Reverse osmosis membrane, preparation method and application thereof

A technology of reverse osmosis membrane and porous filter membrane, which is applied in the field of material preparation technology and membrane separation, can solve the problem of no relevant research reports on reverse osmosis membrane, achieve excellent mechanical and chemical stability, achieve ultra-thin thickness and high quality, The effect of good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

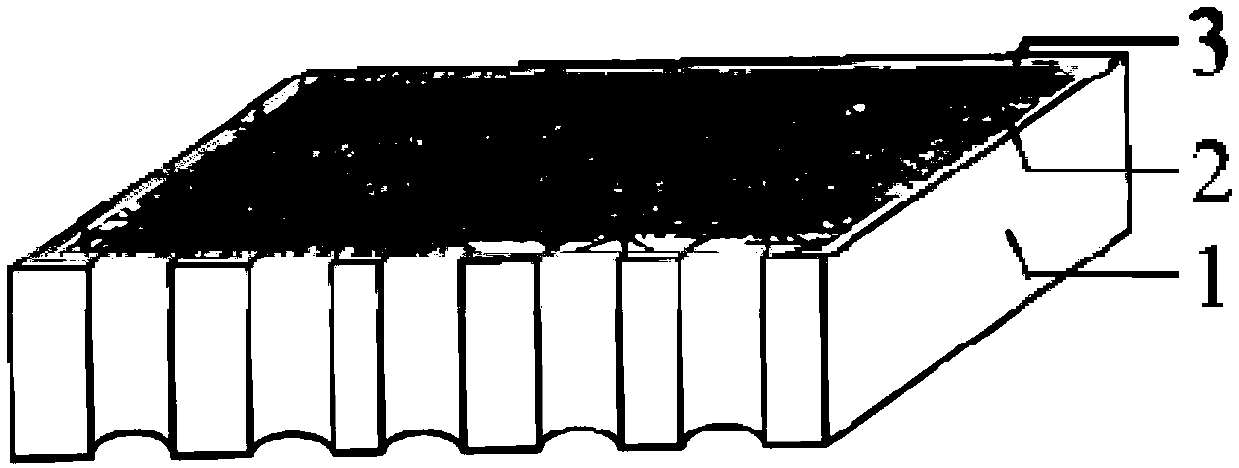

[0046] The embodiment of the present invention also provides a method for preparing the aforementioned reverse osmosis membrane, comprising:

[0047] (1) The dispersion of carbon nanotubes or carbon nanotubes modified by hydrophilic materials is loaded on the surface of the porous filter membrane to obtain a network of carbon nanotubes formed by interspersed stacking of carbon nanotubes or carbon nanotubes modified by hydrophilic materials membrane;

[0048] (2) dissolving polyamines in water, and preparing an aqueous phase solution with a concentration of 0.01g / L to 10g / L; dissolving polyacyl chlorides in an organic solvent, and preparing an organic phase solution with a concentration of 0.001g / L to 10g / L;

[0049] (3) the surface of the carbon nanotube film is contacted with the aqueous solution, and the aqueous solution remaining on the surface of the carbon nanotube film is removed after the aqueous solution completely wets the surface of the carbon nanotube film; The sur...

Embodiment 1

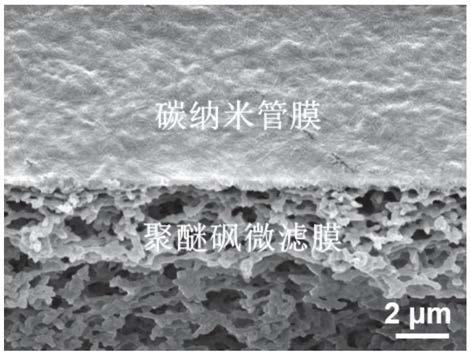

[0066] The polydopamine-modified single-walled carbon nanotubes were loaded onto a polyethersulfone microfiltration membrane with a pore size of 0.22 μm by brushing to obtain a carbon nanotube membrane with a thickness of about 80 nm and an effective pore size of about 30 nm. Prepare an aqueous solution of m-phenylenediamine with a concentration of 0.1 g / L, and a solution of trimesoyl chloride-n-hexane with a concentration of 0.1 g / L. Put the carbon nanotube membrane loaded on the polyethersulfone microfiltration membrane in the m-phenylenediamine solution for 60 seconds, remove the excess m-phenylenediamine solution on the membrane surface with an air knife after taking out the membrane, and then place the membrane in a homobenzene Triformyl chloride solution for 60 seconds. After taking out the membrane, wash the membrane with n-hexane to remove excess trimesoyl chloride solution on the membrane surface. The membrane was heat-treated at 90° C. for 2 minutes to finally obtai...

Embodiment 2

[0069] The polydopamine-modified double-walled carbon nanotubes were loaded onto a polyethersulfone microfiltration membrane with a pore size of 0.22 μm by brushing to obtain a carbon nanotube membrane with a thickness of about 80 nm and an effective pore size of about 30 nm. Prepare an aqueous solution of m-phenylenediamine with a concentration of 2 g / L, and a solution of trimesoyl chloride-n-hexane with a concentration of 0.1 g / L. Put the carbon nanotube membrane loaded on the polyethersulfone microfiltration membrane in the m-phenylenediamine solution for 60 seconds, remove the excess m-phenylenediamine solution on the membrane surface with an air knife after taking out the membrane, and then place the membrane in a homobenzene Triformyl chloride solution for 30 seconds. After taking out the membrane, wash the membrane with n-hexane to remove excess trimesoyl chloride solution on the membrane surface. Heat-treat the membrane at 90 °C for 2 min, place the membrane in 0.1 g / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com