Eccentricity regulating mechanism

A technology of adjusting mechanism and eccentric distance, which is applied in the direction of eccentric wheel, grinding machine parts, crank, etc., can solve the problems of easy displacement of eccentric distance, limited application range, poor reliability and other problems, and achieves wide application range, The effect of reliable performance and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

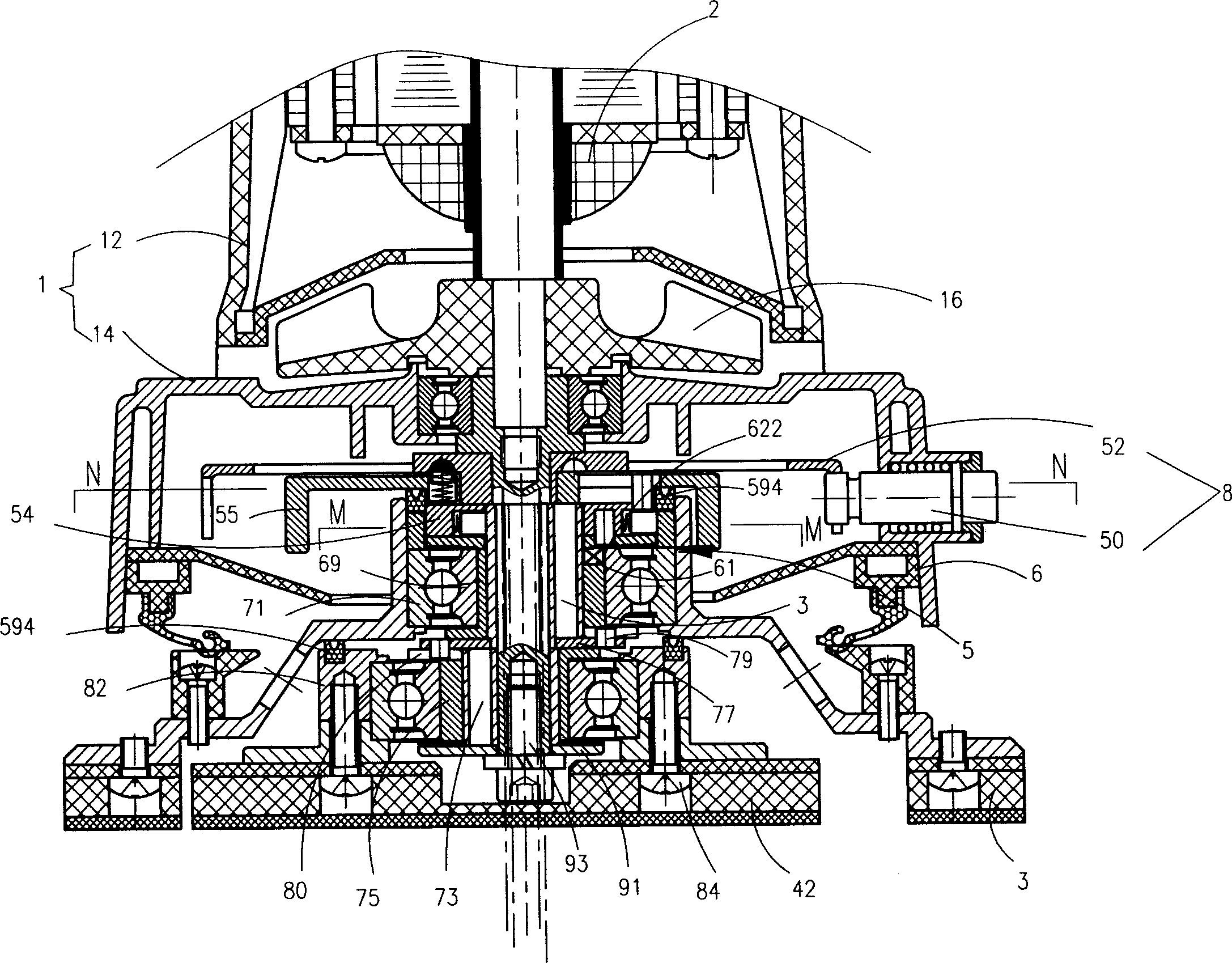

[0018] refer to figure 1 , the sanding electric tool corresponding to the present invention is a sanding machine, shown as a sanding machine corresponding to the first embodiment, which includes a casing 1, a motor 2 vertically arranged in the casing 1, a transmission Main shaft 3, bottom (sand) disc 4 and eccentricity adjustment mechanism 5.

