Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

742results about How to "Will not shift" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

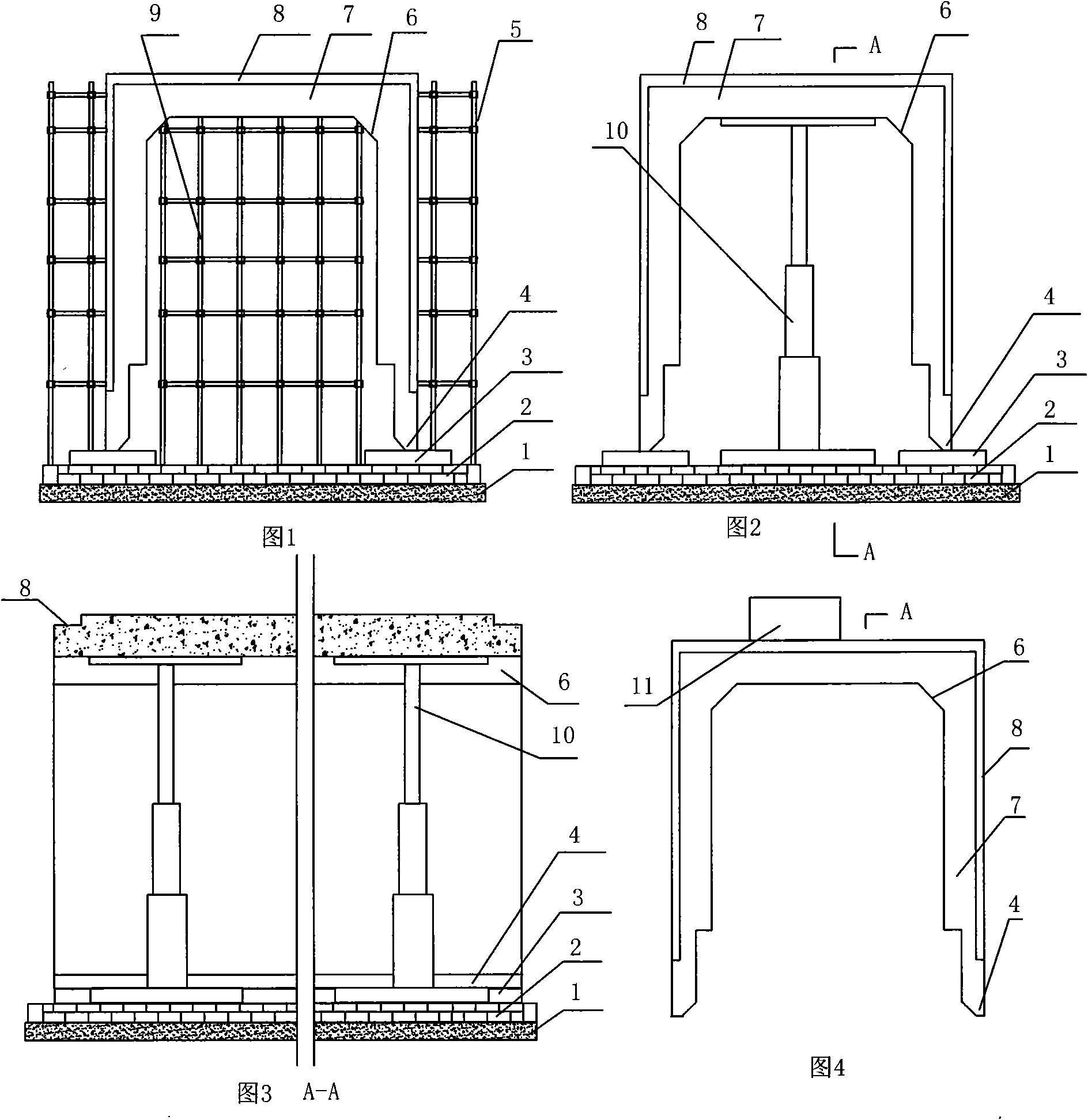

Overlapping integral type prefabricated assembly structure for comprehensive pipe gallery and construction method thereof

ActiveCN106013228ALarge working spaceActive connectionArtificial islandsUnderwater structuresEngineeringAssembly structure

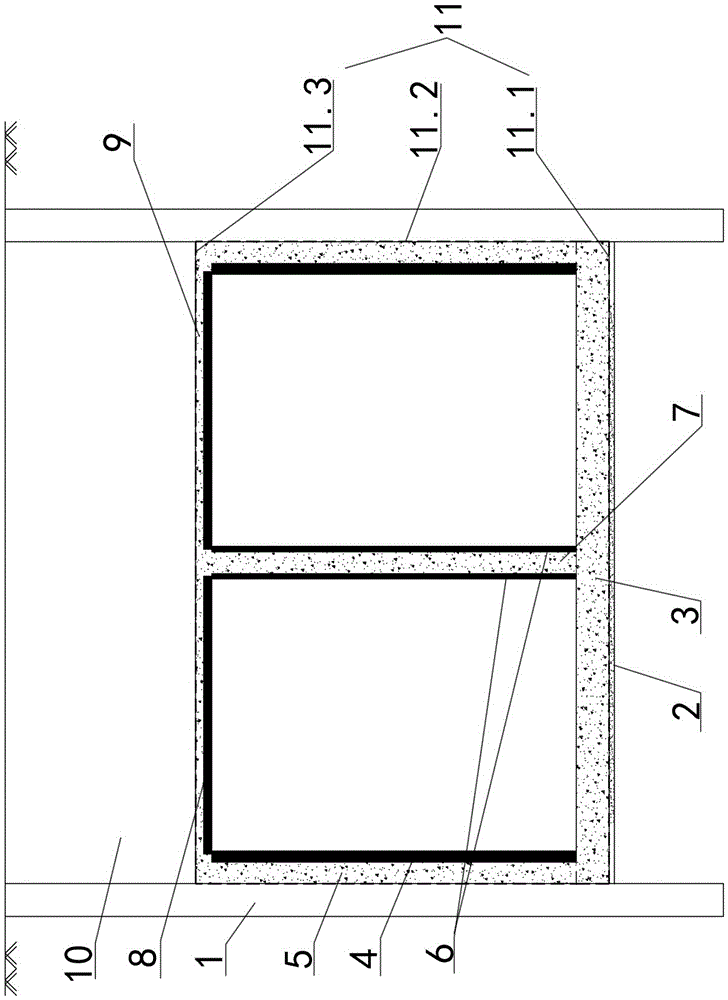

The invention discloses an overlapping integral type prefabricated assembly structure for a comprehensive pipe gallery and a construction method thereof. The overlapping integral type prefabricated assembly structure comprises envelop enclosures, a pipe gallery prefabricated assembly structure body, a bottom plate cushion course and a completely outer-cladding waterproof layer, wherein the envelop enclosures are located in a foundation pit; the pipe gallery prefabricated assembly structure body is arranged between the envelop enclosures; the bottom plate cushion course is arranged under the pipe gallery prefabricated assembly structure body; and the completely outer-cladding waterproof layer is arranged on the outer side surface of the pipe gallery prefabricated assembly structure body in a cladding mode. The upper portion of the pipe gallery prefabricated assembly structure body is filled with backfill earth, and the completely outer-cladding waterproof layer is arranged on the outer side surface of an outer side cast-in-situ part of the pipe gallery prefabricated assembly structure body in a cladding mode. The construction method of the overlapping integral type prefabricated assembly structure comprises the steps of prefabricated component machining, foundation pit excavation, bottom plate pouring, side wall construction, mid-partition construction, top plate construction, earth backfilling and the like. According to the overlapping integral type prefabricated assembly structure for the comprehensive pipe gallery and the construction method thereof, the prominent problems of force bearing of joints, water seepage of connection seams and the like in the underground engineering prefabrication process are solved; and the structural modes of bottom plate casting in situ, side wall single-layer overlapping, mid-partition double-layer overlapping, top plate overlapping, all-joint casting in situ and completely outer-side waterproof layer cladding are adopted, so that effective connection and the waterproof function of the joints are ensured.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Tea-leaf boxing machine

ActiveCN103183140AGuaranteed success rateEliminate the problem of inaccurate positioningIndividual articlesDrive shaftPulp and paper industry

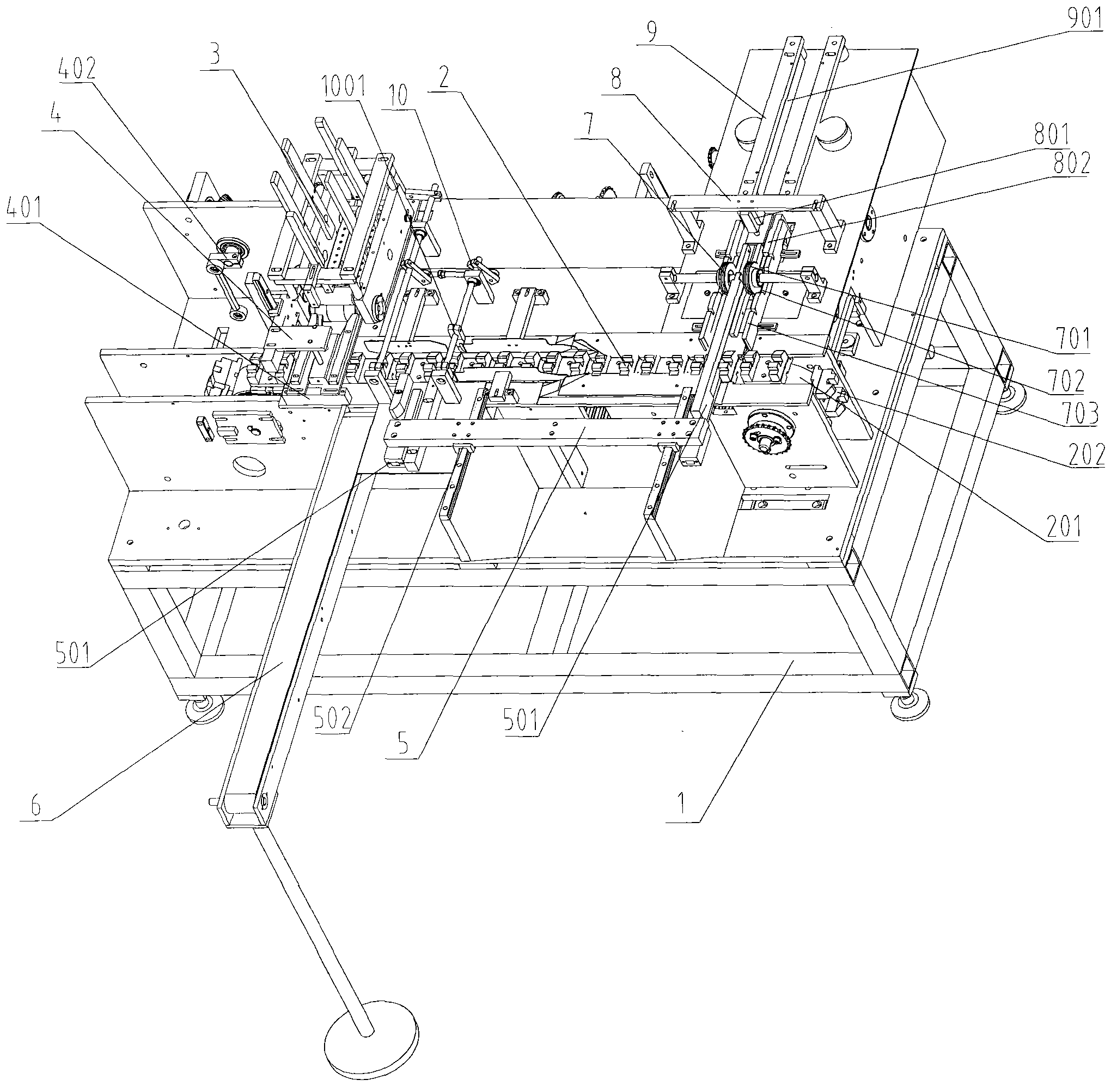

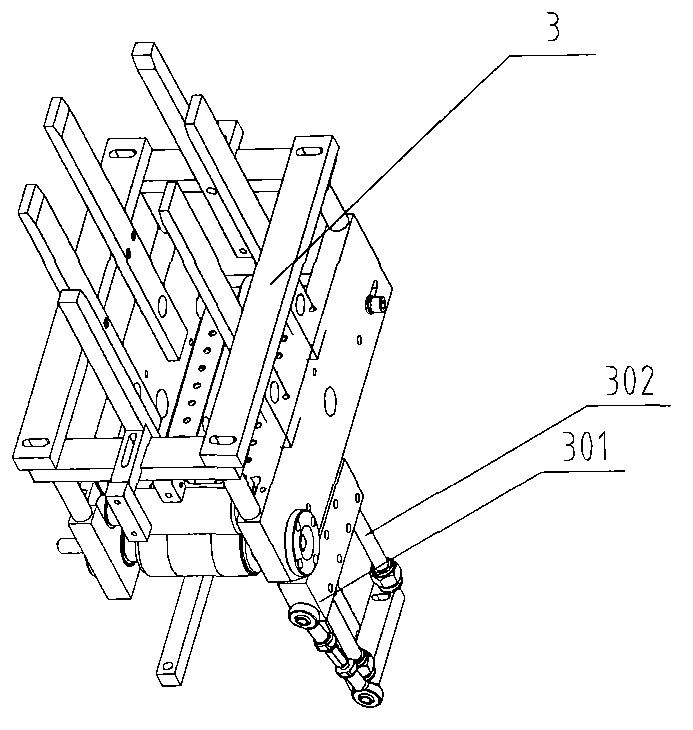

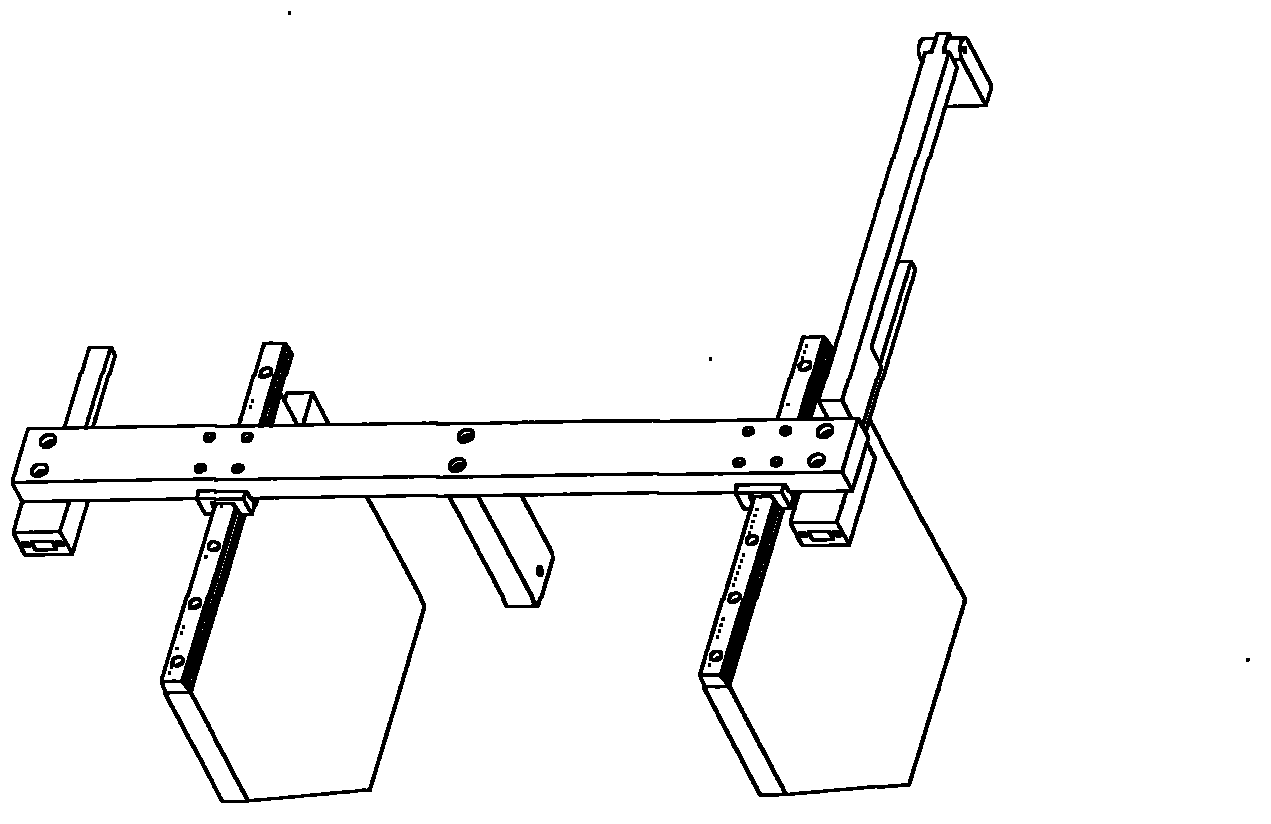

A tea-leaf boxing machine comprises a rack, as well as a paper box bin component, an air suction mechanism, a paper box forming module component, a paper box pressure block component, a paper box lug folding mechanism, a feeding mechanism, a material incoming and box outgoing push mechanism, a box gluing mechanism, a paper box shaping mechanism and an intermittent indexing drive device which are mounted on the rack, wherein the paper box bin component comprises a paper box bin and a paper box pressure block which are located on the same straight line, and the paper box pressure block is located above paper box forming modules; the air suction mechanism is arranged below the paper box bin component, and connected with a first rocker arm of a main transmission shaft; and the paper box forming module component comprises the paper box forming modules and a synchronous belt, the paper box forming modules are uniformly distributed on the synchronous belt, and the synchronous belt is connected with the intermittent indexing drive device. The invention provides the tea-leaf boxing machine which can perform mechanization packing, reduce the cost, and improve the efficiency.

Owner:浙江武义浩伟机械有限公司

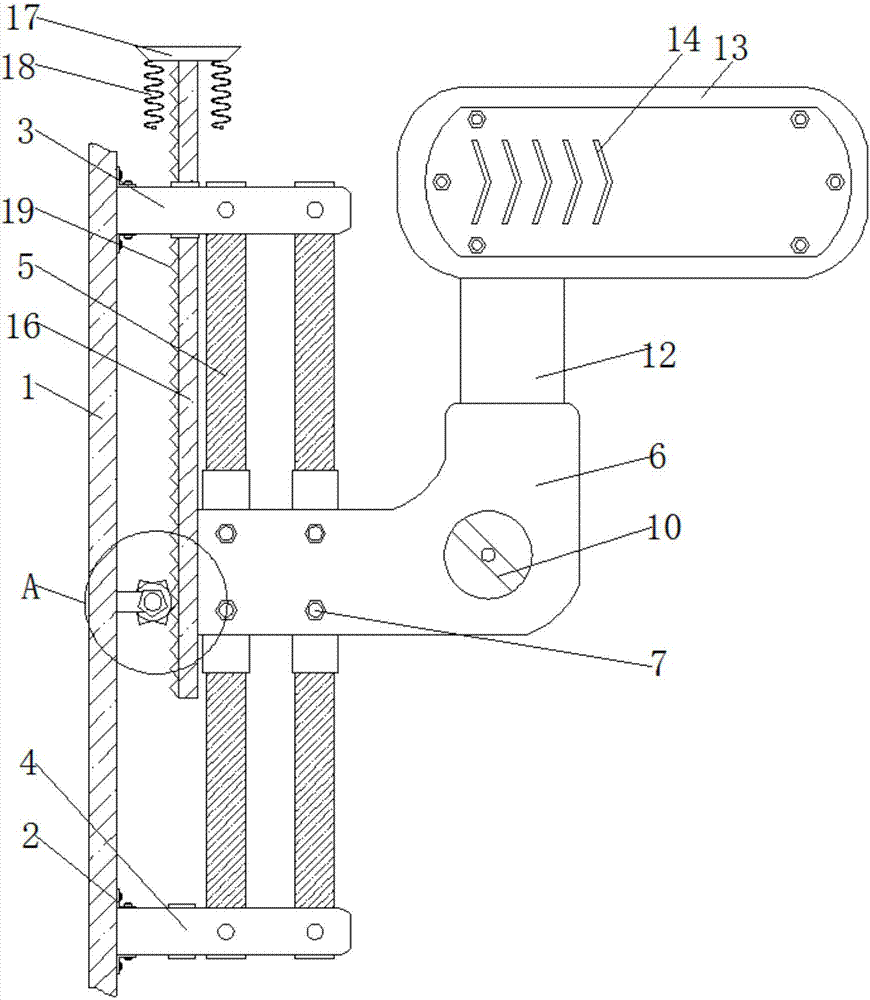

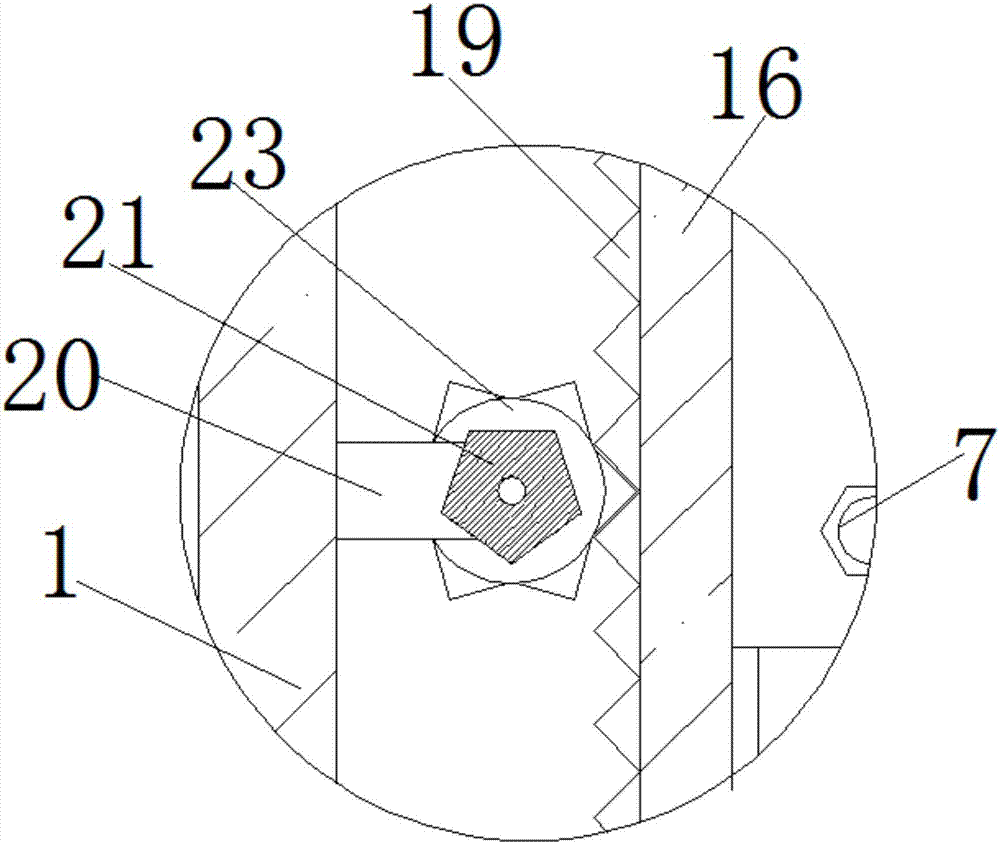

Movable adjustable method of intelligent monitoring device

ActiveCN107339576AAdjust the monitoring rangeAdjust the monitoring directionClosed circuit television systemsStands/trestlesDrive shaftElectrical and Electronics engineering

The invention discloses a movable adjustable method of an intelligent monitoring device. The intelligent monitoring device comprises a base. The two ends of the top surface on the inner side of the base are both fixedly connected with electric push rods. The tail ends of the two electric push rods are both fixedly connected to the middle portions of connecting plates. The middle portions of the bottom faces of the two connecting plates are fixedly connected with limiting telescopic rods. The ends, away from the connecting plates, of the two limiting telescopic rods are both fixedly connected with movable devices. The limiting telescopic rods are inserted into buffer springs. One ends of the two buffer springs are fixedly connected to the bottom faces of the connecting plates. The other ends of the two buffer springs are both fixedly connected to the top faces of the movable devices. A driving shaft is fixedly connected between the two movable devices. According to the movable adjustable method of the intelligent monitoring device provided by the invention, a rotation motor and an adjusting motor are matched with each other, the purpose of adjusting the monitoring device is achieved, the method has the advantage that the monitoring device can be moved and adjusted, and the problem that the monitoring range of an existing movable intelligent monitoring device cannot be adjusted is solved.

