Composite active carbon rod filter element and preparation method

The technology of activated carbon rod and activated carbon powder is applied in the field of composite activated carbon rod filter element and preparation, which can solve the problems of black water, trouble and increase the hidden danger of water leakage, and achieve the effect of smooth surface, good filtering effect and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

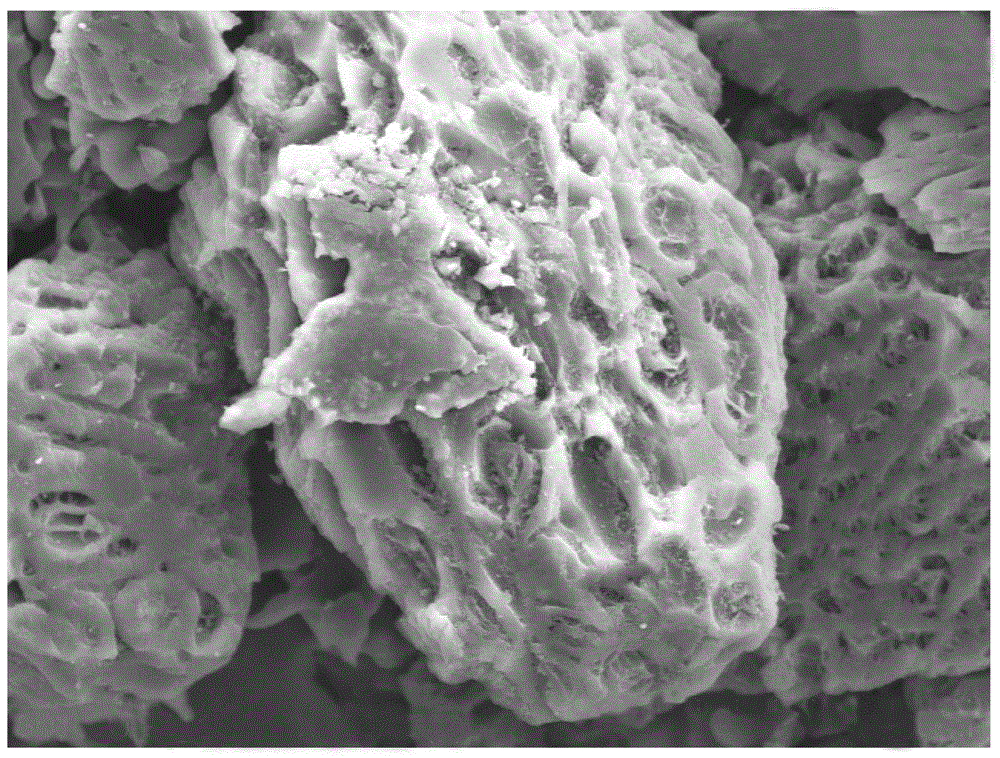

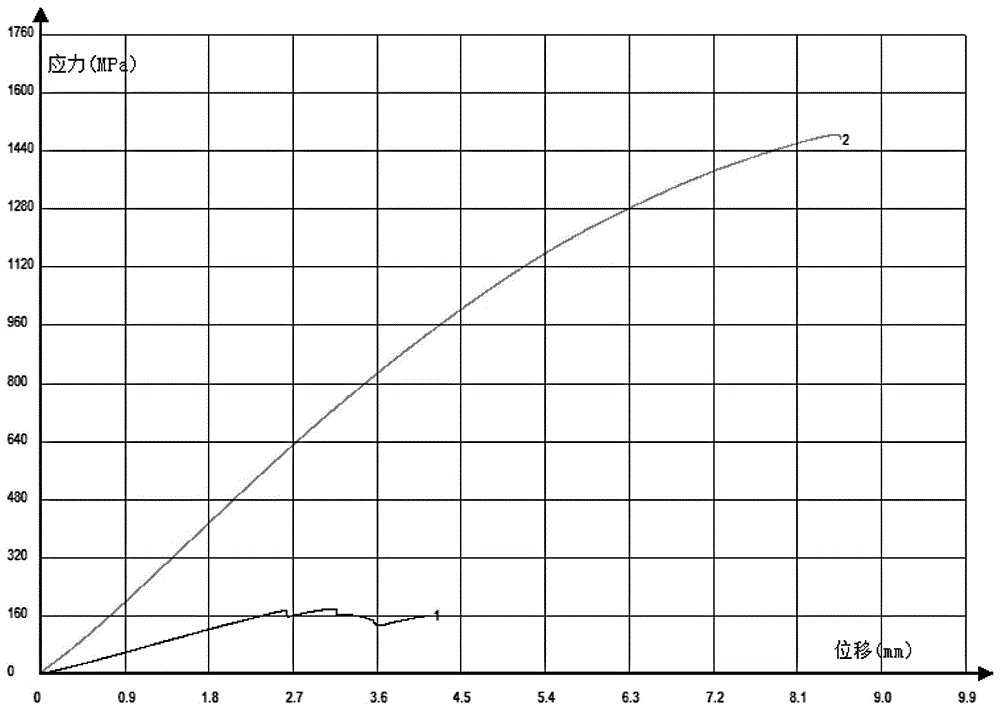

Image

Examples

preparation example Construction

[0034] A method for preparing a composite activated carbon rod filter element, comprising the following steps:

[0035] 1. Ingredients: prepare active carbon powder 30-50 by weight percentage, zeolite powder 5-10, porous carbon nanomaterial 5-10, graphene oxide 5-10, pore-forming agent 5-15, polymer binder 30- 50, antibacterial polymer 0-10; wherein, the polymer binder is ultra-high molecular weight polyethylene and low-temperature polyethylene mixed in a ratio of 7:3-5:5 by weight;

[0036] 2. Premixing: Mix the above ingredients at a speed of 400-800r / min for 10-30min;

[0037] 3. Filling molding: add the premixed material into the mold and press molding;

[0038] Fourth, sintering: heat the formed activated carbon rod and the mold together at 250-280°C for 30-60min;

[0039] 5. Demolding and cooling: Take out the formed compressed activated carbon rod; place the formed carbon rod in an environment of 0-5°C for rapid cooling for 5-10 minutes.

[0040] Add a polymer binder...

Embodiment 1

[0045] A composite activated carbon rod filter element, which is composed of the following components by weight percentage: activated carbon powder 30, zeolite powder 5, porous carbon nanomaterial 8, graphene oxide 7, sawdust 8, polymer binder 40, antibacterial polymer 2; Wherein, the polymer binder is mixed with ultra-high molecular weight polyethylene and low-temperature polyethylene at a weight ratio of 7:3.

