Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

120results about How to "Large dust holding capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

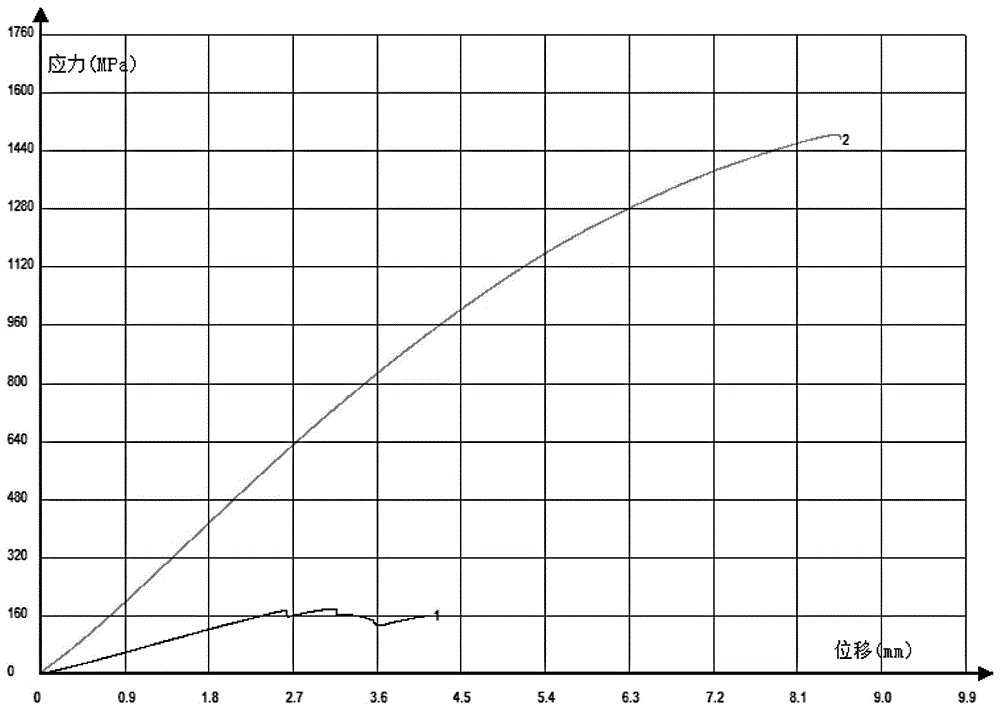

Melt-blow non-woven material capable of effectively filtering PM 2.5 particles, preparation method and production device

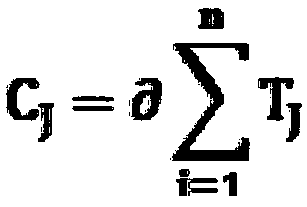

ActiveCN104153119AHigh filtration efficiencyImprove dust collection effectHeating/cooling textile fabricsUltrasonic/sonic fibre treatmentPorosityEngineering

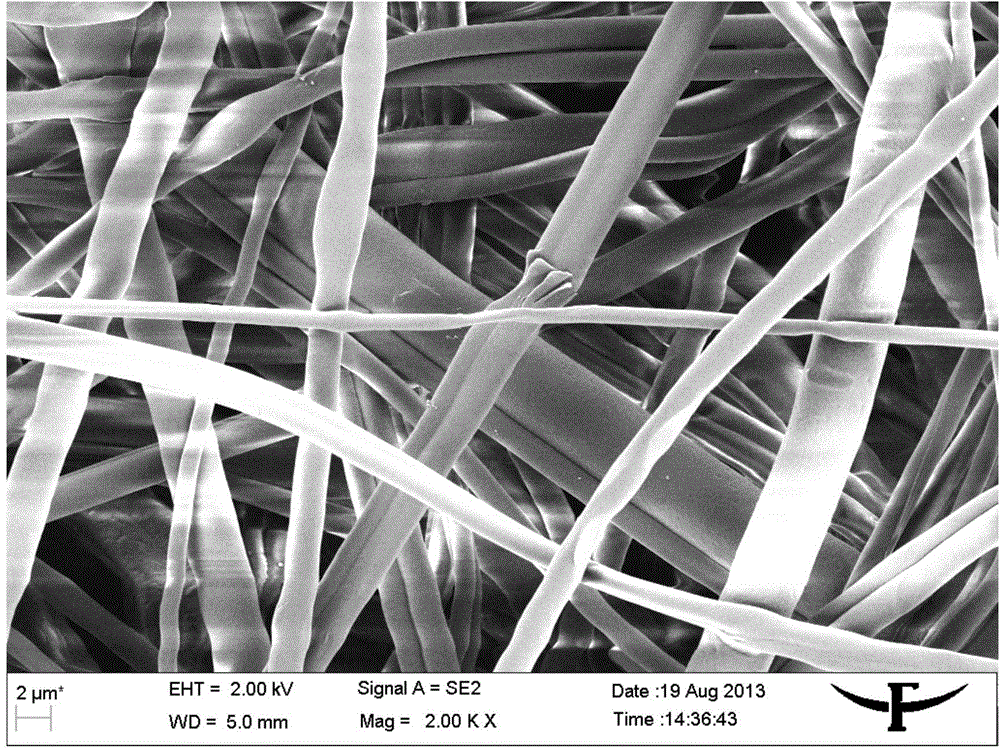

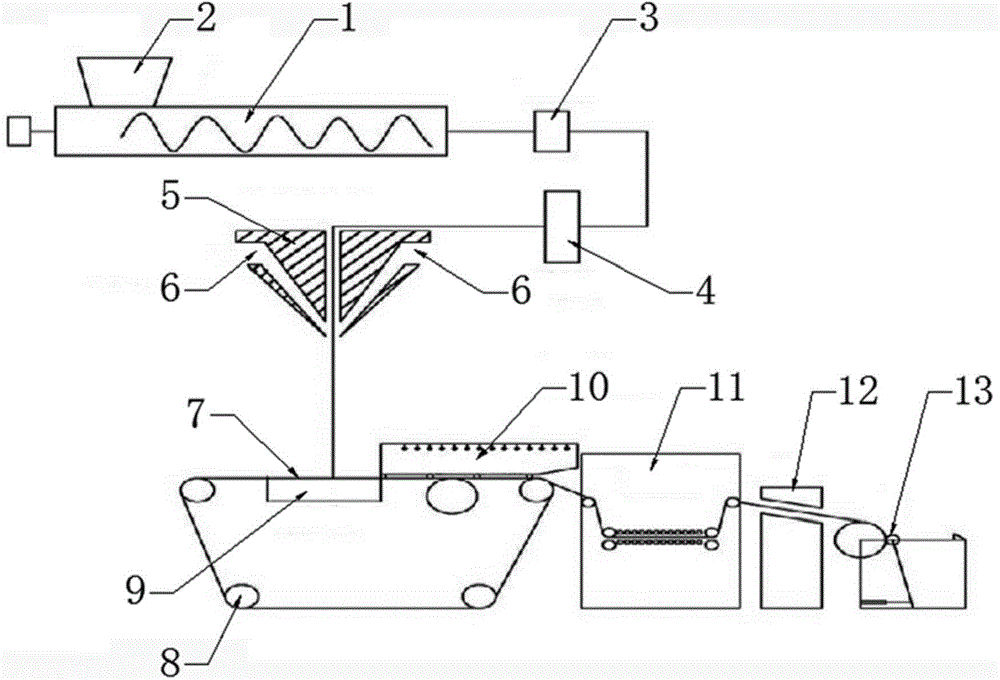

The invention discloses a melt-blow non-woven material capable of effectively filtering PM 2.5 particles, a preparation method and a production device. The melt-blow non-woven material comprises, by weight percentage, 93-97 parts of polypropylene, 3-6 parts of electret master batch and 0.1-1 part of polyvinylidene fluoride. According to the melt-blow non-woven material capable of effectively filtering PM 2.5 particles, the polypropylene, the electret master batch and the polyvinylidene fluoride are compounded, the obtained melt-blow non-woven material is characterized by high porosity, the fiber diameter of smaller than two micrometers, large clogging capacity, high filtering efficiency and low resistance, an electret is good in charge storage performance after electret processing, the charge keeping rate can be above two years, and the electret can be used in a high-temperature and high-humidity environment. The product is environmentally friendly and free of pollution, has the advantages of being long in service life and wide in use range, and is particularly suitable for removing PM 2.5 particles in the air.

Owner:DO FLUORIDE CHEM CO LTD

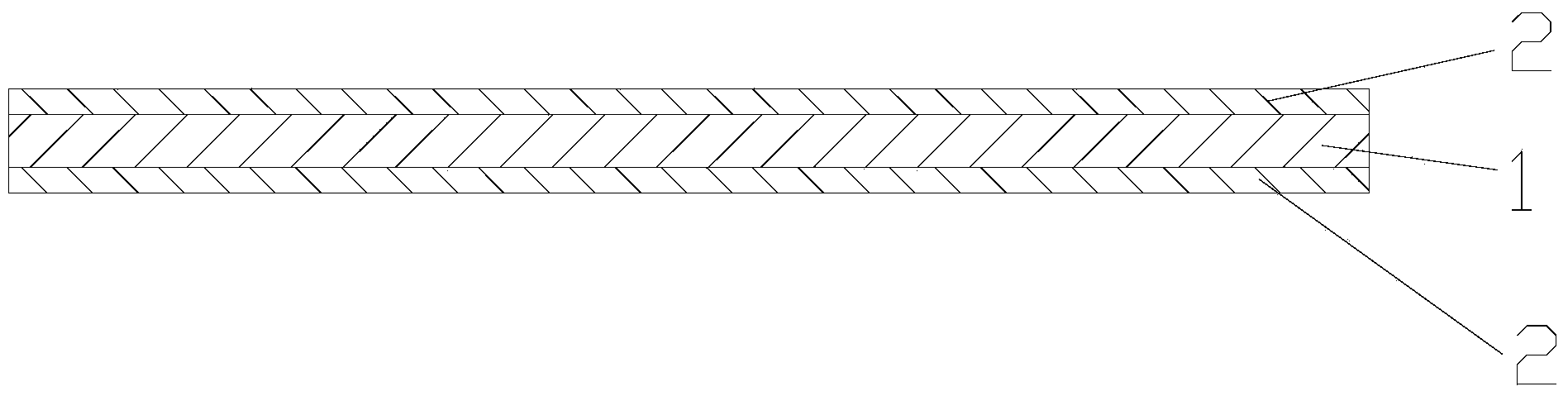

Needling static filter cotton and preparation method thereof

ActiveCN103537142ASmall filter resistanceLarge dust holding capacitySynthetic resin layered productsUltrasonic/sonic fibre treatmentBrute forcePressure resistance

The invention discloses needling static filter cotton. The needling static filter cotton comprises a needling non-woven layer, wherein any surface or two surfaces of the upper surface and the lower surface of the needling non-woven layer is or are provided with a spunbonded nonwoven fabric layer. A preparation method of the needling static filter cotton comprises the following steps of producing a needling cotton, drying, compositing the needling cotton, applying static electricity and packaging a finished product. The needling static filter cotton provided by the invention has the advantages that the needling cotton is composited, the wind pressure resistance of the needling cotton is enhanced, so that the needling cotton plays the supporting role, the high-density electrostatic charge is applied on the needling cotton, so that not only is the filter efficiency greatly improved to enable the filtration efficiency to be more than 98%, and also the filtration resistance is greatly reduced to be reduced to be below 7Pa. The needling static filter cotton after processing has the outstanding characteristics that the filtration efficiency is high, the filtration resistance is ultralow and the service life is long, the physical properties such as longitude and latitude brute force property and a wear-resisting property are excellent, and the needling static filter cotton is greatly superior to the common melt-blow static filter cotton at present.

Owner:常州百朋纺织有限公司

Composite active carbon rod filter element and preparation method

ActiveCN105771422ALow costFlat surfaceOther chemical processesTreatment involving filtrationPolymer sciencePorous carbon

The invention discloses a composite active carbon rod filter element which is prepared from the following components in percentage by weight: 30 to 50 percent of active carbon powder, 5 to 10 percent of zeolite powder, 5 to 10 percent of a porous carbon nano material, 5 to 10 percent of oxidized graphene, 5 to 15 percent of a pore-forming agent, 30 to 50 percent of a macromolecular adhesive and 0 to 10 percent of antibacterial macromolecules, wherein the macromolecular adhesive is formed by mixing ultra-high molecular weight polyethylene and low-temperature polyethylene according to the weight ratio of (7:3)-(5:5). The invention further discloses a preparation method of the composite active carbon rod filter element. The composite active carbon rod filter element prepared by the preparation method has the advantages of high strength, large flux, powerful function, long life, low cost and the like, and can be repeatedly used after being subjected to simple treatment in the process of applying a sewage treatment station or a large-size water treatment system.

Owner:XIAMEN BAILIN WATER PURIFICATION TECH CO LTD

DE type air purification filter material and method for processing the same

ActiveCN101219308AImprove density uniformitySimple structureFiltration separationDomestic articlesFiberPolyester

The invention adopts hollow polyester fiber, polyester short fiber and ES fiber according to mixture ratio of 1-4:1-4:2-8, including the steps of loosening-> quantitative feeding-> hot melting->cold roll forming->hot rolling->air cooling->trim cutting. The fiber of the invention is conglutinated after hot melting treatment; therefore, fiber pad has good toughness and uniform density and stable structure; the produced filtering material has large pore space, good loading capacity which is difficult to be deformed with small resistance and large dust holding performance and good filtering effect.