Owner:金税信息技术服务股份有限公司

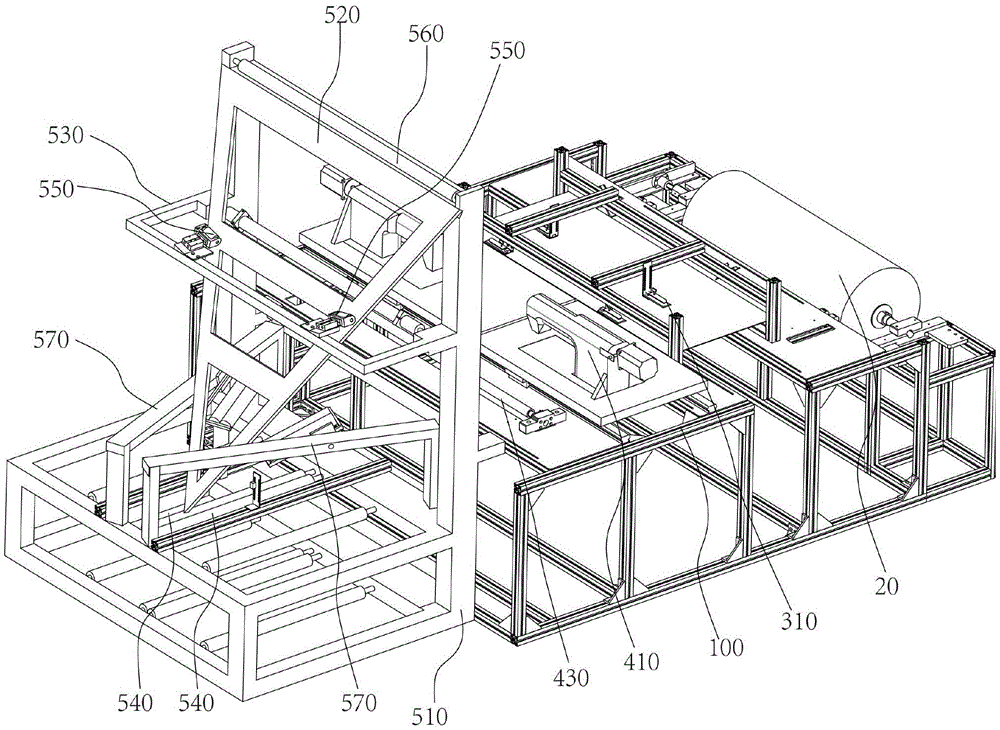

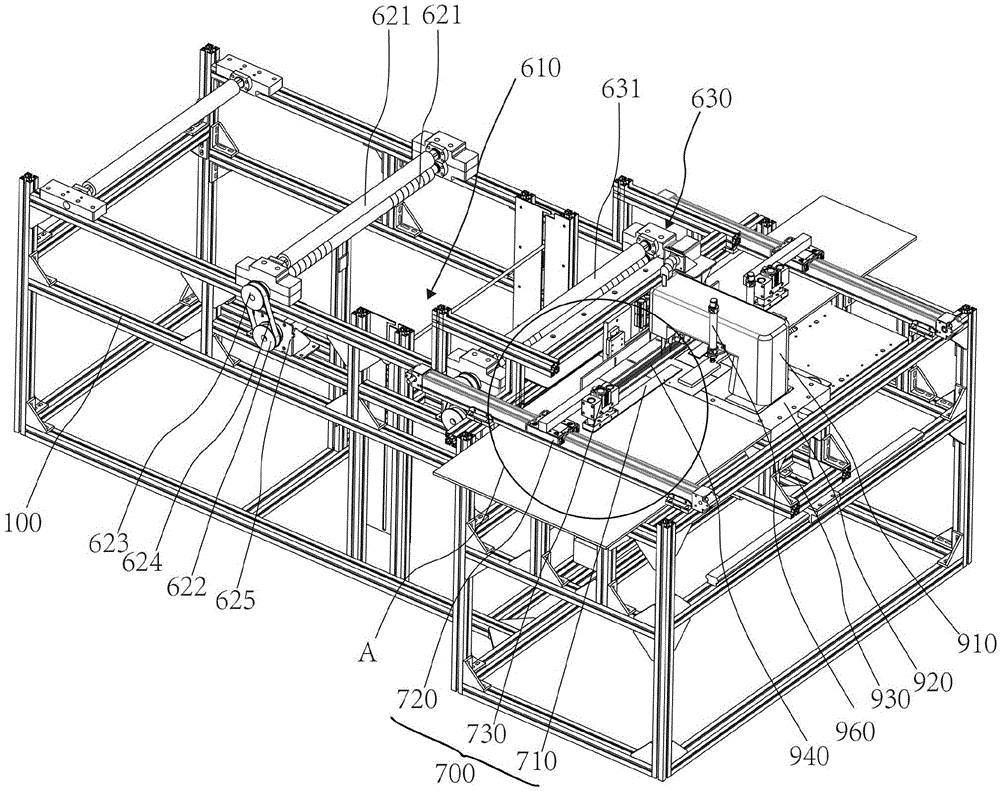

Paper bag machine

ActiveCN103909679AWill not shiftIncrease productivityBox making operationsPaper-makingEconomic benefitsPaper machine

The invention discloses a paper bag machine which comprises a forming mechanism, a feeding mechanism, a snapping mechanism, an edge sealing mechanism and an output mechanism. The forming mechanism, the feeding mechanism, the snapping mechanism, the edge sealing mechanism and the output mechanism are sequentially arranged on a framework. The paper bag machine has the advantages that snapping working procedures can be efficiently and stably carried out by the aid of the snapping mechanism via a set structure, gluing, edge folding and pasting steps in edge sealing working procedures can be continuously completed by the aid of the edge sealing mechanism via a set structure, and accordingly the edge sealing efficiency can be improved; the production efficiency and the bag forming quality of the paper bag machine can be greatly improved owing to excellent modification on the structure of the paper bag machine, and a tremendous economic benefit can be brought to a manufacturer.

Owner:WENZHOU RUIZHI PACKING MACHINERY

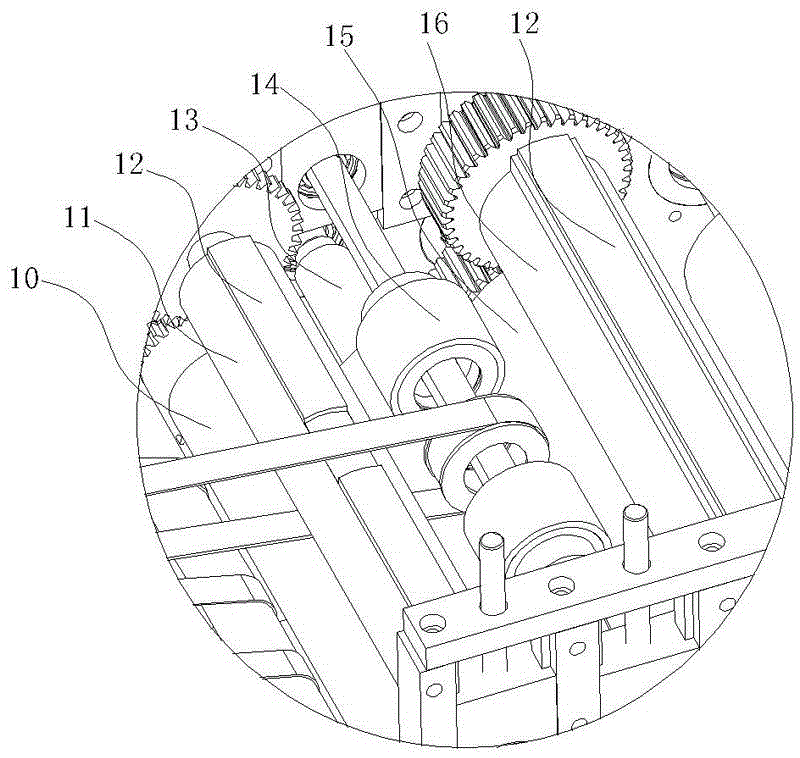

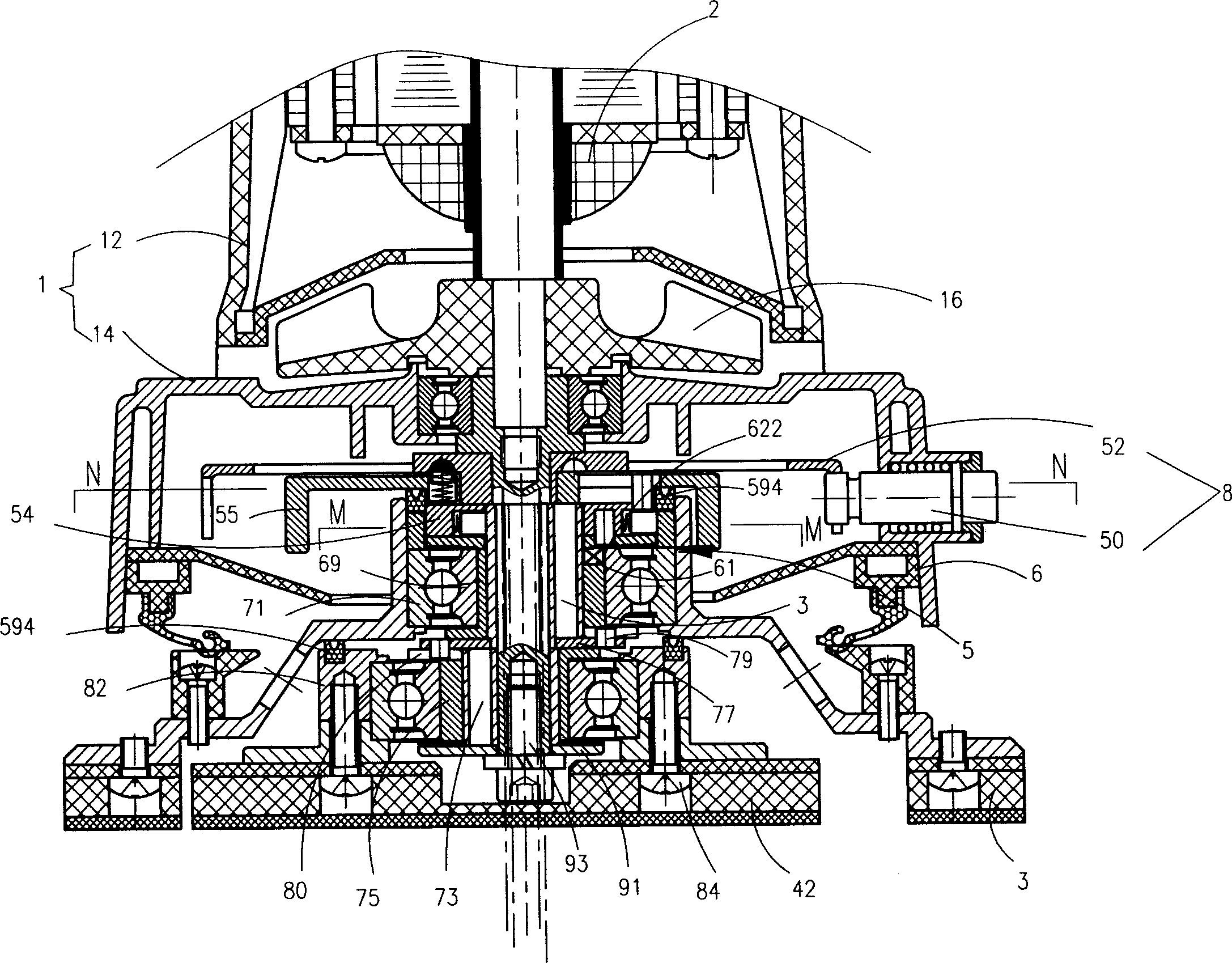

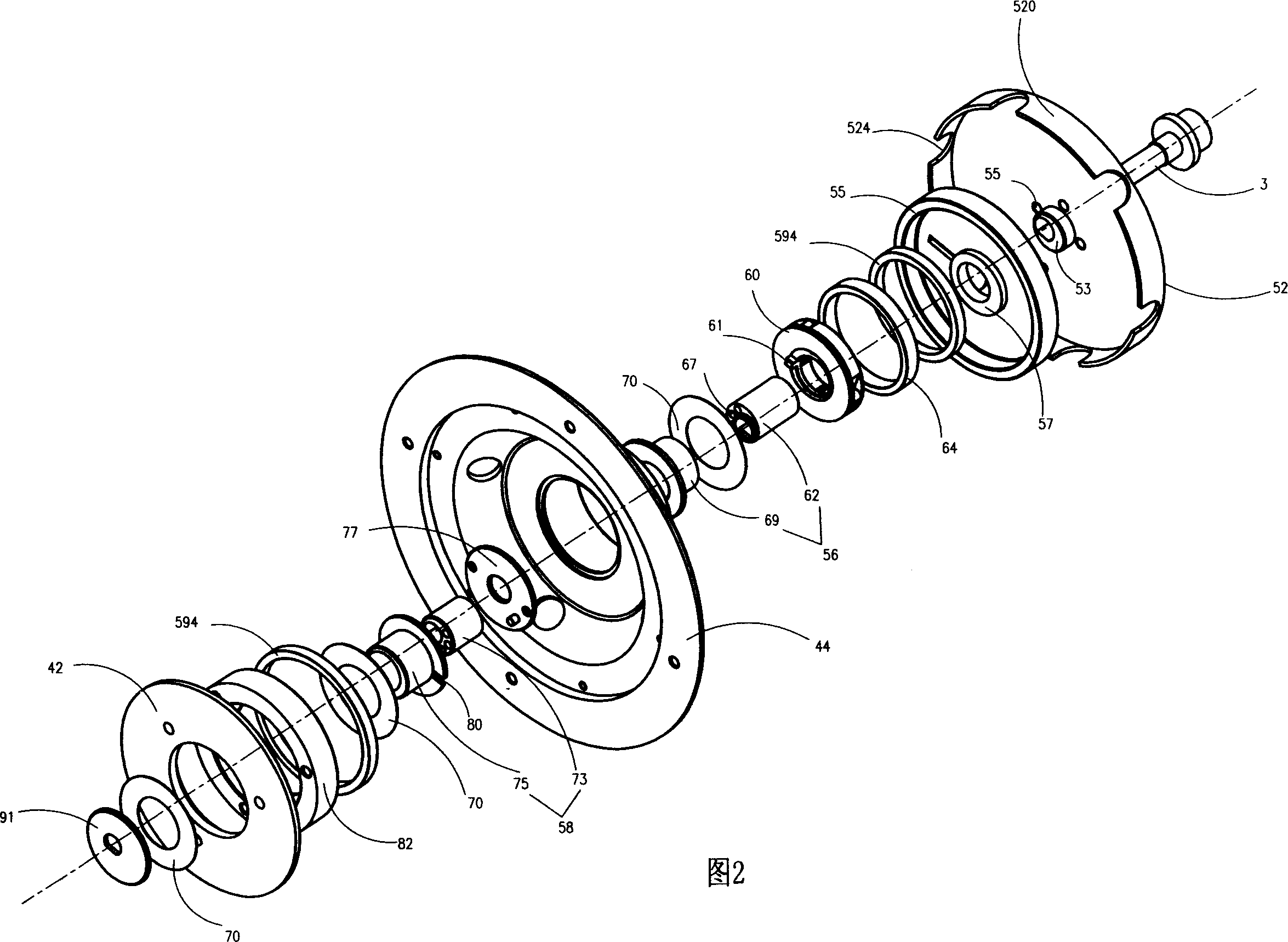

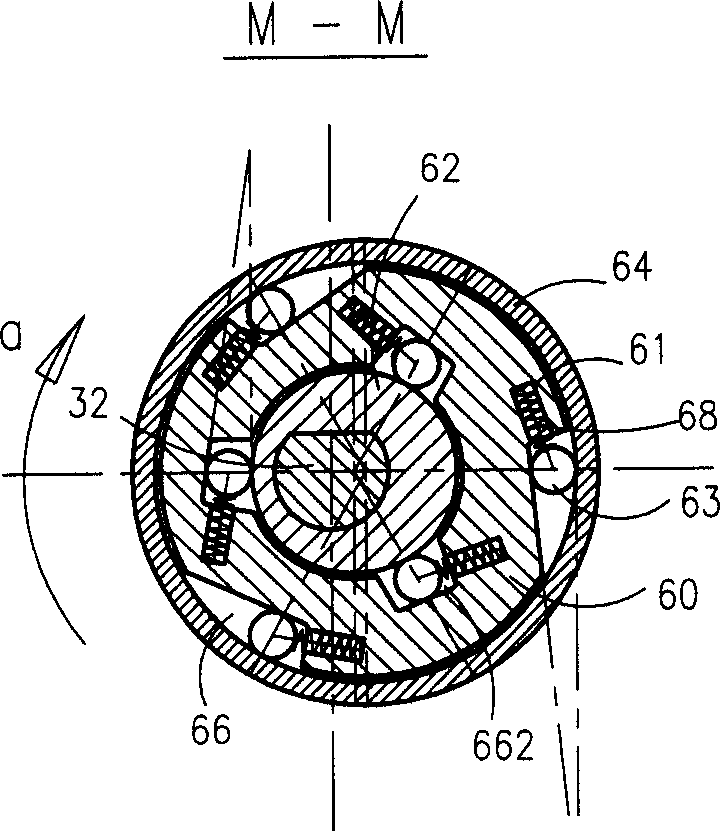

Eccentricity regulating mechanism

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

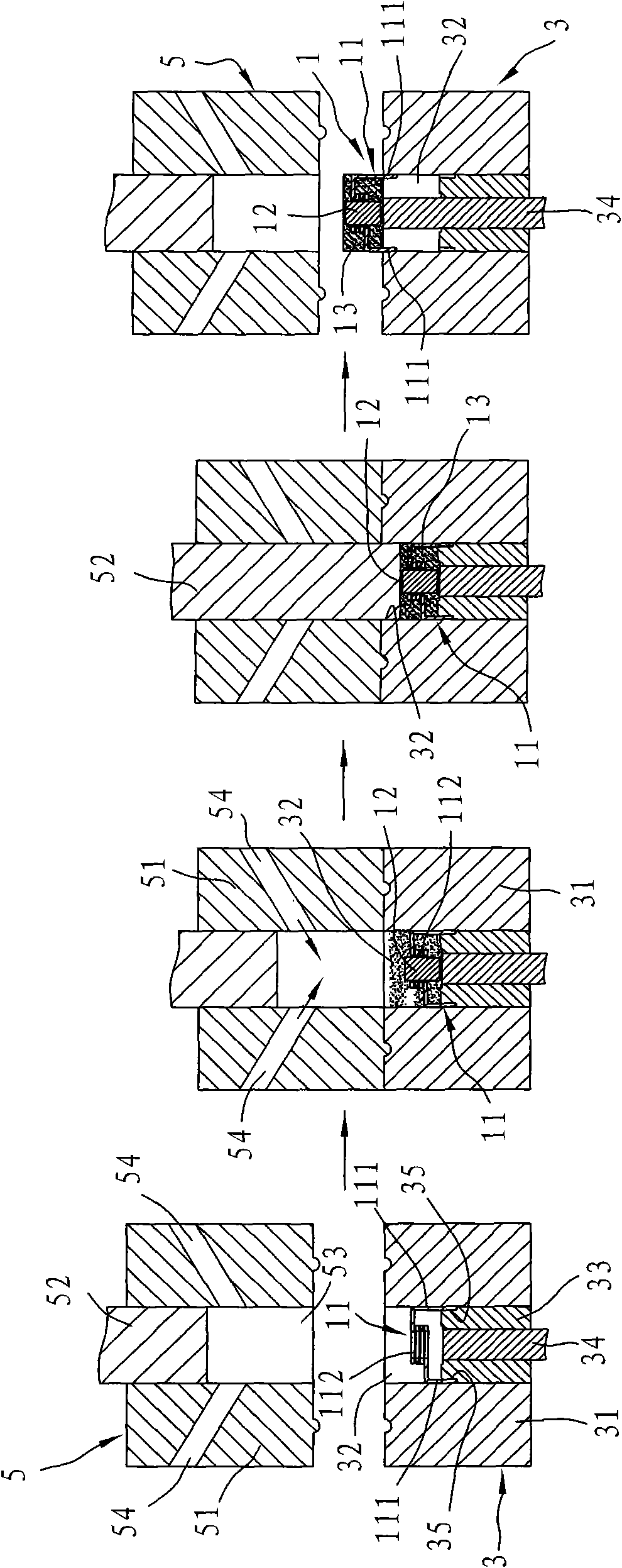

Method and device for manufacturing inductance element

InactiveCN102034588AImprove qualityWill not shiftTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureEngineeringInductor

The invention relates to a method and a device for manufacturing an inductance element. The method comprises the following steps of: firstly, wrapping and fixing a bent at the periphery of a coil and two terminals which are combined with one another, and clamping and pressing the bent by using a pressing die and a lower die to ensure that the coil is accommodated in an upwards opening powder-filling hole coordinately defined by the pressing die and the lower die; secondly, filling magnetic-conductive powder into the powder-filling hole and completely burying the coil; and finally, performing die pressing on the magnetic-conductive powder in the powder-filling hole by utilizing an upper die to form a cured coated block. Therefore, the coil cannot perform displacement in the magnetic-conductive powder filling process or the powder metallurgy die forming process under the stable support of the bent, so that the quality and yield of manufactured inductance elements can be improved.

