Production line for concrete prefabricated piece

A concrete prefabricated part and production line technology, which is applied in manufacturing tools, ceramic molding workshops, auxiliary molding equipment, etc., can solve the problems of increasing the maintenance cost of the curing kiln, increasing the complexity of the curing kiln, and the palletizing frame is easy to rust, etc. Reduced area, similar thermal expansion coefficient, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

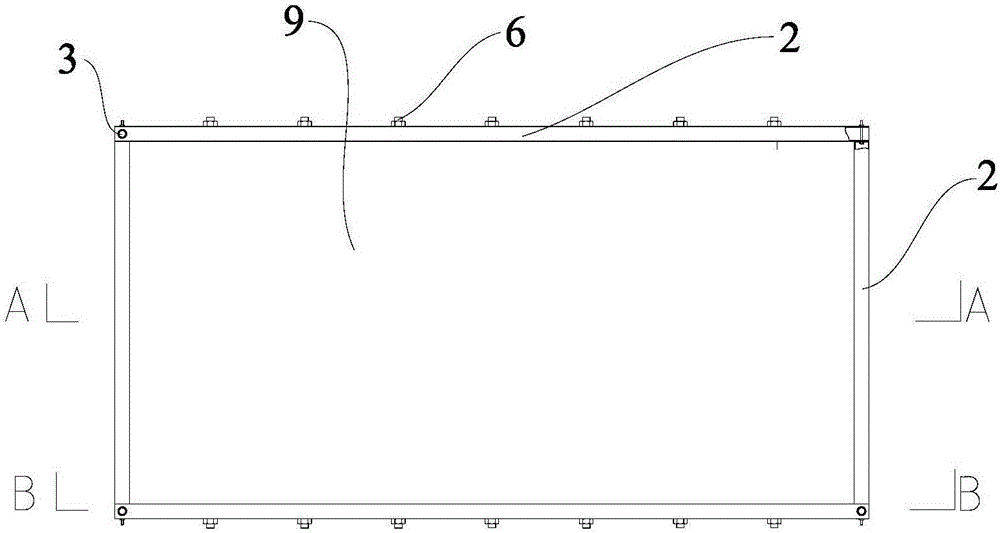

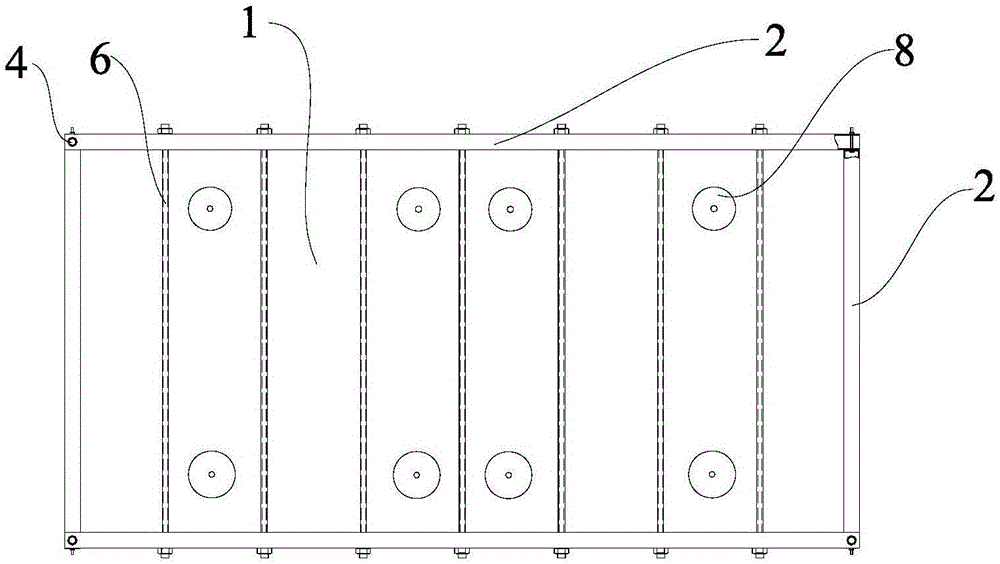

[0092] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments according to the descriptions in this document.

[0093] Embodiments of the present invention are as follows, with reference to figure 1 , a production line for prefabricated concrete, comprising

[0094] Mold pretreatment station 11: used to clean the mold and / or apply a release agent;

[0095] Cloth station 12: for pouring and forming prefabricated parts;

[0096] Mold assembly station 13: used to stack and combine the molds after the cloth has been completed. The bottom and upper parts of the molds are provided with connecting parts. The upper and lower molds are f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com