Owner:丹东天皓净化材料有限公司

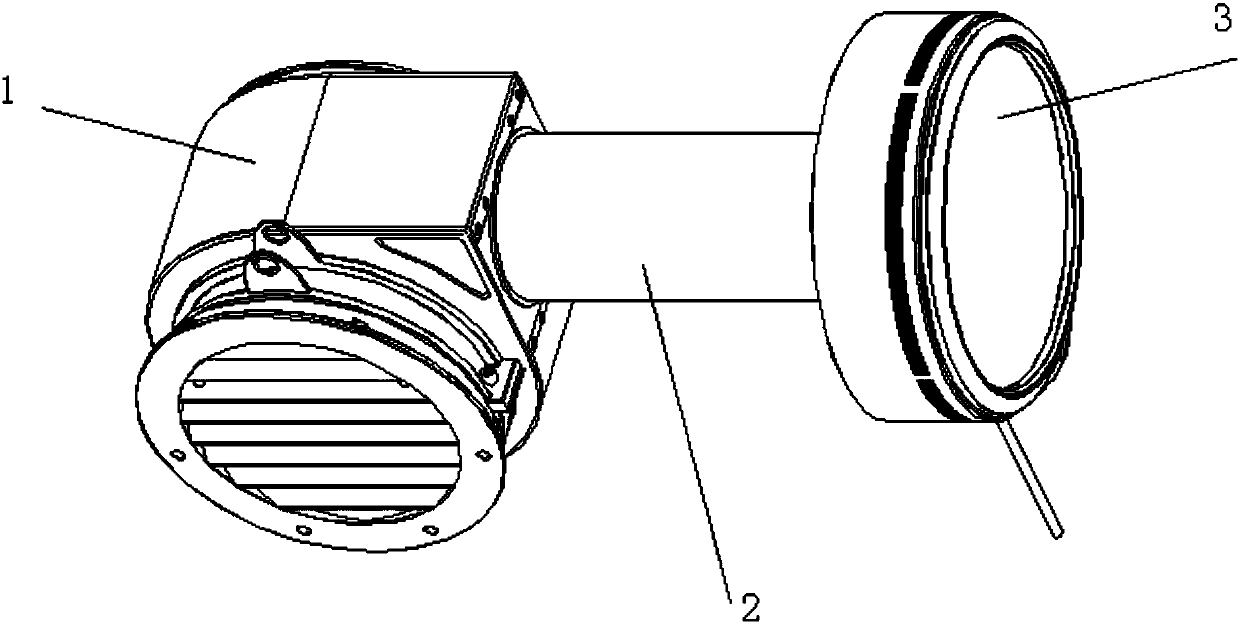

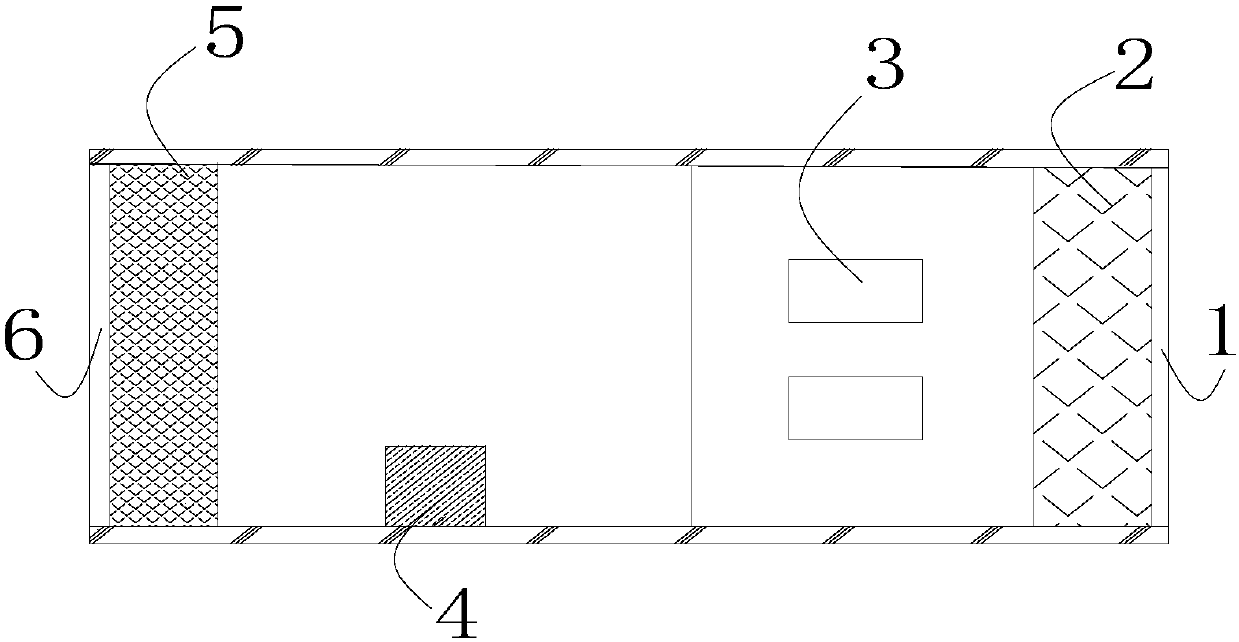

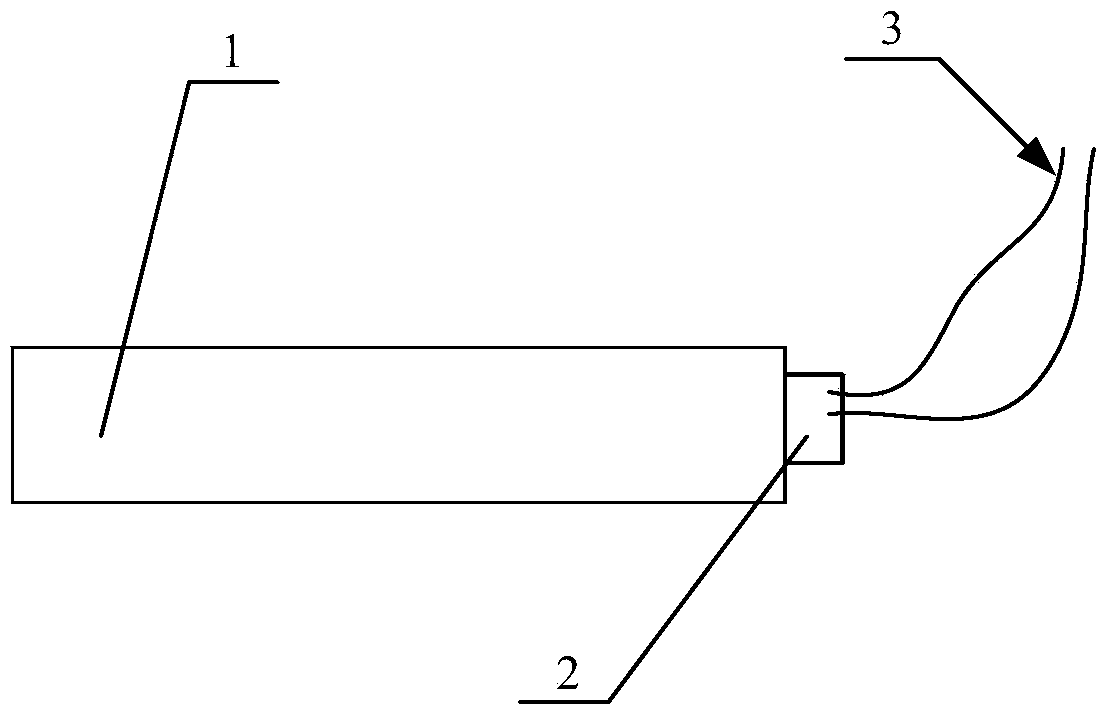

Fresh air system with indoor unit and outdoor unit of separated structure and mounting method

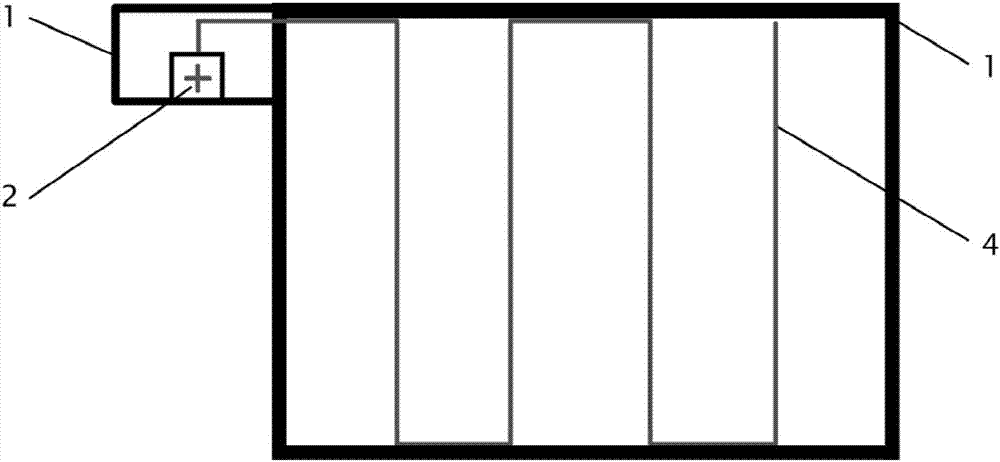

PendingCN107702266AReduce concentrationPrevent mildewLighting and heating apparatusNoise suppressionFresh airEnvironmental engineering

The invention discloses a fresh air system with an indoor unit and an outdoor unit of a separated structure and a mounting method. The fresh air system with the indoor unit and the outdoor unit of theseparated structure comprises a filter and a fan, and is characterized in that the fresh air system further comprises the indoor unit, the outdoor unit and a connecting pipe; the indoor unit is arranged indoors, the filter is arranged in the indoor unit, and a filter screen is arranged in the filter; the outdoor unit is arranged outdoors, and the fan is arranged in the outdoor unit; and the indoor unit and the outdoor unit are connected through the connecting pipe penetrating through a wall. According to the fresh air system with the indoor unit and the outdoor unit of the separated structure, the indoor unit and the outdoor unit are designed independently and connected through the connecting pipe, a noise source can be isolated through the wall, and thus a high-power fan can be adopted;noise can be effectively lowered, the air purification effect is good, and the fresh air system can be mounted conveniently and safely and fully meets the requirement for domestic air purification; and the filter screen is arranged in the indoor unit and thus can be replaced easily.

Owner:苏州纽塔克净化服务有限公司

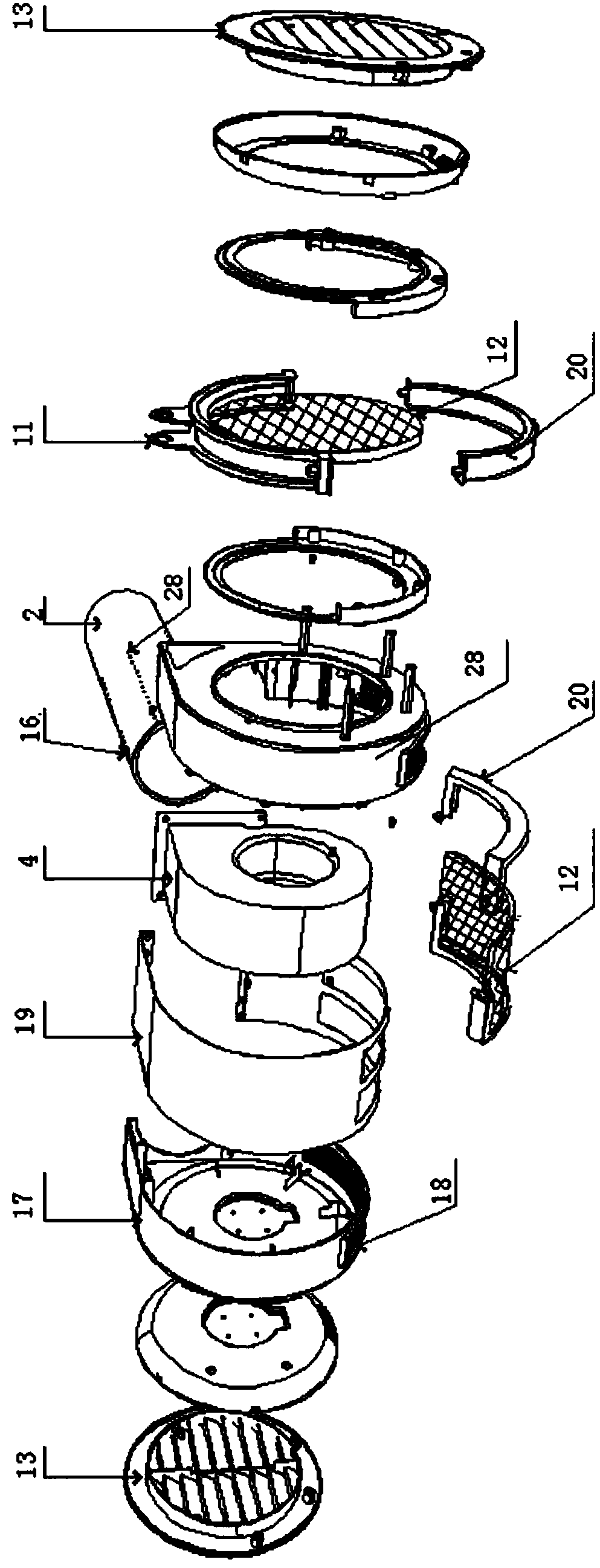

Composite structure filter felt and its preparation method and application

ActiveCN107224783ARenewableImprove filtration efficiencyGas treatmentDispersed particle filtrationElectrospinningFiltration

The invention belongs to the technical field of filter materials and discloses a composite structure filter felt and its preparation method and application. The composite structure filter felt is composed of a filtering function layer and protective layers coating the upper and lower surfaces of the filtering functional layer. The filtering function layer is prepared from a regenerated fiber layer containing 3D crimped structural fibers and an electrospinning nano-fiber layer through compounding. The composite structure filter felt has a fluffy filtering material skeleton structure of renewable micrometer fibers containing 3D crimped structural fibers and utilizes secondary electrospinning nanofibers attached to the micrometer fibers so that a high fiber specific surface area is obtained. The filter felt has the advantages of high filtration efficiency, low resistance and environmental friendliness.

