Airstrainer

An air filter, skin-core type technology, applied in the field of air filter with stable structure, can solve the problems of loose structure, difficult to realize, reduce dust and filter surface adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The method for preparing the air filter of the present invention includes:

[0042] (1) Knitting: Put the sheath-core composite hot-melt bonding wire on the braiding machine along the radial and weft directions. The angle between the radial wire and the weft wire is 30°~90°, and then the warp wire and the weft wire are Interlace in a staggered manner, so that the warp and weft yarns touch at the intersection and weave into a net;

[0043] (2) Heating bonding: heating the knitted net at a temperature of 20°C to 40°C higher than the melting temperature of the skin material and 20°C lower than the melting temperature of the core material to make the warp and weft skin materials Melt and bond at the point of contact.

[0044] In the method of the present invention, the weaving machine can be a conventional weaving machine in the industry, preferably a plain weaving machine or a twill weaving machine.

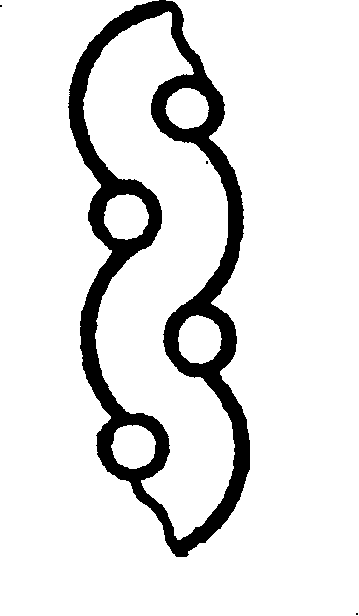

[0045] The outer layer (skin) of the bonding wire is a low melting point pla...

Embodiment 1

[0054] 1. Choose fiber

[0055] Select the core-sheath composite hot-melt adhesive yarn with the skin layer made of polypropylene and the core layer made of high-melting polyester. The yarn's fineness is 60 denier, the melting point temperature of the skin layer polypropylene is 163℃, and the core layer polyester The melting point temperature is 253°C.

[0056] 2. Fiber twisting

[0057] Put the selected sheath-core composite hot-melt adhesive wire into the twisting machine for twisting, the twisting direction is S direction, the twisting multiple is 900, and then the steam setting method is used for heat setting in the heat setting machine to shape The temperature is 90°C and the time is 40 minutes.

