Gas cycle purification device for sealed shaping room

A gas circulation and purification device technology, applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve problems such as power attenuation, insufficient powder melting, insufficient laser incident power, etc., to ensure airtightness and reduce wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

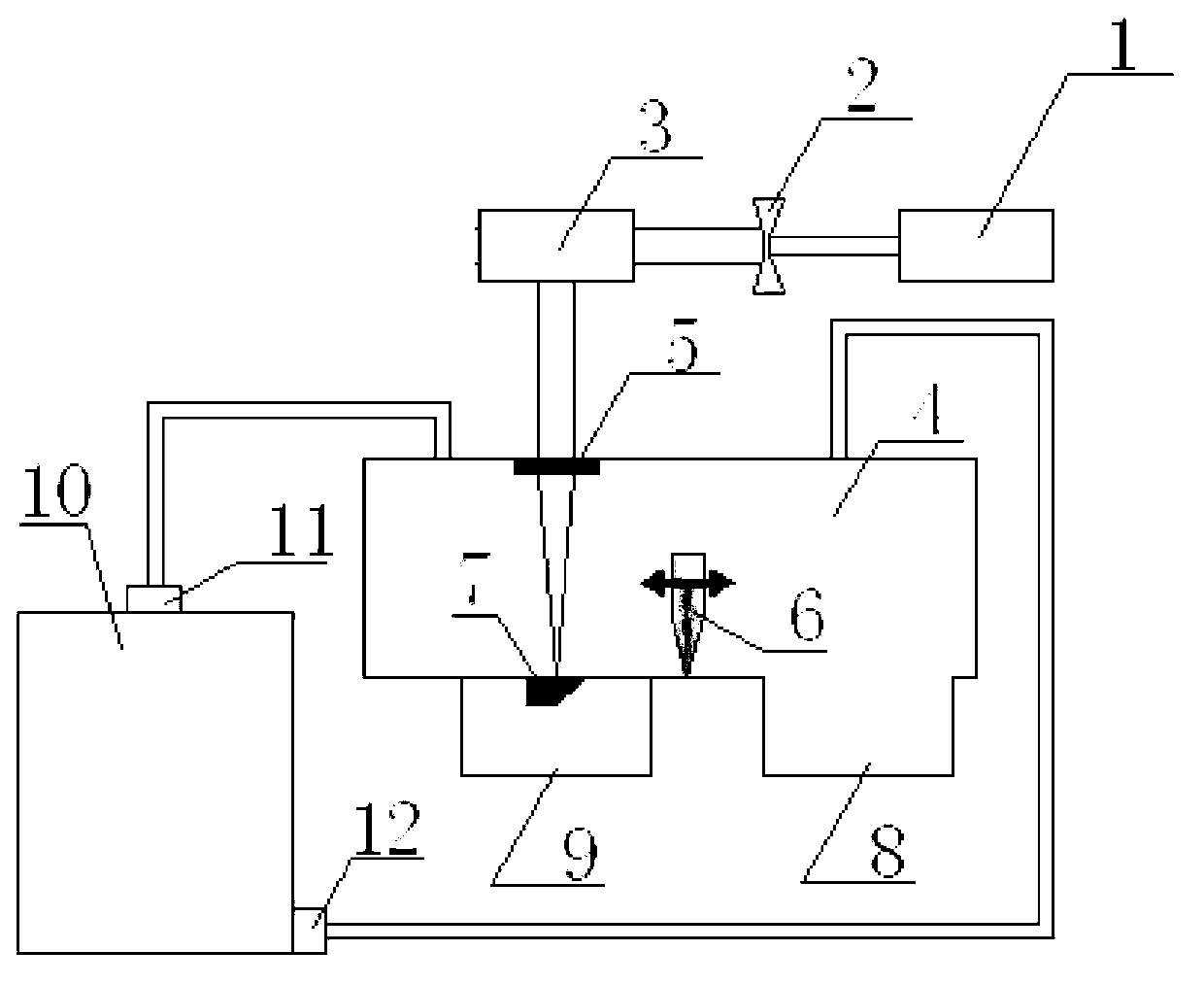

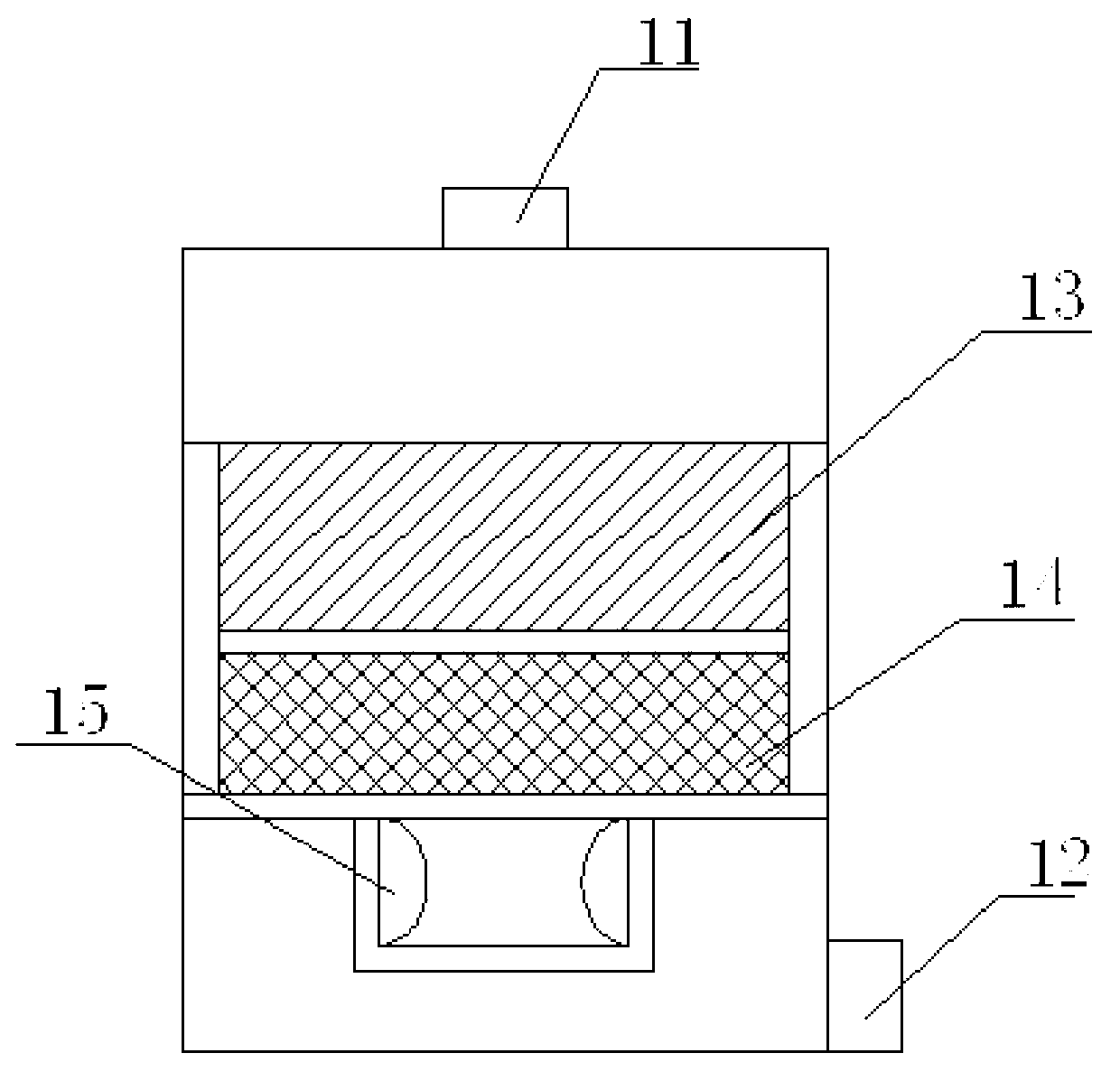

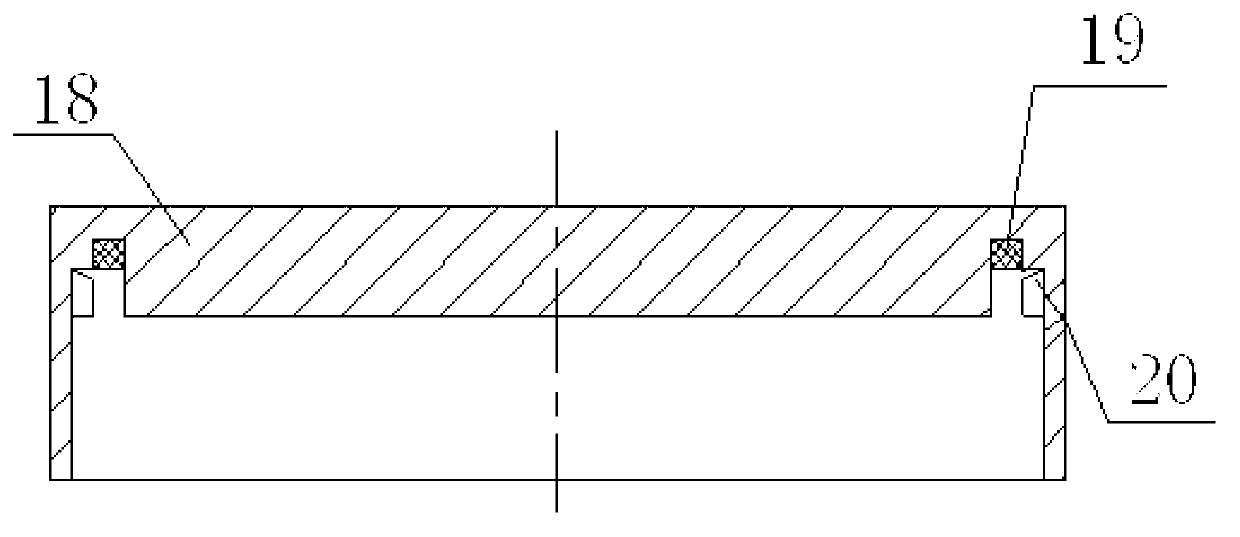

[0023] like figure 1 , figure 2 As shown, the gas circulation purification device of the sealed molding chamber of the present invention includes a molding chamber 4, and the gas circulation purification device 10 includes a sealed box body, and a pre-filter layer 13, a main filter layer 13, and a main filter layer are arranged in the sealed box body from top to bottom. Layer 14 and blower fan 15 are provided with an air inlet 11 on the top of the sealed box, and an air outlet 12 is arranged on one side of the bottom of the sealed box. The air inlet 11 is connected to one end of the molding chamber 4 through a pipeline, and the outlet The tuyere 12 is connected to the other end of the molding chamber 4 through a pipeline.

[0024] The pre-filter layer 13 adopts filter cotton. Capable of absorbing larger soot particles in the airflow.

[0025] The main filter layer 14 adopts a HEPA air filter. The removal efficiency of particles with a diameter of 0.3 microns or more can r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com