Owner:王仕任

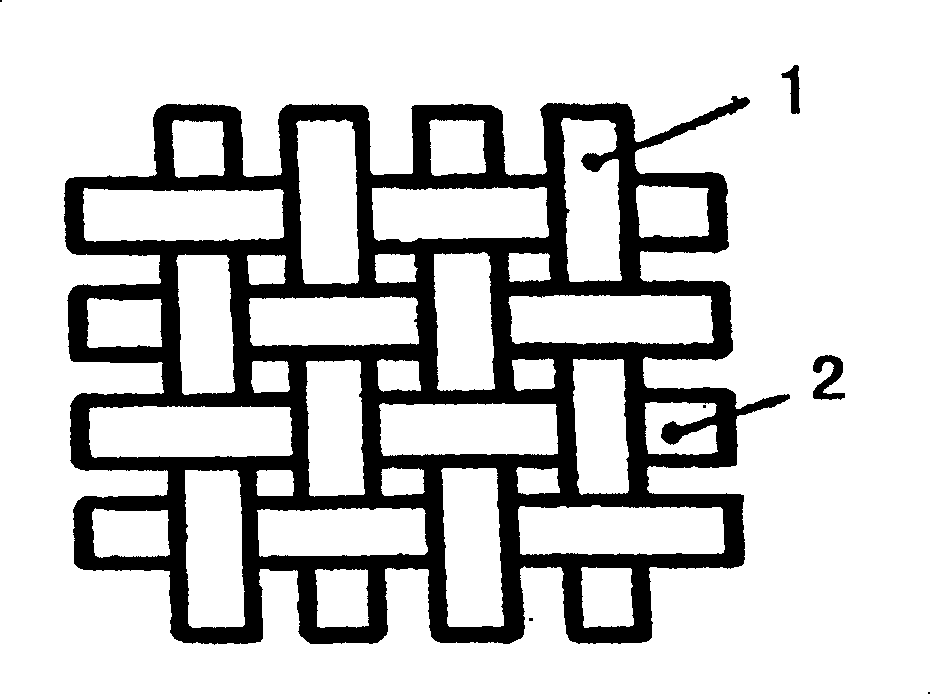

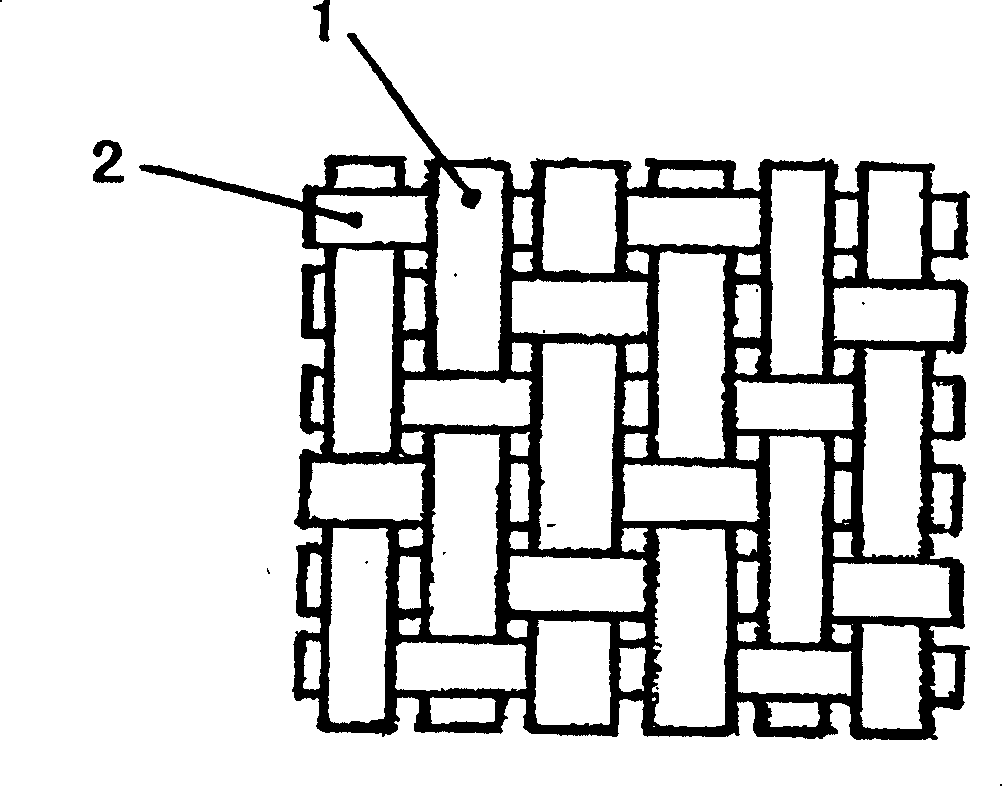

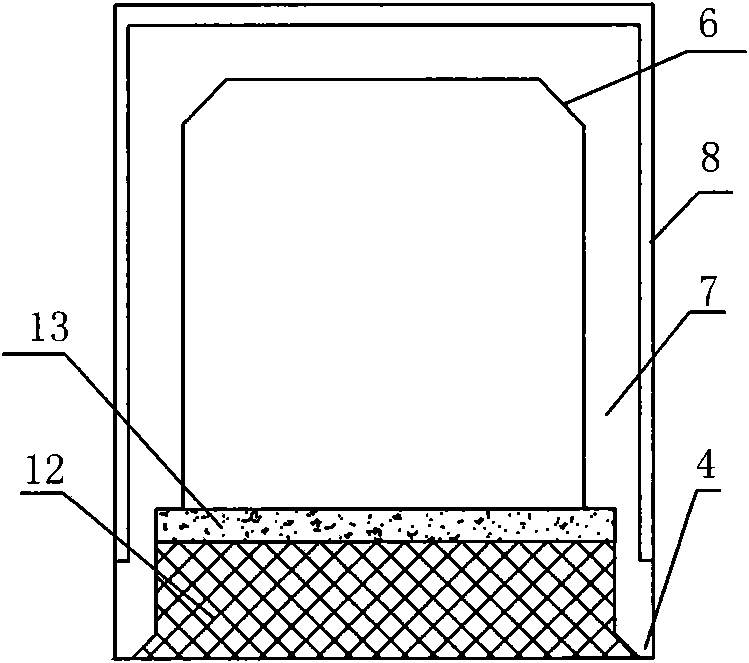

Airstrainer

InactiveCN101204636AImprove filtration efficiencyStable resistanceDispersed particle filtrationLighting and heating apparatusAir filtrationAir purifiers

The invention relates to an air filter screen, a preparation method and application thereof. The air filter screen is produced by knitting composite heat melting adhesive wire of sheath-core type along radial and latitudinal directions; the filter screen is flat; the angle formed by the radial wire and the latitudinal wire is 30-90 degrees; each radial wire and each latitudinal wire are contacted and adhered at the crossing points; the melting point of the core layer material of the sheath-core type composite heat melting adhesive wire is 40 DEG C or higher than the melting point of the sheath material. The preparation method of the filter screen comprises the following steps: net knitting and heating adhesion; the temperature of heating adhesion is 20-40 DEG C higher than the melting temperature of the sheath material, but 20 DEG C or more lower than the temperature of the core layer material. The air filter screen can be applied to a household air-conditioner, an air purifier device or an air refresher. The air filter screen has firm structure; when air filtering and cleaning are carried out, the radial and latitudinal wires can not displace, which enables the filtering efficiency of the filter screen to be stable and air resistance distribution to be even.