Owner:SOUTH CHINA UNIV OF TECH +1

Fresh air purification system capable of adjusting filter level

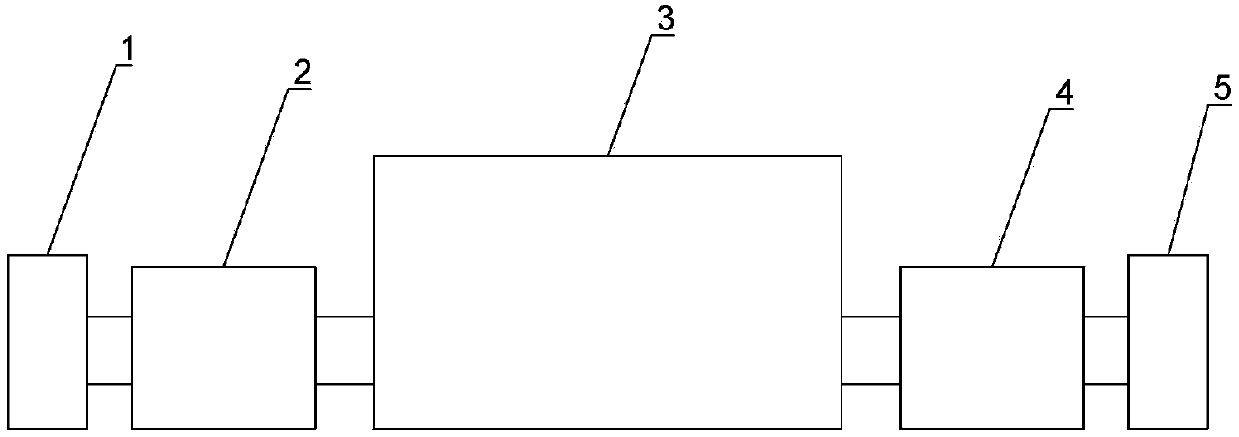

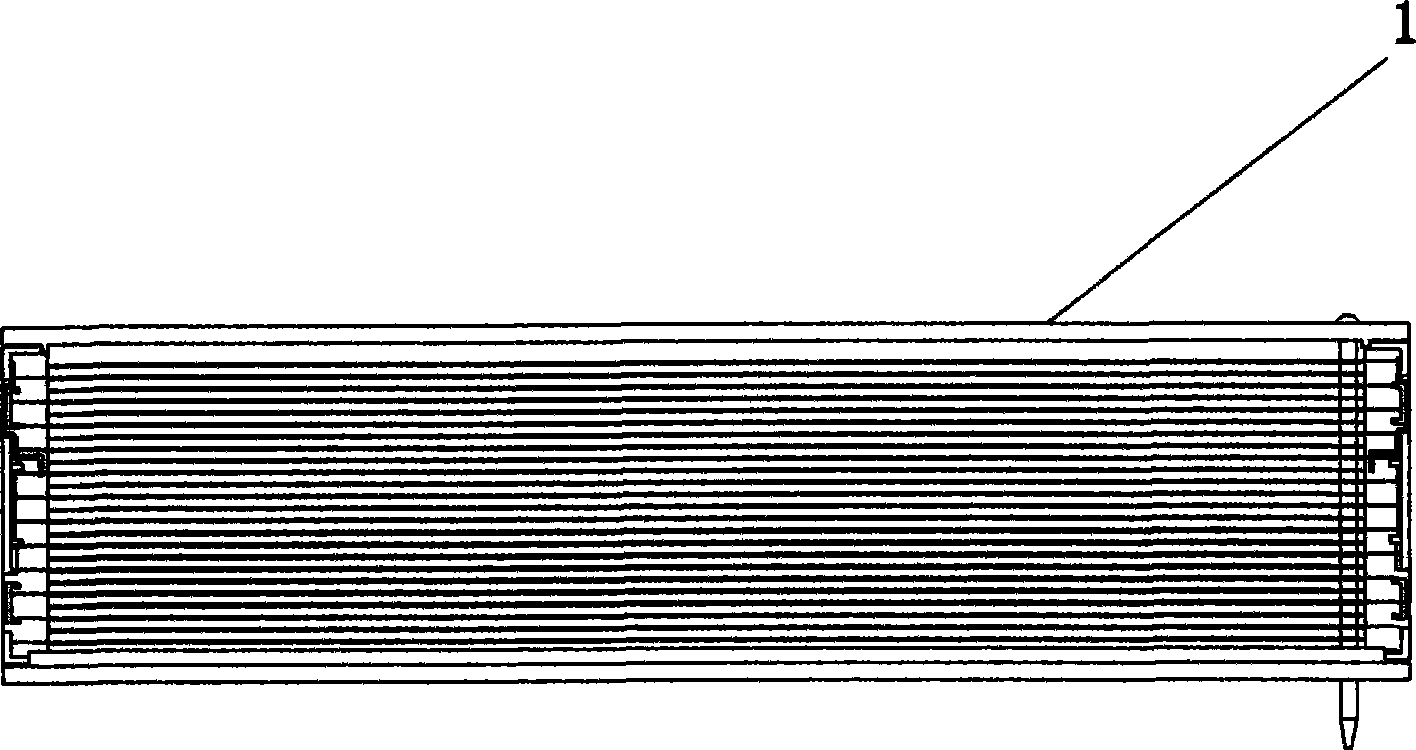

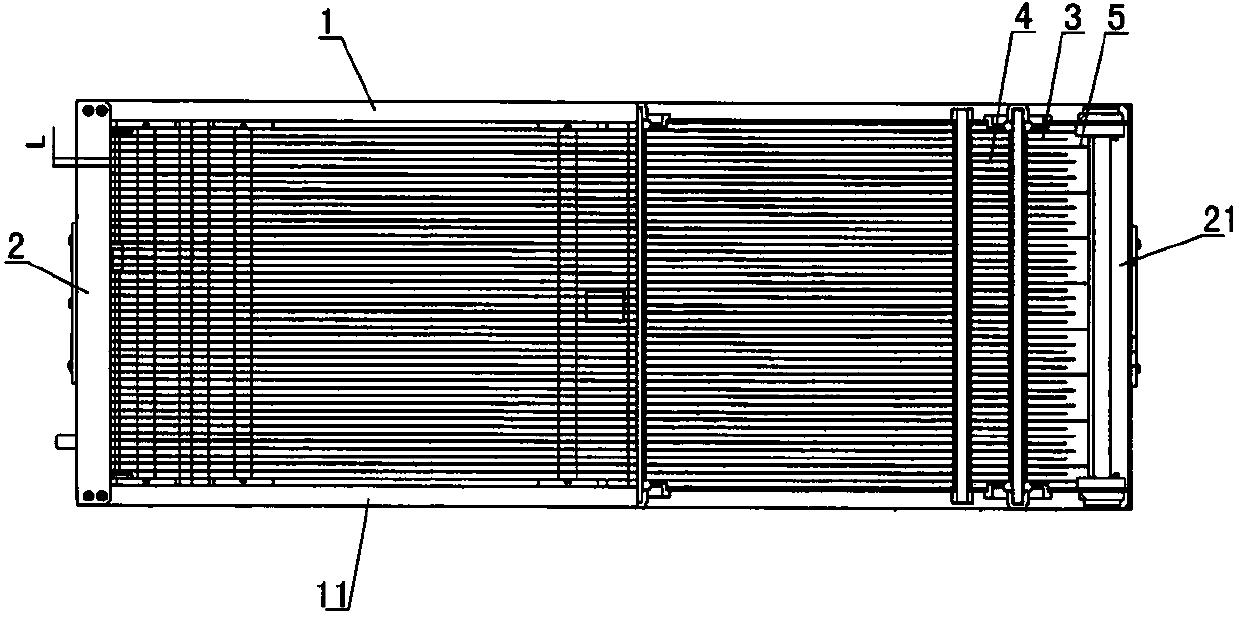

InactiveCN107816776AIncrease the number of filtersGuarantee air qualityMechanical apparatusDispersed particle filtrationFresh airFilter effect

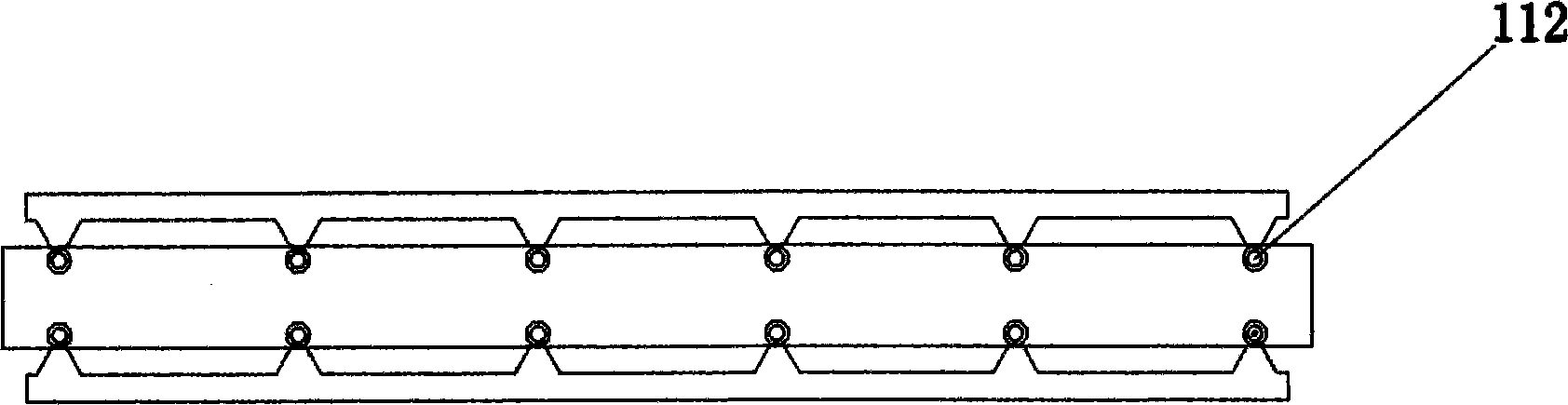

The invention relates to a fresh air purification system capable of adjusting the filter level. A purifying box (3) comprises a box body (31) and a filter device, wherein the filter device comprises afilter screen (32) and a standby filter screen (33) which are arranged in sequence in an air inlet direction, and the standby filter screen (33) is pushed by a hydraulic push device (34) which is connected with a connecting part (333); a monitoring unit (7) comprises a controller (6), a PM2.5 sensor (71) and an ozone sensor (72) which are arranged outside an air outlet (5) and are connected to the input end of the controller (6) as well as an air inlet fan (2), an alarm (8) and the hydraulic push device (34) which are connected to the output end of the controller (6). The fresh air purification system has the advantages of reasonable design, large dust holding capacity, large filter area and low filter noise, the filter effect of the filter device can be effectively increased, and additionally, the filter level can be increased according to the air quality of the air outlet, so that the filter effect is increased.

Owner:苏州格莱威科环保科技有限公司

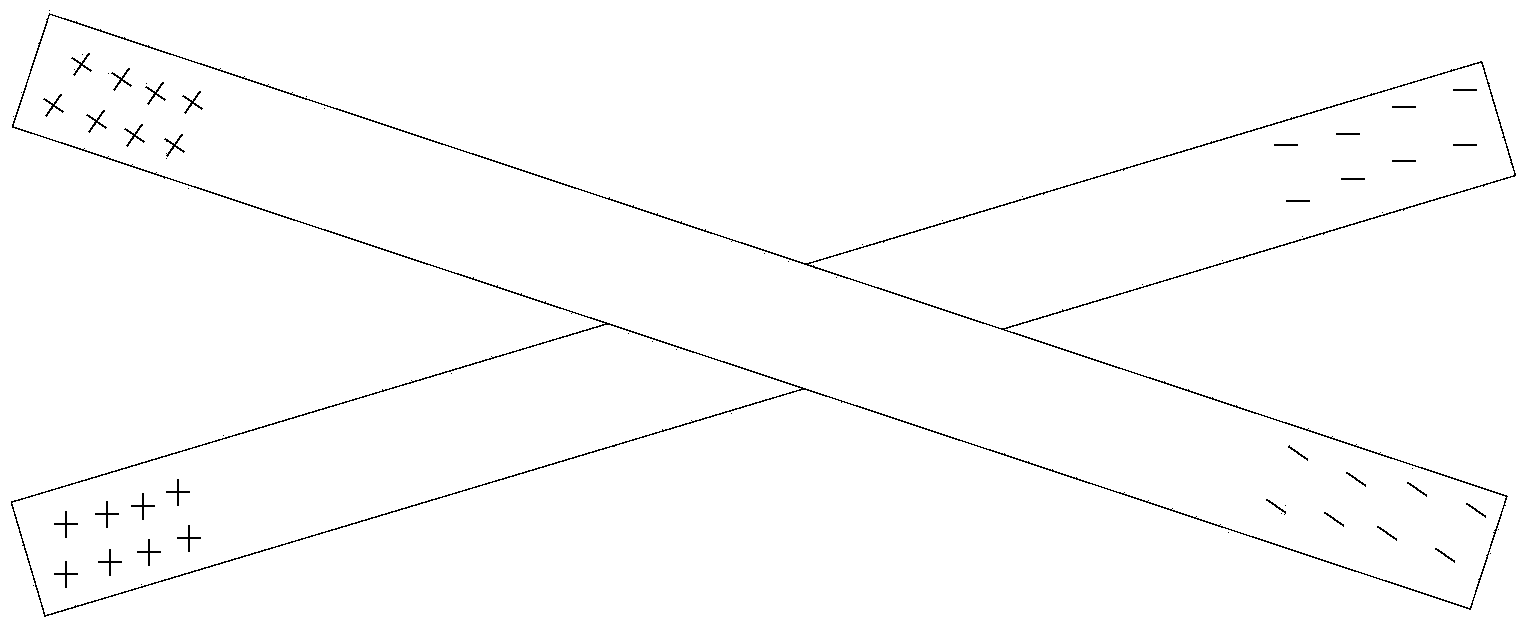

Semi-closed air-conditioner-companied air purifier

ActiveCN103868154AMaintain discharge capacityIncrease widthGas treatmentLighting and heating apparatusAir purifiersEngineering

The invention discloses a semi-closed air-conditioner-companied air purifier, and belongs to the technical field of air purification equipment. The semi-closed air-conditioner-companied air purifier comprises a semi-closed air-conditioner-companied air purification movement, an air inlet window, an air outlet window and a high-pressure pack, wherein the semi-closed air-conditioner-companied air purification movement comprises a static electricity generation band combined body, a positive high-pressure pack electrode joint and a negative high-pressure pack electrode joint; the static electricity generation band combined body comprises semi-closed static electricity generation bands, more than four insulation partition plates, a side plate A, a side plate B and more than eight positioning columns; the semi-closed static electricity generation bands comprise PET (polythylene terephthalate) resin bands and conductive bands; the PET resin bands are macromolecular resin materials; the conductive bands are silver slurry in conductive ink and are point discharge-shaped continuous bands interphased with wide sections and narrow sections; the conductive bands respectively comprise more than two positive electrode conductive bands and negative electrode conductive bands; the number of the positive electrode conductive bands is the same as that of the negative electrode conductive bands; the insulation partition plates are arranged among the semi-closed static electricity generation bands. The semi-closed air-conditioner-companied air purifier has the beneficial effects of stable quality, good purification and dust removal effect, no generation of ozone, high efficiency, low cost, safety and convenience in use.

Owner:NINGBO DONGDA AIR CONDITIONING EQUIP

Automatic filtering net replacement device and PM2.5 filtering net box

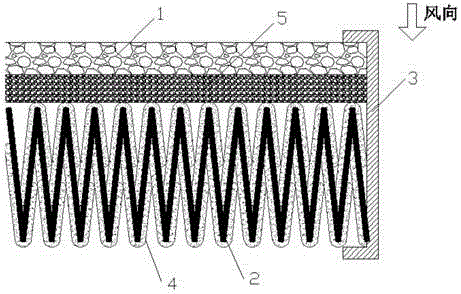

ActiveCN106955536AReduce the hassle of manual operationSmall running resistanceDispersed particle filtrationDrive wheelEngineering

The invention provides an automatic filtering net replacement device and a PM2.5 filtering net box. The automatic filtering net replacement device comprises a driving wheel, a driven wheel, a filtering net, a fixing base, a plurality of hard shafts, sliding pressure blocks and a pressure block opening / closing device, wherein the rear end of the filtering net is wound on the driven wheel, and the front end of the filtering net winds around the plurality of hard shafts and extends to the driving wheel and is wound on the driving wheel; the hard shafts, the sliding pressure block and the pressure block opening / closing device are arranged on the fixing base; the sliding pressure blocks comprise two pairs of inner sliding pressure blocks and outer sliding pressure blocks which are respectively arranged at two ends of the hard shafts; and the pressure block opening / closing device is connected with the sliding pressure blocks. According to the device disclosed by the invention, the filtering net can be automatically replaced, and the running resistance and sealing property of the filtering net can be ingeniously separated by virtue of the opening / closing operation of the sliding pressure blocks, so that the device is capable of smoothly replacing the filtering net and has excellent sealing performance. Moreover, the hard shafts have a W-shaped structure in the space, so that the windward filtering area of the filtering net can be effectively enlarged, and the dust holding capacity of the filtering net is effectively increased.

Owner:兰舍通风系统有限公司

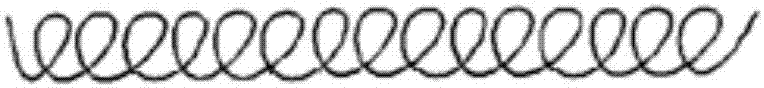

Multi-layer melt-blown non-woven fabric and preparation method thereof

PendingCN111876905AImprove filtration efficiencyExtended service lifeFibre typesUltrasonic/sonic fibre treatmentPolymer scienceFiber diameter

The invention relates to a multi-layer melt-blown non-woven fabric and a preparation method thereof, in particular to an online electret process and a preparation method of the multi-layer melt-blownnon-woven fabric with different fibers. The multi-layer melt-blown non-woven fabric is composed of a melt-blown non-woven fabric layer A, a melt-blown non-woven fabric layer B and a melt-blown non-woven fabric layer C. The melt-blown non-woven fabric layer A is arranged at the upper portion of the melt-blown non-woven fabric layer B, and the melt-blown non-woven fabric layer C is arranged at the lower portion of the melt-blown non-woven fabric layer B. The multi-layer melt-blown non-woven fabric is a melt-blown non-woven fabric composed of three melt-blown non-woven fabric layers with different fiber diameters, namely the melt-blown non-woven fabric layer A, the melt-blown non-woven fabric layer B and the melt-blown non-woven fabric layer C. According to the multi-layer melt-blown non-woven fabric, the diameter range of the melt-blown fibers can be adjusted in a large range according to particles with different sizes in reality, so that the fabric can have higher dust containing capacity when large-particle particles in air are filtered, and can have higher filtering precision and efficiency when smaller particles are filtered; and the service life of the multi-layer melt-blown non-woven fabric is greatly prolonged.

