Preparation method of composite powder of mullite precursor in situ enveloped carbon nanometer tube

A carbon nanotube composite and carbon nanotube technology is applied in the field of preparing nano-mullite precursor in-situ coated carbon nanotube composite powder, which can solve the problems of not getting satisfactory results and achieve the effect of simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

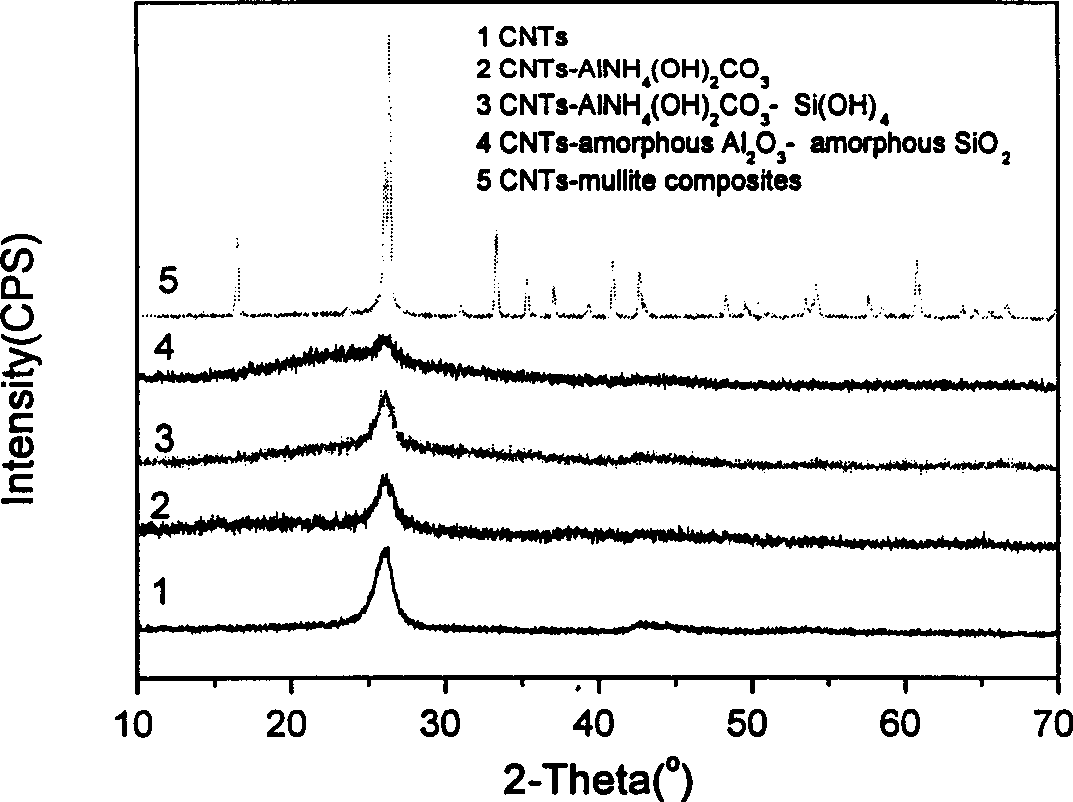

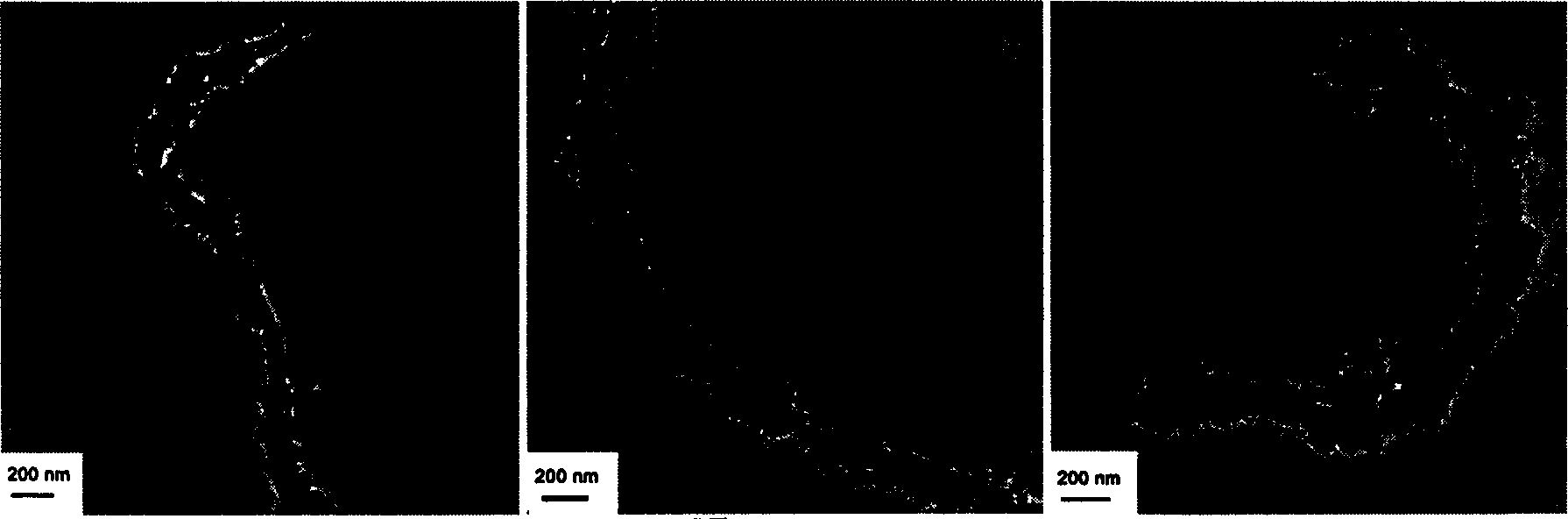

[0030] The carbon nanotubes were baked in an oven at 100° C. for 24 hours to remove moisture in the carbon nanotubes, then refluxed in concentrated nitric acid for 24 hours, washed with deionized water, and dried. 5g of acidified carbon tubes were immersed in 2.0M aluminum ammonium carbonate aqueous solution, stirred on a magnetic stirrer after ultrasonic dispersion for 60 minutes, dripped with a concentration of 0.3M aluminum ammonium sulfate solution, reacted at room temperature for 12 hours, and then obtained The product was washed three times with water and absolute ethanol, and dried to obtain a composite powder of aluminum ammonium carbonate-wrapped carbon nanotubes. The obtained suspension was heated in a water bath at 55°C, and ethyl orthosilicate was dropped into it. React under low temperature for 12 hours to obtain a composite powder wrapped in ammonium aluminum carbonate and silicon oxide. The product is washed three times with water and absolute ethanol, and the co...

Embodiment 2

[0032] The carbon nanotubes were baked in an oven at 100° C. for 24 hours to remove moisture in the carbon nanotubes, then refluxed in concentrated nitric acid for 24 hours, washed with deionized water, and dried. 