Flame retardant cable sheath material with high malleability and preparation method

A flame retardant cable, ductility technology, applied in the field of high ductility flame retardant cable sheath material and its preparation, can solve the problems of poor elasticity and ductility of the sheath material, and achieve good flame retardant effect, high ductility, high Effect of elongation at break and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

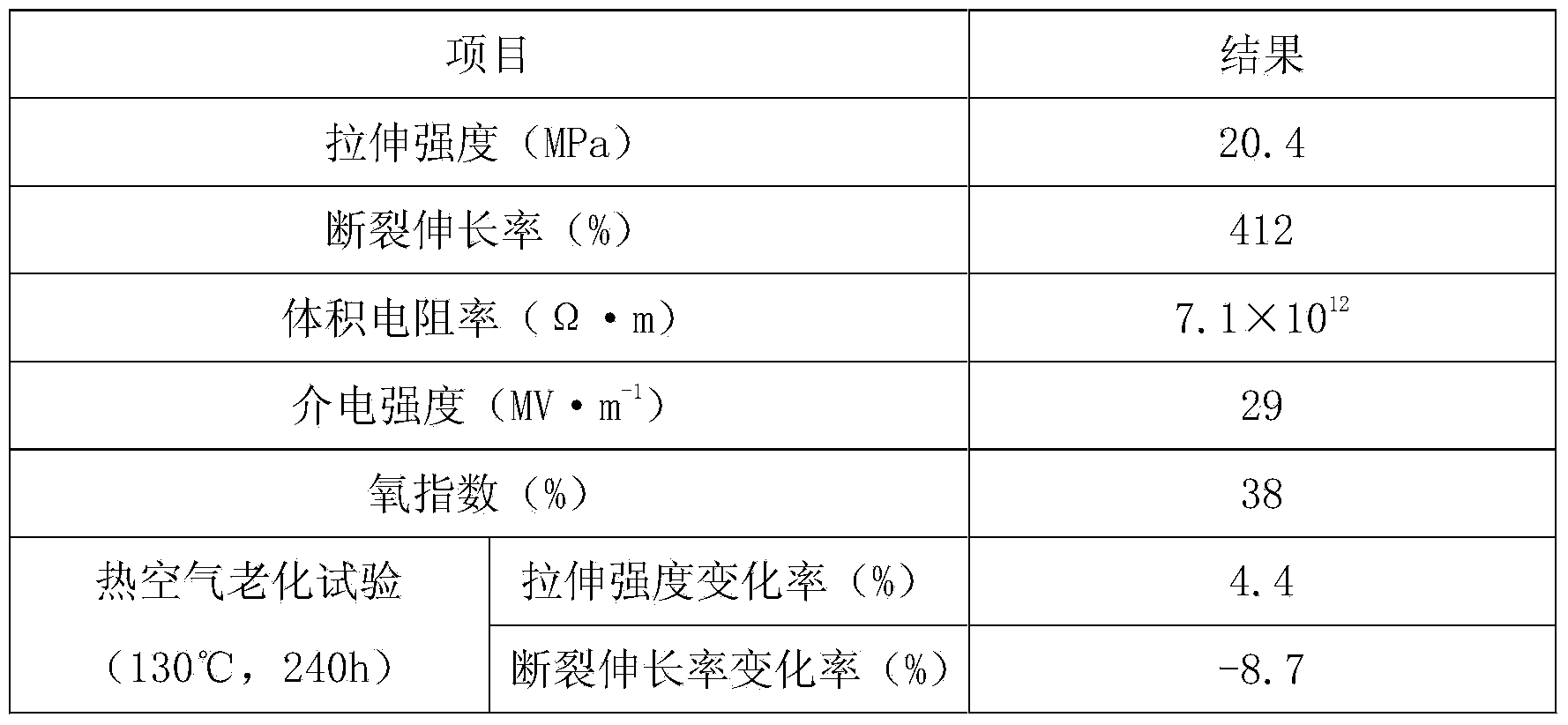

[0014] A high ductility flame retardant cable sheath material, made of the following raw materials in weight (kg): acrylate rubber 70, polyurethane rubber 30, EVA10, EVA-g-MAH7, basic sodium aluminum carbonate 6, ammonium polyphosphate 8. Zinc borate 10, ammonium molybdate 4, carbon black N55018, basic magnesium carbonate 4, zinc stearate 2, bis(γ-triethoxysilylpropyl) tetrasulfide 2, anti-scorch agent CTP1 , polyethylene wax 5, dicumyl peroxide 0.6, triallyl isocyanurate 2, nano potassium feldspar 15, potassium titanate whisker 8, composite filler 4;

[0015] The preparation method of the composite filler is as follows: a. Weigh kaolin, diatomite, and dolomite in a weight ratio of 5:6:3, pulverize, mix evenly, wet ball-milling for 22 hours, then dry at 115° C., and then heat at 570 calcined at ℃ for 1 hour, cooled to room temperature, added an appropriate amount of water to make a slurry with a concentration of 45%, then added a 12% concentration of hydrochloric acid solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com