[0046] A method for preparing a composite activated carbon rod filter element, comprising the following steps:

[0047] 1. Ingredients: Active carbon powder 30, zeolite powder 5, porous carbon nanomaterial 8, graphene oxide 7, sawdust 8, polymer binder 40, antibacterial polymer 2; among them, polymer binder Be ultra-high molecular weight polyethylene and low-temperature polyethylene mixed in a ratio of 7:3 by weight;

[0048] 2. Premixing: Mix the above ingredients at a speed of 500r / min for 20min;

[0049] 3. Filling molding: add the premixed material into the mold...

Embodiment 2

[0053]A composite activated carbon rod filter element, which is composed of the following components by weight percentage: activated carbon powder 40, zeolite powder 5, porous carbon nanomaterial 8, graphene oxide 5, sawdust 5, polymer binder 35, antibacterial polymer 2; Wherein, the polymer binder is mixed with ultra-high molecular weight polyethylene and low-temperature polyethylene at a weight ratio of 6:4.

[0054] A method for preparing a composite activated carbon rod filter element, comprising the following steps:

[0055] 1. Ingredients: Active carbon powder 40, zeolite powder 5, porous carbon nanomaterial 8, graphene oxide 5, sawdust 5, polymer binder 35, antibacterial polymer 2; among them, polymer binder Be ultra-high molecular weight polyethylene and low-temperature polyethylene mixed in a ratio of 6:4 by weight;

[0056] 2. Premixing: Mix the above ingredients at a speed of 400r / min for 30min;

[0057] 3. Filling molding: add the premixed material into the mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com