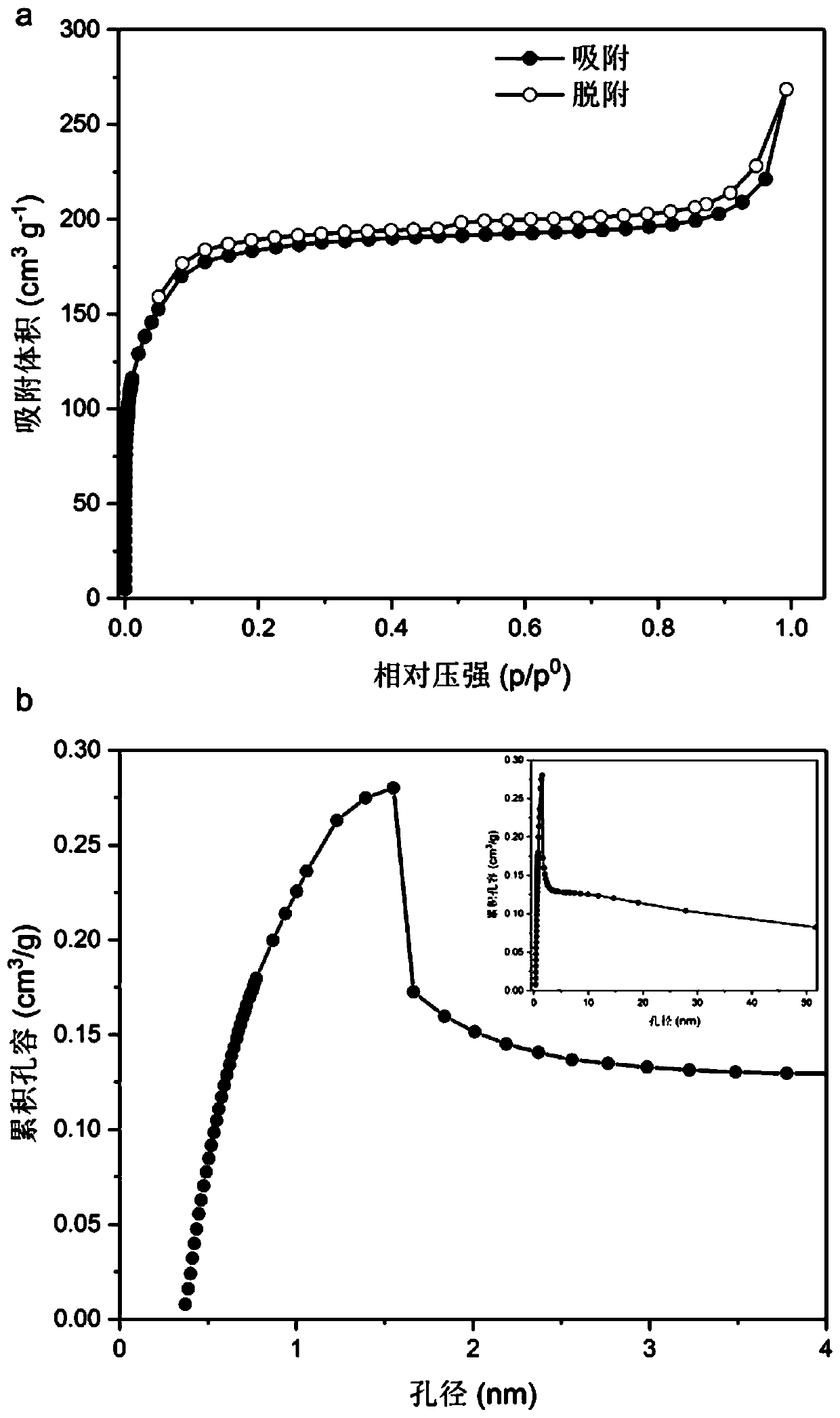

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com