Porous aluminium oxide micro/nanospheres and preparation method thereof

A technology of porous alumina and micro-nano balls, applied in the field of nano-materials, can solve problems such as complicated operation process and difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

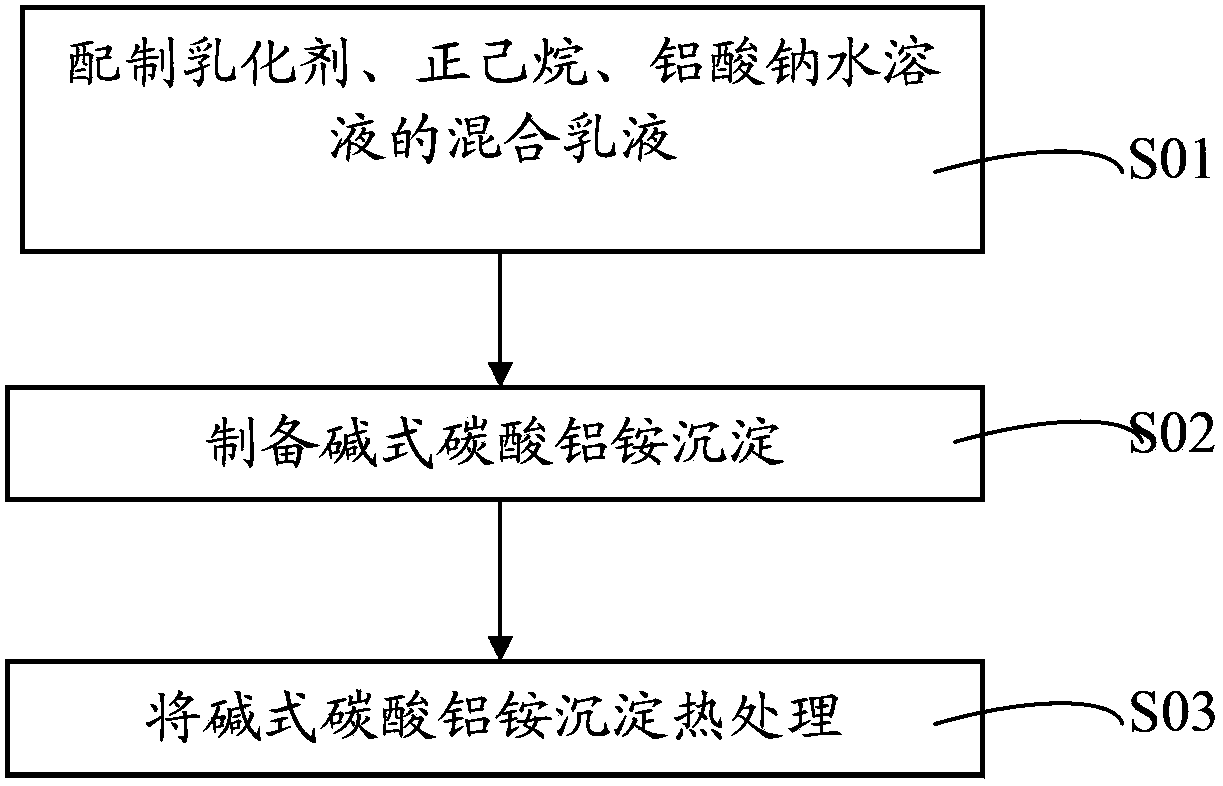

[0024] The embodiment of the present invention provides a method for preparing porous alumina micro-nanospheres with simple process and easy controllable conditions. The process flow of the preparation method of the porous alumina micro-nanospheres is as follows: figure 1 shown, including the following steps:

[0025] Step S01. Prepare a mixed emulsion of emulsifier, n-hexane, and sodium aluminate aqueous solution: mix the emulsifier, n-hexane, and sodium aluminate aqueous solution and perform emulsification treatment to prepare a mixed emulsion; wherein, the emulsifier, n-hexane, aluminum The dosage ratio of sodium acid is 0.5g: 10-40mL: 1.0-5.0g;

[0026] Step S02. Precipitation of basic ammonium aluminum carbonate: add the mixed emulsion prepared in step S01 to an aqueous ammonium bicarbonate solution with a concentration of 0.9-1.0 mol / L for precipitation reaction, perform solid-liquid analysis after the reaction is completed, wash and dry Precipitation, obtain basic alu...