Owner:ZHEJIANG GOLDENSEA ENVIRONMENT TECH

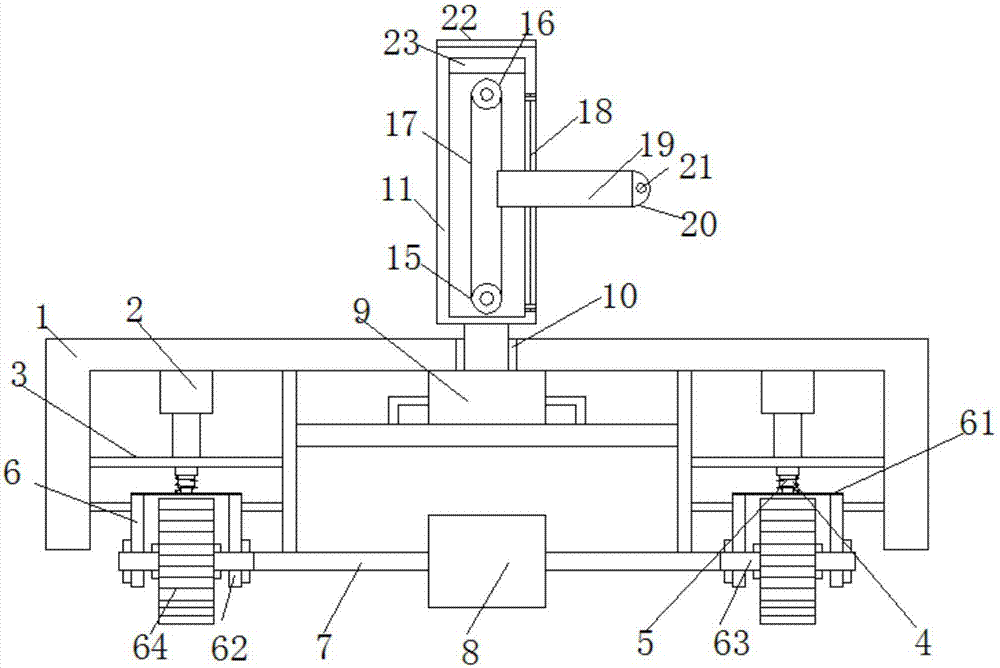

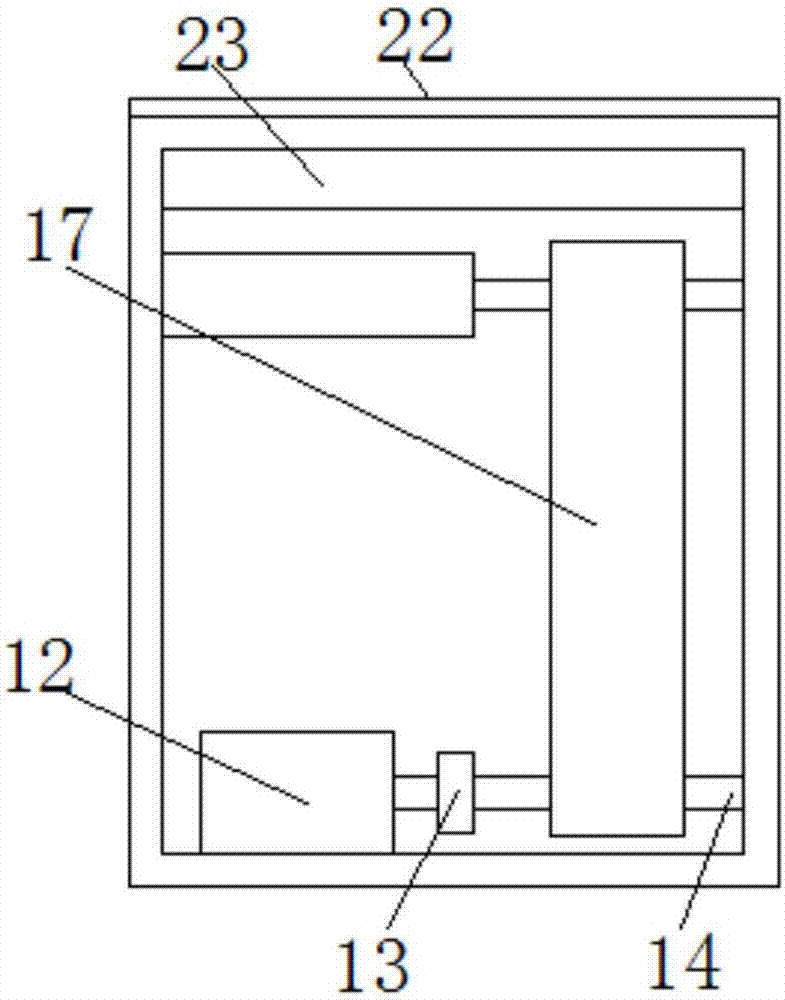

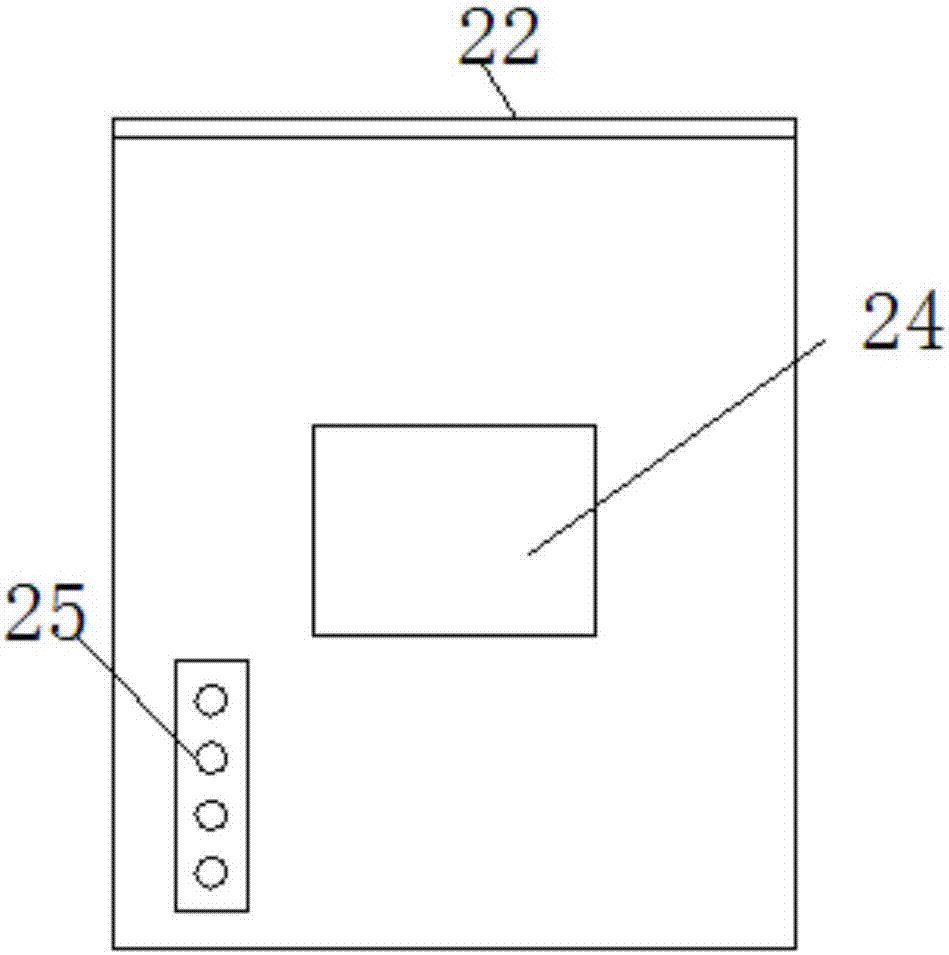

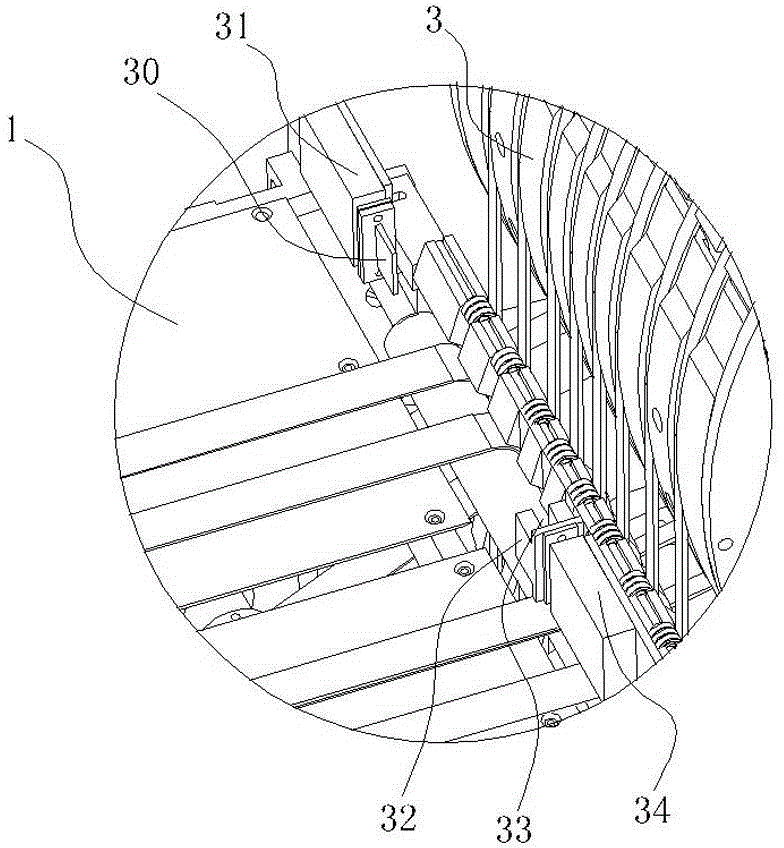

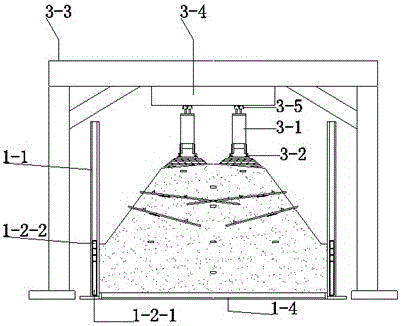

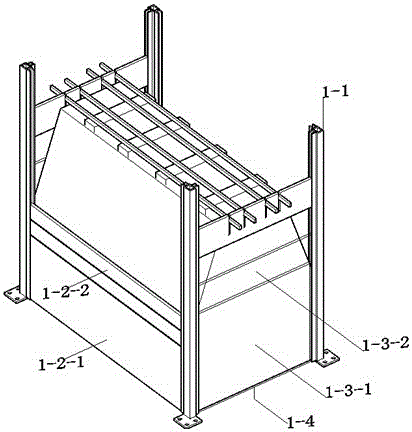

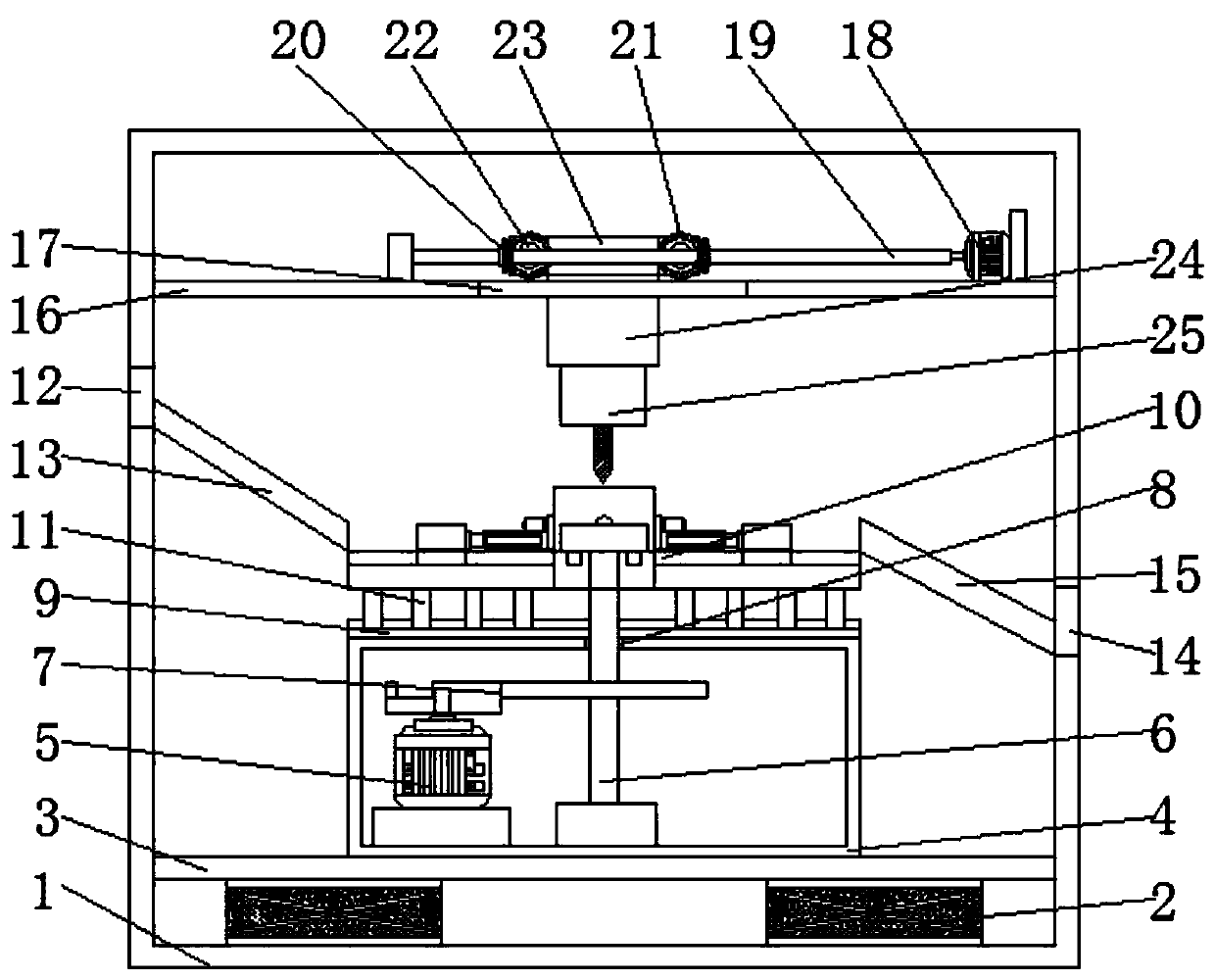

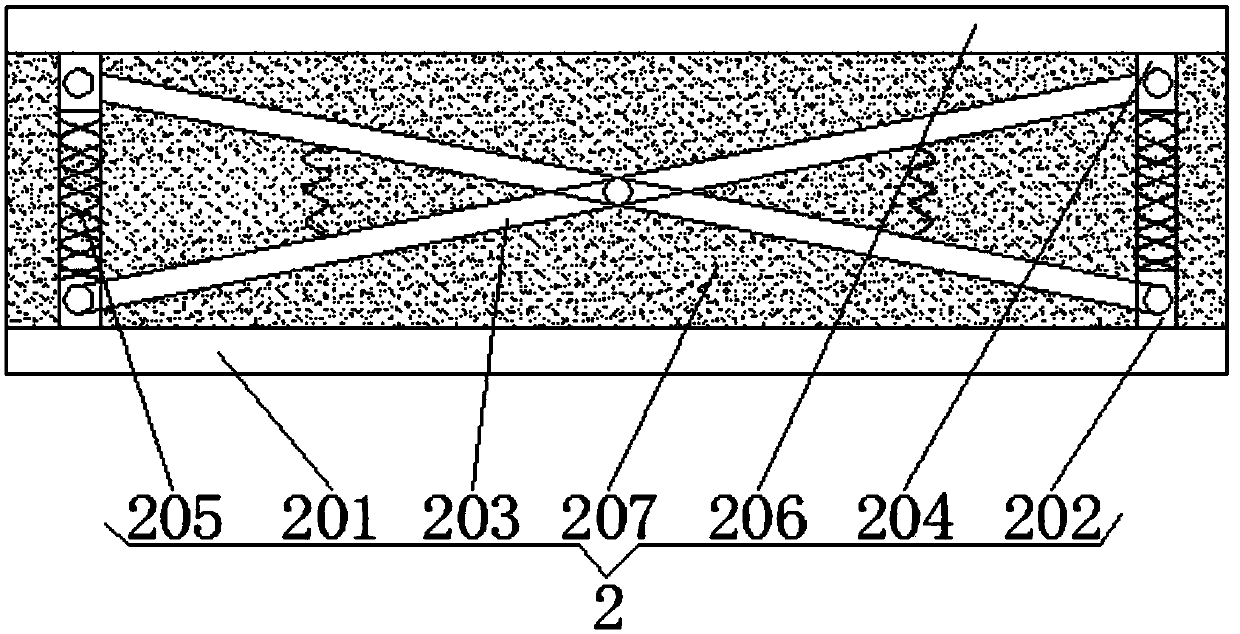

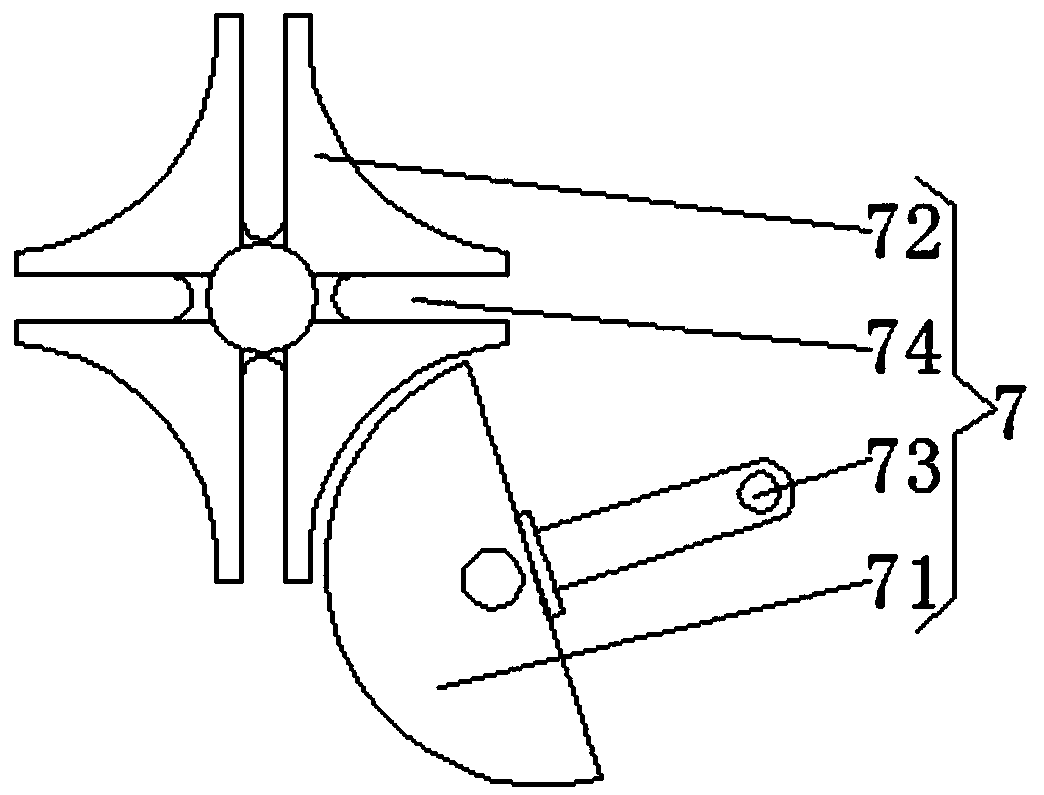

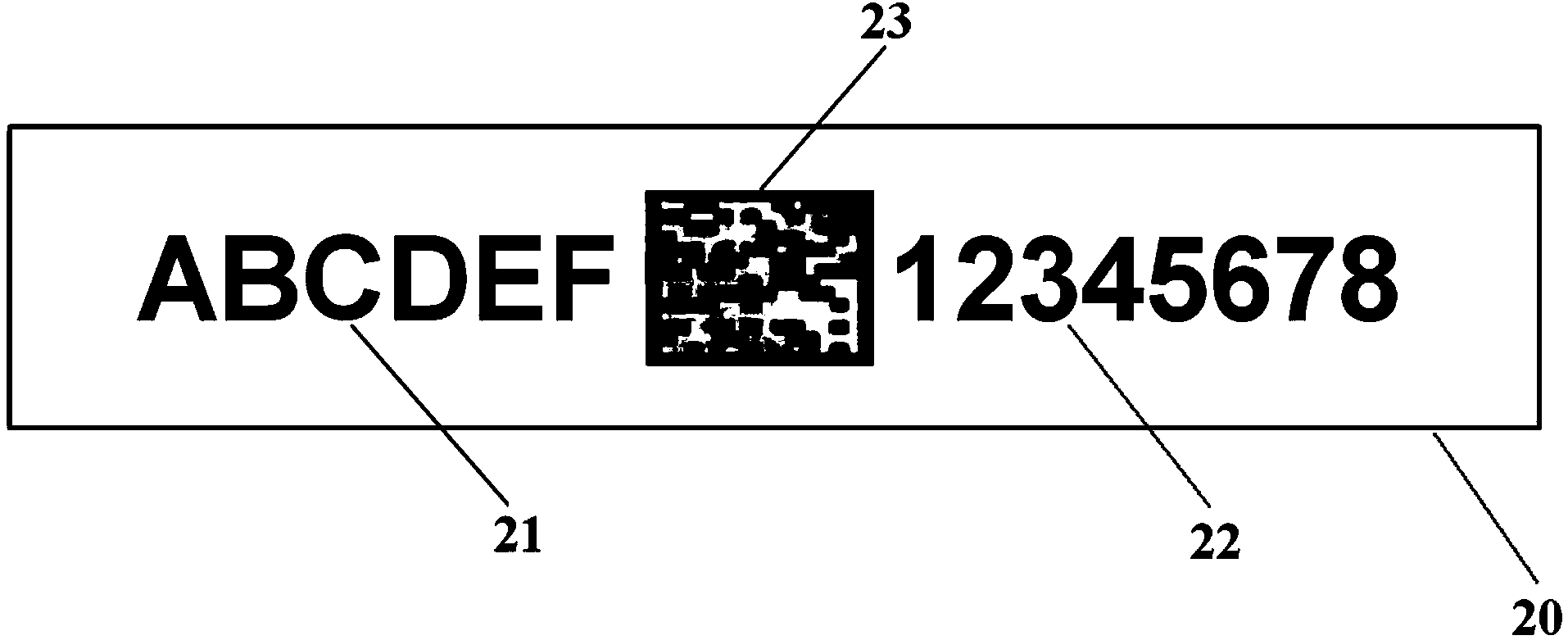

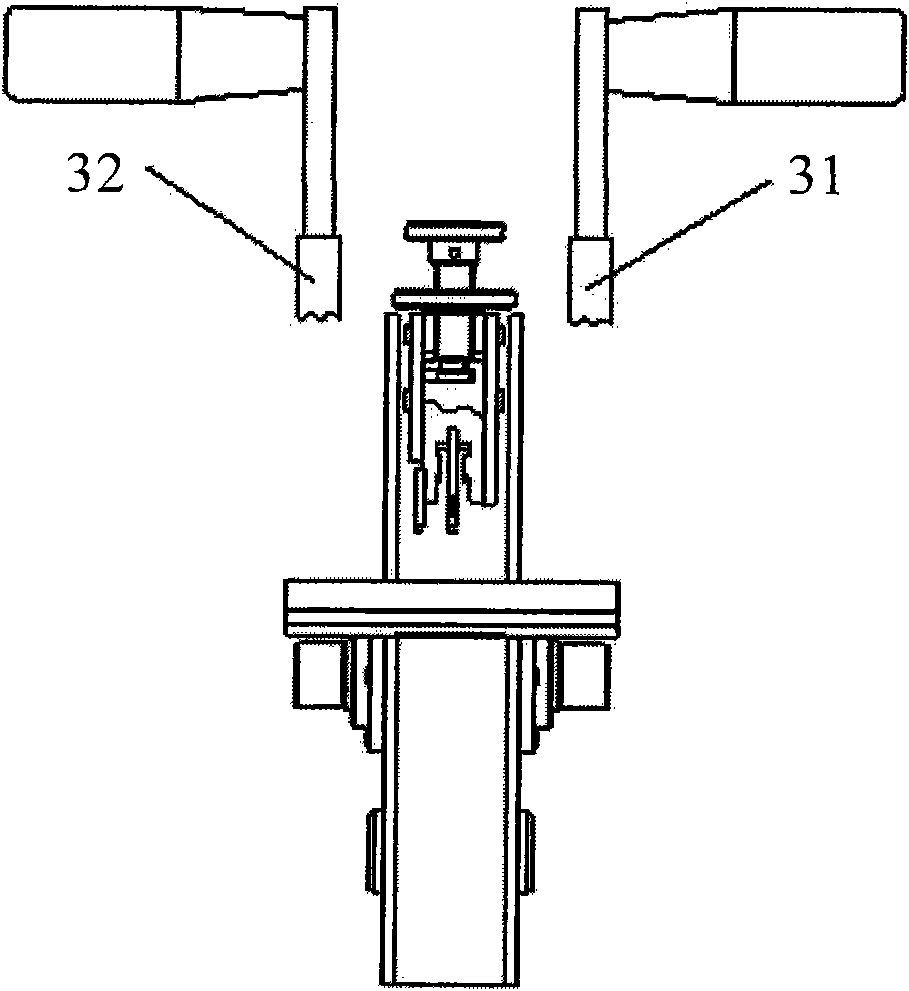

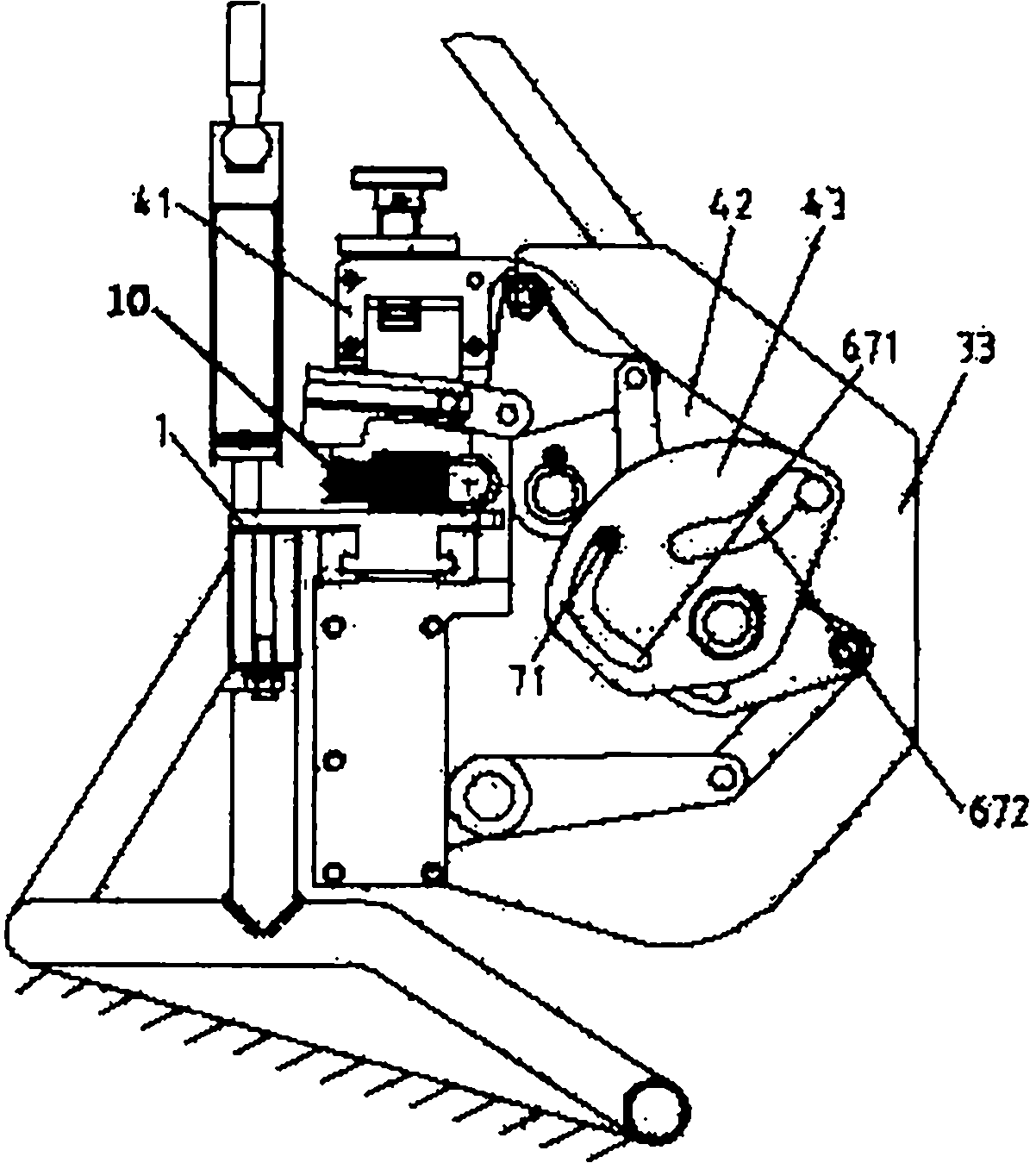

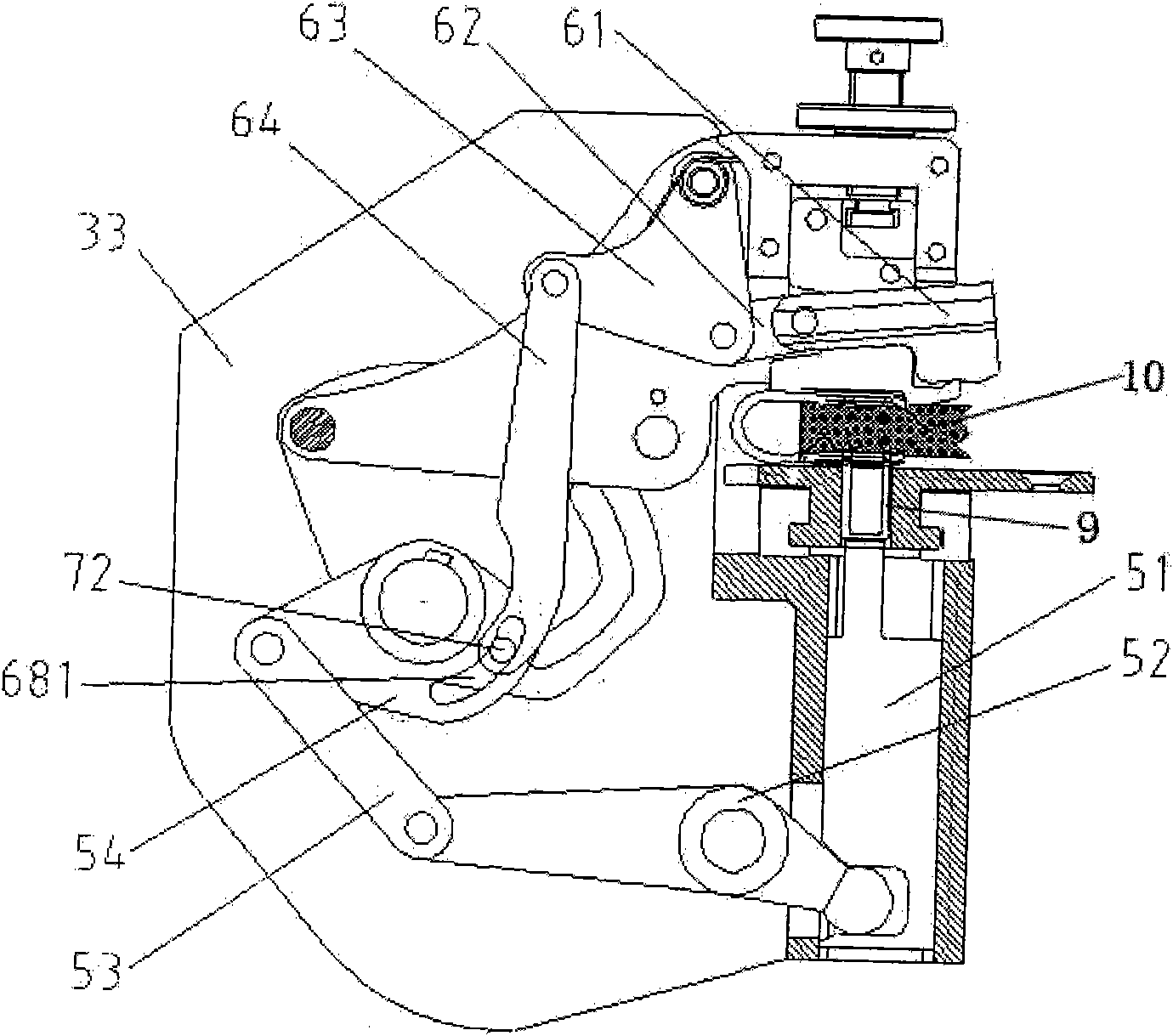

Testing system for roadbed power loading model

ActiveCN106501079AFlexible adaptation to production requirementsWill not shiftMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesBogiePilot system

The invention discloses a testing system for a roadbed power loading model. The testing system for the roadbed power loading model consists of a testing box, two reinforcing pile build-in devices, a loading device, and two brake devices. The impact produced in the train dead load and running process is respectively simulated by a jack and a vibration exciter, a motor drives a model bogie to be moved on a model rail in high speed, and the action effect that carriages pass through the section of the roadbed successively can be simulated by using limited model bogies through the rationally setting the distance between the model bogies and the length of the model rail. The problem that the load cannot be moved while the train load is simulated by the linkage of the single-point excitation and multi-actuator is solved, the impact produced in the running of the train is considered so as to accord with the actual situation. The testing system can be used for testing the roadbed dynamic response under the heavy load train action and checking the reinforcement effect of the slant high pressure jet grouting pile for reinforcing the roadbed.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

Intelligent camera with adjusting function

Owner:鲲鹏数字技术有限公司

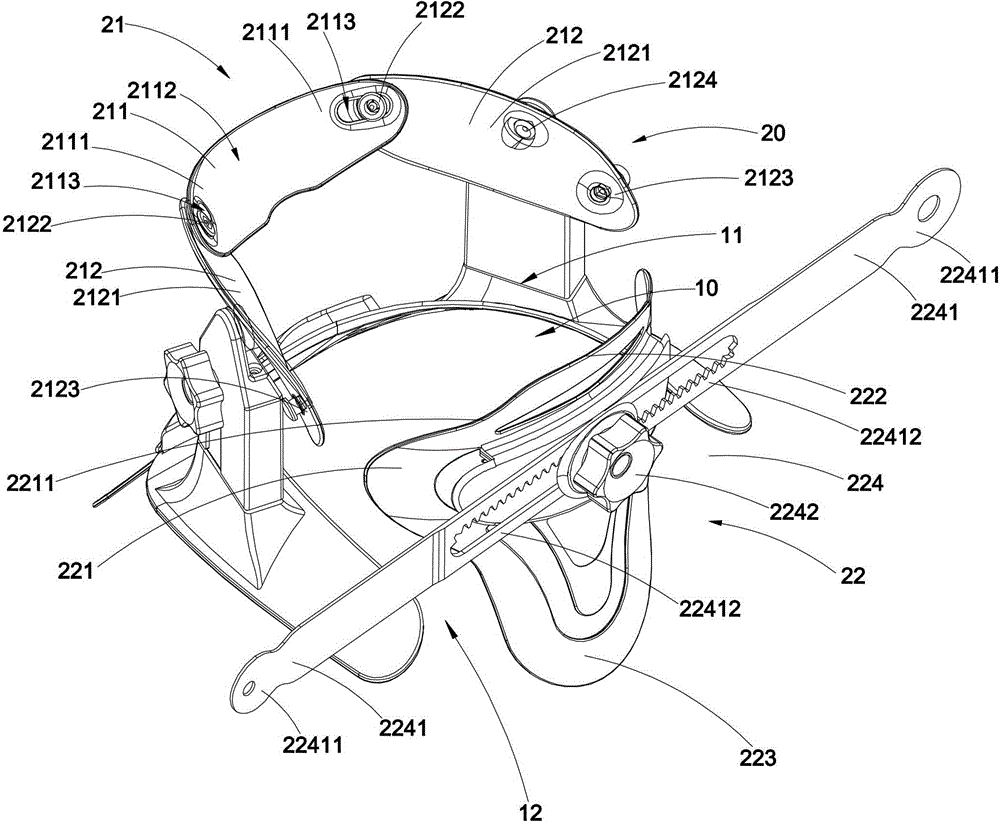

Cervical vertebra stretching device

The utility model discloses a lower jaw supporting device. The lower jaw supporting device is applied to a cervical vertebra pushing-stretching device. The cervical vertebra pushing-stretching device comprises a neck support and a pushing-stretching mechanism. The lower jaw supporting device comprises a jaw tip support. The two end portions of the jaw tip support are provided with two connecting mechanisms and two cheek supports respectively. Each cheek support further comprises a jaw tip connecting portion. One jaw tip connecting portion is arranged at one end portion of each cheek support and connected with one connecting mechanism of the jaw tip support. The two connecting mechanisms of the jaw tip support are connected with the two jaw tip connecting portions of the two cheek supports respectively so as to enable the jaw tip support to move and rotate along the jaw tip connecting portions, therefore, the jaw tip support is adjusted, and a user feels comfortable.

Owner:JIANGSU ALPHAY MEDICAL DEVICE

Construction method of municipal drainage culvert sinking trough

InactiveCN101597888AGuarantee security requirementsReduced security requirementsGround-workState of artLine tubing

The invention provides a construction method of municipal drainage culvert sinking trough. The construction method comprises the following steps: manufacturing a groove-type culvert prefabricated part with a cutting foot at the lower part by adopting the ground or semi-underground cast-in-place segmental method on the construction line of municipal drainage culvert; excavating earthwork in the cutting foot which is at the lower part of the groove-type culvert prefabricated part; sinking the earthwork to a predetermined depth by the own gravity of the groove-type culvert prefabricated part or by external force; manufacturing a culvert base plate by the cast-in-place method between the cutting feet which are at the lower part of the groove-type culvert prefabricated part; backfilling to the height of the original ground surface or road surface with sediments outside the groove-type culvert prefabricated part. Compared with the prior art, the construction technology has the advantages of high rigidity, strong safety, little influence on adjacent buildings and various pipes; the invention further has the advantages that little precipitation and displacement occur on the earth surface; the solidity and durability are better than that of open municipal drainage pipeline construction, and the invention overcomes various drawbacks that the current drainage pipelines with major diameters are not easy to manufacture, transport and construct and are easy to leak.

