Slag oil hydro-demetallization catalyst and its preparing method

A residue hydrogenation and catalyst technology, which is used in refining to remove heteroatoms, etc., to achieve the effects of improved performance, easy implementation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

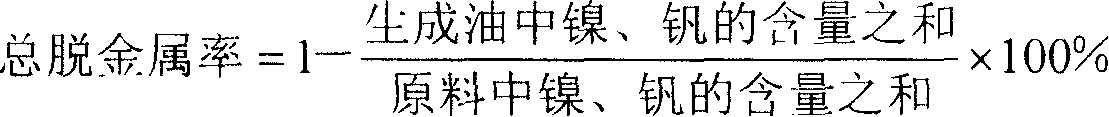

Method used

Image

Examples

example 1

[0033] Take by weighing aluminum sulfate (Beijing chemical plant product) 666 grams, add deionized water and dissolve into molar concentration and be the solution a1 of 0.3, take by weighing 1000 grams of ammonium bicarbonate (Beijing chemical plant product), add deionized water and dissolve into molar concentration of 2.5 solution b1. Add solution a1 and solution b1 to a 10-liter gelation tank in a co-current manner for reaction. During the reaction, control the pH value to 7.5 and the temperature at 40°C. The resulting white precipitate is precipitated at 40°C for 1.5 hours. Filter, the filter cake is washed three times with 10 times (weight) of deionized water at 40°C, and dry at 120°C for 4 hours in a drying oven to obtain ammonium aluminum carbonate F1, whose chemical formula is (NH 1 ) 0.2 AlO(OH)(HCO 3 ) 0.2 4H 2 O, the sulfate ion content is 0.3% by weight.

example 2

[0035] Take by weighing 483 grams of aluminum chloride (product of Beijing Chemical Plant), add deionized water to dissolve into a solution a2 with a molar concentration of 1, take by weighing 800 grams of ammonium bicarbonate (product of Beijing Chemical Plant), add deionized water to dissolve into a molar concentration is solution b2 of 2. Add solution a2 and solution b2 into a 10-liter gelation tank simultaneously in parallel flow for reaction. During the reaction, the pH value is controlled to be 8.0 and the temperature is 30°C. The resulting white precipitate is precipitated at 30°C for 1.5 hours and filtered. , the filter cake was washed twice with 20 times (weight) of deionized water at 30°C, and dried at 120°C for 4 hours in a drying box to obtain ammonium aluminum carbonate F2, whose chemical formula is (NH 4 ) 0.4 AlO(OH)(HCO 3 ) 0.4 2H 2 O, the chloride ion content is 0.4% by weight.

example 3

[0037] Take by weighing aluminum nitrate (Beijing chemical plant product) 750 grams, add deionized water and dissolve into molar concentration and be 1 solution a3, take by weighing 800 grams of ammonium bicarbonate (Beijing chemical plant product), add deionized water and dissolve into molar concentration of 2.5 solution b3. Add solution a3 and solution b3 to a 10-liter gelation tank in parallel and react simultaneously. During the reaction process, the pH value is controlled at 7.0 and the temperature is 25°C. The resulting white precipitate is precipitated at 25°C for 1.5 hours. Filter and dry at 120°C for 4 hours in a drying oven to obtain ammonium aluminum carbonate F3, whose chemical formula is (NH 4 ) 0.5 AlO(OH)(HCO 3 ) 0.5 ·3H 2 O.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com