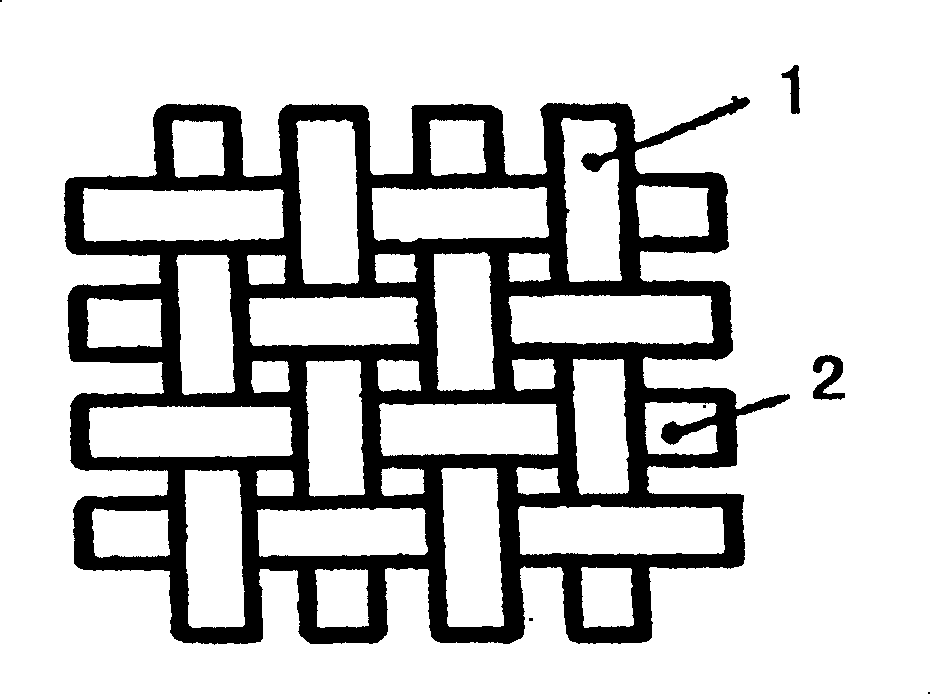

[0058] 3. Weave into a net

[0059] Put the twisted sheath-core composite hot-melt adhesive yarn on the plain weave machine, one as the warp yarn and the other as the weft yarn, so that the angle between the warp yarn and the weft yarn is 90°, and then weave it, such as figure 1 As...

Embodiment 2

[0065] 1. Choose fiber

[0066] (1) Non-conductive bonding wire: Choose a sheath-core composite hot-melt bonding wire whose skin layer is made of low-melting polyester and core layer is made of high-melting polyester, with a fineness of 75 denier and a skin layer of low-melting polyester The melting point temperature is 173°C, and the melting point temperature of the core layer high melting point polyester is 253°C.

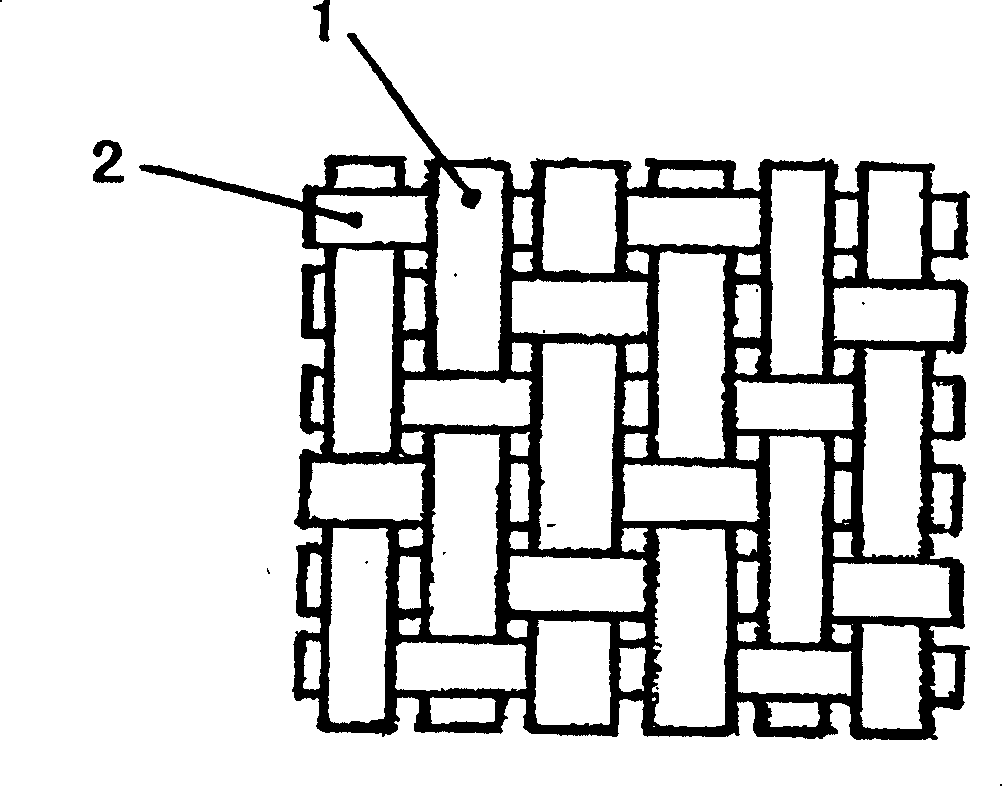

[0067] (2) Conductive bonding wire: select the skin-core composite hot-melt bonding conductive wire with the skin layer made of low-melting polyester and the core layer made of high-melting polyester, with a fineness of 75 denier, and a skin layer of low-melting polyester The melting point temperature is 173℃, the melting point temperature of the core layer high melting point polyester is 253℃, and the resistance value is 10 5 Ω, the content of the conductive component carbon black is 9% by weight, based on the weight of the conductive adhesive yarn.

[0068] 2. Fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com