Owner:江苏金美达新材料有限公司

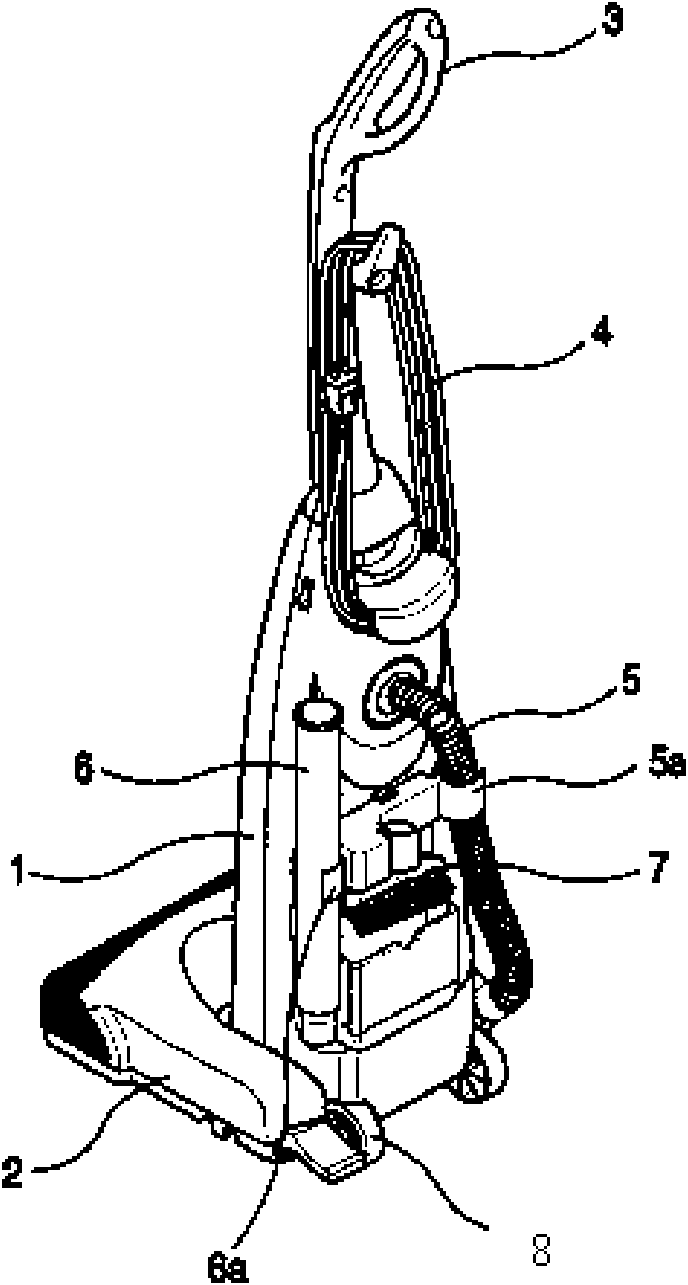

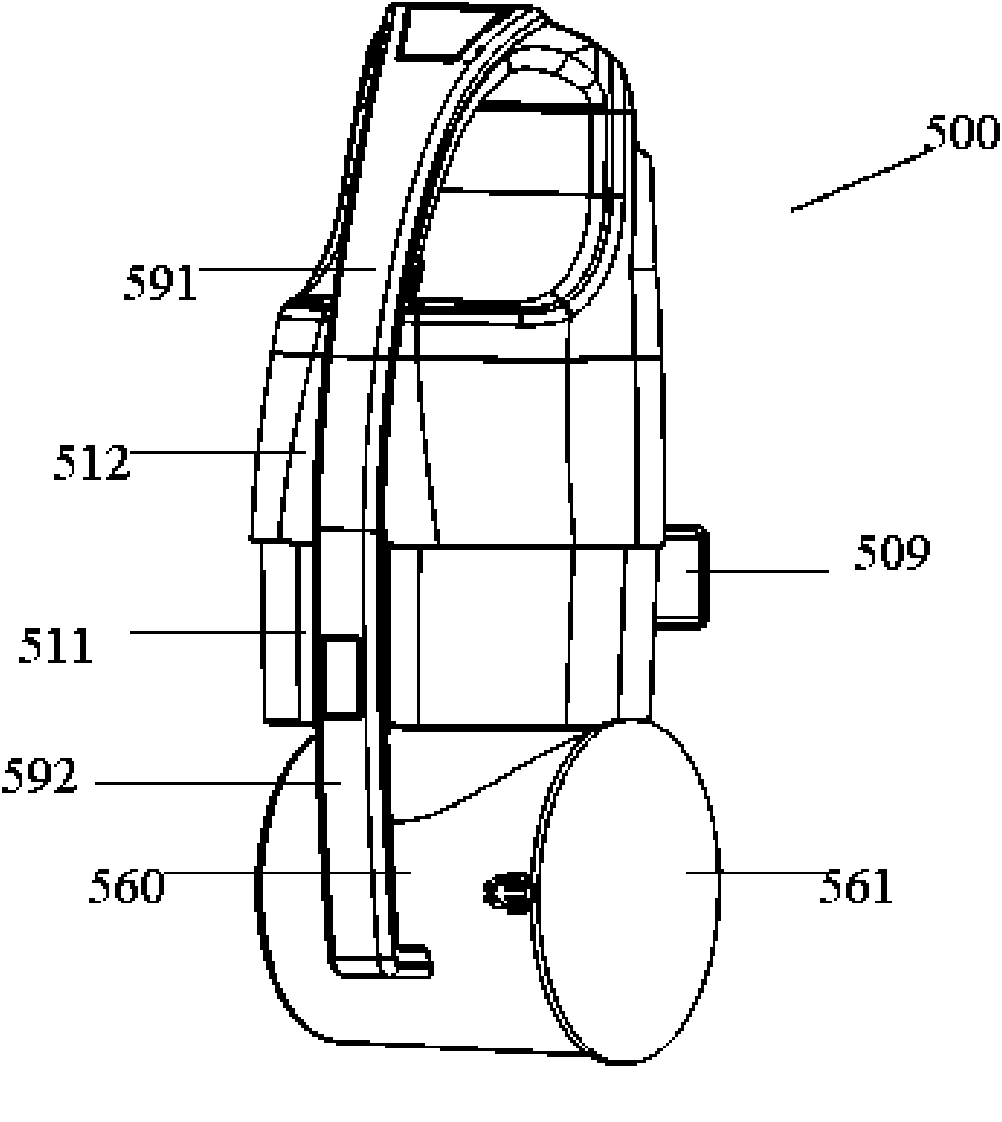

Autonomous vacuum cleaner

InactiveCN103338689AImprove performanceImprove cleaning efficiencyAutomatic obstacle detectionTravelling automatic controlCycloneControl system

An autonomous vacuum cleaner (10) comprising a chassis (12), traction means (14) for supporting the vacuum cleaner on a surface, drive means for driving the traction means and a control system configured to control the drive means to guide the vacuum cleaner across a surface to be cleaned. The vacuum cleaner further includes a cleaner head (22) 50 having a dirty air inlet facing the surface to be cleaned and a separating apparatus (51) carried by the chassis and communicating with the cleaner head in order to separate debris from an airflow entering the separating apparatus via the dirty air inlet. The separating apparatus (51) comprises a first upstream cyclone (74) and a plurality of second cyclones (72) arranged in parallel with one another and located downstream of the first cyclone.

Owner:DYSON TECH LTD

Multifunctional electrostatic precipitator

ActiveCN103990546AHigh densityEasy dischargeElectric supply techniquesElectrode constructionsElectric dischargeEngineering

The invention relates to a multifunctional electrostatic precipitator, which includes an upper end plate, a lower end plate, a left insulating plate and a right insulating plate. High voltage plates, dust collecting plates, and tungsten wires are alternately arranged between the upper end plate and the lower end plate. 2 conductive shrapnels are mounted on the left insulating plate or the right insulating plate, and respectively connected to the high voltage plates and the tungsten wires. A high voltage insulating layer and a dust collecting insulating layer are respectively disposed on the high voltage plates and the dust collecting plates by plastic coating. The alternating space L between the high voltage plates and the dust collecting plates is 2-3mm, the width L1 of the high voltage plates is identical to L2 of the dust collecting plates, i.e. 110.5mm. According to the scheme involved in the invention, the high voltage insulating layer and the dust collecting insulating layer are respectively disposed on the high voltage plates and the dust collecting plates by plastic coating to reduce electric discharge between the high voltage plates and the dust collecting plates and reduce the ozone generation probability, so that the space between the high voltage plates and the dust collecting plates can be reduced, the density of the dust collecting plates can be increased, and the dust holding capacity is also increased. Also, the width of the high voltage plates and the dust collecting plates is increased from the existing 80mm to 110.5mm, so that dust is difficult to escape, and the dust removal effect is improved.

Owner:浙江普瑞泰环境设备有限公司

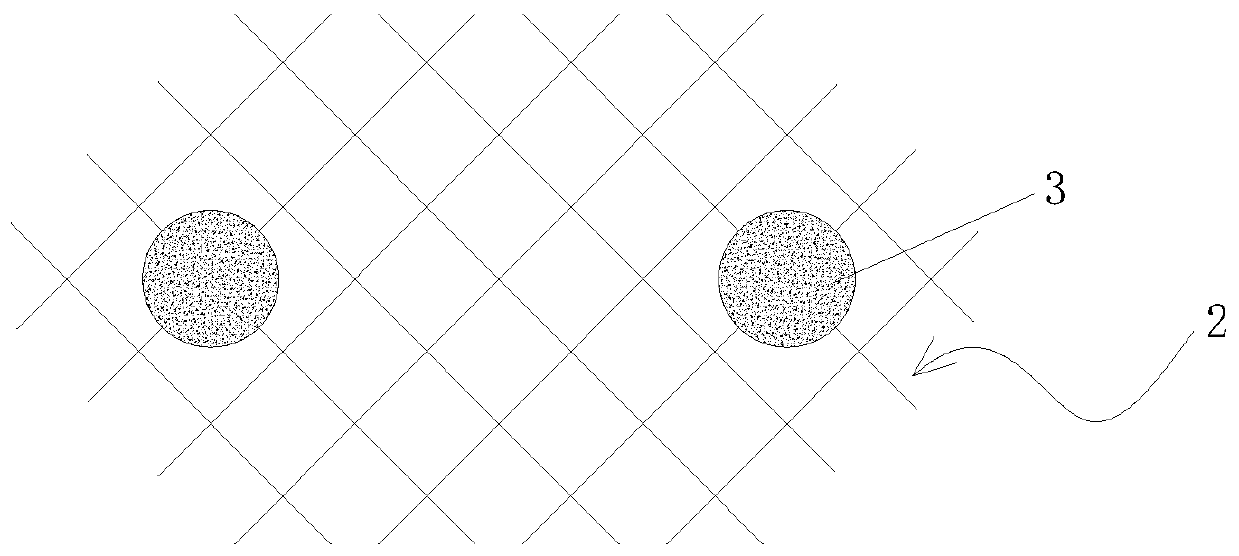

Gluing dust capture system for coal mine driving face dust removal

ActiveCN107023315AReduce corrosion and agingImprove comfortOther chemical processesCyclodextrin adhesivesEngineeringWater spray

The invention discloses a gluing dust capture system for coal mine driving face dust removal. The gluing dust capture system comprises a ventilation power subsystem, a gluing dust capture subsystem and a control subsystem; the gluing dust capture subsystem comprises a dust removal chamber, a glue spraying device, a glue spraying pump, a water spraying device, a water spraying pump and a dust removal filtering net boom, and dust capture gluing agents are evenly coated on the dust removal filtering net boom; the gas outlet end of the ventilation power subsystem is in fluid communication connection with the gas inlet end of the dust removal chamber, and the gas outlet end of the dust removal chamber is in fluid communication with atmosphere; and the dust removal filtering net boom is arranged in the dust removal chamber, the gas inlet end and the gas outlet end of the dust removal chamber are arranged on the two sides of a grid mesh of the dust removal filtering net boom, and gas flowing to the gas outlet end of the dust removal chamber from the gas inlet end of the dust removal chamber passes through the grid mesh of the dust removal filtering net boom. In this way, dust in dust air flow can be efficiently removed, the structure is simple, operation is convenient, and the phenomenon that humidity is too high due to mist spraying for dust fall can be reduced.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