Owner:JINAN URBAN CONSTR GRP

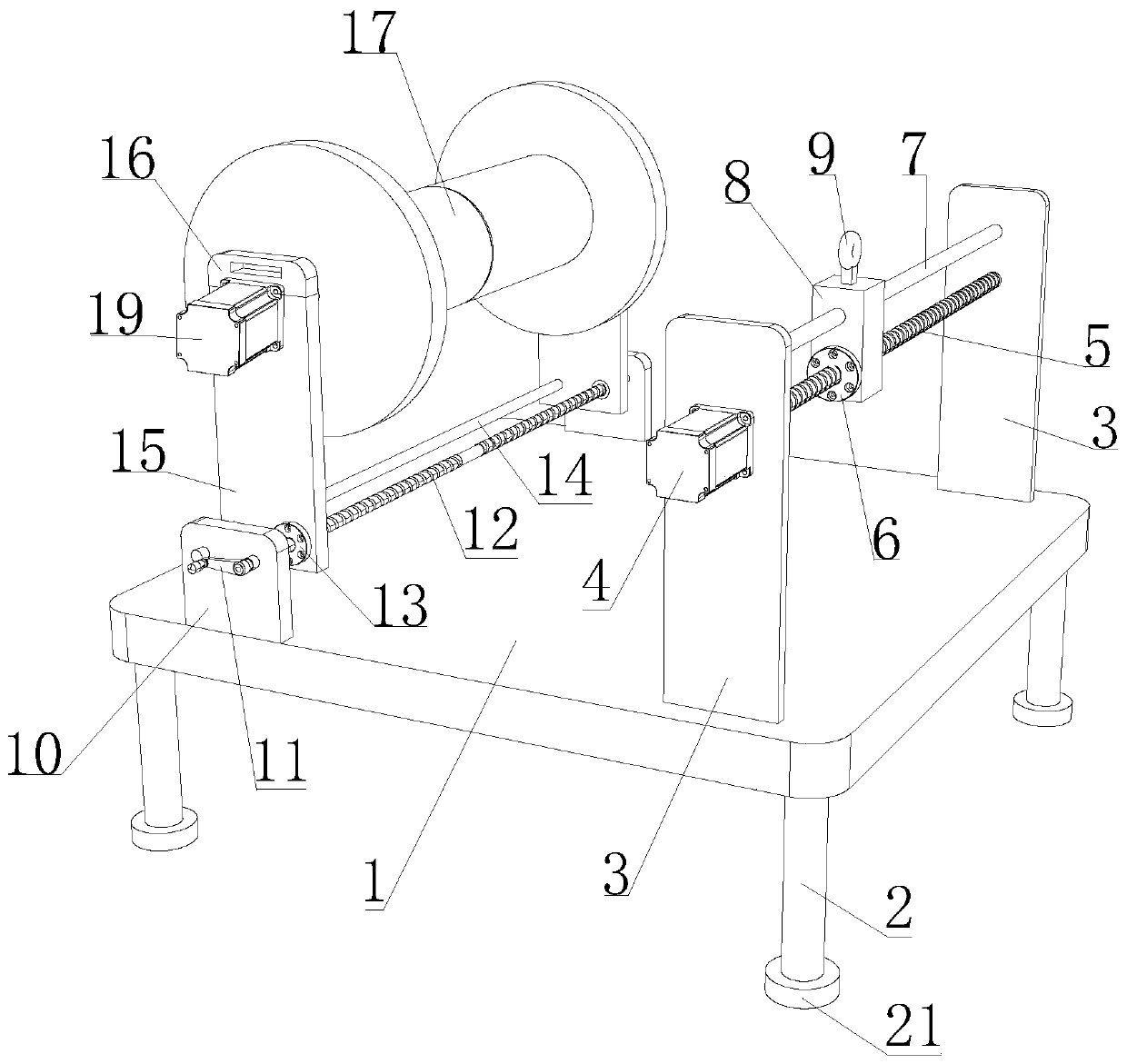

Chemical fiber yarn winding device

The invention belongs to the field of storage devices and particularly relates to a chemical fiber yarn winding device. Aiming at the problems of irregular and nonuniform winding of existing yarn winding devices, a scheme is proposed. According to the scheme, the chemical fiber yarn winding device comprises a workbench, supporting columns, a first support, a first driving device, a lead screw, a first lead screw nut, a first guide rod, a moving table, a lead frame, a second support, a rocking handle, a bidirectional lead screw, a second lead screw nut, a second guide rod, moving plates, a winding roller assembly and a second driving device; the first driving device is arranged on the first support and is in transmission connection with the lead screw; the first lead screw nut is connectedwith the lead screw and is connected with the moving table; a lead hole is formed in the lead frame, and the lead frame is arranged on the moving table; the moving plates are arranged on the second lead screw nut, and the top of the moving plates are provided with installation grooves; the winding roller assembly comprises a winding roller, limiting plates and a rotating shaft; and the second driving device is arranged on the moving plates. By means of the chemical fiber yarn winding device, yarn storage is more regular, ordered and uniform.

Owner:沛县谦和纺织有限公司

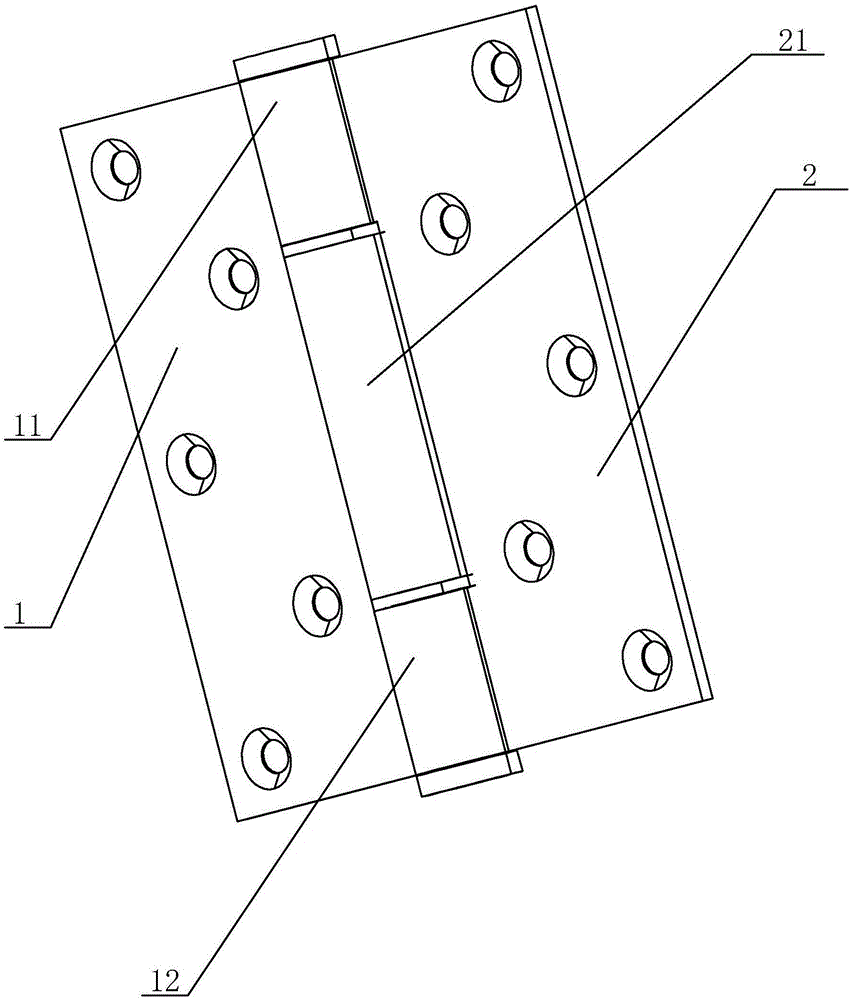

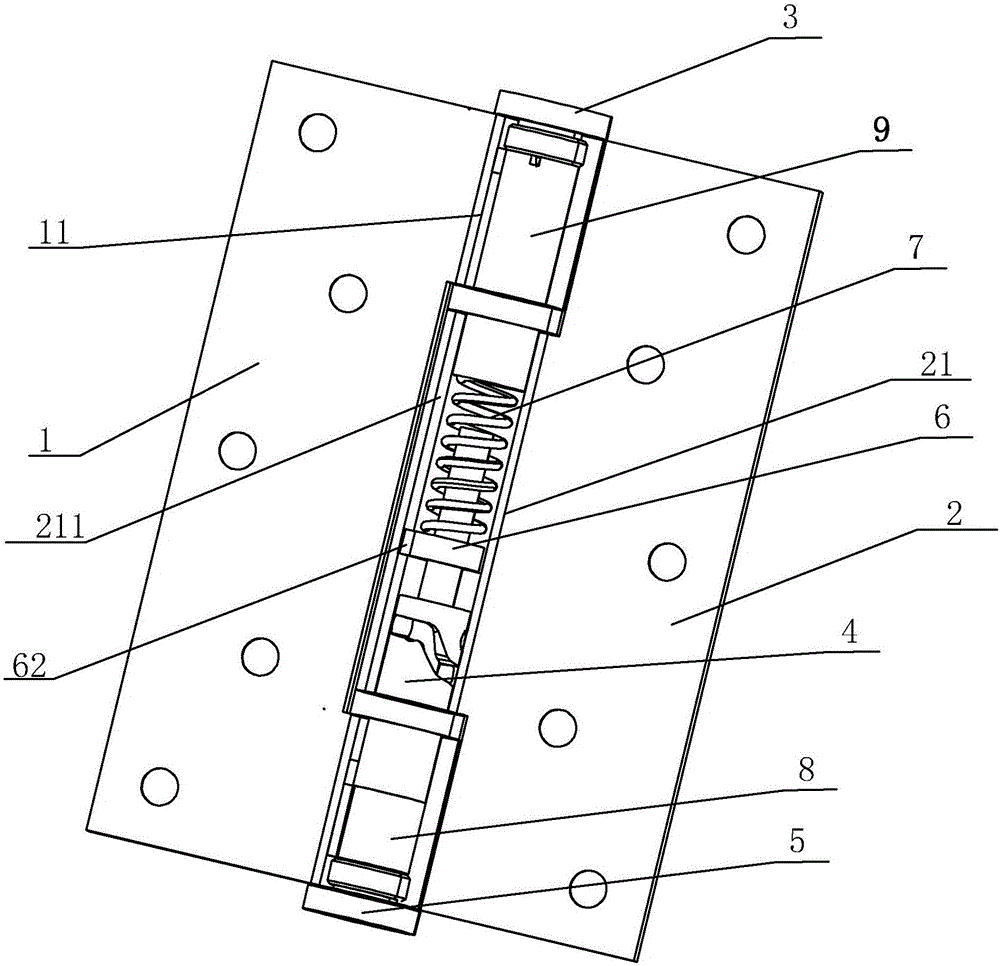

Screw type buffer hinge

ActiveCN106761082AGuarantee the size of the rotation forceAvoid collisionBuilding braking devicesPin hingesEngineeringMechanical engineering

The invention discloses a screw type buffer hinge. Upper and lower portions of one side of a left hinge piece are provided with an upper sleeve and a lower sleeve. One side of a right hinge piece is provided with a middle sleeve. An upper end cover is disposed in the upper sleeve. A fixing sleeve, a damper and a lower end cover are disposed in the lower sleeve. A side wall of one end portion of the fixing sleeve is provided with a rotating chute. A screw member is disposed in the middle sleeve. One end portion of the screw member is fixedly sleeved with a spring. One end of the spring extends towards the inside of the upper sleeve and is fixed in the upper sleeve. The other end portion of the screw member is provided with a rotating pin cooperated with the rotating chute. When the rotating pin moves in the rotating chute, the screw member is driven to move in the middle sleeve up and down, and the screw member drives the right hinge piece to rotate relative to the left hinge piece, so that a door is closed. The door can be closed without being powerfully pushed by a user, collision between the door and a doorframe can be effectively prevented, and compared with a hydraulic hinge, the screw type buffer hinge has the advantages that the screw type buffer hinge is simple in structure and long in service lifetime, and oil leakage can be prevented.

Owner:温州瓯海利尔达五金制品有限公司

Machining device for measuring equipment

InactiveCN107726942ALong processing cycleIncrease processing costMicrometersMetal working apparatusMeasuring equipmentRoller screw

Disclosed is a machining device for measuring equipment. The machining device comprises a box. A first motor is fixedly connected to one side of the bottom of an inner cavity of a rotating box. A supporting rod is rotationally connected to the middle of the bottom of the inner cavity of the rotating box. The output end of the first motor is rotationally connected with the supporting rod through adriving device. An objective table is fixedly connected to the end, away from the bottom of the inner cavity of the rotating box, of the supporting rod. The inner surface of a second bevel gear is fixedly connected with a roller screw through a flat key, a lifting device is fixedly connected to the side, close to the objective table, of a movable block, and a machining device is fixedly connectedto the side, away from the movable block, of the lifting device. The invention relates to the technical field of physical measurement, continuous machining can be performed, the machining period is shortened, the efficiency is improved, a workpiece is positioned and fixed, it is ensured that the workpiece cannot deflect in the machining process, the machining quality is ensured, the machining precision is improved, workpieces of different models can be machined through automatic adjustment according to the size of the workpieces, and the cost is lowered.

Owner:佛山杰致信息科技有限公司

Display panel, production method thereof and display

ActiveCN103472614AWill not shiftReduce border widthRecord carriers used with machinesNon-linear opticsDisplay deviceLarge size

Owner:BOE TECH GRP CO LTD +1

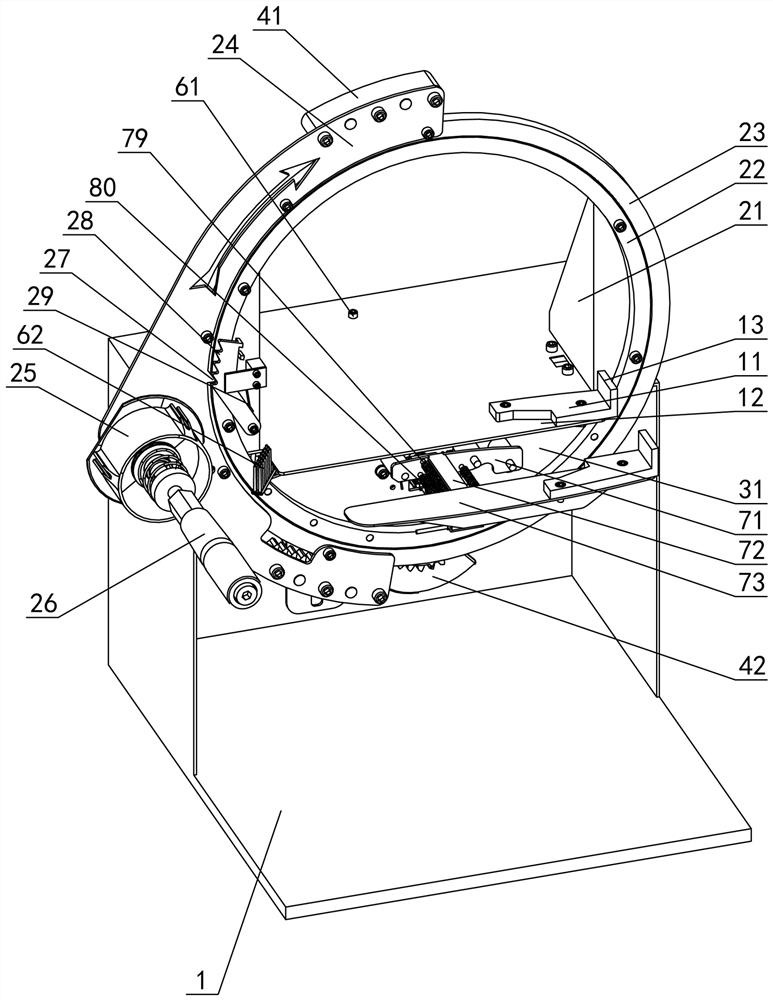

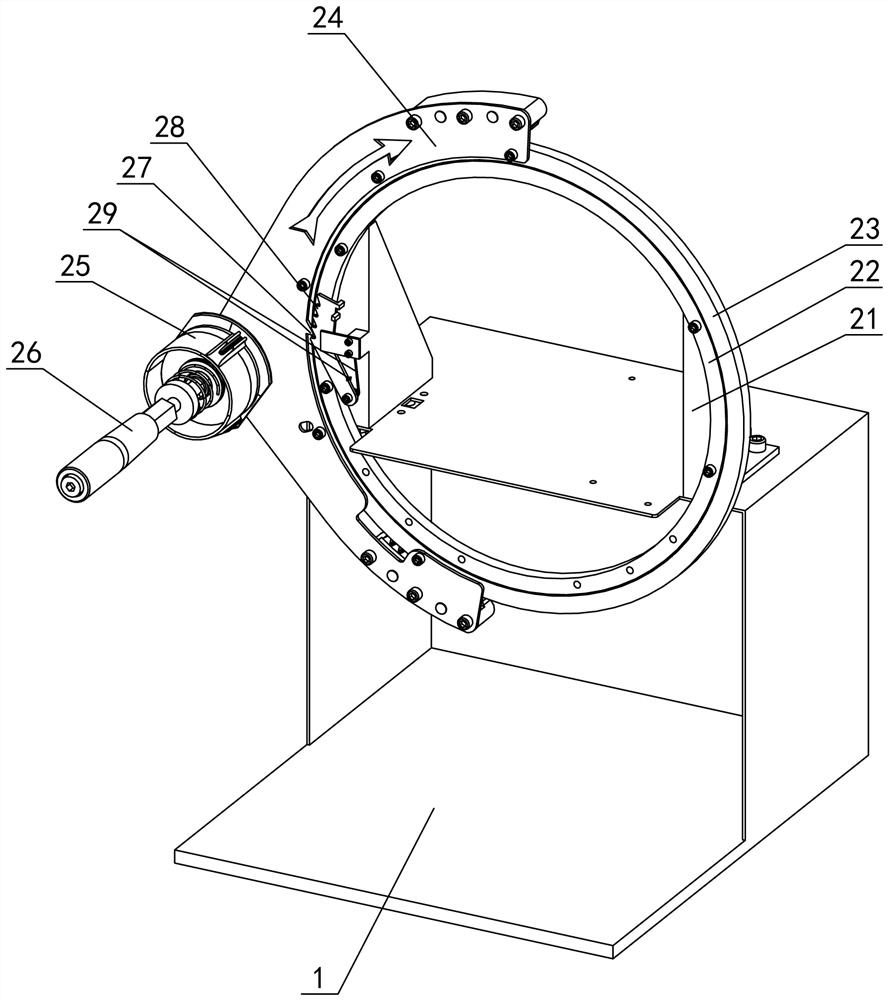

Surrounding type adhesive tape box sealing packaging machine

PendingCN112441293AAccurate wrap around the boxSmooth wrapping around the boxWrapper twisting/gatheringAdhesive beltEngineering

The invention relates to a surrounding type adhesive tape box sealing packing machine. The surrounding type adhesive tape box sealing packing machine comprises a fixing base, wherein an adhesive tapewhole-ring winding rotating device, an automatic adhesive tape cutting and loosening device, a linkage type packing box bottom adhesive tape attaching device and a platform bridging structure are arranged on the fixing base; the adhesive tape whole-circle winding rotating device comprises a support, and the support is fixed to the upper end of the fixing base; an annular bearing inner ring is arranged on one side of the support, an annular rotating disc is arranged on the outer wall of the annular bearing inner ring, and the annular rotating disc is in rotating fit with the annular bearing inner ring; a rotating plate is arranged on the annular rotating disc and fixed to the annular rotating disc through a fastener; an adhesive tape fixing ring and a handle are arranged on the rotating plate; and an adhesive tape roll is arranged on the adhesive tape fixing ring. According to the surrounding type adhesive tape sealing packing machine, the adhesive tape can seal a packaging box in a surrounding mode, and the bottom adhesive tape of the packaging box is automatically brushed flat for the first time, cut off and brushed flat for the second time; operation is convenient and labor-saving, the labor intensity of people is relieved, and the box sealing efficiency is improved; and moreover, the adhesive tape is firmly attached to the packaging box, and thus the box sealing effect is guaranteed.

Owner:朱宏杰

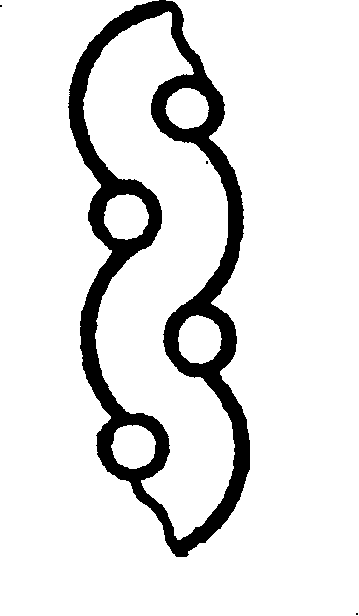

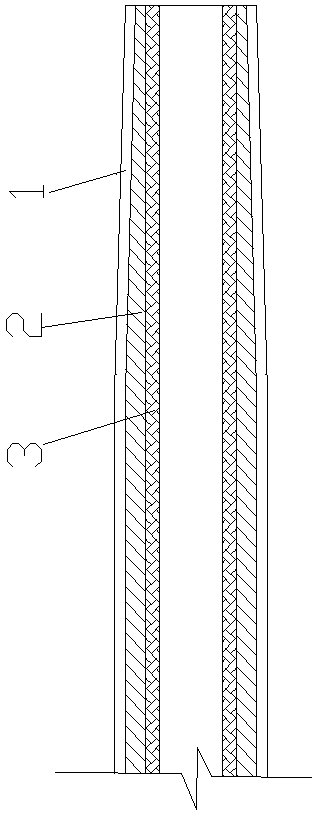

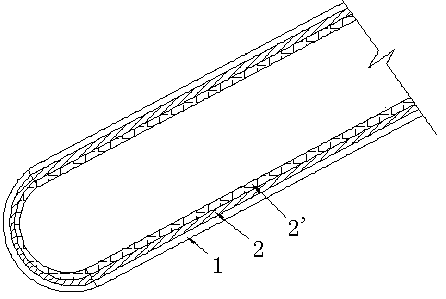

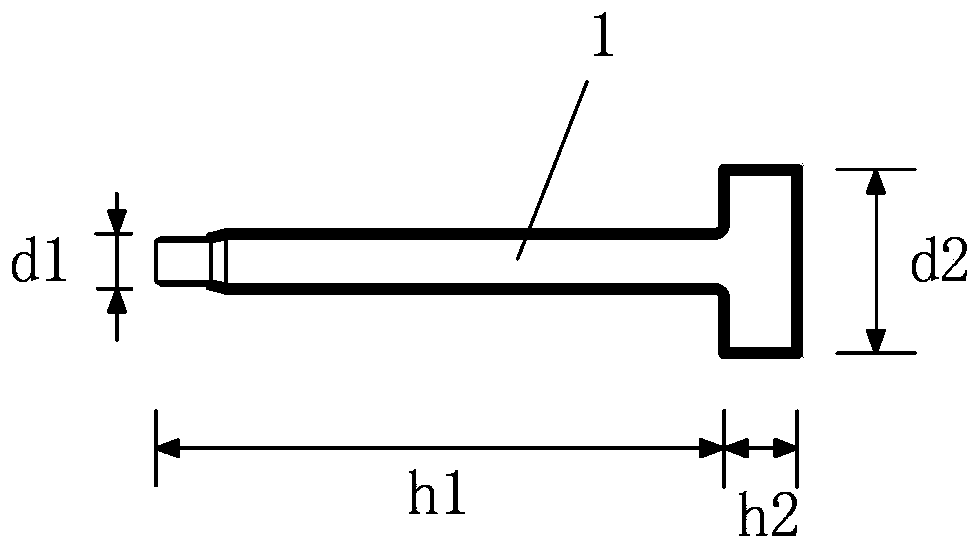

Catheter of composite structure

The invention discloses a catheter of composite structure. The catheter comprises a high-molecular pipe on the outer layer, a tubular woven net or spring net on the middle layer and a smooth inner layer. The high-molecular pipe on the outer layer is made of nylon, nested polyetheramide elastomer, polyurethane or silicone rubber; the wall thickness of the far end of the woven net or spring net on the middle layer is smaller than or equal to the wall thickness of a woven net body or spring net body; the inner layer is made of polytetrafluoroethylene or high-density polyethylene or nested polyetheramide elastomer containing a friction coefficient reducing additive. Compared with a conventional plastic catheter, the composite catheter has the advantages that the same mechanical performance requirement is met, and the wall thickness can be greatly reduced; the passing performance, folding resistance and controllability of the composite catheter are greatly improved, the composite catheter can be pushed to deeper and smaller blood vessels under the same conditions, and the operative successful rate is increased.

