Multifunctional high-efficiency filter screen capable of cleaning and method for producing the same

A manufacturing method and filter screen technology, which are applied in filtration and separation, separation methods, dispersed particle filtration, etc., can solve the problems of low filtration efficiency, static electricity loss, and filtration efficiency decline, and achieve higher dust holding capacity, less deformation, and increased use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

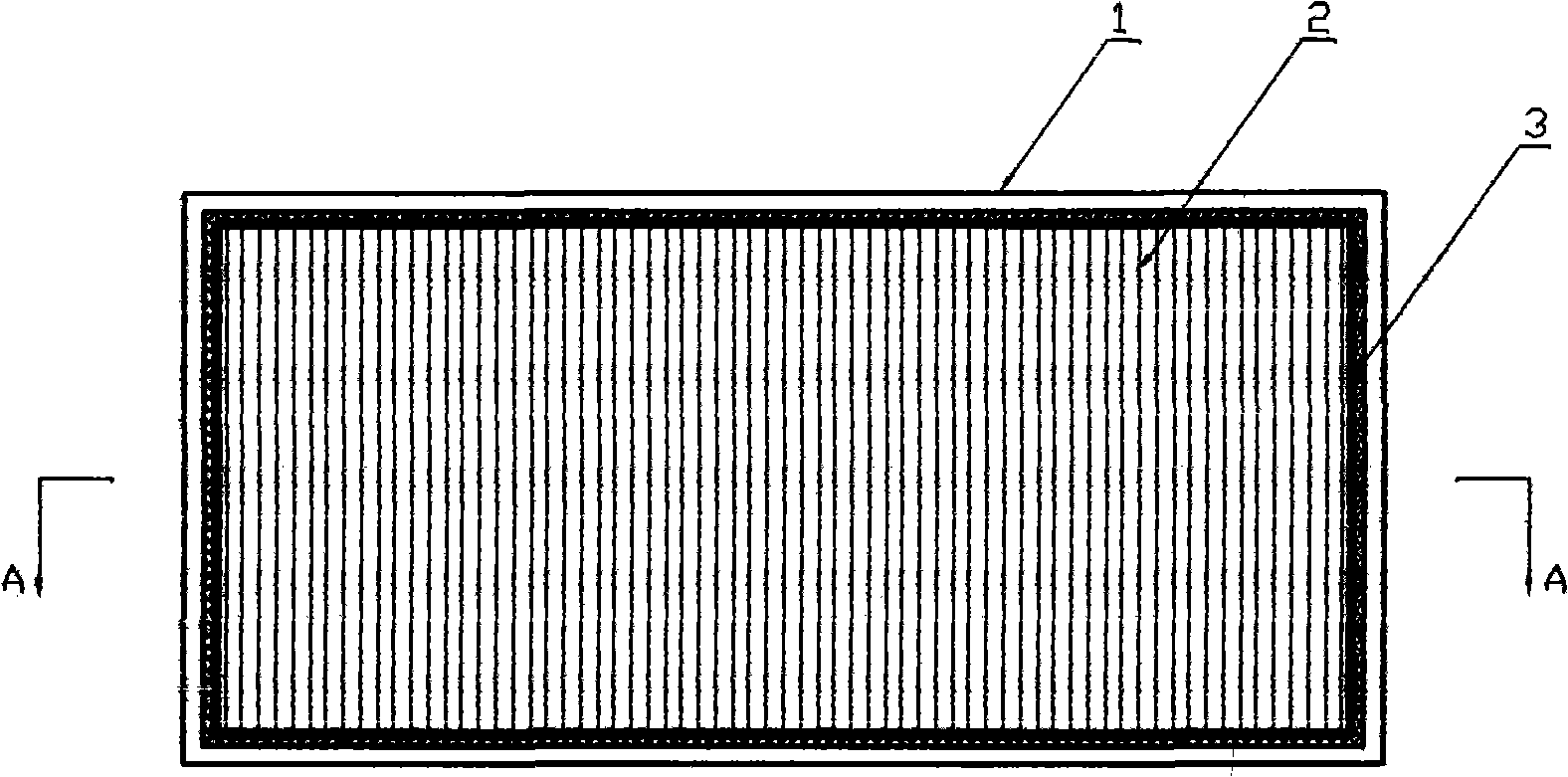

[0025] A kind of multifunctional high-efficiency cleanable filter screen and its manufacturing method: such as figure 1 , figure 2 , image 3 As shown, the multi-function, high-efficiency and cleanable filter screen includes a frame 1, a multi-purpose cleanable filter material 2, a multi-functional filter screen 4, and glass fibers 5 are fixed in the frame 1 by adhesives 3. The cleanable filter material 2 is formed by superimposing two layers of reinforcement net 6 , filter material 7 and glass fiber 8 . Its manufacturing method is that two layers of multi-functional reinforcing net 6 sandwich a layer of filter material 7 and a layer of glass fiber 8, process it with a folding machine, and then process it into the required size with a cutting machine, and then compound the multi-functional filter net 4 and The glass fiber 5 is finally fixed in the frame 1 by an adhesive 3 . The multifunctional and cleanable filter material 2 and the frame 1 can be injection molded at one t...

Embodiment 2

[0028] A multi-functional high-efficiency cleanable filter screen and its manufacturing method, characterized in that: a multi-functional high-efficiency cleanable filter screen, including a frame 1, characterized in that: multiple cleanable filter materials 2, multi-functional filter screen 4, glass The fibers 5 are fixed in the frame 1 by adhesives 3 . The cleanable filter material 2 is formed by superimposing two layers of reinforcement net 6 , filter material 7 and glass fiber 8 . Its manufacturing method is that two layers of multi-functional reinforcing net 6 are sandwiched with a layer of filter material 7 and a layer of glass fiber 8, processed by a folding machine, and then processed into a suitable size by a cutting machine, and then compounded with multi-functional filter net 4 and glass fiber. The fibers 5 are finally fixed in the frame 1 by adhesives 3 . The multifunctional and cleanable filter material 2 and the frame 1 can be injection molded at one time.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com