High-efficient low-resistance compound filter material and preparation method thereof

A filter material and composite filtration technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of low filtration efficiency, poor stiffness, instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 Preparation of high-efficiency and low-resistance composite filter material

[0029] Put the melt-blown filter material and glass fiber filter material on the discharge rack, pass through the guide roller, apply fiber glue to the surface of the glass fiber with a hot-melt adhesive fiber gun, then attach the melt-blown filter material to it, and finally wind up finished product.

[0030] The fineness of the hot melt adhesive fiber is 30 microns, and the amount of viscose glue per square is 5g.

[0031] The melt-blown filter material is prepared by the following process: the modified polypropylene chips are extruded through the spinneret in a molten state, and the melt leaving the spinneret holes is blown into ultrafine fibers under the action of high-speed hot air, The fibers fly to the condensate curtain at high speed to form a fiber web, and then formed by electret to obtain a melt-blown filter material. The physical parameters of the prepared meltblown ...

Embodiment 2

[0037] The preparation conditions of the melt-blown and glass fiber materials in Example 1 were changed to obtain composite filter materials with different thicknesses, fineness, grammage, filtration efficiency and resistance.

[0038] The physical parameters of the prepared meltblown filter material are: thickness = 0.10mm, gram weight = 15g / m 2 , Filtration efficiency = 81% (test particle size: 0.3 μm, test filtration rate 5.3cm / s), resistance = 13Pa.

[0039] The physical parameters of the prepared glass fiber filter material are: thickness=0.20mm, gram weight=65g / m 2 , Filtration efficiency = 92% (test particle size: 0.3 μm, test filtration rate 5.3cm / s), resistance = 88Pa.

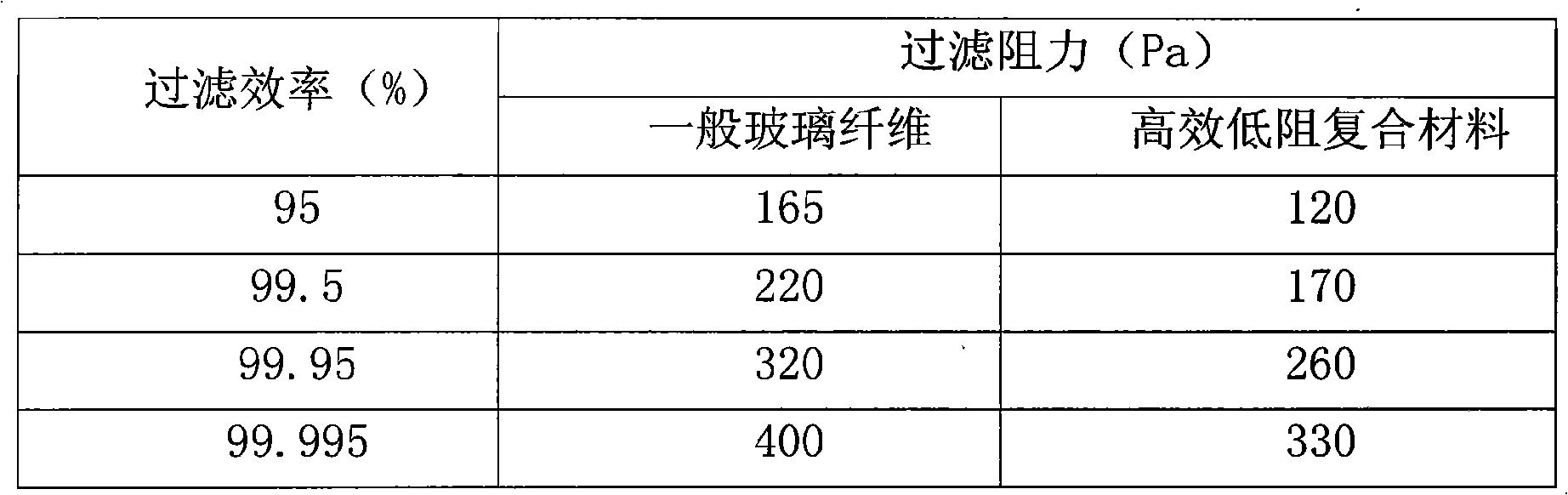

[0040]The performance test results of the high-efficiency and low-resistance composite filter material obtained by combining two layers of melt-blown filter material with the two surfaces of a layer of glass fiber filter material are shown in Table 3:

[0041] table 3

[0042] Filtration e...

Embodiment 3

[0044] The preparation conditions of the melt-blown and glass fiber materials in Example 1 were changed to obtain composite filter materials with different thicknesses, fineness, grammage, filtration efficiency and resistance.

[0045] The physical parameters of the prepared meltblown filter material are: thickness = 0.14mm, gram weight = 25g / m 2 , Filtration efficiency = 96% (test particle size: 0.3 μm, test filtration rate 5.3cm / s), resistance = 18Pa.

[0046] The physical parameters of the prepared glass fiber filter material are: thickness=0.20mm, gram weight=65g / m 2 , Filtration efficiency = 99.7% (test particle size: 0.3 μm, test filtration rate 5.3cm / s), resistance = 220Pa.

[0047] The performance test results of the high-efficiency and low-resistance composite filter material obtained by combining a layer of melt-blown filter material with a layer of glass fiber filter material are shown in Table 4:

[0048] Table 4

[0049] Filtration efficiency (%)

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com