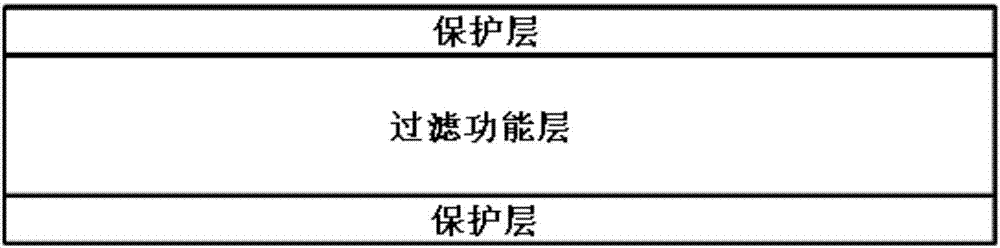

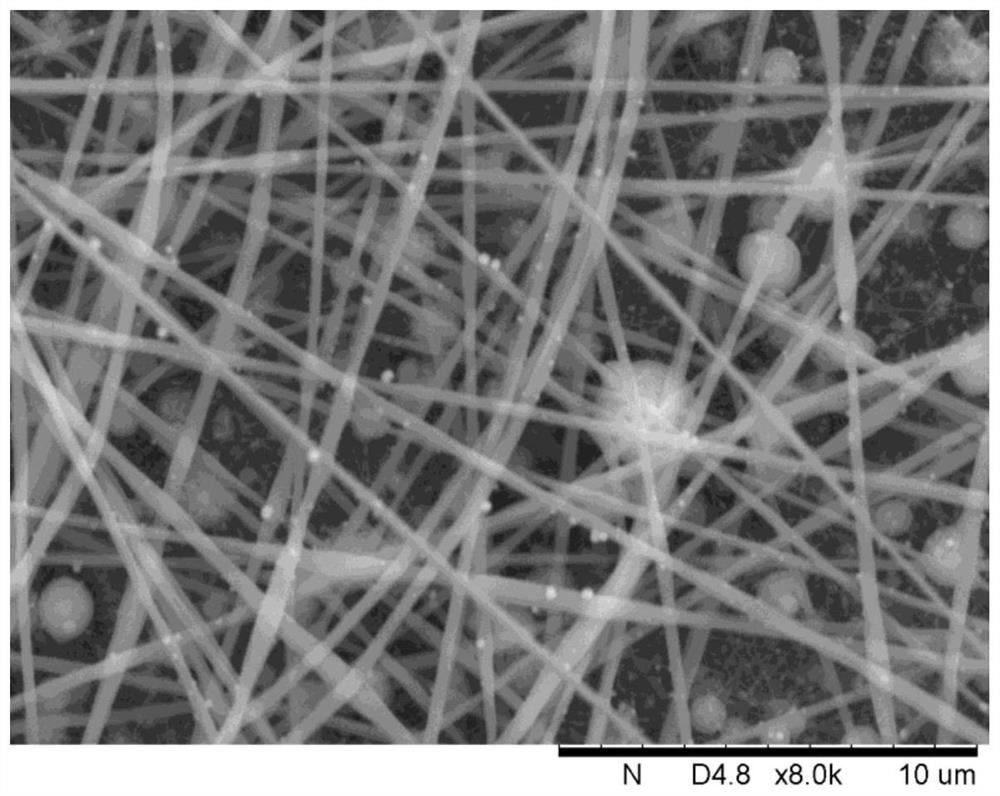

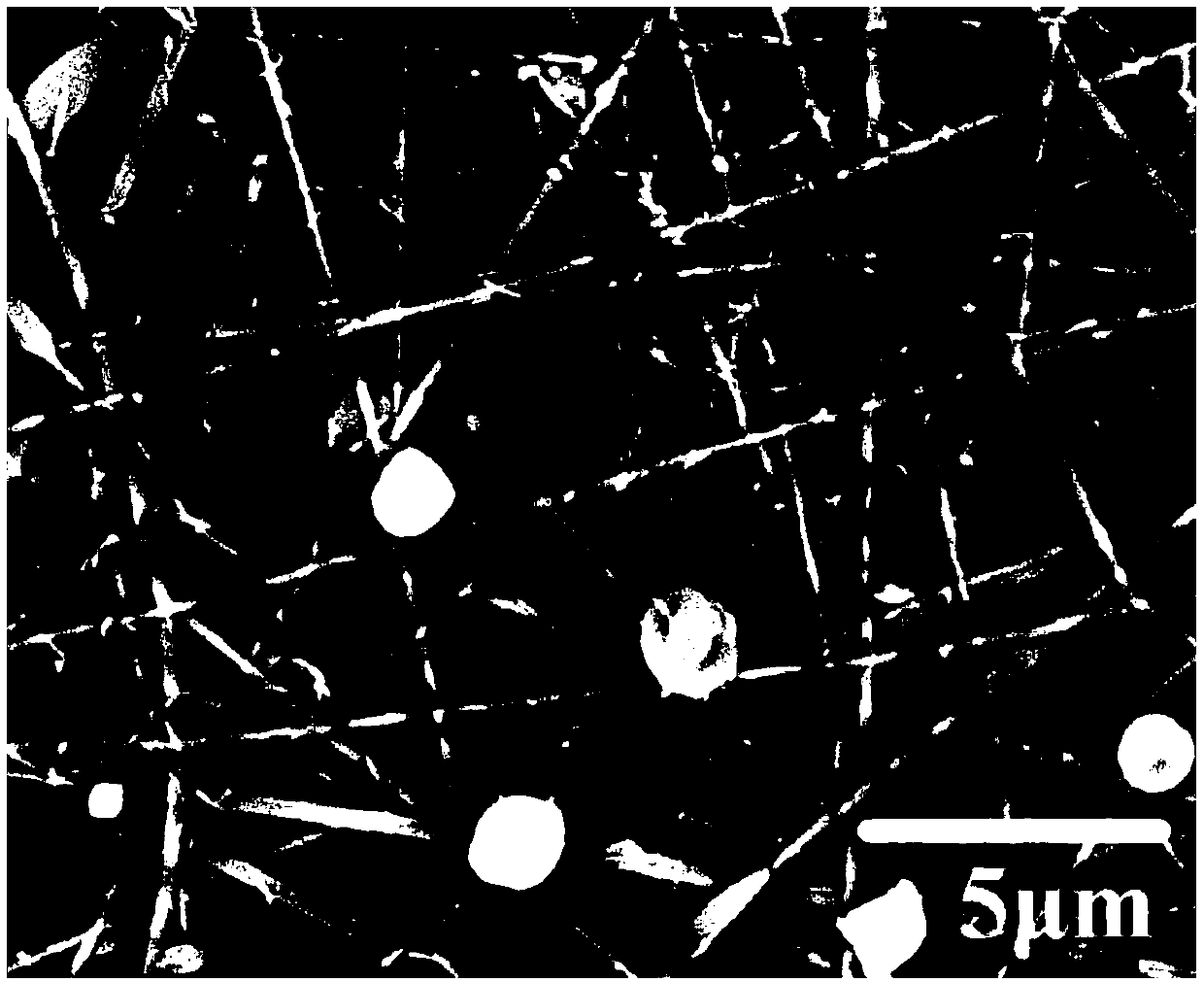

Multi-combination functional electrostatic spinning sub-micron fiber air filtering material and preparation thereof

ActiveCN112755651AImprove uniformitySmall apertureHuman health protectionElectro-spinningFiberPolymer science

The invention relates to a multi-combination functional electrostatic spinning sub-micron fiber air filtering material and preparation thereof. The material is of a sandwich structure formed by sequentially arranging a spun-bonded non-woven fabric, a sub-micron fiber / microsphere composite film and a spun-bonded non-woven fabric. The preparation method comprises the following steps: preparing a low-concentration electrostatic spinning solution with additional functionality, preparing a high-concentration electrostatic spinning solution with additional functionality, preparing an electrostatic spraying polymer solution with additional functionality, preparing a sub-micron fiber composite membrane / non-woven fabric composite material, and preparing the sub-micron fiber air filtering material. The preparation method has simple and controllable process parameters, and the prepared filter material has good structural controllability.

Owner:DONGHUA UNIV

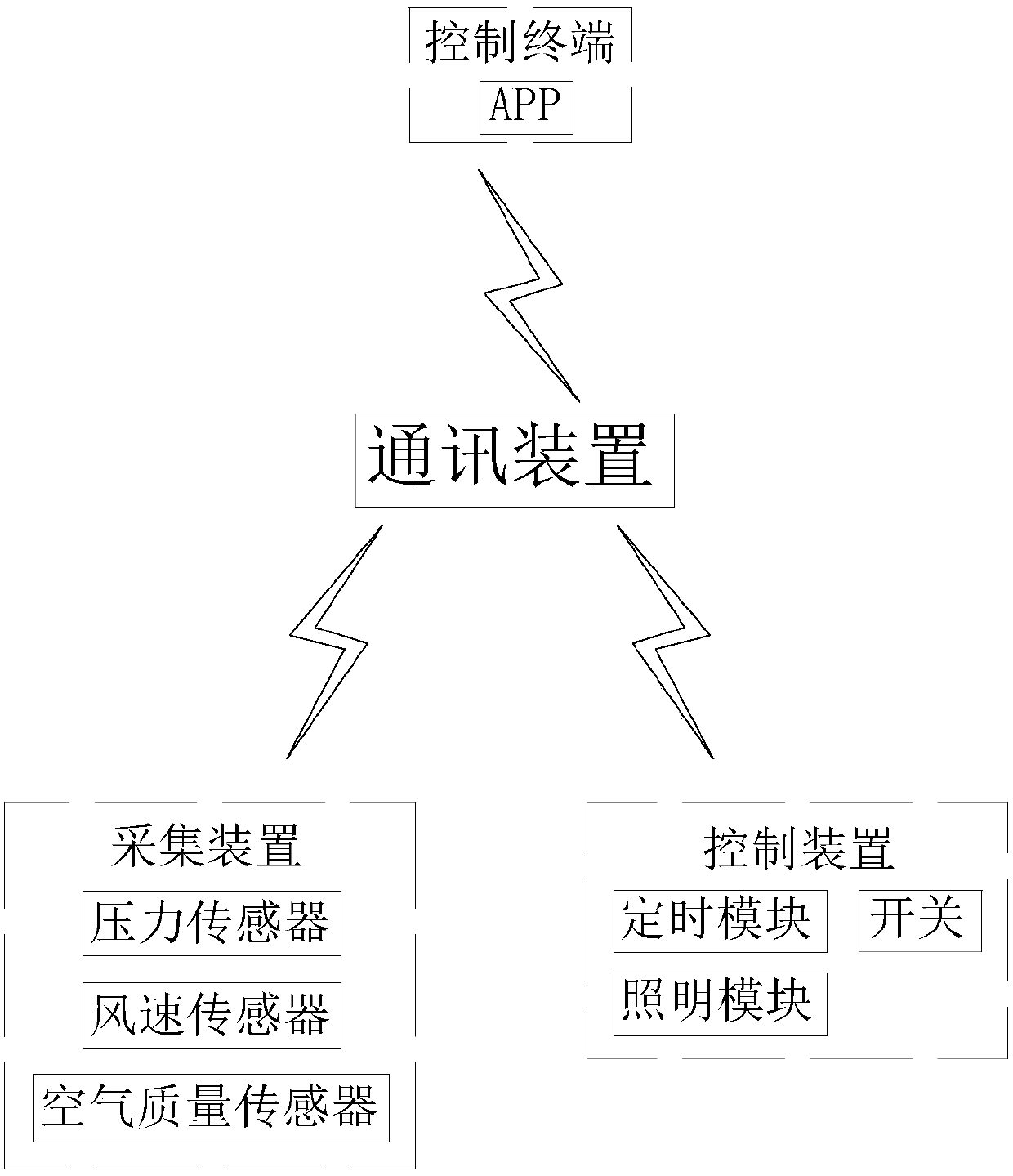

Air purifier based on APP control

InactiveCN108413575AEasy remote controlEasy for remote observationMechanical apparatusSpace heating and ventilation safety systemsQuality dataEngineering

The invention relates to an air purifier based on APP control. The air purifier comprises a control terminal with an APP and an air purifier interacting with the control terminal in data and command through the APP. The air purifier also comprises a collecting device, a control device and a communicating device. The air purifier based on APP control provided by the invention can be controlled by auser through the APP based on the control terminal, so that the user can control the air purifier remotely, and detects the inner and outer pressure data of the air purifier through a pressure sensorand detect the flow rate data of air speed in the air purifier. An air quality sensor can collect air quality data indoors, and the control terminal displays the pressure data, the flow rate data andthe air quality data, so that staff can observe remotely. The air purifier can be started and controlled automatically through a memory starting unit, and the air purifier can be started and stoppedautomatically, so that the air purifier can be started and stopped automatically every day.

Owner:北京望远迅杰科技有限公司

Air filtering device based on rough effect filter screen

ActiveCN107115727AReduce resistanceEfficient removalDispersed particle filtrationTransportation and packagingElectricityParticulates

The invention discloses an air filtering device based on a rough effect filter screen, and belongs to the field of indoor air purification. The device comprises a metal plate with a hole, a metal discharge filament, the rough effect filter screen and a metal net which are arranged in an openable insulating shell port area along an air flowing direction in sequence, wherein a positive polarity output power supply is arranged in a non-runner area of an openable insulating shell; a positive electrode of the power supply is connected with the metal discharge filament; an earth electrode of the power supply is respectively connected with the metal plate with the hole and the metal net; the rough effect filter screen is detachably connected with the openable insulating shell by a fixed part. According to the device disclosed by the invention, through a particulate pre-charged part between the metal plate with the hole and the metal discharge filament and a rough effect filter screen polarity part between the metal discharge filament and the metal net, the filtering efficiency of a single layer of rough effect filter screen is enhanced. The device has a simple structure and small occupied space, and provides a way of long-term realization of low-resistance high-efficient removal of indoor particulates.

Owner:TSINGHUA UNIV

Novel formula and processing process of polypropylene melt-blown nonwoven

PendingCN111334931AAdvantages of processing technologyGood light fastnessSpinning solution de-aeratingNon-woven fabricsAlkanePolymer science

The invention discloses a novel formula of a polypropylene melt-blown nonwoven. The novel formula comprises the following ingredients in percentage by weight: 2 to 15 percent of a graphene material, 0.001 to 0.1 percent of high-carbon alkanes, 80 to 87 percent of polypropylene particles, 1 to 6 percent of an auxiliary agent and 5 to 9 percent of titanium dioxide. The graphene material comprises one of graphene and oxidized graphene, or a combination of the graphene and the oxidized graphene. The auxiliary agent comprises any one of a coupling agent, a dispersant and an antioxidant, or a combination of more of the coupling agent, the dispersant and the antioxidant. The dispersant is any one of triethyl hexyl phosphate, methyl anyl alcohol, cellulose derivatives, polyacrylamide and fatty acid polyethylene glycol ester. The coupling agent comprises titanates, and the titanates comprise butyl titanate and titanium tetraisopropanolate. The polypropylene melt-blown nonwoven has an antibacterial property and a charge adsorption property; the filtering effect is good; the dust holding capacity is great; the use safety is high; and the quality and the performance of the melt-blown nonwovenare excellent. A preparation method has the advantages of mild melting condition and low production difficulty.

Owner:嘉兴市阿福信息科技有限公司

High-flame-retardancy filter cotton and preparation method thereof

InactiveCN105113128AImprove flame retardant performanceReduced flame retardancyFiltration separationNon-woven fabricsFiberPolymer science

The invention discloses high-flame-retardancy filter cotton. The filter cotton comprises, by mass, 10%-40% of 2-5D flame-retardant fibers, 20%-35% of 7D flame-retardant fibers, 25%-40% of 12D flame-retardant fibers and 5%-25% of 18-20D flame-retardant fibers. The flame-retardant fibers are formed in the mode that a fire retardant is added before fiber forming, and then drawing is carried out. The invention further discloses a preparation method of the flame-retardant filter cotton. The method includes the steps of (1) preparation of the flame-retardant fibers, (2) cotton blending, (3) opening, (4) combing, (5) lapping and (6) hot air setting. The flame-retardant filter cotton is good in flame-retardant effect. The flame retardant is added in the fiber preparation process, so that the flame-retardant effect is greatly improved. The flame-retardant filter cotton prepared through the preparation method of the flame-retardant filter cotton is good in flame-retardant effect and long in service life.

Owner:GUANGZHOU CLEAN LINK FILTRATION TECH CO LTD

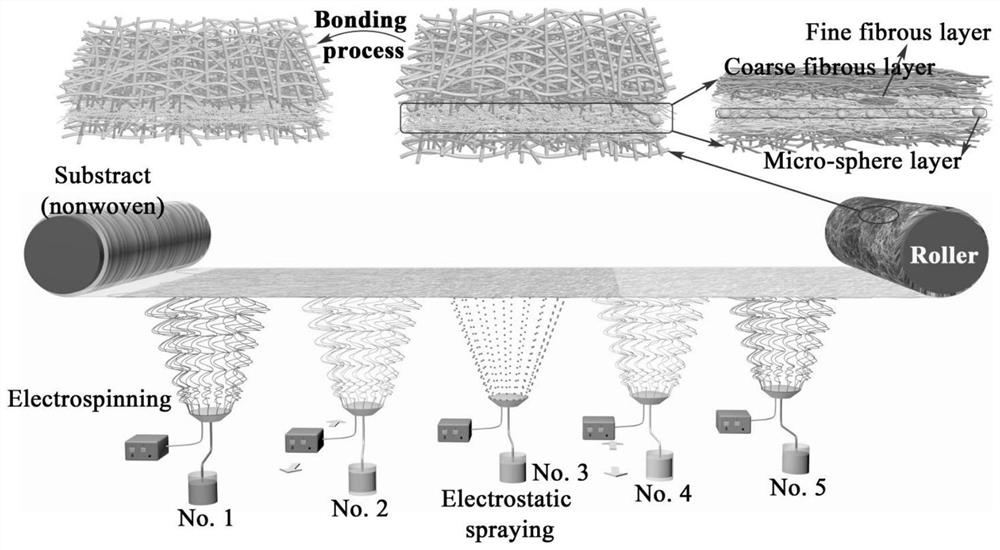

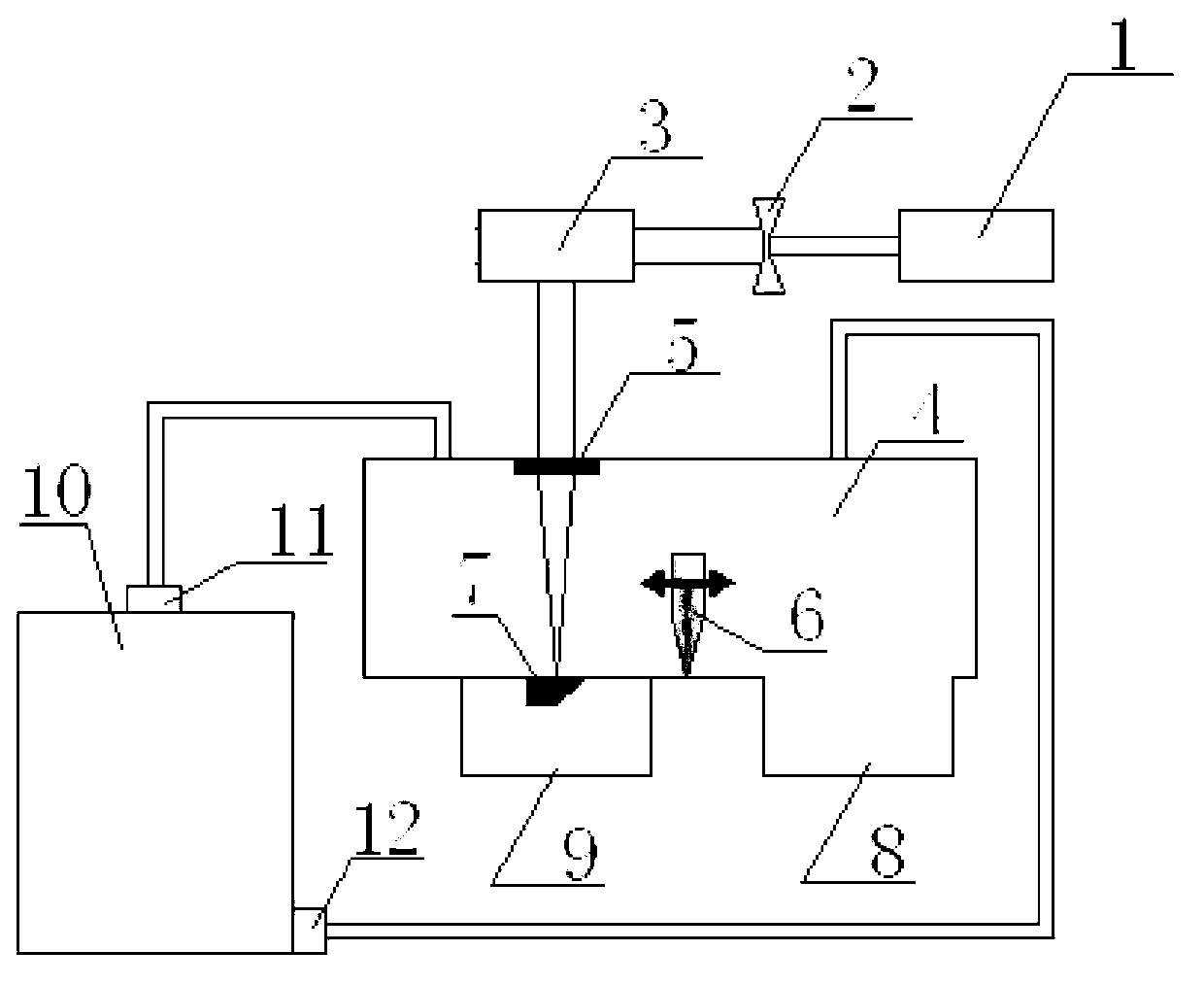

A high-efficiency and low-resistance electrospun nanofiber air filter material and its batch preparation method