Owner:南京普微森医疗科技有限公司

Mechanical button sewing machine

The invention discloses a mechanical button sewing machine. The mechanical button sewing machine comprises a button loading plate, a machine head which can move along the button loading machine and a handle; the machine head comprises a button pressing mechanism, a nail penetrating mechanism, and a nail bending mechanism; the button pressing mechanism comprises a press head, a press head supporting plate and a left turning block; the nail penetrating mechanism comprises a nail penetrating hammer, a nail penetrating oscillating bar, a nail penetrating connection rod, and a right turning block; the nail bending mechanism comprises a rivet plate, a rivet connection rod, a triangular turning block, and a nail bending push rod; and the handle comprises a left handle and a right handle; and the left handle is fixedly connected with the left turning block in an eccentric way. In the mechanical button sewing machine, the left tuning block and the right turning block which are provided with curved chutes are adopted, and the left and right turning blocks are driven by the left and right handles to rotate to drive a travelling mechanism, the button pressing mechanism, the nail penetrating mechanism and the nail bending mechanism, so that the functions of penetrating, bending and pressing the nail can be realized at one position sequentially, and simultaneously, the button can be sewed by the travelling mechanism at an interval of a plurality of belt buttons; and the buttons are not needed to be sewed sequentially, and the button can be sewed on a belt accurately and firmly.

Owner:SHANGHAI GORO CONVEYOR EQUIP CO LTD

Basket ring spring hook butt welding machine

The invention discloses a basket ring spring hook butt welding machine which comprises a base plate. The base plate is arranged on a mobile support. A first guide assembly and a transmission mechanism are arranged between the base plate and the mobile support, and two loading discs are arranged on the surface of the base plate in the moving direction. The loading discs are connected with the base plate through a rotating assembly, a plurality of first quick clamps are arranged on the surfaces of the loading discs along the same circumference, and a plurality of butting positioning parts are further arranged between the edges of the plurality of first quick clamps and the outer circumferences of the loading discs along the same circumference. The first quick clamps and the butting positioning parts are matched with clamping spring hooks, the loading discs between the first quick clamps and the corresponding butting positioning parts are provided with butt welding avoiding grooves, and the butt welding machine is arranged on one side of each loading disc. The basket ring spring hook butt welding machine can effectively position the spring hooks and is high in welding efficiency and good in quality.

Owner:LIRUIBAO SPORTS EQUIP WUJIANG

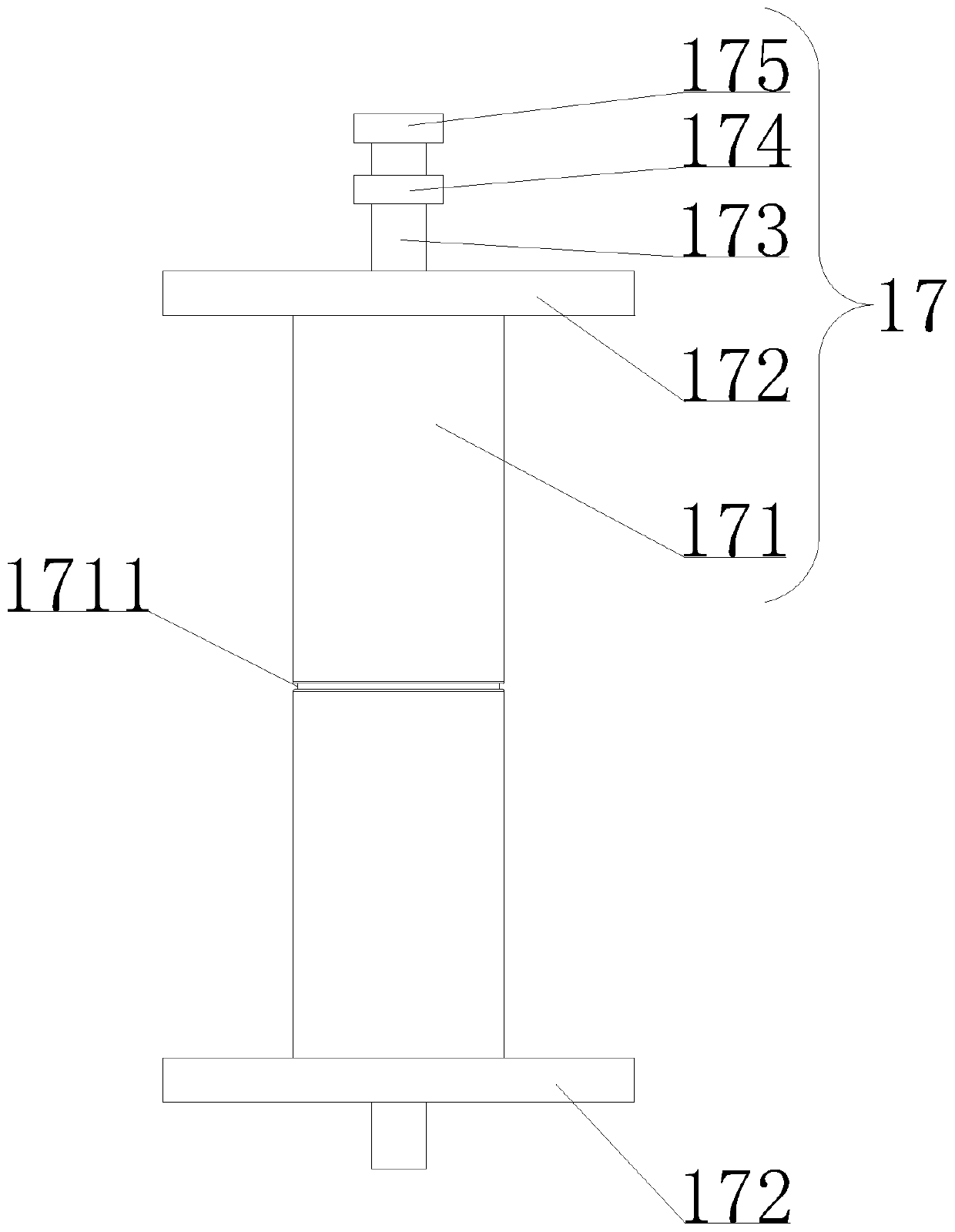

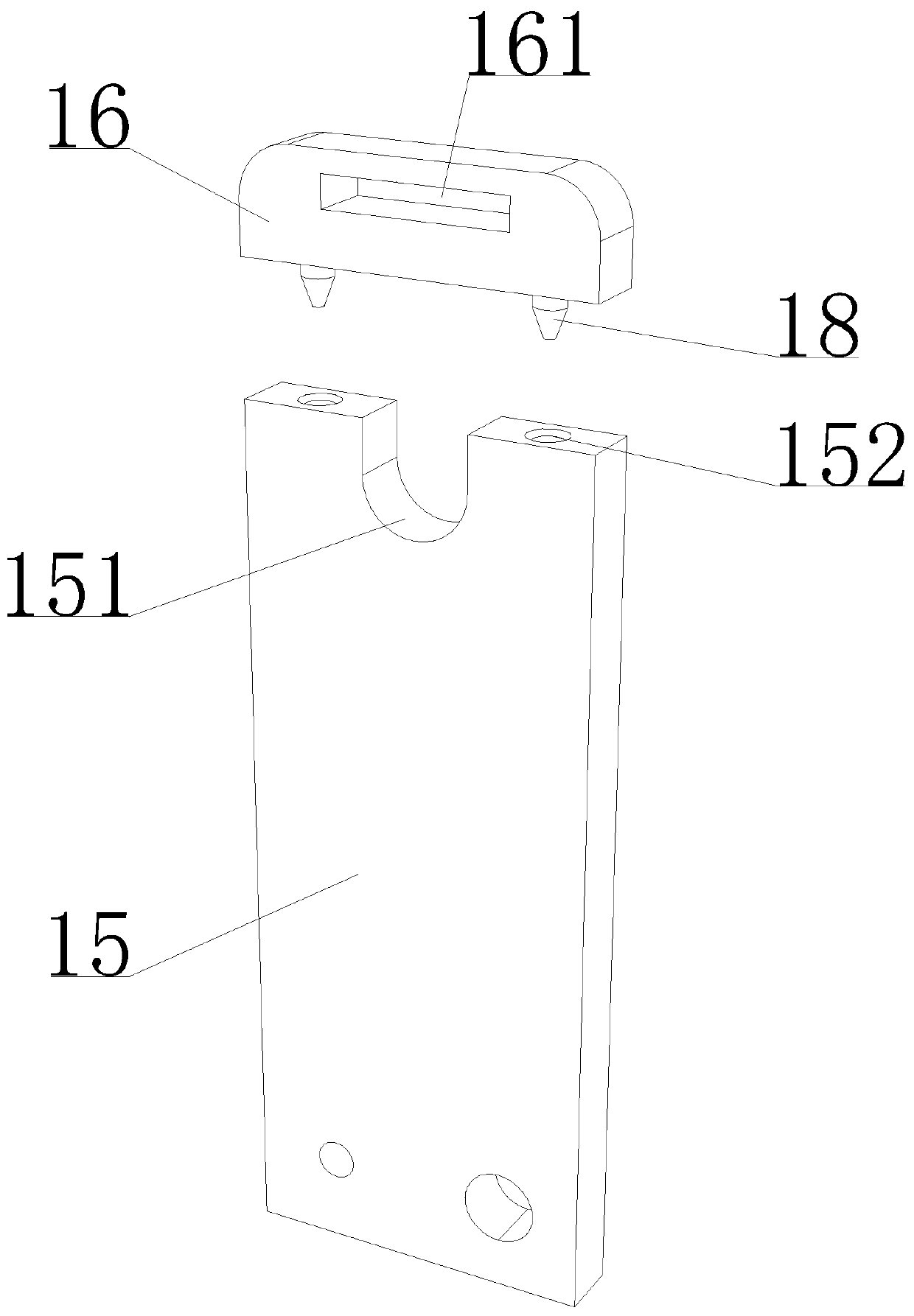

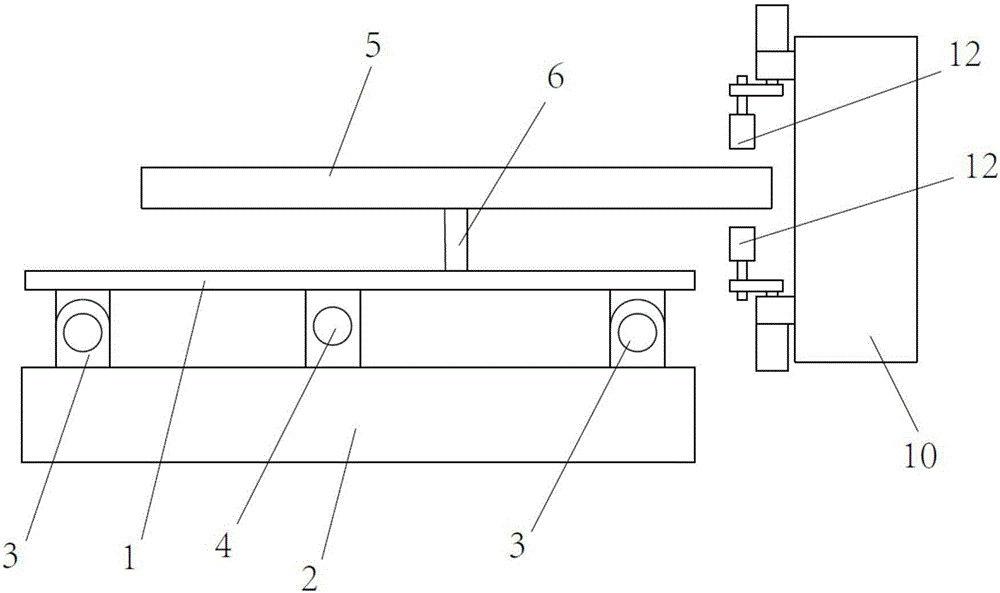

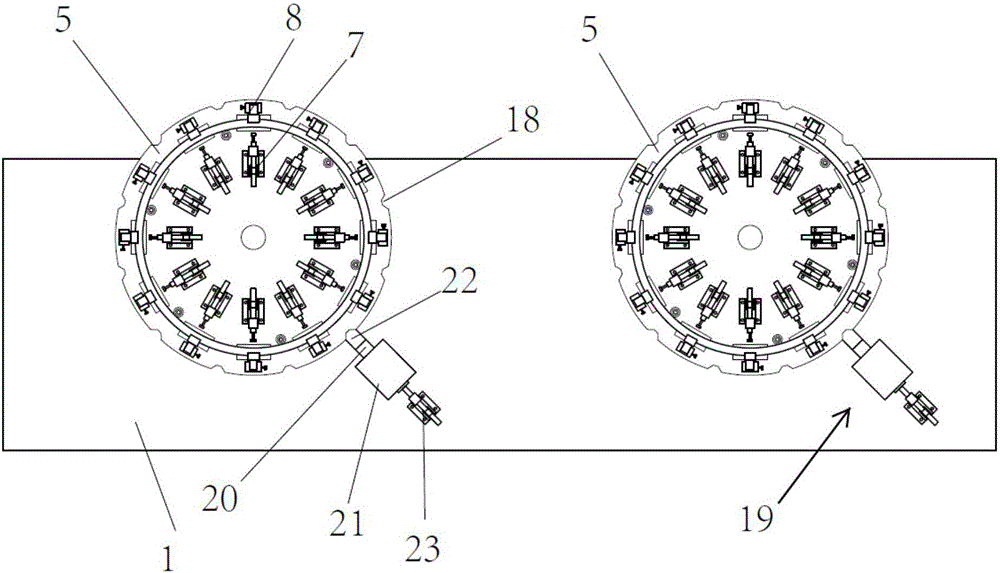

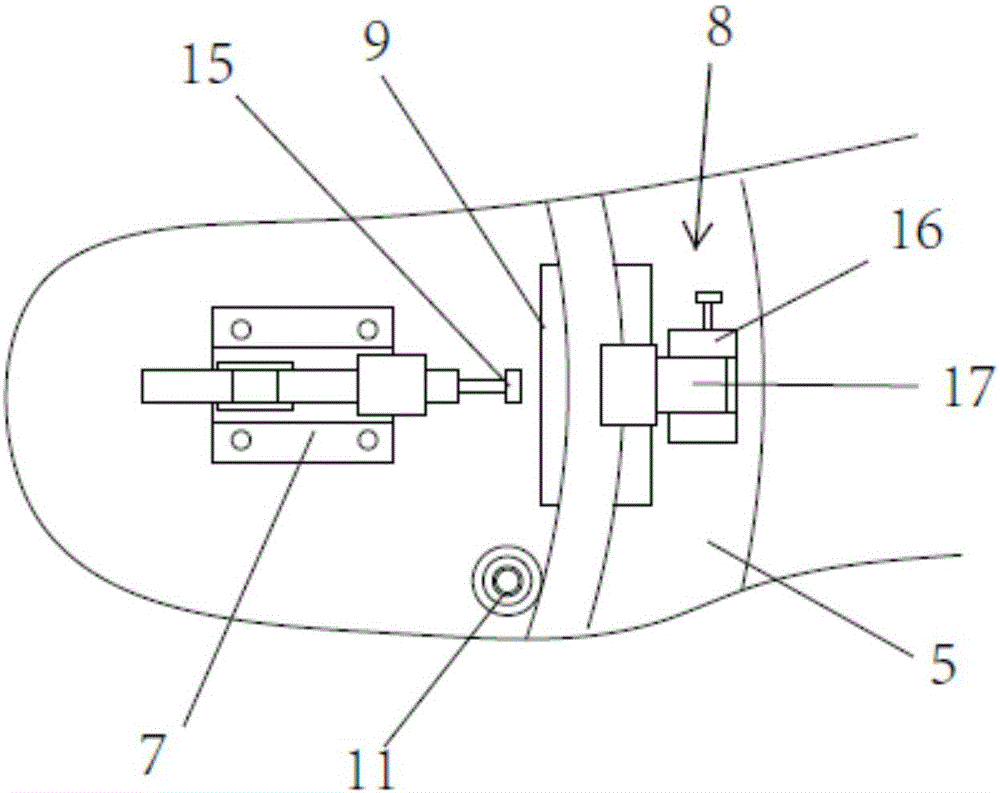

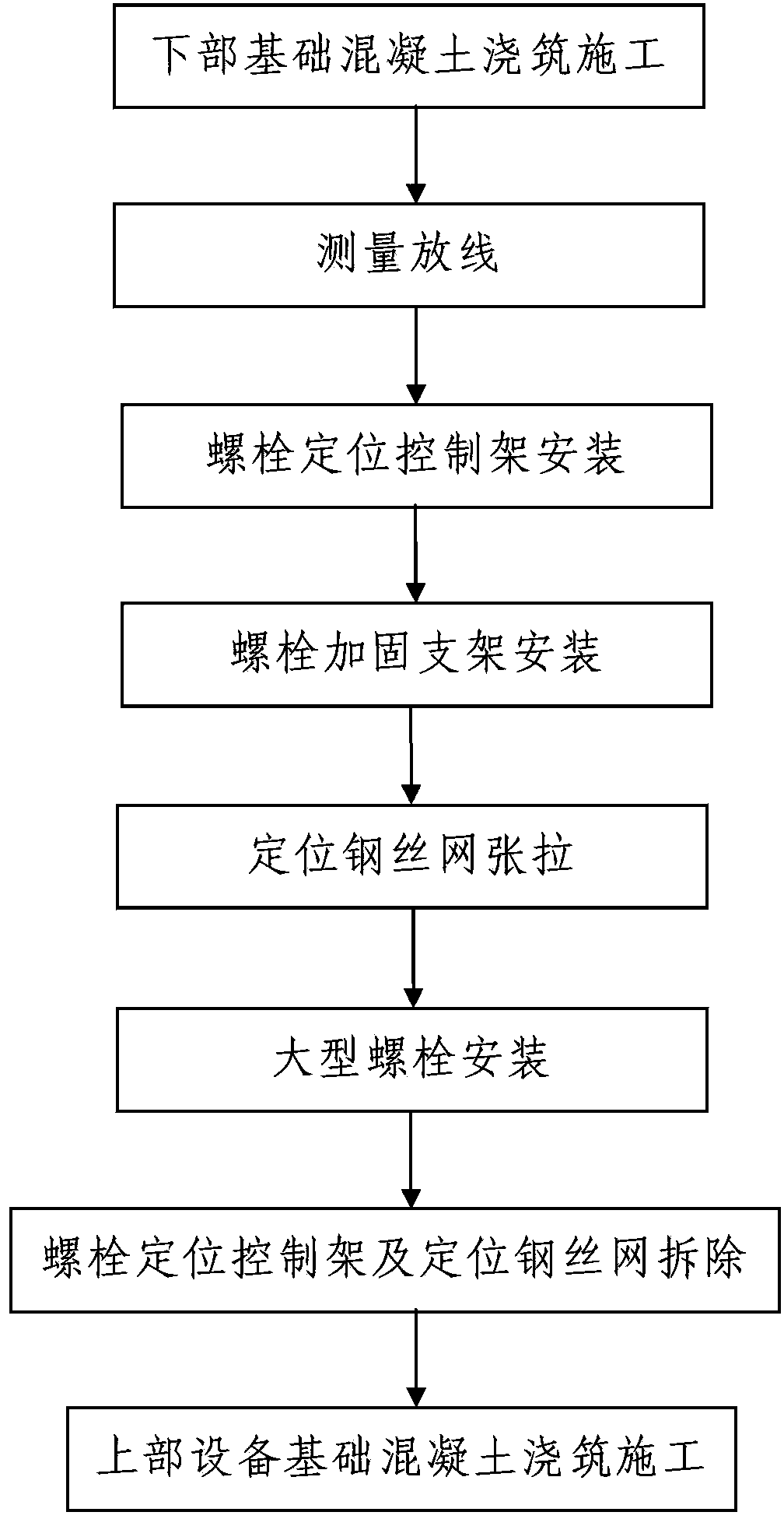

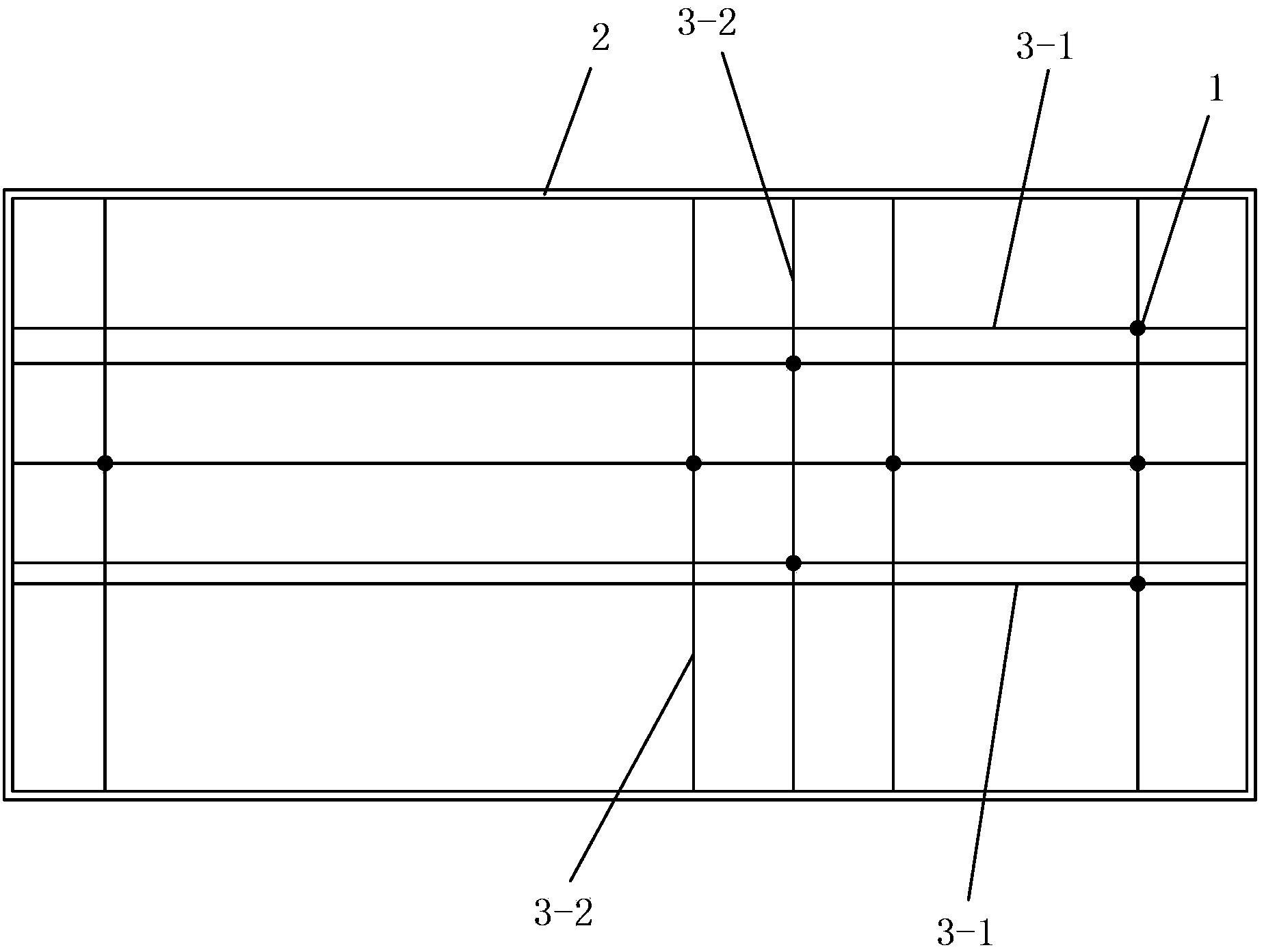

Large-scale bolt high-precision pre-burying construction method

ActiveCN103352476ASimple structureReasonable designFoundation engineeringCushionBuilding construction