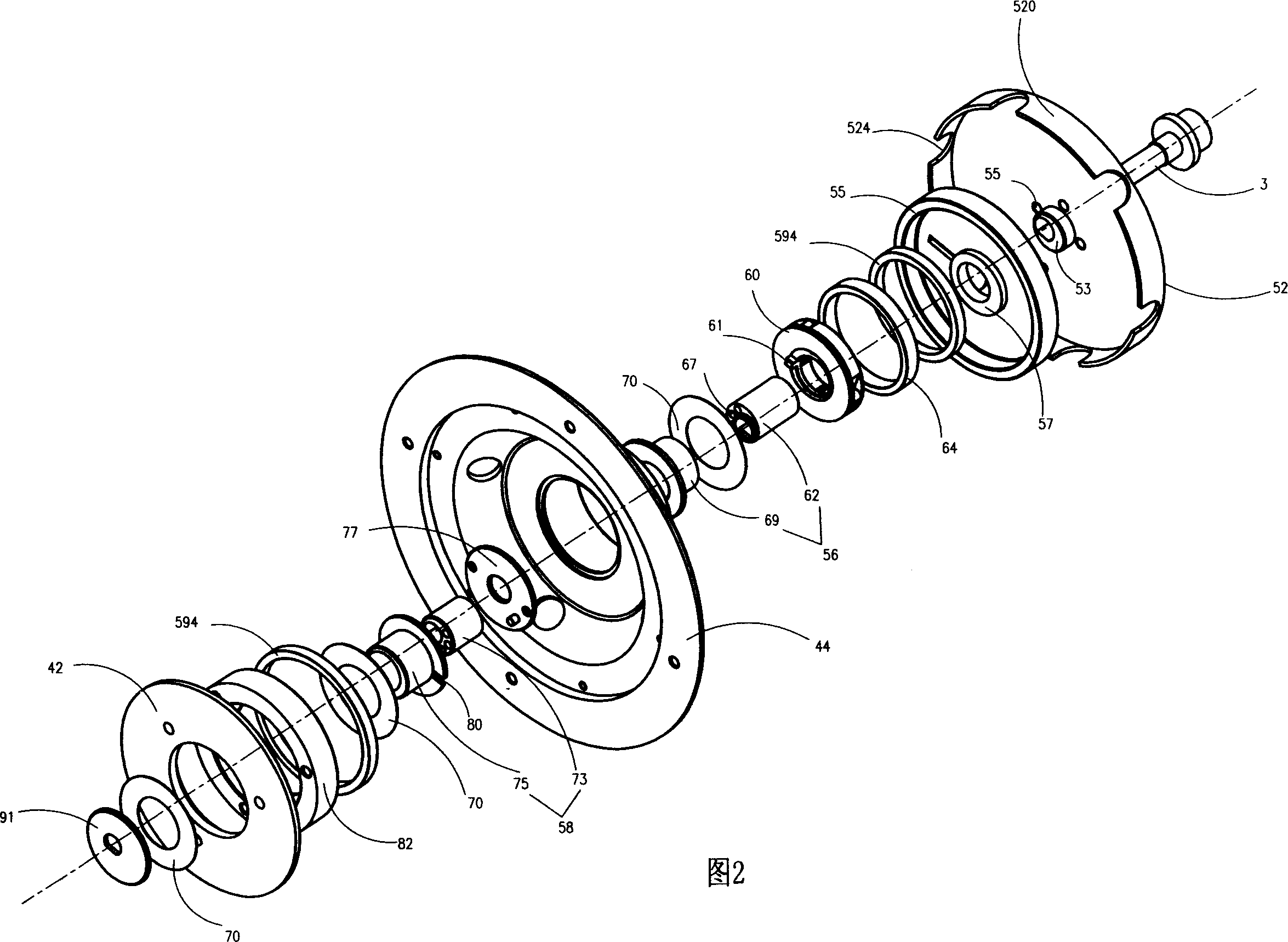

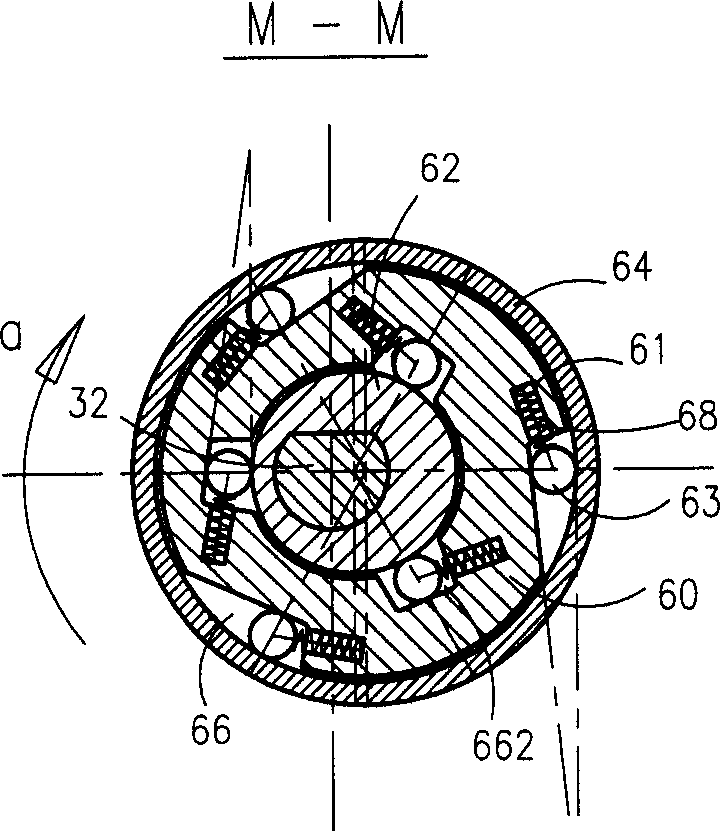

[0019] With further reference to Figure 2 to Figure 6 , the casing 1 is divided into an upper half casing 12 and a lower half casing 14, which are fixedly connected. The fan 16 is fixedly sleeved on the transmission shaft 3 . Corresponding to the preferred embodiment of the present invention, the drive shaft 3 includes an armature shaft 30 and a connecting shaft 32 fixedly connected to the lower end of the armature shaft 30. The connecting shaft 32 is coaxially arranged with the armature shaft 30, and has a central axis X0, and has a profiled profile. In addition, the connecting shaft 32 can also be integrally formed with the armat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com