Catheter of composite structure

A composite structure and catheter technology, which is applied in the field of medical devices, can solve the problems of increased catheter wall thickness, vascular intima damage, punctured blood vessels, etc., and achieve the effects of reduced catheter wall thickness, improved stenotic blood vessel ability, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

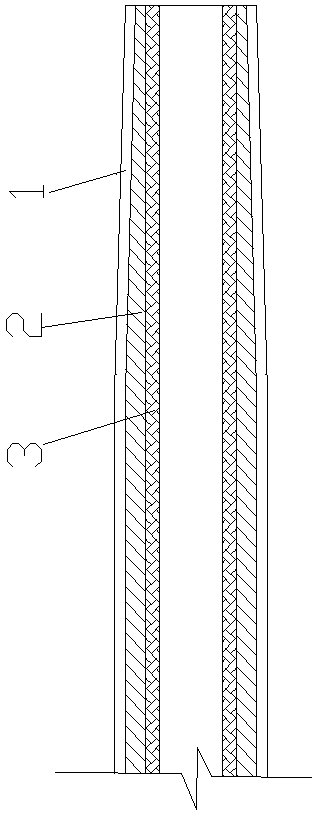

[0047] The composite structure conduit of the present invention (hereinafter referred to as the composite conduit) comprises a circular tubular plastic conduit 1 and a circular tubular braided mesh 2 nested together in the plastic conduit, such as figure 1 shown. In addition, in order to reduce the friction of the inner wall of the composite catheter, preferably a smooth inner layer 3 is attached to the innermost layer of the composite catheter, and the inner layer 3 is an ultra-thin polytetrafluoroethylene tube (PTFE) or high-density polyethylene tube (HDPE) , is a block polyetheramide elastomer Pebax containing additives to reduce the coefficient of friction.

[0048] Because the wall thickness of the distal part of the braided mesh 2 in the middle of the catheter is gradually reduced, the outer diameter of the distal end of the catheter of the present invention is also gradually reduced, and the hardness of the distal end of the catheter is gradually reduced. This design is...

Embodiment 2

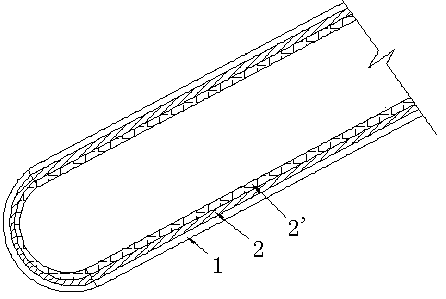

[0066] The composite catheter of the present invention comprises a circular tubular polymer tube 1 and a circular tubular braided net 2 and a spring net 2' nested together in the polymer tube, such as figure 2 shown. In addition, in order to reduce the frictional force of the inner wall of the composite conduit, preferably an ultra-thin polytetrafluoroethylene tube (not shown) is attached to the innermost layer of the composite conduit.

[0067] The material of the polymer tube is nylon, block polyetheramide elastomer, polyurethane or silicone rubber.

[0068] The metal wire material of the woven mesh and spring mesh is tweezers titanium alloy, cobalt-chromium alloy or stainless steel, or pure platinum, pure gold, pure tungsten or pure tantalum, or pure platinum alloy, pure gold alloy, pure tungsten alloy or Pure tantalum alloy.

[0069] The spring mesh can improve the bending resistance of the composite catheter, and the braided mesh can improve the axial tensile performa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com