Embodiment 1

[0047] A porous alumina micro-nanosphere and a preparation method thereof. The preparation method is as follows:

[0048] (1) Add 0.5g Span80 to 18mL1.0mol / L sodium aluminate solution, then add 36mL n-hexane, emulsify at 10000rpm / min with a high-speed emulsifier for at least 1min, and prepare a mixed emulsion;

[0049] (2) Add the mixed emulsion prepared in step (1) to the pre-prepared 0.94mol / L NH 4 HCO 3 In the solution, stirring was continued at 500 rpm / min for 3 h. After the reaction was complete, the product was repeatedly washed four times with deionized water and absolute ethanol, and finally dried in a drying oven at 60°C for 12 hours to obtain a white precipitated product.

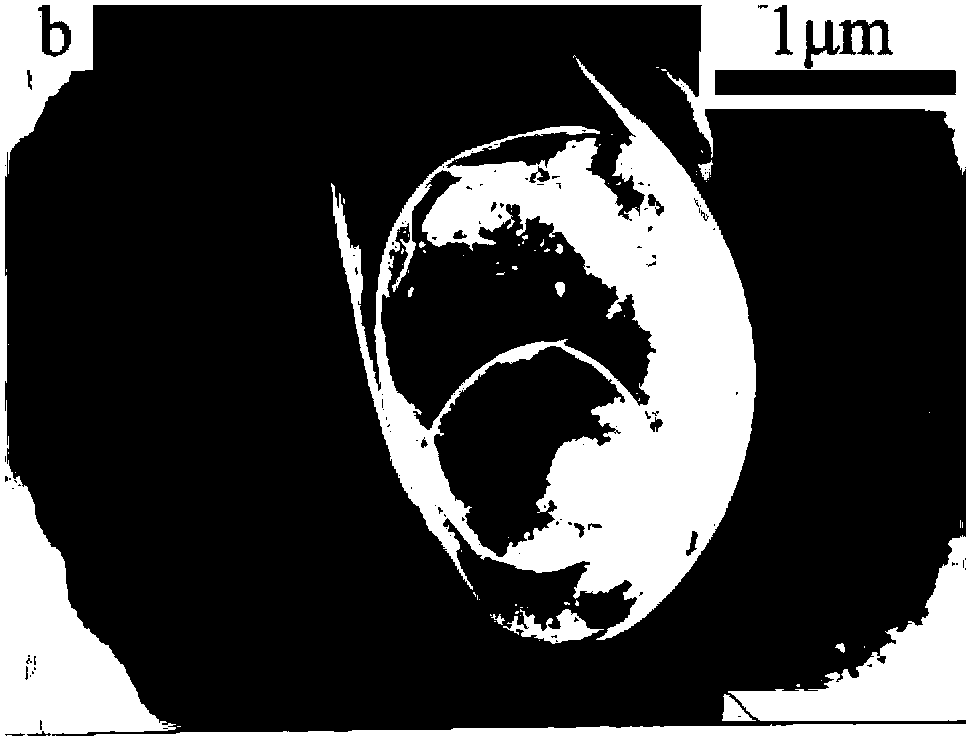

[0050] (3) Put the white precipitate product prepared in step (2) in a porcelain crucible and directly heat it to 600°C in a muffle furnace at a heating rate of 10°C / min for 5 hours, then place the prepared sample in air naturally After cooling to room temperature, porous alumina micro-nanosph...

Embodiment 2

[0058] A porous alumina micro-nanosphere and a preparation method thereof. The preparation method is as follows:

[0059] (1) Add 0.5g of Span80 to 20mL of 2.0mol / L sodium aluminate solution, then add 40mL of n-hexane, and emulsify with a high-speed emulsifier at a speed of 10000rpm / min for at least 1min to prepare a mixed emulsion;

[0060] (2) Add the mixed emulsion prepared in step (1) into the pre-prepared 1.0mol / L NH 4 HCO 3 In the solution, stirring was continued at 500 rpm / min for 3 h. After the reaction was complete, the product was washed repeatedly four times with deionized water and absolute ethanol, and finally dried in a drying oven at 60° C. for 12 hours to obtain a white precipitated product.

[0061] (3) Put the white precipitate product prepared in step (2) in a porcelain crucible and directly heat it to 600°C in a muffle furnace at a heating rate of 15°C / min for 5 hours, then place the prepared sample in the air naturally After cooling to room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com