Low-smoke flame-retardant acrylonitrile butadiene styrene (ABS) alloy material

An alloy material, a low-smoke flame-retardant technology, applied in the field of low-smoke flame-retardant ABS alloy materials, to achieve the effect of reducing the rate and amount of smoke released, significant social benefits and industrial application value, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

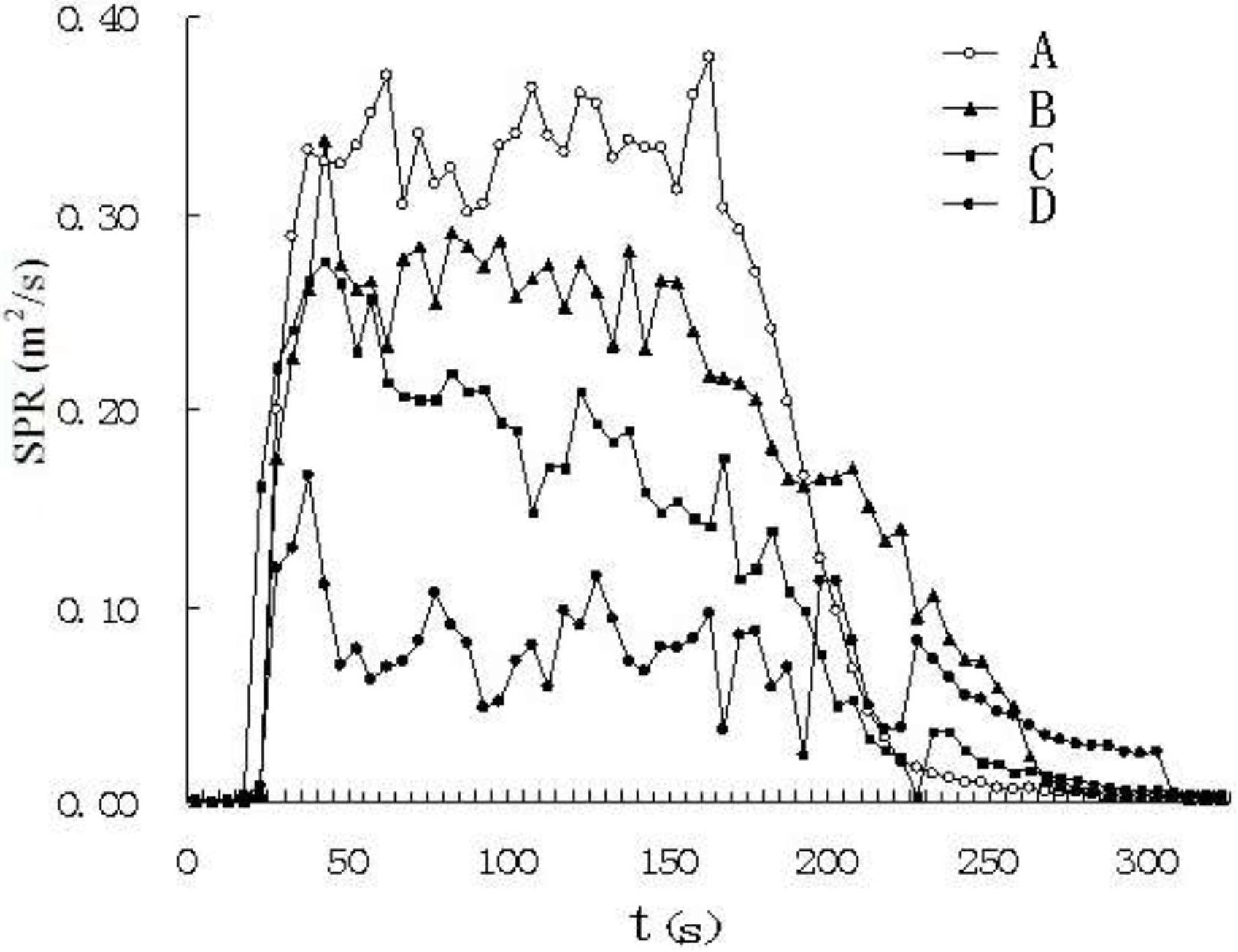

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific examples, and the listed examples only further illustrate the present invention, and do not thereby limit the present invention.

[0027] A preparation process of a low-smoke flame-retardant ABS alloy material has the following steps:

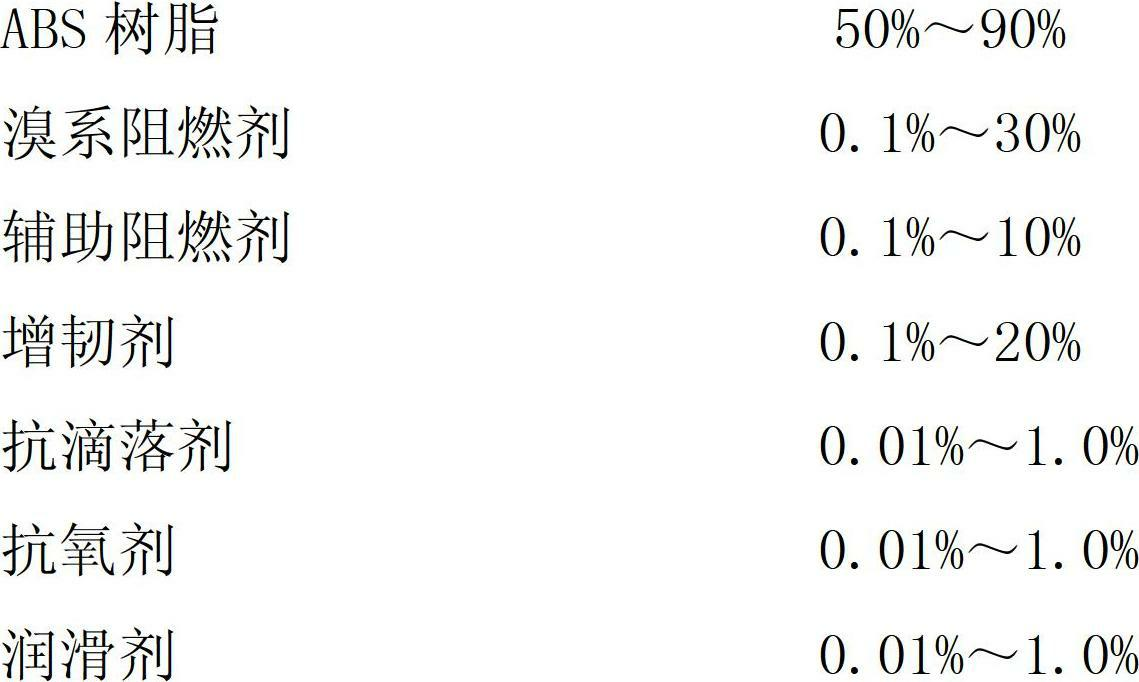

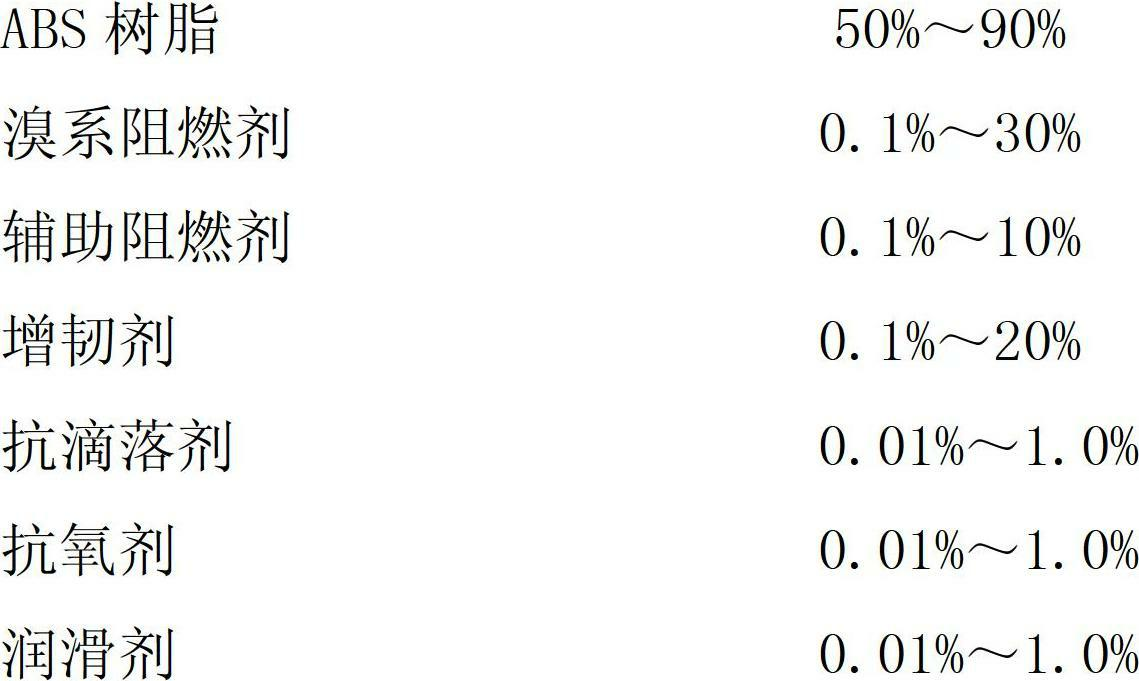

[0028] (1) Prepare ABS resin, brominated flame retardant, auxiliary flame retardant, toughening agent, anti-dripping agent, antioxidant and lubricant, and add the above materials into the high-speed mixer in order and mix well;

[0029] ABS resin is obtained by mixing AG12A1 by emulsion method and HR9661 by bulk method at a mass ratio of 54:18; the brominated flame retardant is tris(tribromophenyl)triazine with the brand name FR245 of Jiangsu Haohua.

[0030] The antimony-sodium-silicon composite flame retardant in the auxiliary flame retardant is T930 from United Chemical Corporation, the zinc borate is Firebrake ZB from Rio Tinto, the basic aluminum magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com