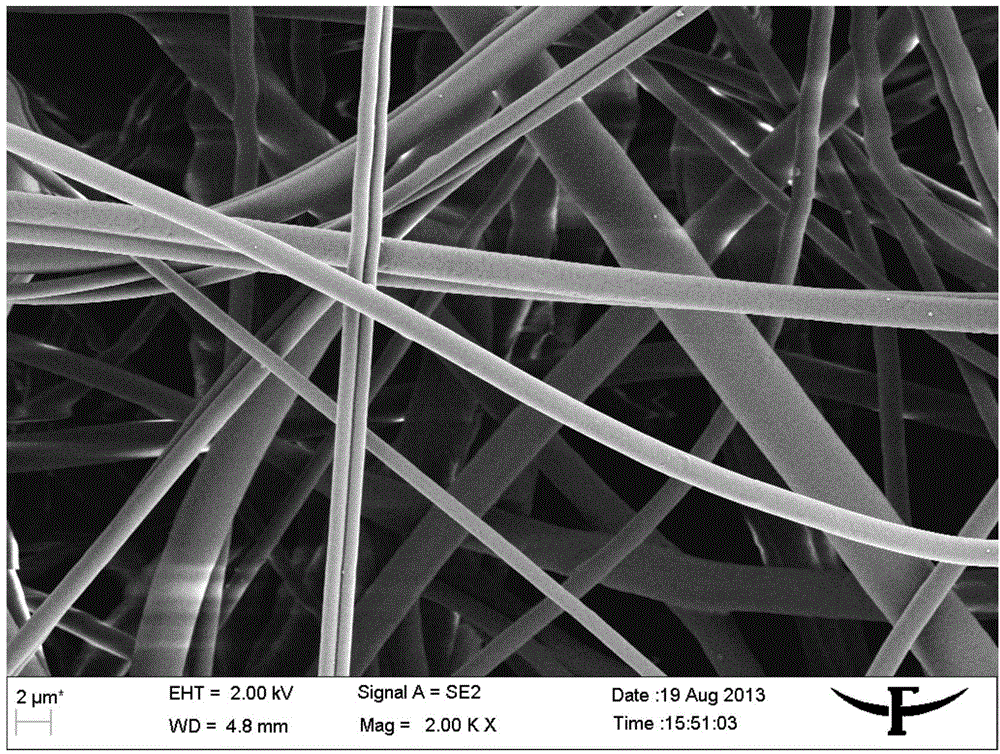

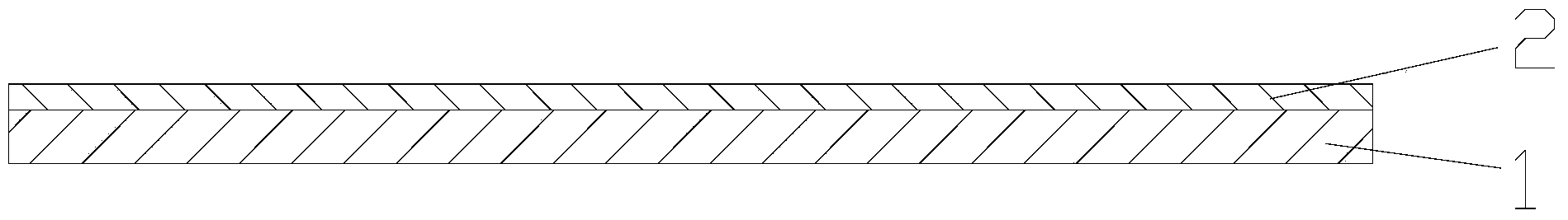

InactiveCN106237717BAvoid damageHigh strengthElectro-spinningFiltration separationFiberElectrospun nanofiber

The invention relates to an efficient and low-resistance electrospun nanofiber air filter material and a batch preparation method. The filter material is of a sandwich structure formed by alternately arraying spun-bonded nonwovens and nanofibers; by the adoption of a pinfree type electrostatic spinning nozzle and by an electrostatic spinning and electrostatic spraying synchronous combination technology, a nanofiber / microsphere composite film is prepared; a revolving rotary drum is used as a receiving device, and the spun-bonded nonwoven is used as a receiving matrix, so that a nanofiber / nonwoven composite material is obtained; a layer of spun-bonded nonwoven covers the surface of the nanofiber / nonwoven composite material to form the sandwich structure with the spun-bonded nonwovens and the nanofibers which are alternately arrayed; the sandwich structure is bonded to obtain the efficient and low-resistance electrospun nanofiber air filter material. The preparation process is simple, and high in controllability and repetitiveness, and the prepared air filter material has the characteristics of high efficiency and low resistance, and is uniform in thickness and stable in filter performance; batch production of the nanofiber filter material can be realized; the efficient and low-resistance electrospun nanofiber air filter material has very good application prospect in the field of air filtering.

Owner:DONGHUA UNIV

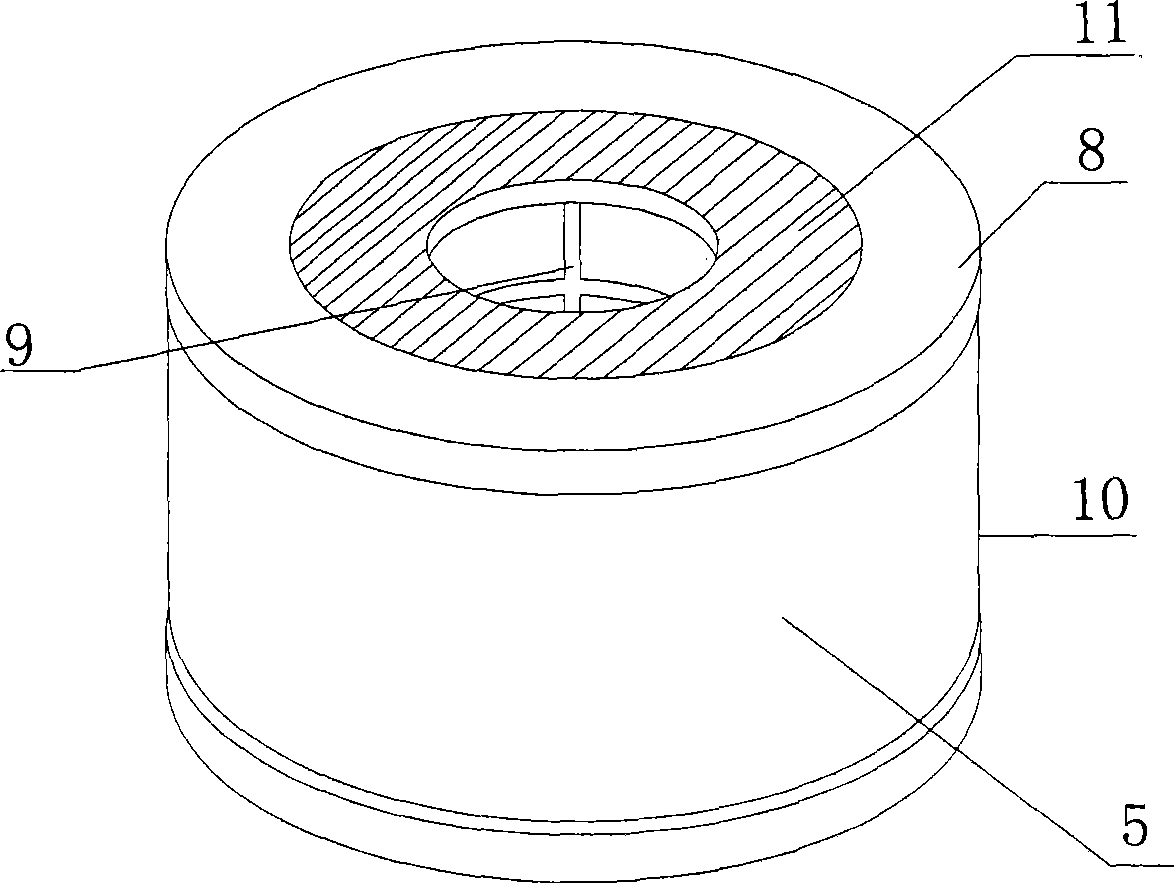

Tail gas emission filter

InactiveCN101519992AHigh temperature resistantImprove breathabilityExhaust apparatusSilencing apparatusGlass fiberFilter media

The invention discloses a tail gas emission filter. The filter comprises a base, an upper cover and a filter core, wherein the center of the upper cover is provided with a gas outlet interface connected with a gas outlet of the filter core; the upper cover and the base are in screwed connection and sealed by a sealing ring; the bottom part of the base is provided with a gas inlet interface; the bottom end of the filter core is closed and fixed by fixed screws; the filter core takes glass fiber as a filter medium; and the filter core is completely sleeved in the base to form a cavity. The filter is simple and small in structure, so that the filter is convenient for assembly and use and is easily maintained; and the glass fiber is used as the filter medium, the glass fiber has the advantages of high-temperature resistance, good gas permeability, big dust containing capacity and the like, and the filter core end face central gas inlet mode existing in the prior filter is changed into the filter core side face gas inlet of the filter, thereby improving the gas inlet efficiency and achieving extremely good filtering effect on tail gas of an automobile, particularly carbon particle impurities.

Owner:DONGGUAN LUAO FILTER

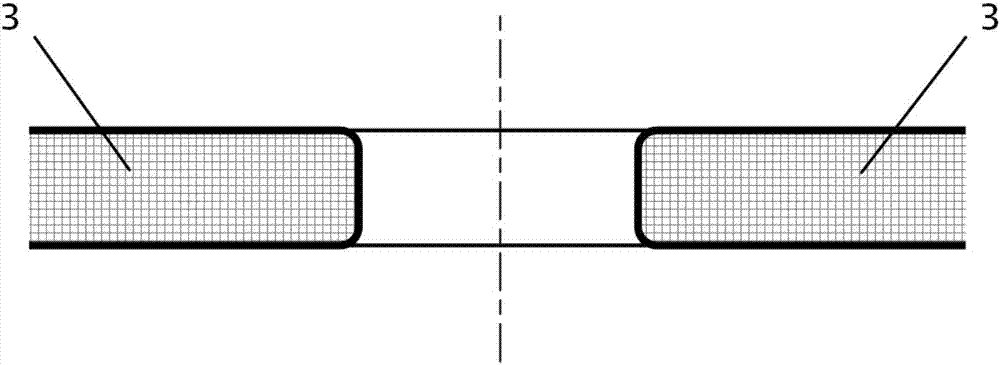

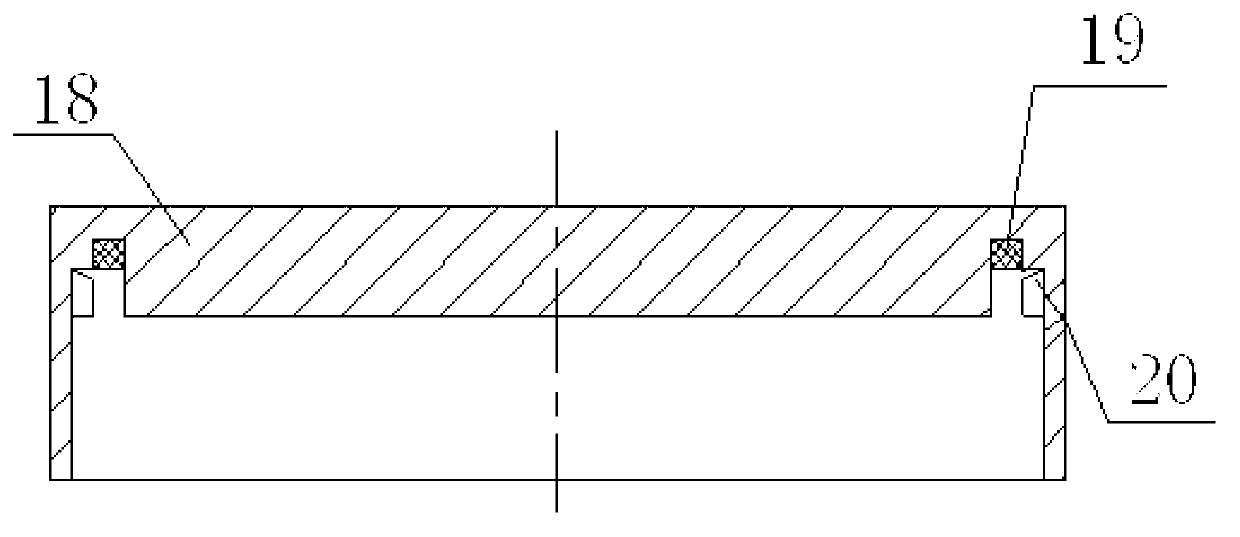

Glass fiber composite filter material for methanol filters

PendingCN109731398AGuaranteed filtering effectImprove stiffnessFiltration separationBursting strengthGlass fiber

The invention discloses a glass fiber composite filter material for methanol filters. The glass fiber composite filter material comprises a filter paper layer. Support nets are arranged on the upper surface and the lower surface of the filter paper layer. The glass fiber composite filter material for the methanol filters has the advantage that the glass fiber composite filter material is high in integral stiffness, low in flow resistance, large in dust holding capacity, good in bursting strength and favorable for guaranteeing methanol filter effects.