The invention discloses a large-scale bolt high-precision pre-burying construction method. The number of pre-buried large-scale bolts is N, all the large-scale bolts are pre-buried in a construction device foundation, the large-scale bolts comprise screw rods and bases, external threads are arranged at the top ends of the screw rods, the bases are arranged on the bottom portions of the screw rods, and the device foundation is divided into a lower foundation cushion layer and an upper device foundation with the plane where the bottom portions of the bases of the large-scale bolts are located as a boundary. The method comprises a first step of carrying out concrete pouring construction on the lower foundation cushion layer, a second step of carrying out measurement and paying off, a third step of mounting a bolt locating control rack, a fourth step of mounting a bolt reinforcing support, a fifth step of tensioning a locating steel wire net, a sixth step of mounting the large-scale bolts, a seventh step of removing the bolt locating control rack and the locating steel wire net, and an eighth step of carrying out concrete pouring construction on the upper device foundation. The method is simple in process, reasonable in design, convenient to achieve, good in using effect, and capable of simply, conveniently and fast achieving the high-precision pre-burying process of the large-scale bolts in the device foundation in high quality.

Owner:陕西建工第十一建设集团有限公司

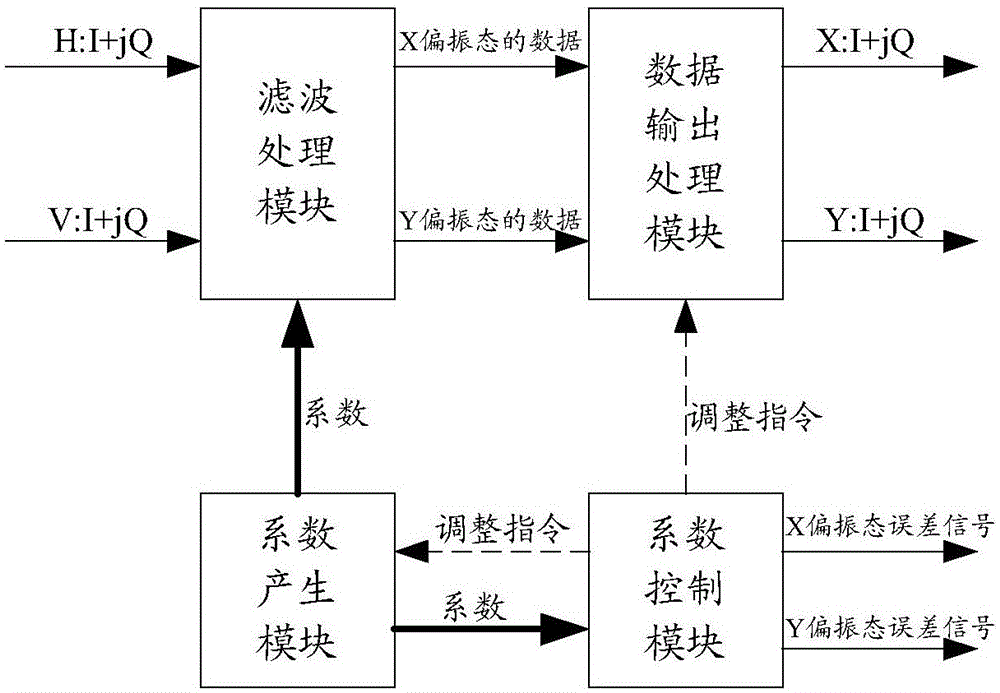

Adaptive equalizer and method for realizing adaptive equalization processing by the adaptive equalizer

ActiveCN106330320AControl approachWill not shiftDistortion/dispersion eliminationTransmitter/receiver shaping networksEqualizationSelf adaptive

The invention discloses an adaptive equalizer and a method of realizing adaptive equalization processing by the adaptive equalizer. The method comprises the steps obtaining an X polarization state error signal and a Y polarization state error signal according to the first distance between a calculated coefficient centre of gravity mapped from H and V to X and a coefficient tap center, and the second distance between the calculated coefficient centre of gravity mapped from H and V to Y and the coefficient tap center; and carrying out interpolation processing on data of an X polarization state and the data of a Y polarization state in clock synchronous processing. According to the technical scheme of the equalizer and the method, the X polarization state and the Y polarization state are taken into consideration for error calculation, the data of the X polarization state and the data of the Y polarization state are adjusted, and the coefficients of the X polarization state and the Y polarization state are flexibly and effectively controlled to be close to a tap center location. Further, according to the equalizer and the method, the coefficients and output data are adjusted according to the coefficient energy mapped from the H and V to the X, and the coefficient energy mapped from the H and V to the Y, when the coefficient energy is on a tap boundary.

Owner:ZTE CORP

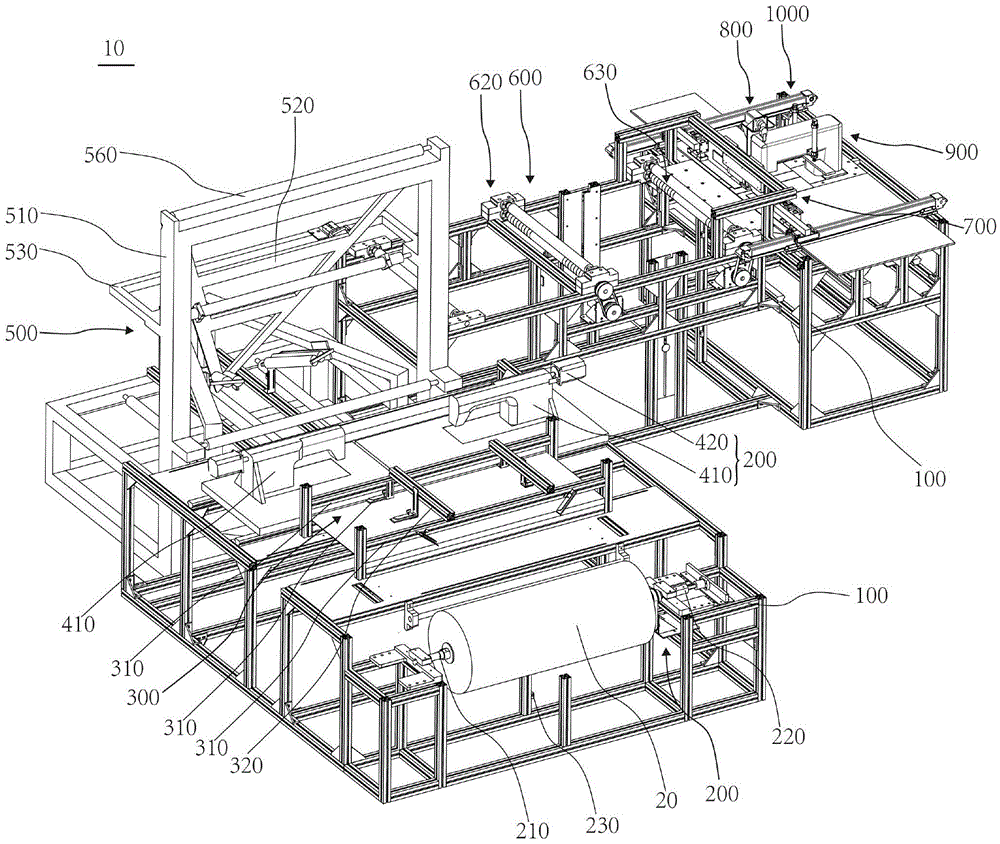

Automatic cloth bag sewing system

ActiveCN105624930ANo human intervention requiredRealize automated productionSack sewingMiddle lineMechanical engineering

The invention discloses an automatic cloth bag sewing system. The system comprises a machine table, an edge folding device, an edge sewing device, a folding device, a cloth pulling device, a cutting device, a jointing device and a control device, wherein the edge folding device is used for folding the edges on the two sides of tubular cloth, the edge sewing device is arranged on the machine table to be used for sewing the folded edges on the two sides of the tubular cloth, the folding device is arranged on the machine table to be used for folding the tubular cloth along the middle line the tubular cloth, and the folded tubular cloth advances in a bent mode; the cloth pulling device is arranged on the machine table to be used for pulling the tubular cloth to pass through an edge folding element, the edge sewing device and the folding device in sequence; the cutting device is arranged on the machine table to be used for cutting the folded tubular cloth in the direction perpendicular to the middle line according to a preset shape and size, so that a cloth bag middle body is formed; the jointing device is arranged on the machine table to be used for sewing the cloth bag middle body, so that a cloth bag is formed; the control device is electrically connected to the edge sewing device, the cloth pulling device, the cutting device and the jointing device. The system is high in production efficiency and low in cost.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

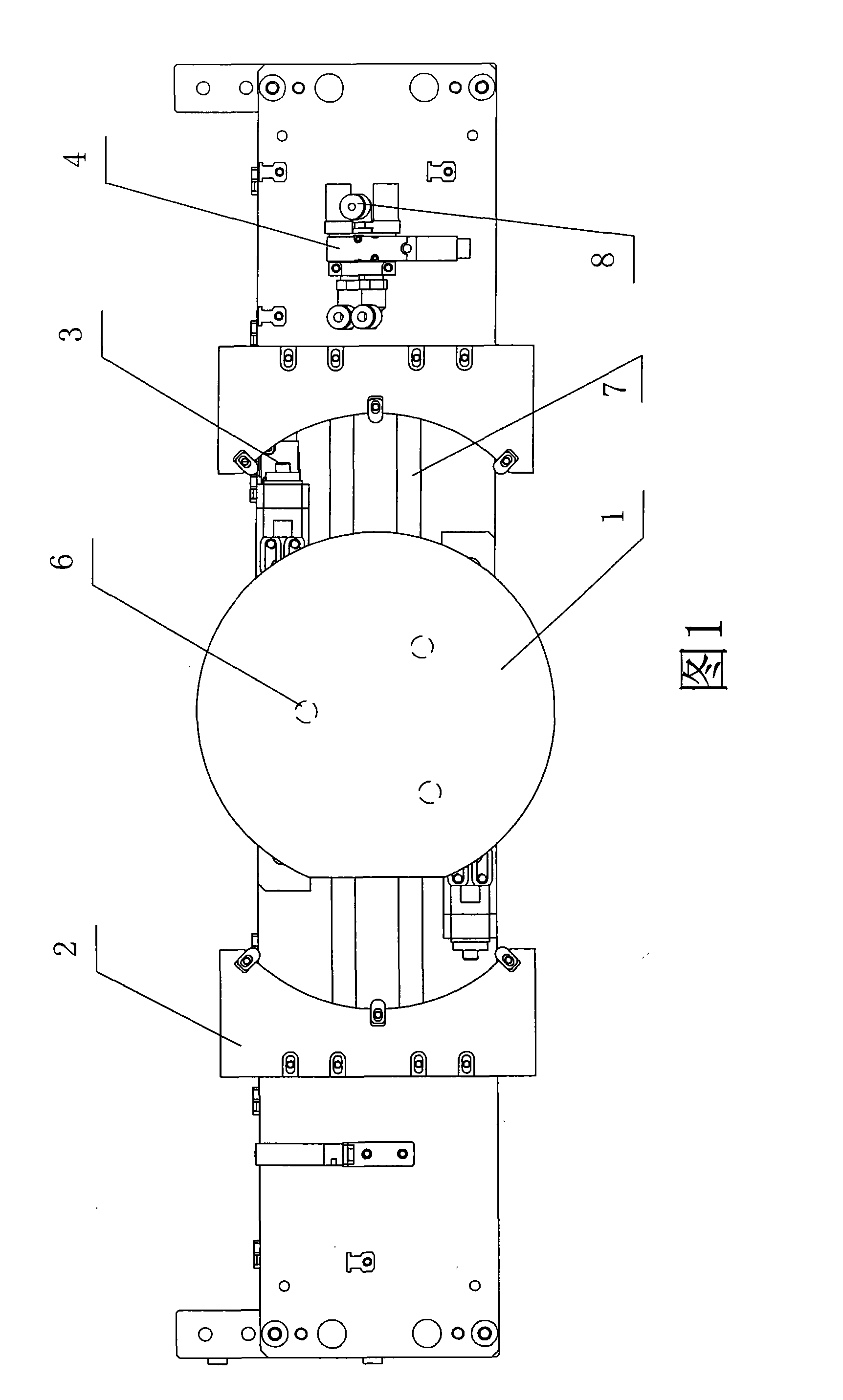

Centering unit

ActiveCN101494188AGuaranteed accuracyNo offsetSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The invention relates to a centering unit in semiconductor equipment during the process of wafer conveying. The centering unit is particularly applicable to the centering conveying of wafers with thicker glue films, thus solving the problems such as centering failure of the wafer, the occurrence of hit and crush when the wafer returns to a wafer box and the like. The centering unit is provided with a wafer centering component, a wafer bearing pillar and clamping cylinders. The wafer bearing pillar is arranged on a supporting bracket bearing the wafer to be processed and provided with a vacuum passage communicated with a vacuum line; and two sides of the wafer bearing pillar are provided with the clamping cylinders. The centering unit not only comprises all functions of former centering units, but also is applicable to the centering process of equipment with a relatively thick glue film and thick sealing, thus preventing the center of the wafer from deviation caused by the sticking of glue during the centering process.

Owner:SHENYANG KINGSEMI CO LTD

Sensing unit, touch screen detector and touch device

InactiveCN102902387AImprove anti-interference abilityLow costInput/output processes for data processingSignal-to-noise ratio (imaging)Circuit noise

The invention provides a sensing unit, a touch screen detector and a touch device. The touch device comprises a substrate, a plurality of non-crossing sensing units and a detection module. The sensing units are formed on the substrate. Each sensing unit is provided with first electrodes and second electrodes opposite to each other and comprises a plurality of first structures and a plurality of second structures, and the first structures are connected end to end through the second structures. By the use of the sensing unit, the touch screen and the touch device, signal-to-noise ratio of a circuit can be increased effectively, circuit noise can be lowered, and sensing linearity can be improved.

Owner:BYD CO LTD

Display screen module and terminal

InactiveCN106707577AImprove reliability and terminal qualityGood user experienceStatic indicating devicesNon-linear opticsLiquid-crystal displayFlexible circuits

The invention discloses a display screen module and a terminal. The display screen module comprises a flexible circuit board, a display driving chip and an overall fixing part used for being matched with a middle frame fixing part on a terminal middle frame. Through the cooperation of the overall fixing part and the middle frame fixing part, fixation of the relative positions of the display screen module and the terminal middle frame can be achieved, it is guaranteed that the display screen module does not shift after the terminal is assembled, then the position of the display driving chip in the terminal is fixed, the situation that due to shifting, the display driving chip makes contact with other internal devices of the terminal or squeezes other devices to be damaged is avoided, the reliability of the liquid crystal display module and the quality of the terminal are improved, and good user experience is guaranteed.

Owner:NUBIA TECHNOLOGY CO LTD

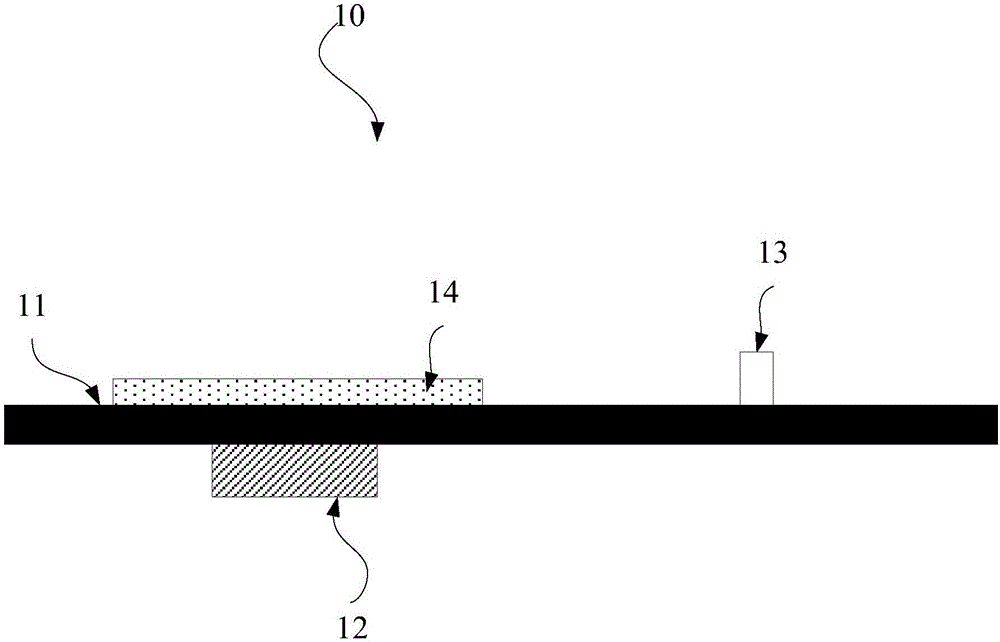

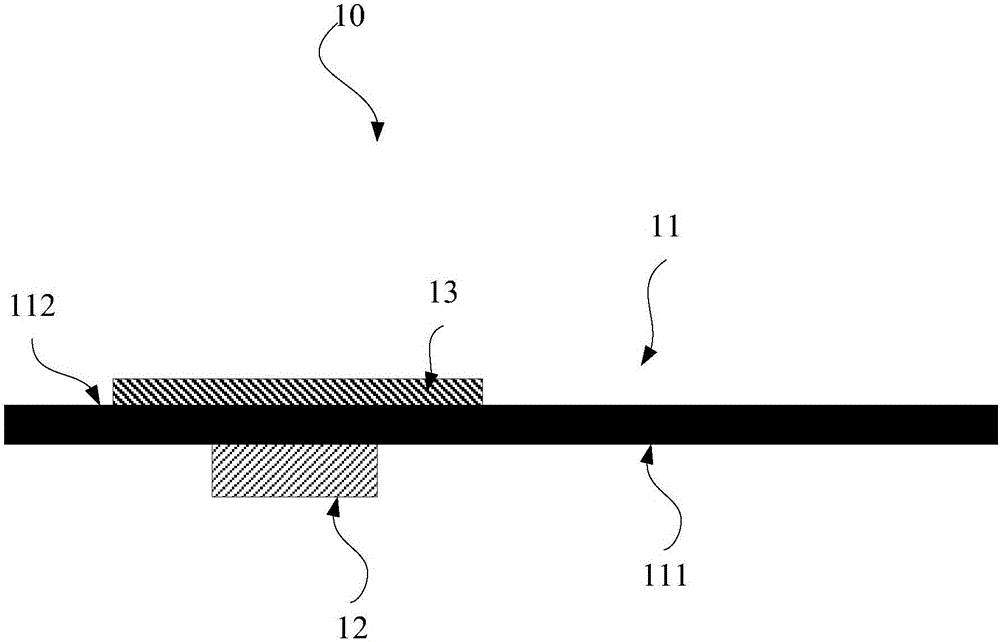

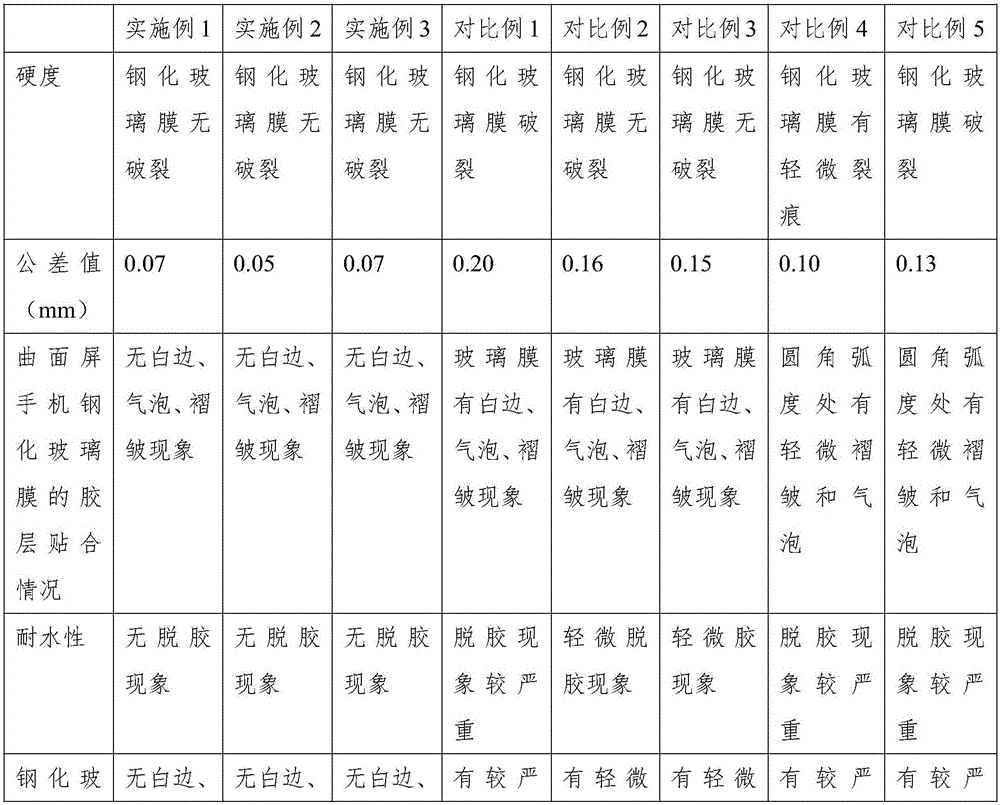

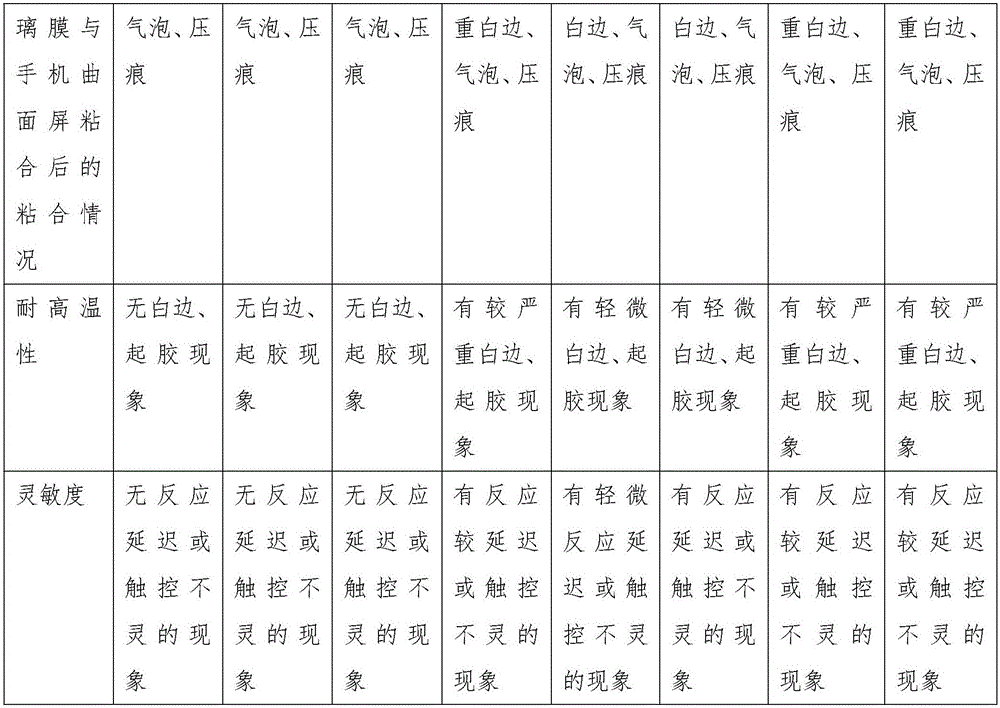

Preparation method of curved screen phone tempered glass film

ActiveCN106827776AAvoid the problem of not being able to fit the screen completelyGuarantee the effect of hot bendingLamination ancillary operationsLaminationAdhesiveThermoplastic polyurethane

