Heating yarn and woven or knitted fabric using this heating yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]Hereinafter, the invention will be described in detail with reference to FIGS. 1 to 6. The description here is illustrative in purpose and is simply intended to describe example embodiments of the invention. The purpose is to provide description of the principle and conceptual characteristics of the invention in the most effective and comprehensible manner possible. Regarding this, there is no intent to give any structural detail of the invention beyond what is necessary to gain a fundamental understanding of the invention. The way in which various modes of the invention are actually embodied is made evident to one skilled in the art by the description together with the drawings.

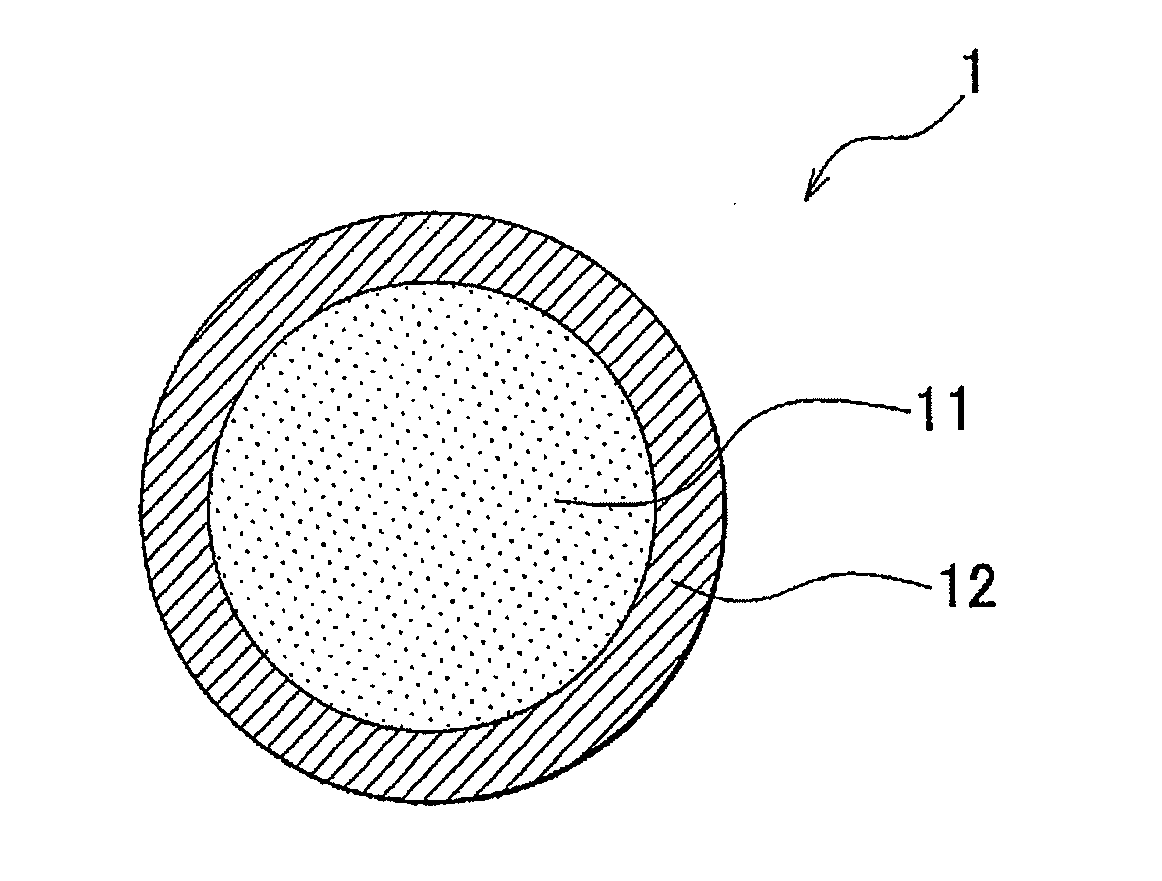

[0019]A heating yarn 10 of one example embodiment of the invention includes an insulating yarn 101 and a conductive yarn 1 that is wound around this insulating yarn 101. The conductive yarn 1 has an insulating core yarn 11 and a plated layer 12 formed on the peripheral surface of the insulating core ya...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com