Owner:高博集团有限公司

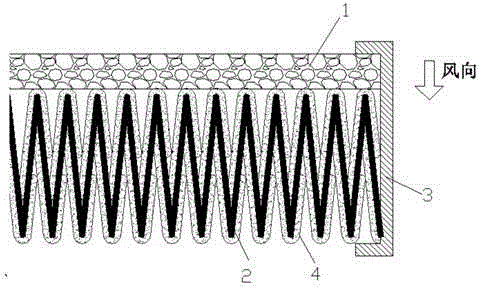

Air filter

InactiveCN105080224AReduce resistanceLow dust holding capacityDispersed particle filtrationLayered productsAir filterEngineering

The invention relates to an air filter with advantages of high efficiency, low resistance and large dust containing capacity. The air filter is capable of filtering PM2.5 particles with high efficiency, and comprises at least a layer of coarse and / or immediate non-woven fabrics and a pleated non-woven fabrics filter core. A method for producing the air filter comprises the following steps: paving a layer of coarse non-woven fabrics on a layer of high efficiency non-woven fabrics filter core with reciprocated pleating and interrupt gluing, or paving a layer of immediate non-woven fabrics between the coarse non-woven fabrics and the high efficiency non-woven fabrics filter core, and covering the peripheral part by a frame. The filtering efficiency of the air filter is more than or equal to 90% for the air dust particle with diameter being more than 0.5 mum, pressure loss at initial stage under condition of face velocity being 1.5m / s is less than 60 Pa, and dust containing capacity of a filter when pressure loss at initial stage is 2.5 is greater than or equal to 1000 g / m<2>.

Owner:ZHEJIANG GOLDENSEA ENVIRONMENT TECH

Air conditioner and air purifying device thereof

InactiveCN104048394AGood removal effectReduce wind resistanceLighting and heating apparatusElectrostatic separationHoneycombElectret

The invention discloses an air purifying device which is used in an air conditioner and for removing PM2.5. The air purifying device comprises a polymer electret. According to the polymer electret, specifically, after molecular polarization of a high polymer material is carried out, a constant self-generating electrostatic field is obtained. The polymer electret can be made into a honeycomb-shaped structure, wherein the wall of each hole is quite thin, the dust holding capacity is high, and the wind resistance is small. The electrostatic field of the polymer electret does not need an additional power supply and is constant, stable and free of generation of ozone, and therefore the PM2.5 removing effect of the air conditioner can be improved. In addition, ozone generation is avoided, and the situation that after an air conditioner is powered off and stopped, adsorbed dust is released again due to disappearance of an electrostatic field is avoided. The polymer electret is light in weight and small in density, can be conveniently installed on a filter net of the air conditioner and is convenient to clean. Adsorbed dust on the polymer electret can be removed through a dust collector, like the filter net. The invention further discloses the air conditioner comprising the air purifying device.

Owner:GUANGDONG CHIGO AIR CONDITIONING

Alcohol-soluble phenolic resin dip-coating glue liquid, oil-water separation fuel oil filter paper and preparation method of oil-water separation fuel oil filter paper

ActiveCN107090744AImprove water repellencyHigh porosityReinforcing agents additionPaper/cardboardFiltrationFine particulate

The invention relates to an alcohol-soluble phenolic resin dip-coating glue liquid, oil-water separation fuel oil filter paper and a preparation method of the oil-water separation fuel oil filter paper. The oil-water separation fuel oil filter paper is prepared from the alcohol-soluble phenolic resin dip-coating glue liquid through dipping and curing, wherein the dipping amount is 20%-26%. The alcohol-soluble phenolic resin dip-coating glue liquid contains the following raw material components in percentage by weight: 45%-55% of oil-water separation phenolic resin LD-1 and 45%-55% of methanol, wherein the solid content of the oil-water separation phenolic resin LD-1 is 55%-60%. By adding synthetic fibers and carrying out dip-coating by virtue of the alcohol-soluble phenolic resin with an oil-water separation function, the obtained oil-water separation fuel oil filter paper has high filtration precision and is capable of filtering fine particulate matters mixed in fuel oil and is long in service life.

Owner:山东龙德复合材料科技股份有限公司

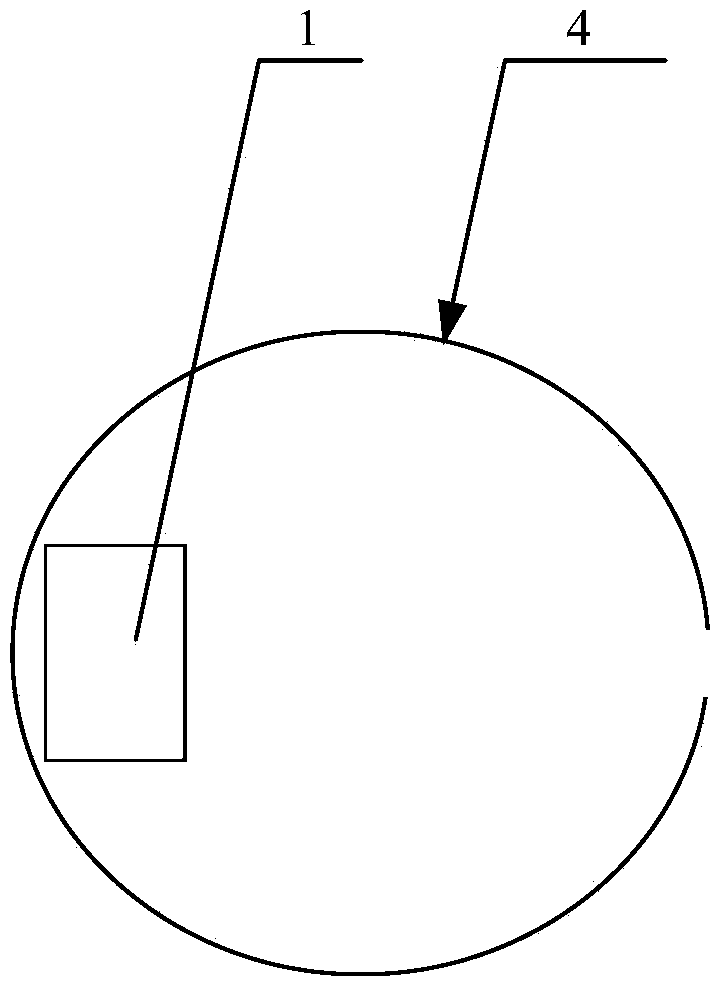

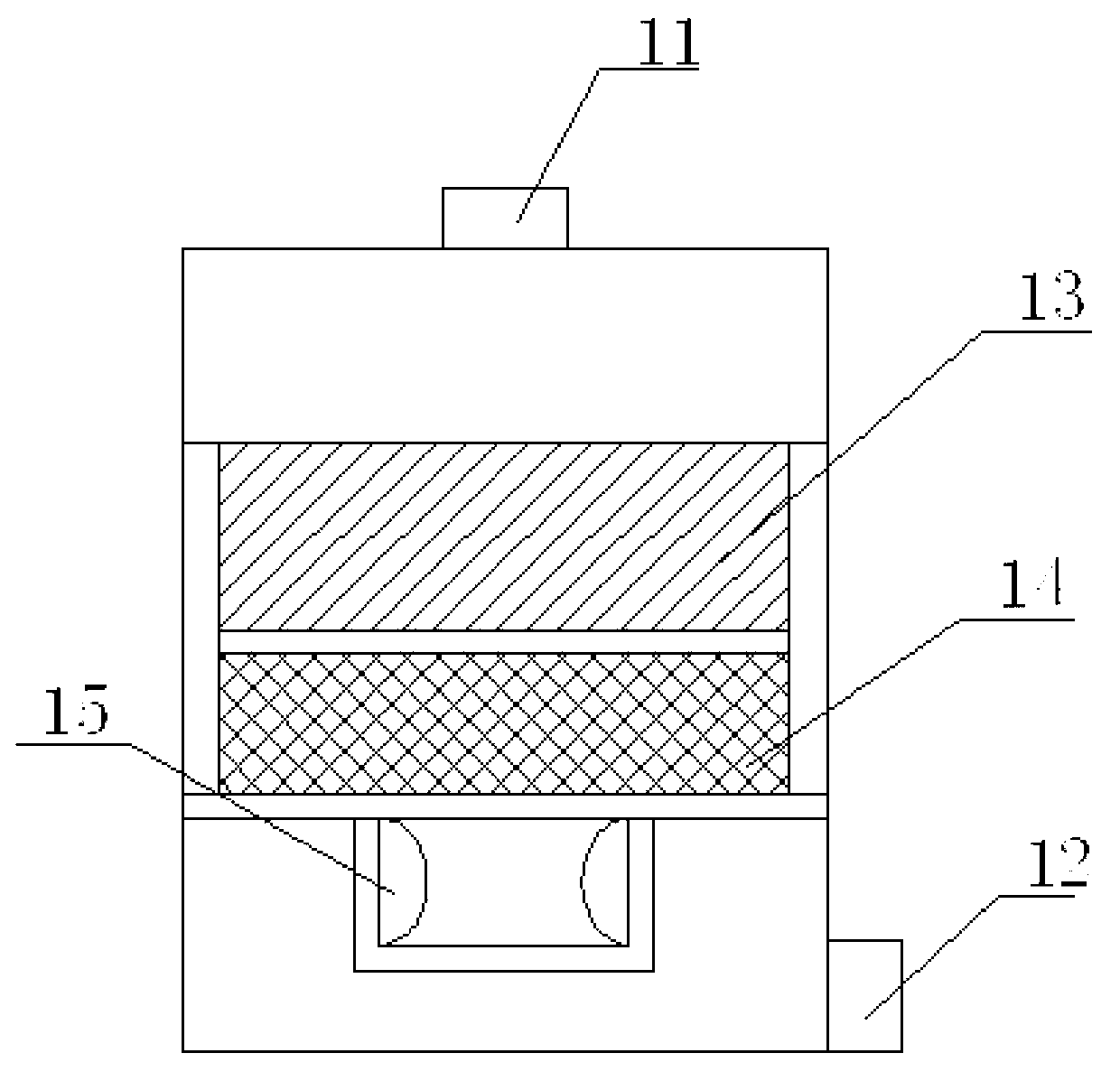

Gas cycle purification device for sealed shaping room

InactiveCN103272444AReduce wearEasy to achieve tightnessDispersed particle filtrationEngineeringLaser

The invention discloses a gas cycle purification device for a sealed shaping room. The gas cycle purification device comprises a shaping room, and also comprises a sealed box body, wherein a pre-filtering layer, a main filtering layer and a fan are arranged in the sealed box body from top to bottom; an air inlet is formed in the top of the sealed box body; an air outlet is formed in one side of the bottom of the sealed box body; the air inlet is connected with one end of the shaping room through a pipeline; and the air outlet is connected with the other end of the shaping room through a pipeline. According to the gas cycle purification device for the sealed shaping room, the sealing structure of the conventional product is improved, the smoke dust generated by processed metals in laser melting equipment shaping room in a selected area is subjected to gas purification, and the purified gas returns to the shaping room to protect the metal processing. The gas cycle purification device has the advantages of simple and feasible technical means, low cost, convenience in use and maintenance and the like.

Owner:SOUTH CHINA UNIV OF TECH

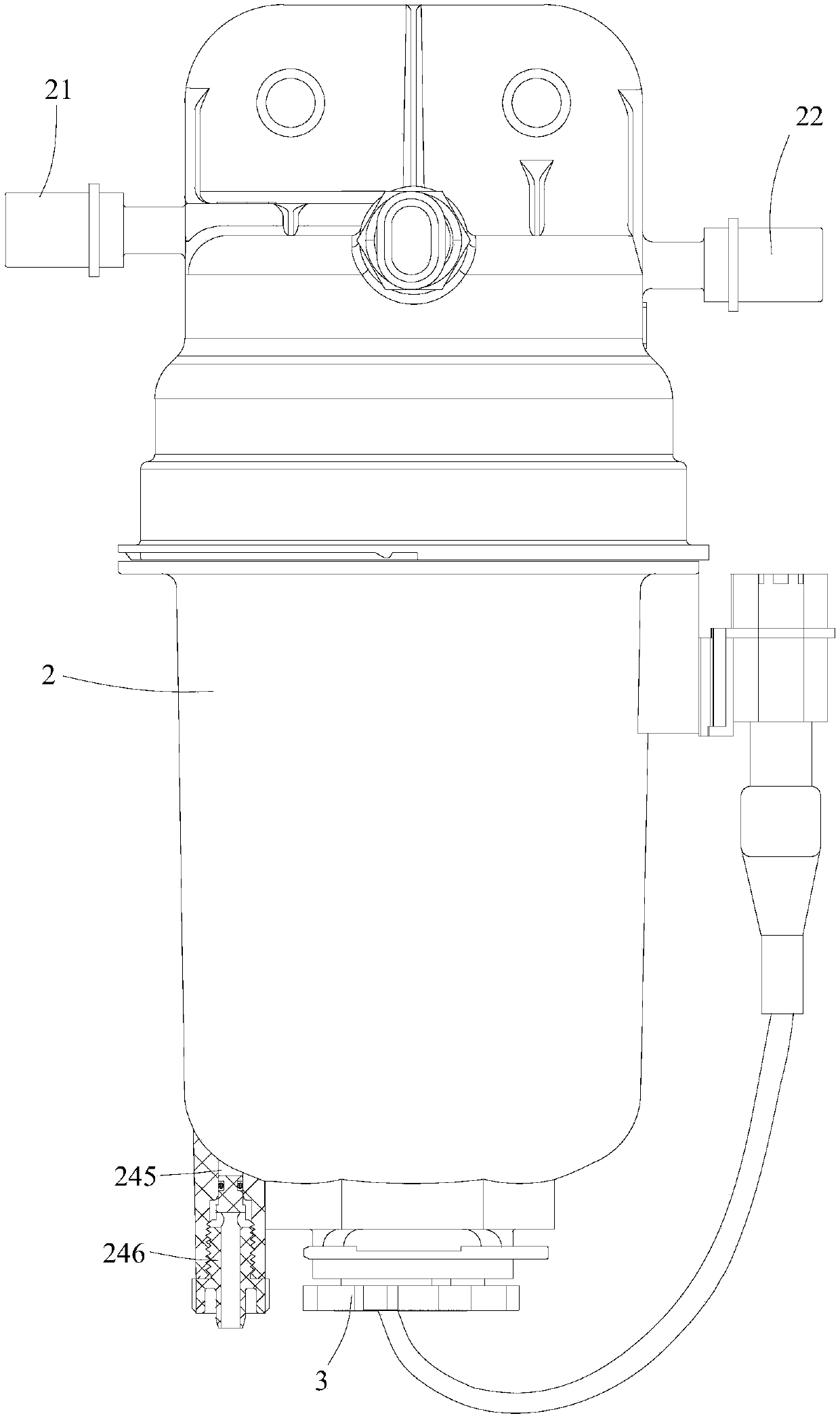

Fuel filter

PendingCN107806385AEasy to installEasy to disassembleMeasurement devicesMachines/enginesFuel filterEngineering

The invention discloses a fuel filter. The fuel filter comprises a shell, a filter element and a combined sensor. The shell is provided with an oil inlet pipe and an oil outlet pipe. The filter element comprises saw-toothed folded tubular filter paper, an inner net, an upper cover plate and a lower cover plate. The inner net is inserted in the tubular filter paper and forms a filtering space. Theupper cover plate and the lower cover plate are fixed to the two ends of the tubular filter paper correspondingly. The upper cover plate is provided with a first through hole allowing the oil outlet pipe to communicate with the filtering space. The lower cover plate is provided with a second through hole allowing the combined sensor to be inserted in. An annular cavity is formed between the filterelement and the inner wall of the shell. The oil inlet pipe communicates with the cavity. The combined sensor is inserted in the lower end of the shell, extends into the filtering space through the second through hole and is used for sensing the fuel temperature in the filtering space and heating fuel in the filtering space. According to the fuel filter, mounting and dismounting operation of thefuel filter can be simplified, a circuit structure is simple, the strength, filtering precision and water separation efficiency are improved, the clogging capacity is increased, and thus the service life is prolonged.