The invention belongs to the technical field of phone protective films, and particularly relates to a preparation method of a curved screen phone tempered glass film. The preparation method comprises the following steps: attaching an OCA optical adhesive with a specific thickness to the upper surface of a TPU (thermoplastic polyurethane) substrate, attaching a silica gel with a specific thickness to the lower surface of the TPU substrate to obtain a TPU film, and attaching the TPU film to a glass film subjected to hot bending tempering treatment. The curved screen phone tempered glass film has the advantages of favorable hardness, favorable water resistance and favorable high-temperature resistance, and can achieve favorable effects of impact resistance, scratch resistance, wear resistance and drop prevention. The curved screen phone tempered glass film can be completely attached to the phone curved screen without the phenomena of bubbles, degumming, press marks and the like, can effectively enhance the aesthetic property of the phone, can not influence the sensitivity of the phone screen after being attached to the phone curved screen, and is an ideal curved screen phone tempered glass film.

Owner:GUANGZHOU EHANG ELECTRONICS CO LTD

Honeycomb paper core high speed paper feeding and trimming device

ActiveCN103978514AFast cutting speedExtend exercise timeMetal working apparatusReciprocating motionHoneycomb

The invention discloses a honeycomb paper core high speed paper feeding and trimming device. The honeycomb paper core high speed paper feeding and trimming device comprises a work platform, a moving cutter and a fixing cutter which are arranged above the work platform and set in up and down horizontal tangent mode, a moving cutter driving mechanism used to drive the moving cutter to perform horizontal reciprocating movements so as to achieve paper cutting, a paper feeding roller and a paper pressing roller arranged in the horizontal direction above paper cutting stations of the moving cutter and the fixing cutter at an interval and used to convey honeycomb paper cores, a servo motor used to drive the paper feeding roller to rotate and a signal controller used to drive the servo motor to work, wherein a honeycomb paper core delivery passage for the honeycomb paper cores to pass is arranged between the paper feeding roller and the paper pressing roller, and the signal controller controls work efficiency of the servo motor according to work efficiency of the moving cutter driving mechanism. The honeycomb paper core high speed paper feeding and trimming device greatly improves paper feeding speed, further improves paper cutting speed of the moving cutter, can achieve 600-800 cutting times / min of high trimming speed, and greatly improves production efficiency of the honeycomb paper cores.

Owner:SHANGHAI LVSHUN PACKAGING MACHINERY

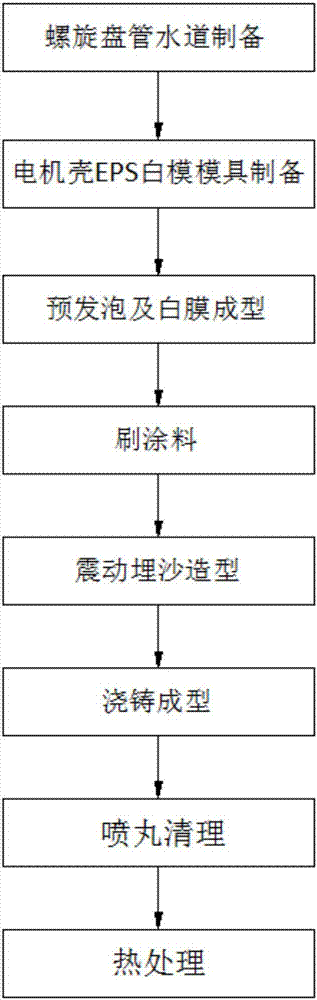

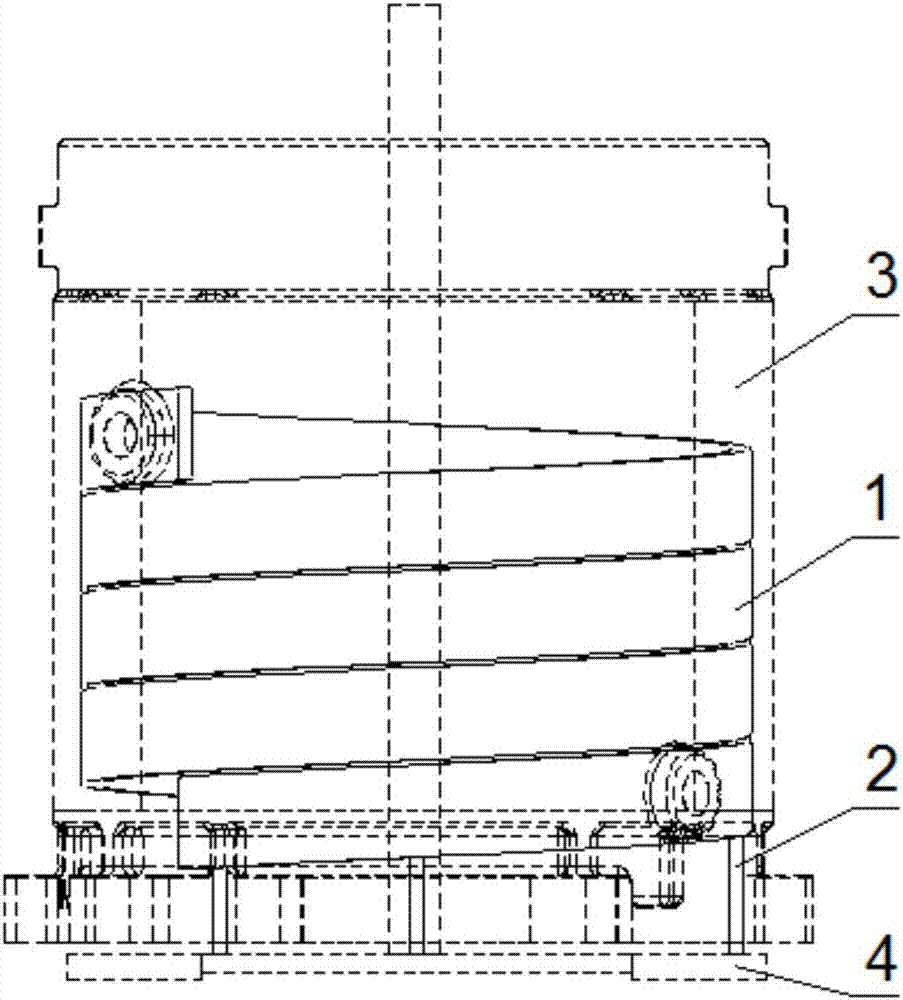

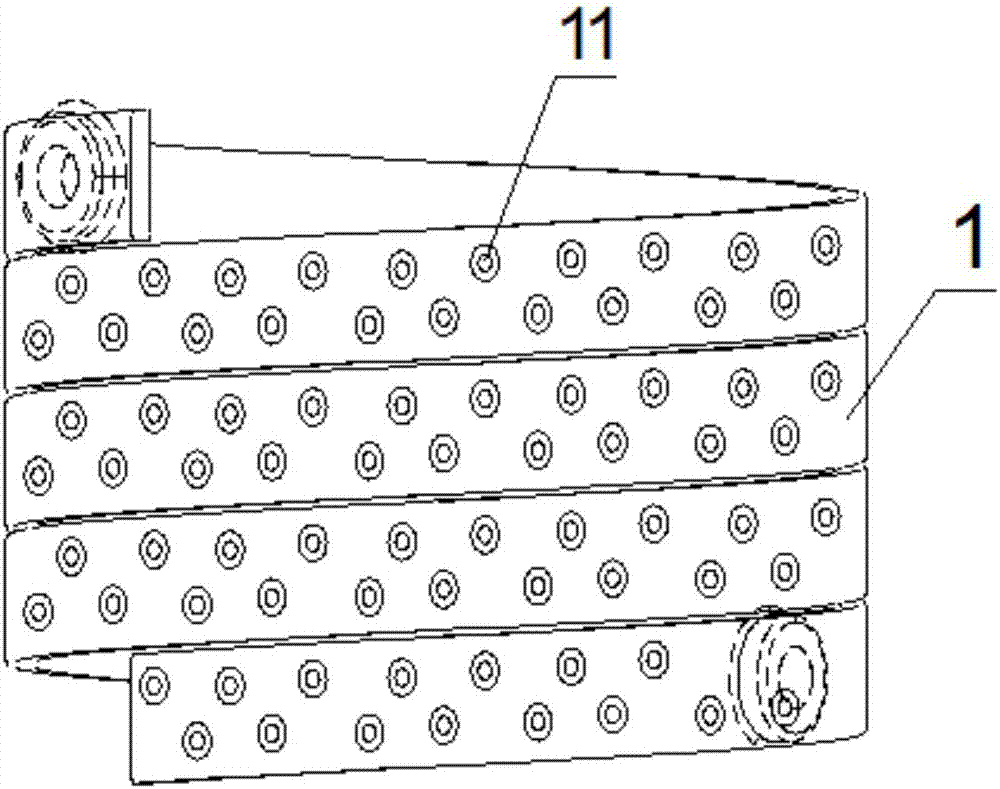

Expendable pattern casting technique for aluminum alloy internally provided with spiral coiled tube water passage

InactiveCN107282886ATightly boundReduce internal stressFoundry mouldsFoundry coresCooling effectCopper

The invention discloses an expendable pattern casting technique for an aluminum alloy internally provided with a spiral coiled tube water passage. According to the technique, the spiral coiled tube water passage made of stainless steel or copper is prefabricated firstly, and the upper end and the lower end of the spiral coiled tube water passage are provided with a water inlet and a water outlet which are capable of being exposed out of the column face of a motor shell correspondingly. A foaming mold is utilized for positioning and forming, an integrated motor shell EPS white mold internally comprising the prefabricated spiral coiled tube water passage can be machined through one-time forming, and then through the expendable pattern casting technique, the aluminum alloy motor shell internally provided with the spiral coiled tube water passage in an embedded mode is casted. An auxiliary structure capable of being tightly combined with the casted aluminum alloy shell is arranged on the spiral coiled tube water passage, internal stress generated by cold-hot change is reduced, and the shell is prevented from cracking. The spiral coiled tube water passage is further connected with a casting technique supporting framework, the aluminum alloy motor shell internally provided with the spiral coiled tube water passage can be stably and reliably casted on a large scale through an expendable pattern, the prefabricated spiral coiled tube water passage does not need to be filled with sand before casting, the water passage is smooth and not prone to being plugged, and it is ensured that the cooling effect is good.

Owner:FUJIAN JU NENG MACHINERY MFG CO LTD

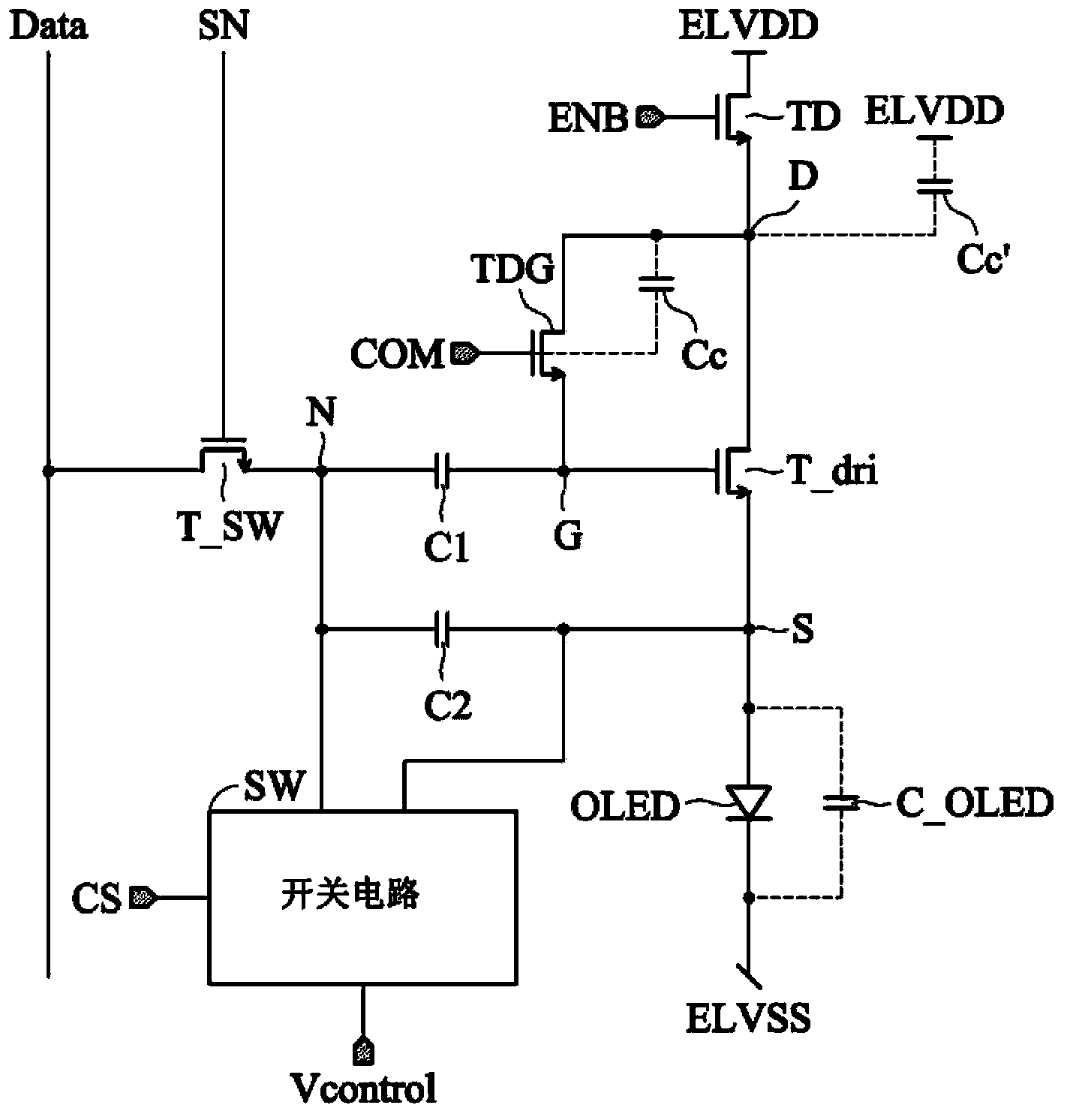

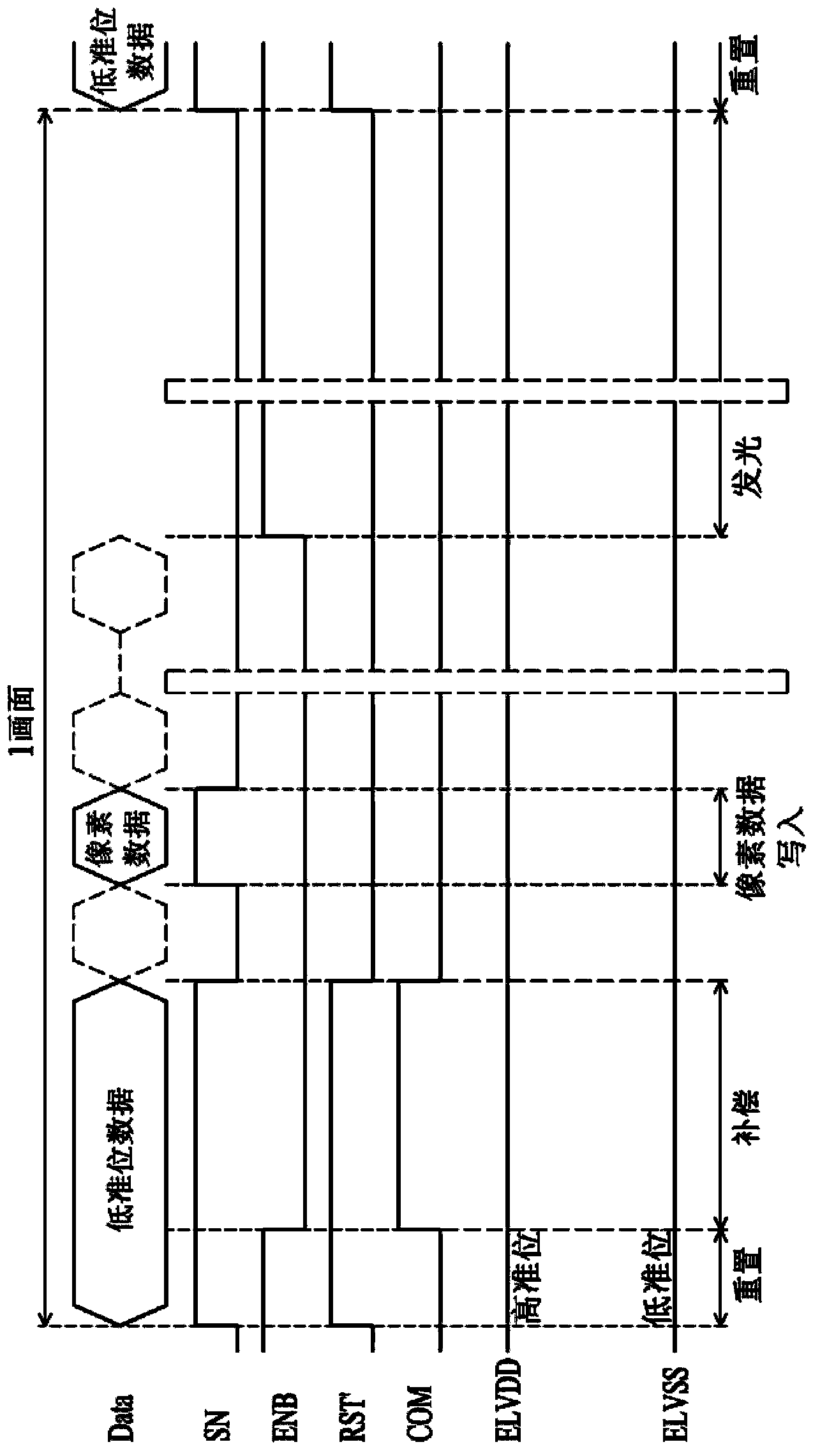

Organic light-emitting diode pixel circuit and displayer

The invention discloses an organic light-emitting diode pixel circuit and a displayer. According to the disclosed pixel circuit, a driving transistor of an organic light-emitting diode is driven to provide a reset operation and a compensation operation for the pixel circuit under control so that a critical voltage numerical value of the driving transistor is memorized on the control end of the driving transistor. In the compensation operation, a connecting point between the driving transistor and the organic light-emitting diode is needed to be particularly controlled. According to the pixel circuit, a switch circuit is disclosed, wherein the connecting point is coupled with a control potential according to a control signal. An enabling interval of the control signal covers effect intervals of the reset operation and the compensation operation.

Owner:INNOCOM TECH SHENZHEN +1

Deviation rectifying device of gypsum board production line

ActiveCN102785288AImprove control accuracy and automationImprove production efficiency and product qualityCeramic shaping plantsAuxillary shaping apparatusGypsumAutomation

The invention provides a deviation rectifying device of a gypsum board production line. The deviation rectifying device comprises a sensor, a deviation rectifying controller and a driving mechanism. The sensor detects edge positions of coiled materials and sends detected position information to the deviation rectifying controller, the deviation rectifying controller receives the position information sent by the sensor to conduct calculation and judgment to generate control instructions and sends the control instructions to the driving mechanism, and the driving mechanism receives the control instructions sent by the deviation rectifying controller and moves according to the control instructions. The deviation rectifying device uses the sensor to measure position situations of the coiled materials on line, the deviation rectifying controller timely generates deviation rectifying instructions, a deviation rectifying framework is driven by the driving mechanism to enable the coiled materials to be placed in the middle, skewing is basically avoided, control accuracy and automation degree are high, and production efficiency and product quality are greatly improved.

Owner:HUAINAN BEIXIN BUILDING MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com