5g of acidified carbon tubes were immersed in 0.2M aluminum ammonium carbonate aqueous solution, ultrasonically dispersed for 15-60 minutes and then stirred on a magnetic stirrer, then dripped with a concentration of 0.1 aluminum ammonium sulfate solution, reacted at room temperature for 12 hours, and then Wash the obtained product three times with water and absolute ethanol, and dry to obtain a composite powder of carbon nanotubes wrapped in ammonium aluminum carbonate. React under neutral conditions for 12 hours to obtain a composite powder wrapped in ammonium aluminum carbonate and silicon oxide. The product is washed three times with water and absolute ethanol, and the composite powder obtained after drying is then calcined in air at 450°C for 2 hours. , that is,...

Embodiment 3

[0034] The carbon nanotubes were baked in an oven at 100° C. for 24 hours to remove moisture in the carbon nanotubes, then refluxed in concentrated nitric acid for 24 hours, washed with deionized water, and dried. Immerse 5g of acidified carbon tubes in 0.1M aluminum ammonium carbonate aqueous solution, ultrasonically disperse for 15-60 minutes, stir on a magnetic stirrer, drop into a solution of aluminum ammonium sulfate with a concentration of 0.015, react at room temperature for 12 hours, and then Wash the obtained product three times with water and absolute ethanol, and dry to obtain a composite powder of carbon nanotubes wrapped in ammonium aluminum carbonate. React under neutral conditions for 12 hours to obtain a composite powder wrapped in ammonium aluminum carbonate and silicon oxide. The product is washed three times with water and absolute ethanol, and the composite powder obtained after drying is then calcined in air at 450°C for 2 hours. , that is, a composite pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com