Owner:ANHUI PHOENIX INT CO LTD

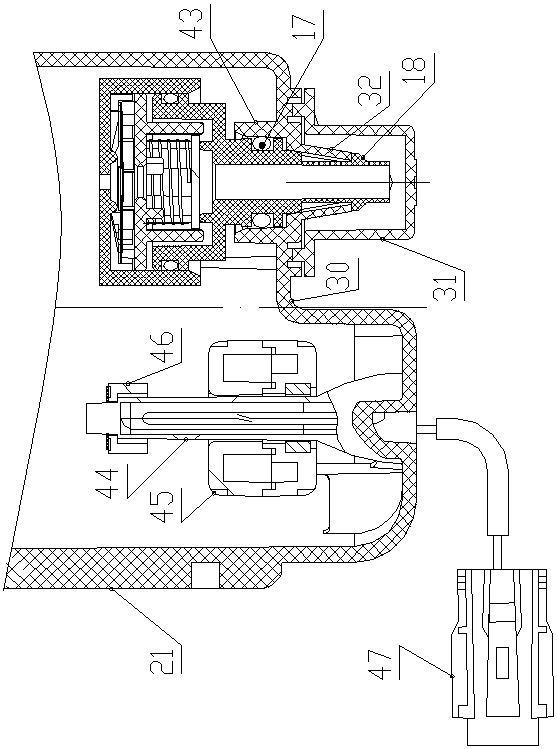

Non-return temperature-control valve and modular environment-friendly fuel filter adopting same

PendingCN109653919ASimple structureFirmly connectedMachines/enginesThermal treatment of fuelTemperature controlFuel filter

The invention discloses a non-return temperature-control valve. The non-return temperature-control valve comprises a valve seat and a bonnet; a valve plate is tightly pressed against an annular supporting seat by a spring so as to seal a lower-part round pipe when the spring is in the free relaxed state; double metal sheets are arranged inside an upper cavity; when the temperature at a bonnet oiloutlet is higher than 58 DEG C, the double metal sheets bulge upwards and seal an annular sealing bulge; and when the temperature at the bonnet oil outlet is lower than 28 DEG C, the double metal sheets bulge downwards and are separated from the annular sealing bulge. The invention further discloses a modular environment-friendly fuel filter adopting the non-return temperature-control valve. The fuel filter comprises a casing; a top cover is arranged at the top of the casing; a manual oil pumping structure is arranged inside the top cover; a straight-through type filter element is arranged atthe upper part inside the casing; and a float water-level alarm and the non-return temperature-control valve are arranged inside the casing and located below the straight-through type filter element.By the aid of the non-return temperature-control valve and the fuel filter, air is removed through manual oil pumping, fuel is filtered, the fuel inside the fuel filter is heated by the aid of returned oil of an engine, blockage of the filter element due to inside wax precipitation of the fuel is prevented, and energy is saved.

Owner:PINGYUAN FILTER

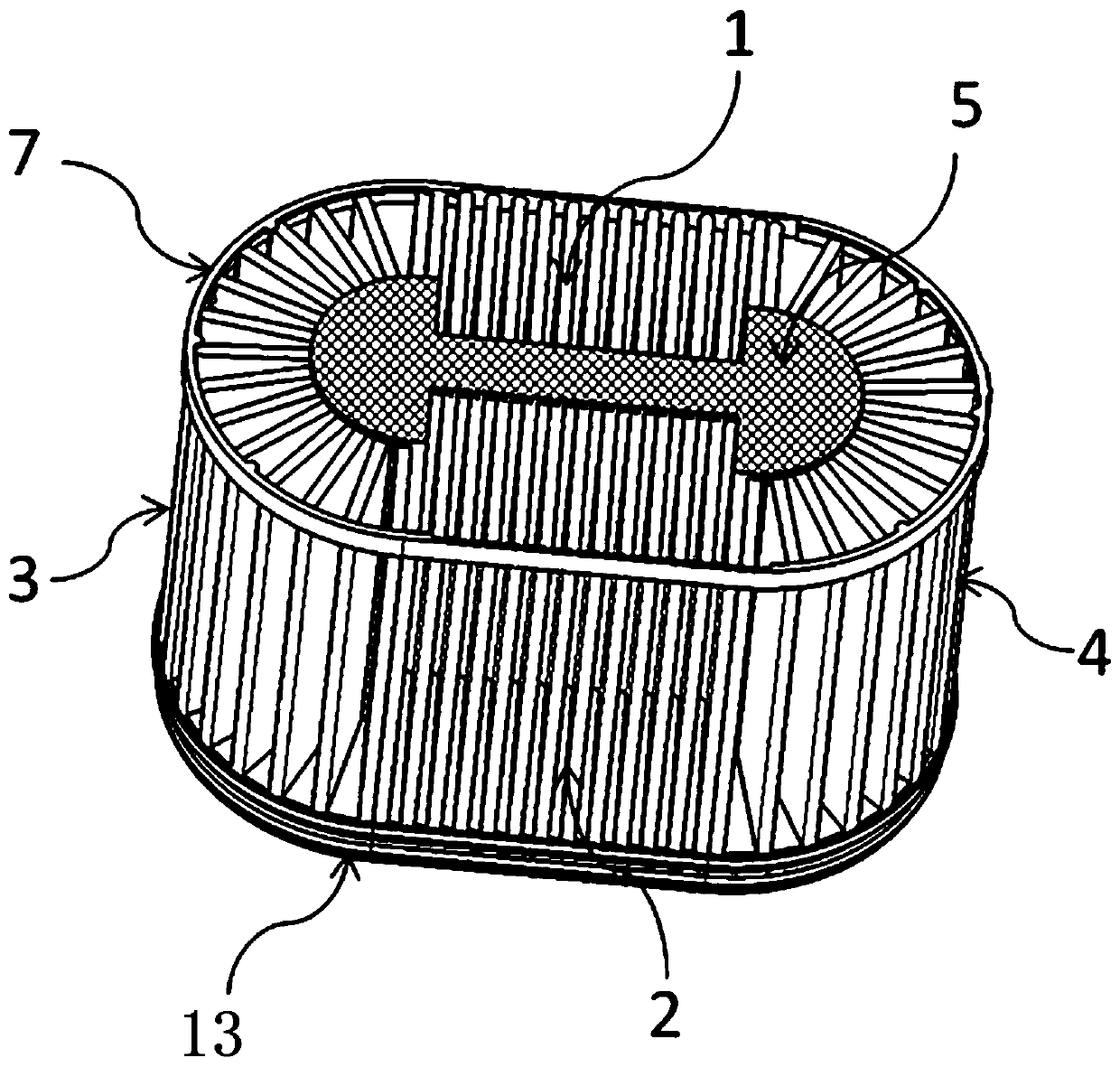

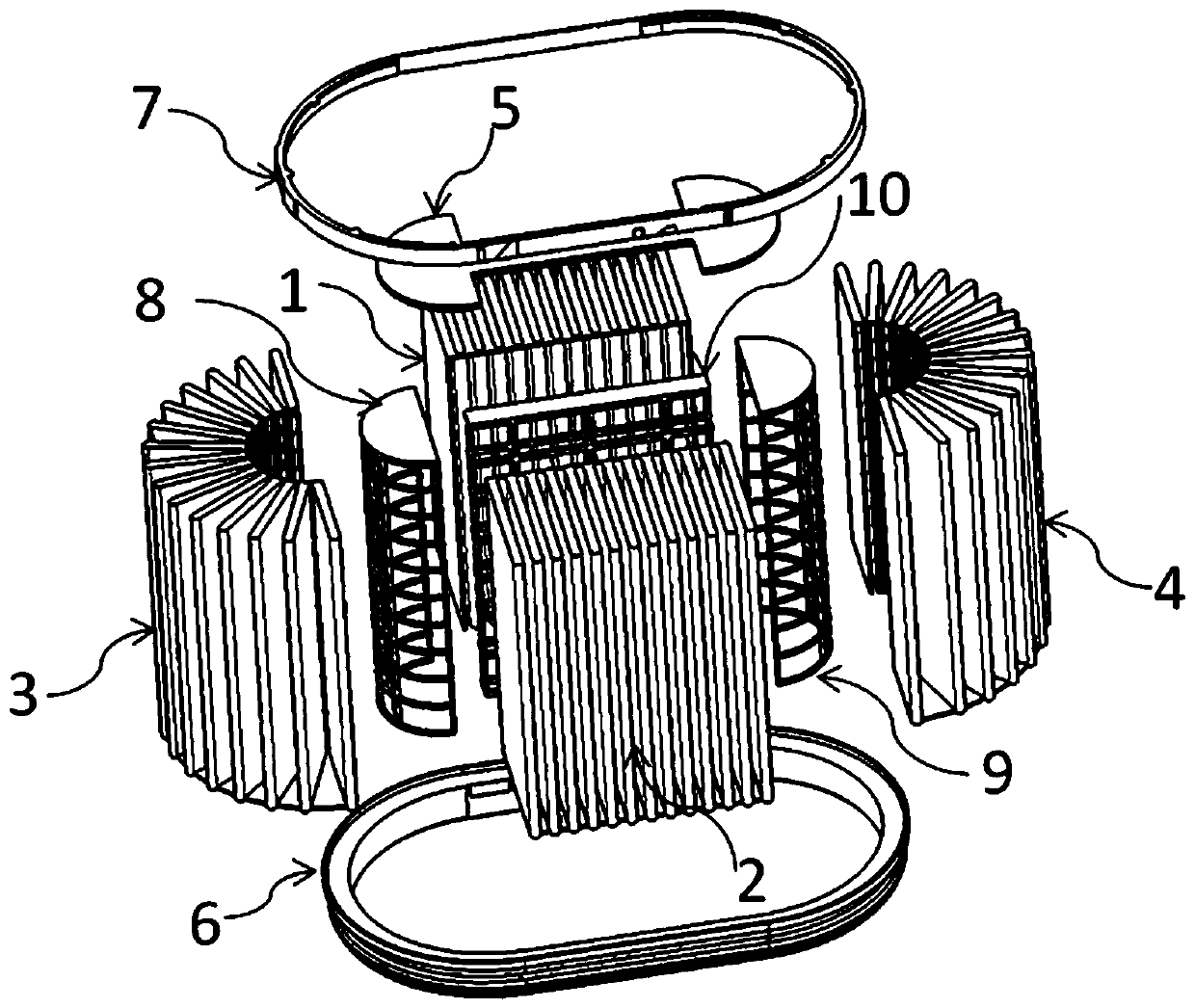

Combined air filter element

PendingCN110523151AReduce intake resistanceLarge dust holding capacityGas treatmentDispersed particle filtrationAir filterEngineering

The invention discloses a combined air filter element of which a first filter element and a second filter element are cubic or rectangle-shaped; the second filter element and the first filter elementare distributed in symmetry front and back; a third filter element and a fourth filter element are symmetrically distributed on both sides of the first filter element and the second filter element; the third filter element and the fourth filter element are of semicircular or semi-arched ring structures; and the first filter element, the second filter element, the third filter element and the fourth filter element form a waist-shaped or elliptic three-dimensional annular filter element. The defect that the space of a hollow filter element of a conventional annular cylindrical filter element isinsufficiently utilized can be overcome; due to adoption of the first filter element, the second filter element, the third filter element and the fourth filter element, a conventional hollow part canbe sufficiently utilized; and due to up and down opened end surfaces, air flows penetrate through the filter elements in an axial direction, so that the air inlet resistance of the filter elements canbe reduced, the filtering are can be increased, a filter element of a same shape and volume has a large air inlet quantity and a dust containing capacity, and thus a high filtering efficiency and a long service life can be achieved.

Owner:SHANGHAI BINDAO FILTER

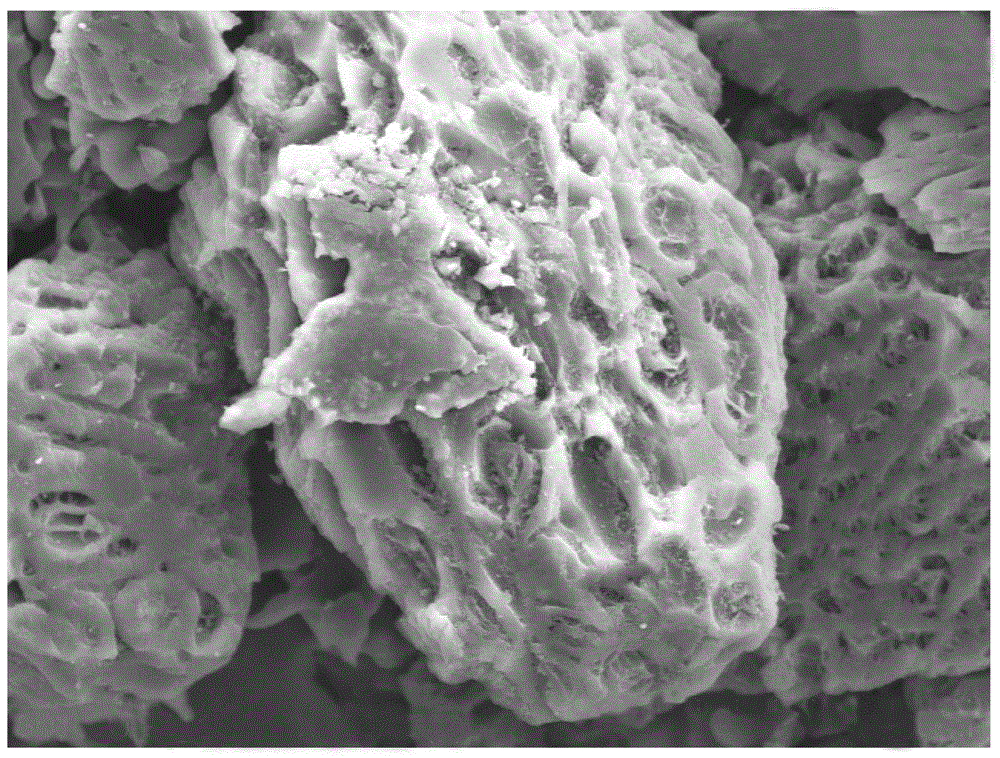

A microbead/nanofiber composite air filter material with gradient structure and preparation method thereof

ActiveCN105999852BImprove filtration efficiencyIncrease dust holding capacityLayered product treatmentSynthetic resin layered productsAir filtrationCompound a

The invention relates to a microbead / nano-fiber composite air filtration material with a gradient structure and a preparation method thereof. The preparation method consists of: introducing microbeads into a nano-fiber layer, adjusting the mass ratio of a spinning solution for spinning the microbeads to a spinning solution for spinning the nano-fiber to control gradual increase of the microbead content along the filter material thickness direction from the bottom up, thus obtaining a microbead / nano-fiber layer with a gradient structure, and compounding a nonwoven substrate, the microbead / nano-fiber layer and a nonwoven covering layer by hot rolling process so as to obtain a sandwich structure composite air filtration material. According to the invention, the preparation process is simple, refitting of an electrospinning machine is not needed, the application range is wide, and the prepared composite filtration material has the advantages of high filtration efficiency, small resistance pressure drop, large dust holding capacity and long service life.

Owner:河北华纺纳米科技有限公司

Dust collection barrel of dust collector

The invention discloses a dust collection barrel of a dust collector, which is used for accommodating dust and impurities filtered from in-take air. A rotary compression piece is arranged in the dust collection barrel and is used for compressing dust and impurities in the dust collection barrel through mutual action with a fixed compression piece; the fixed shaft of the fixed compression piece is horizontally arranged inside the horizontal dust collection barrel provided with a cavity along the central shaft of the dust collection barrel of the dust collector; the rotating shaft of the rotary compression piece is inserted into the cavity of the fixed shaft in a rotating manner; a dust cover is retractably hinged at the opening end of the dust collection barrel; and a driving rod of a transmission gear penetrates through the lateral bottom surface of the dust collection barrel and is connected with the rotating shaft. The rotary compression piece is arranged on the horizontal shaft in the center of the dust collection barrel and is combined with the vertical fixed compression piece in a rotating manner to compress dust, so as to effectively compress dust in all directions, and enlarge the dust containing capacity; and since the dust cover is arranged on the side surface, the dust dumping is more labor-saving and convenient.

Owner:NANJING LG PANDA APPLIANCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com